Search the Community

Showing results for tags 'automatic'.

-

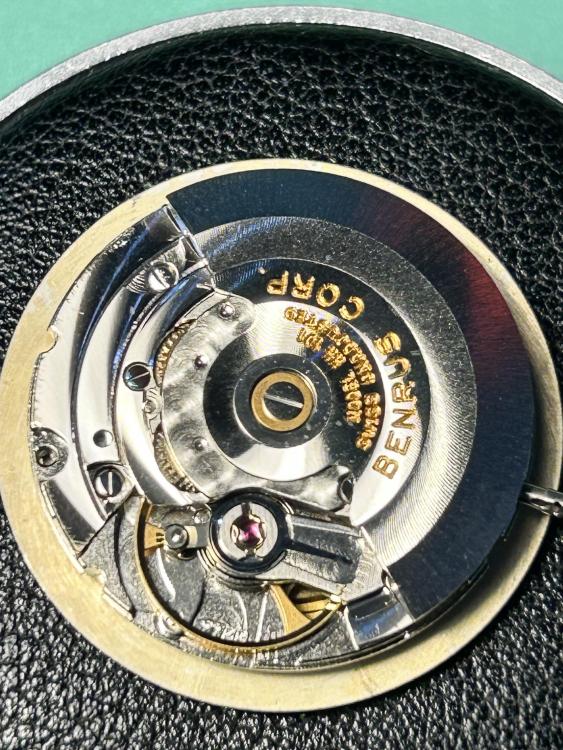

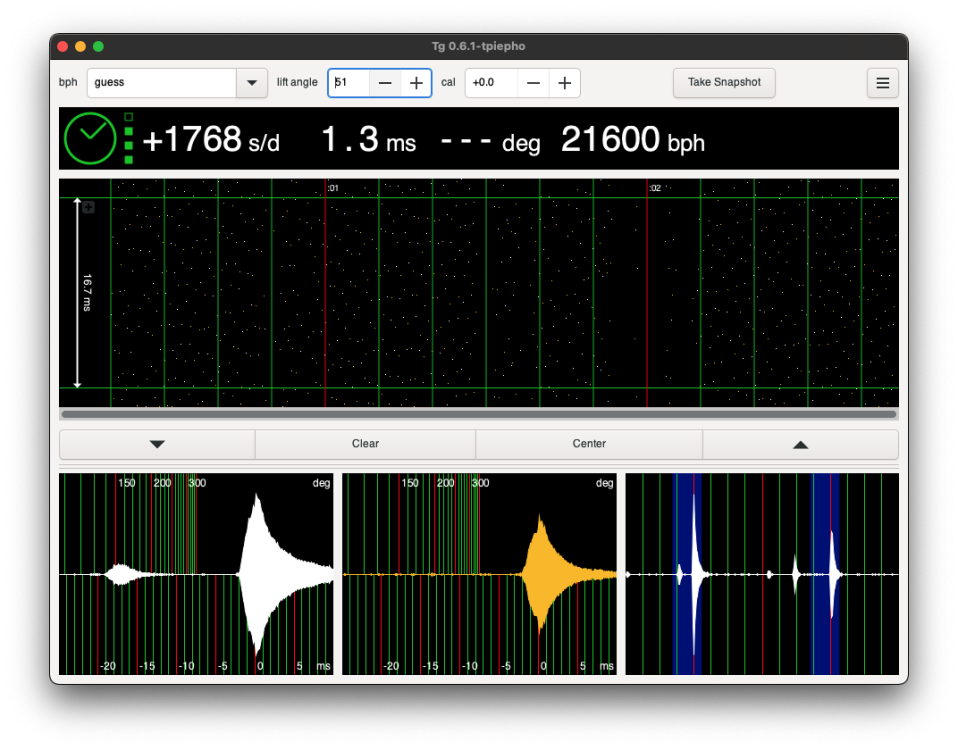

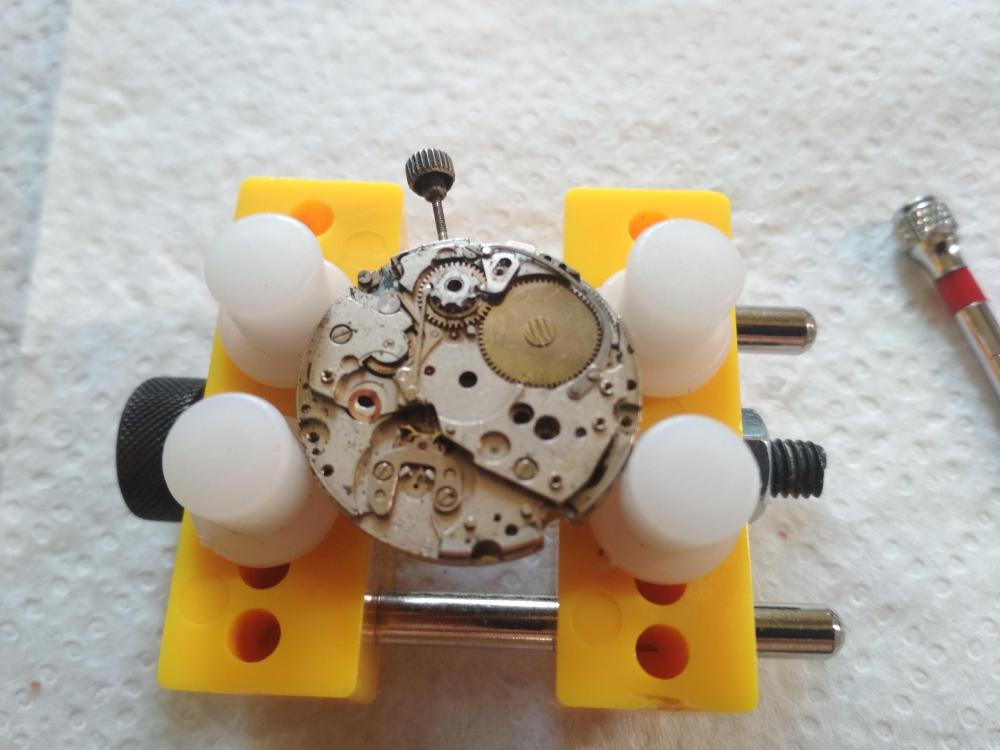

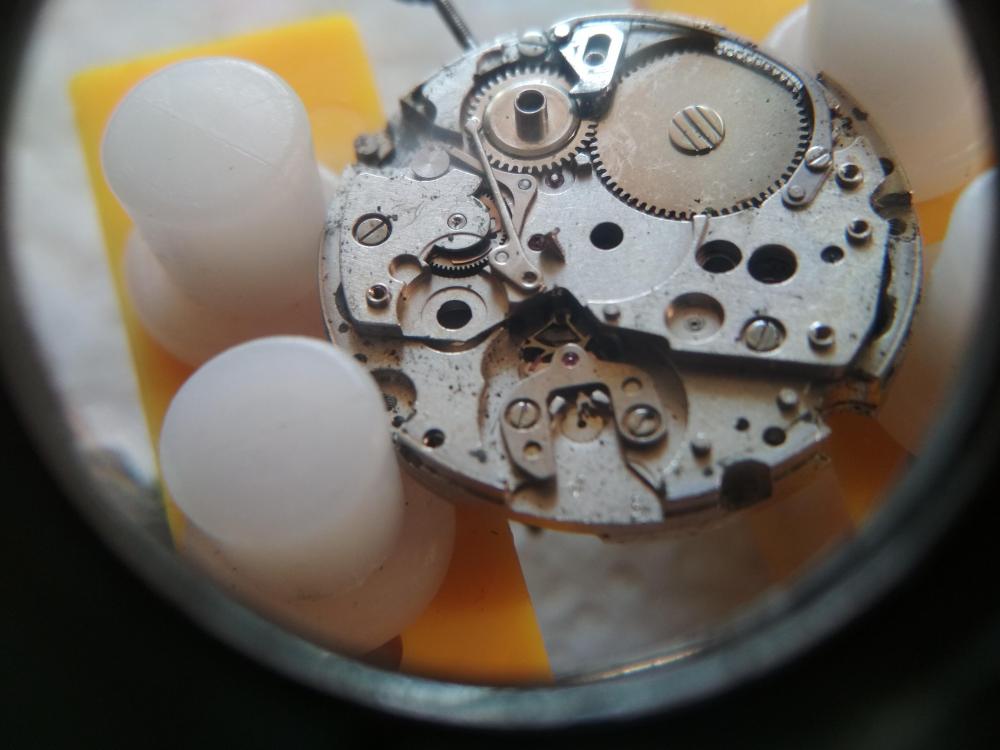

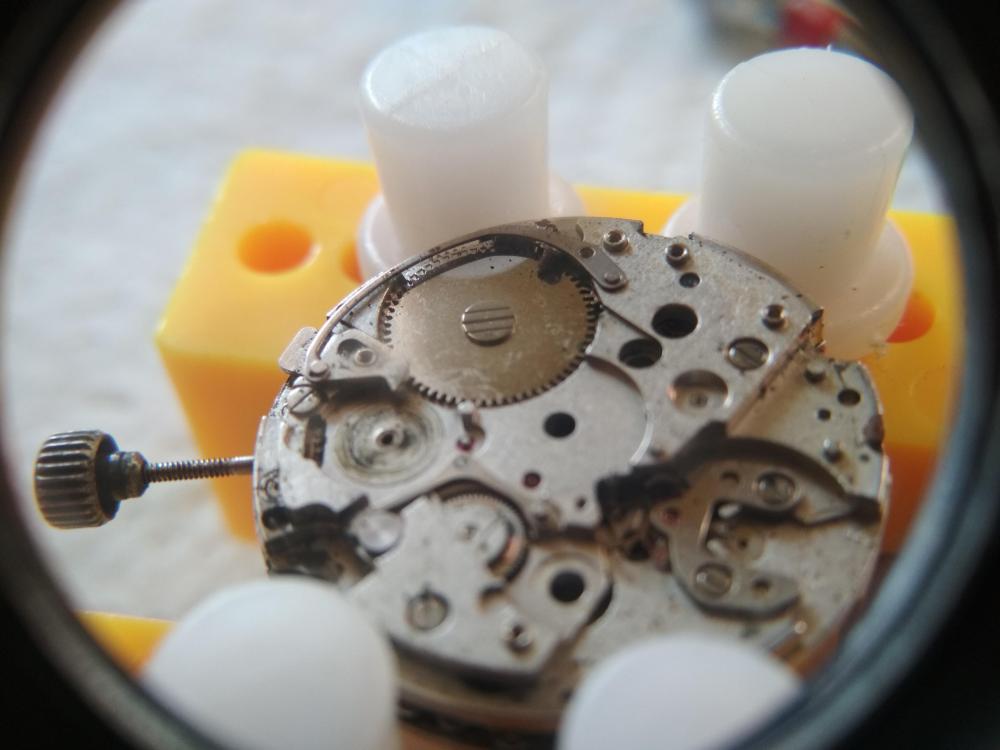

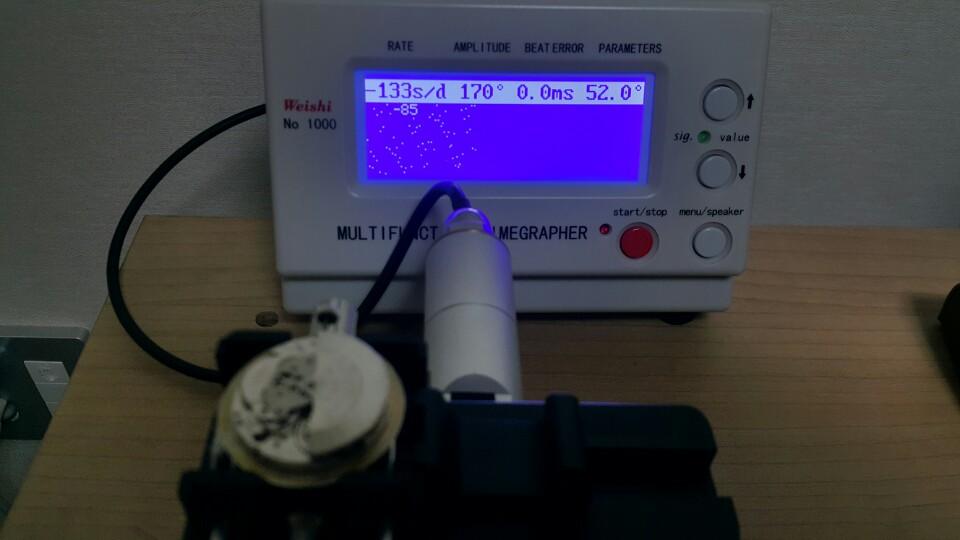

I've been following the standard array of Watch repair youtubers for a while now, getting interested and excited about this new hobby. I've collected some tools: Magnification sources, good quality screwdrivers, poor quality screwdrivers, some decent tweezers, etc. The basics -- no mainspring winders or any of the "big" tools like a press or anything. Finally, I've been trawling ebay, filtering out the plethora of frankenseikos and replica rolexes. I found a nice looking, likely candidate in a Benrus automatic. It's a bit beat up but nothing super serious. I don't hate a we bit of visible wear. Once I received it I found that the only way to get some activity on the dial was to give the machine a bit of a gentle spin to activate the Automatic works. Great news that it runs and I don't have to call the seller a liar, bad news is that the manual wind either doesn't work, or doesn't exist. I can pull the crown out and set the time though, and the day/date turn over at roughly the correct time. I decided to put the thing on a timegrapher to see how well it runs. I googled "Benrus Automatic Lift Angle, and the most recent thing I came across seemed to list all Benrus' as having 50º of lift. That's.... not amazing. While I'm no expert at reading this stuff, I think that gaining 30m a day, and having no detectable degrees of rotation on the balance wheel seems bad. I should note that I did try throwing in different bph and lift angles. This was the best it got. To make a short story long; I learned what a split crown meant, and got the movement out of the case after employing my crystal claw. And this is where I'm nervous! It looks like this movement has not seen the light of day since its original installation, the beautiful ranfft.de site seems to list all Benrus movements as some sort of ETA variant, and this does look very similar to the pictures that I saw on the site, but the reversing gears on the Auto works look different than all of the automatics that ranfft has listed for the benrus. Googling the Model "HH 1D1" doesn't seem to give me the kind of information that I know how to parse. I guess what I'm asking is for help determining the actual model of movement I have here. I'd like to read up on or find a service guide for it before I get too rammy! Please let me know what more information would be useful, I'm happy to provide.

- 18 replies

-

- newbie

- movement id

-

(and 2 more)

Tagged with:

-

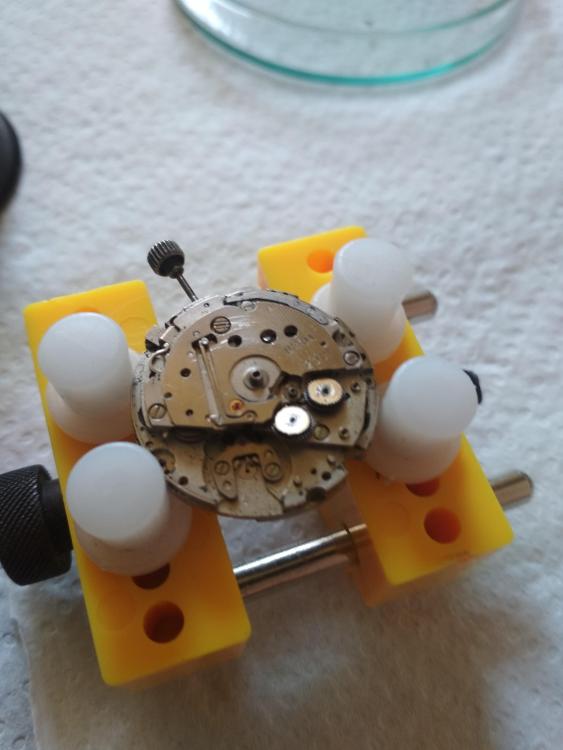

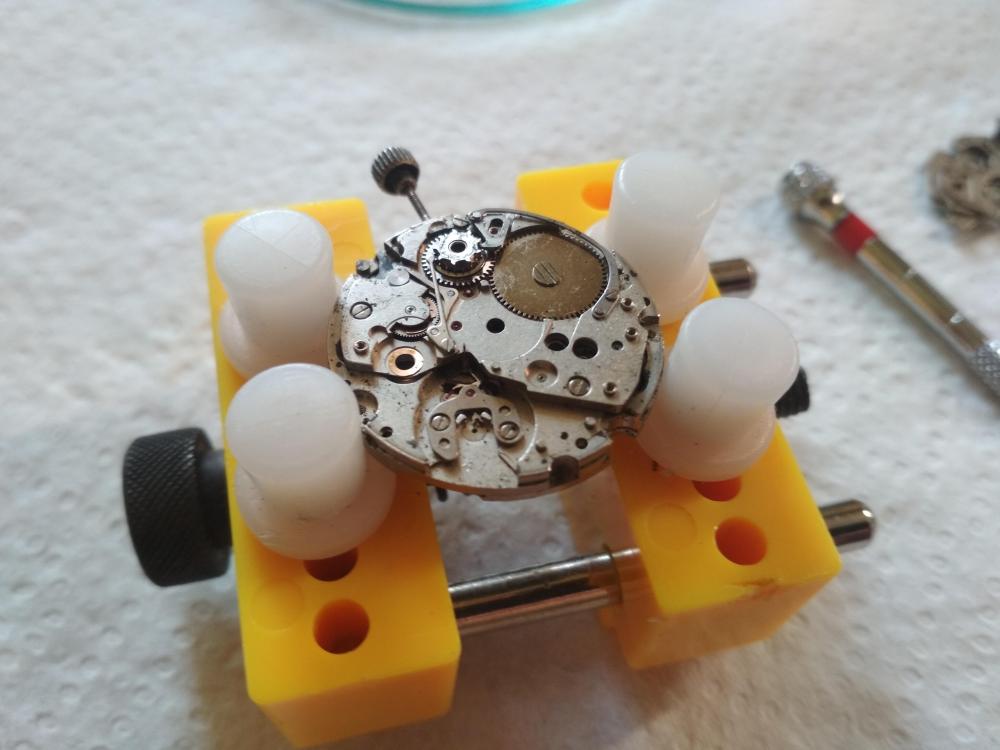

Hello All, Since my last post about an Omega and a Seiko, I have fallen deeper and deeper into the buying vintage watches and cleaning the putting-back-together hole. So I picked up this guy from one of the auction sites for about $10 I stripped everything down, cleaned everything, and tried to put it all back together. Seems everything went well I am however stuck at the calendar wheel and spring. Seems the last guy that came in here lost the spring and made one of those guitar string type spring. I know that it works as I tested it before I took things apart. Only thing is it does not sit flush and its a juggling affair to get the spring to sit pushing on the calendar lever sitting just so the date wheel without flying into space. Then only I can put this plate on. As far as I can tell, the plate is what is holding this precarious spring lever date wheel sandwich all in its place. I can take it apart, I am amazed at the previous guy to get it all in just so. Can I get any advice on how I can get this done? The options I looked at are 01. Place the spring and lever, have the lever away from the spring, put the plate on, and try to slide the date wheel in. *** Nope does not work that way 02. Try to have the date wheel a little away, place the lever away from the spring and try to adjust after one of the screws are placed. *** Nope The spring does not like to stay in place 03. Have not tried this but I am thinking of super gluing or somehow fixing the spring down. Screw the plate on and then shove the lever into place *** What do you think? 04. Track down the actual spring and get either a donor movement or part. *** seems like an expensive way to repair something that was about $10 05. Black out all the dates and call it a design and also call it a day *** translation Giving up. I would really appreciate the opportunity to learn how the last guy actually did it.

-

Hi all, hope you had a nice new years. I was working on a UG 218 and am finishing it up when I noticed the microrotor weight rattled. Upon inspection the axel seem wormed and I replaced it. However when replacing it I noticed that that the weight itself is two parts. The first part is the weight and the second part is the the jewels that attach to the axel. The two parts are held together with pins that run the length. and on my weight the pins are no longer holding together tight so the weight is pinging off the second jeweled part. My question is, is it possible to to tighten these two pins or do I need a whole new weight? I have circled the two pins I’m speaking of in green.

- 13 replies

-

- universal geneve

- polerouter

-

(and 3 more)

Tagged with:

-

Hi I've tried to service a tiny Seiko 2601 Automatic movement very small for me (18 mm) So I finished yesterday all was ok I've rewinded and I was happy because the balance started I've not checked amplitude or precision (for me just ticking it's already something) Today I check and the watch have stopped and do not restart even when I rewind manually. Now when I put the main spring back in the barrel I've broken the end part at the opposite side of the pinion it was like a V because I don't have a main spring rewinder so I make it manually (Shame on me). So I suspect that the main spring is not clamped in the barrel and it's just spinning inside without giving any power to the movement. The question is what method can I use to check my assumption. Not forget It's an automatic movement. Thanks

-

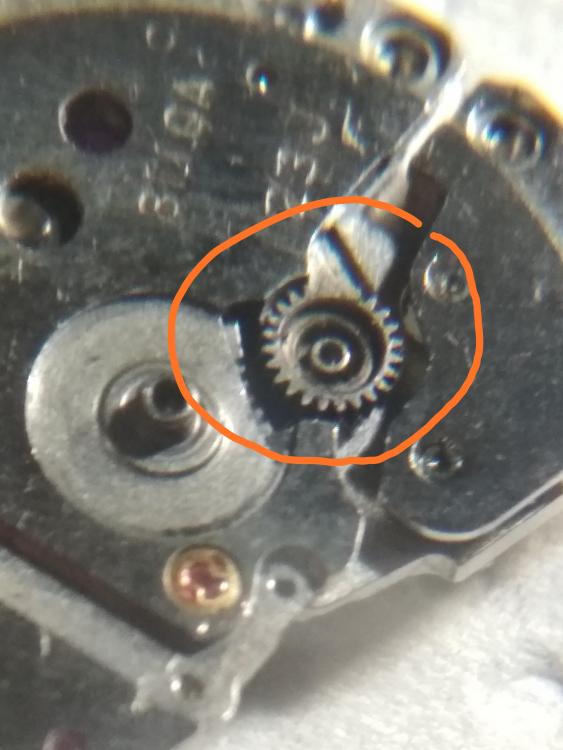

I have a watch movement that I have hunting for a case for a long time now. I bought the movement rather cheaply as I absolutely love the patina on the dial. The movement is an Wittnauer 11arg (as 1361). When the rotor turns the automatic assembly slips (or maybe the mainspring). The pictured gear slips when the rotor turns. I can still wind the movement by hand however the automatic assembly slipping I believe causes the mainspring to unwind. Does anyone know what is wrong/ what I can do to remedy it? Thanks for your help, Amateurwatchbreaker

-

I bought a vintage bulova sea king automatic at a antique mall for 80 dollars and I discovered the reason for its lower cost. It appears that it was someone's project watch that they sold. It has a 11 Anacd movement and the rotor is stuck. It can move but it grinds against the metal underneath it. The middle portion of the rotor(with the engraving) is loose and moves independently of the rest of the rotor. I have no clue how to remove the rotor as there are no screws on it. Is this a deeper problem than just the rotor or can I fix/ replace the rotor?

-

Automatic not winding. Manual also goes rough. Rotor moves freely but it has difficulty pushing the spring. If wound runs normal 42 hours. Came back from Brazil (five years) , took all watches in airplane and many automatics now have difficulty? Can they have gotten covid? Never had watch issues so exploring . Others with issues. Dubey aerodyn X2 this is the GMT alarm. Dubey Worldtimer works fine. Citizens x2 bullheads, x2 8180 and the diver as well issues (not sure number is correct) issues, the Seiko 6139s x4 steady as they go....no issues Omega coaxial all good. ???? Very upsetting. Let's focus on this one first. As here the winding is rough, the others this seems fine and don't have the glass back to validate .

- 9 replies

-

- dubey schaldenbrand

- automatic

-

(and 2 more)

Tagged with:

-

Hello everybody,I open this thread to archive works on Citizen 8110A Bullhead. I purchased this watch in poor condition as You can see on the photos. Cause I have serviced few chronographs in the past I decide to try restore this watch. Maybe is not ractional from the economical aspect but we do this because we love it So let's open it. Hands are in good condition (required repaint and relume) but the dial has broken legs and tachy scale is faded :/ I think it's really hard to find orginal and there is no gold aftermarket replacement - sad. Look at the movement. Gosh, what a dirty place It needs good cleaning and oiling. But the biggest problems are this. Broken post on main spring bridge and missing rocking bar core and screw in gear train. I need to find replacement.While I'll be working on movement the case and pushers are send to renew - putting new gold plated coat Stay tuned

- 18 replies

-

- 1

-

-

- automatic

- chronograph

-

(and 2 more)

Tagged with:

-

Been struggling through a number of #31 movements. This particular one was bought as a "running" watch, but it's been anemic from the start with some 80° of amplitude, just no momentum at all. I've cleaned it, oiled it, checked it and repeated some 3 times now, with nothing seeming to help. One thing I've noticed is that the unlubricated movement always sticks hard on the trailing palette pin. Give the pin or balance wheel a flick and the escapement wheel kicks the first pin out easily and then hangs on the 2nd. I've lubed the pins before (which is a bit tough) and this (along with other general oiling) gets it going with the poor amplitude, but never for long. Could the pin be bent in towards the wheel? Doesn't look it. Hairspring seems nicely shaped. I've lubed both pivots of the balance shaft and attempted to remove end-shake, but that adjustable brass pivot is getting pretty mauled. I'm really trying to avoid taking this movement apart completely. Any thoughts? Thanks!

-

So there is this timex automatic i found online from a reputable seller. I cant find much about it anywhere. Ive been looking for a timex automatic but already have a few watches that look like the marlin. This one is a little different and i like it. Any info would be greatly appreciated

-

Miyota Automatic Service - "Three Screws to Rule Them All" Now for something completely different, a Japanese Automatic from Miyota. This is a budget driver's watch from a fashion brand called Scorpion, and I had no idea what I'd find when I removed the caseback :huh: Whatever! I just wanna work on watch movements, increase my knowledge, and the repertoire of movements I've had experience with. It's also a blessing to post these to help people with reference photos and walkthrough of various movements. When put on the timegrapher, it was quickly obvious that this movement was not running well at all. Extremely low amplitude, high beat error, and a graph that looks like the pepper in your mash potatoes :P Well, it happened to be a Miyota Automatic Movement ... I have no idea of the caliber, as there are no stampings on any of the plate ... beside the brand name. Once removed from the case, I pulled the Hands... ...and then the Dial. After that, I flipped it over and removed the oscillating weight to get a better look at the movement itself. Notice anything scary about this already?? There are only 3 screws holding the complete movement together!! :o Ack!! Visions of the Seiko 5J22A Kinetic "Auto Relay" , with it's 9 pivot gear train plate flashed before my eyes!! This was NOT going to be fun putting back together :P But I do so love a challenge. As per usual, I removed the tension from the Mainspring, and removed the Balance and Fork. Note: The red arrow is pointing to a very thin spring which you pull back to disengage the Click. Here's a closer reference photo of it after I'd pulled the plate off So as the title says ... Three Screws to Rule Them All .... Bam! The whole movement has to be located into ONE plate, that's only held by three screws ... this is not Rolex quality gentlemen ^_^ After tipping the movement up-side-down and telling the complete movement fall onto the desk (just kidding), you are left with only the Centre Wheel. Once the Centre Wheel Bridge was removed, the fault with the movement running so badly came to light ... RUST on the lower piviot! Rust also on the Pinion Over to the Calendar and Keyless Work ... looking way over complicated for a simple Date Wheel, as all the springs are there for a day complications as well; minus just the Day Wheel :( ... Gotta love cheap movements. Reference photos of the Keyless Work. One last thing to note with this movement. The setting lever is riveted into the Main Plate, so it's not able to be removed. Well this little gem is in the Watch Cleaner, and I've got a few weekend chores to do, so I'll put it back together tonight and post the results later. Hope you enjoyed this write-up, and got a few giggles out of it as well :)

-

lubricating barrle wall for automatic movement

east3rn posted a topic in Watch Repairs Help & Advice

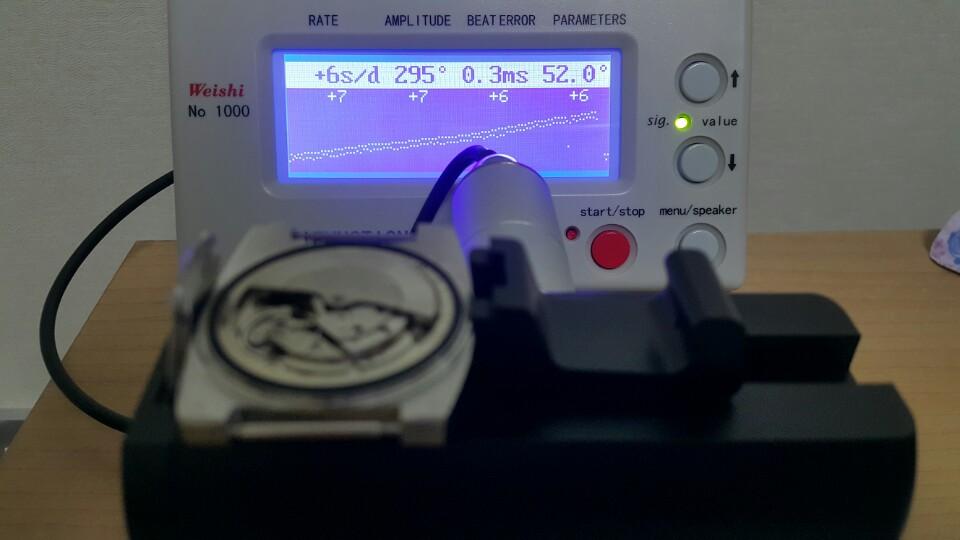

Hello. I recently serviced a PUW 1561 automatic movement. This was my first time servicing automatic movement and I am not confident on lubricating barrel wall. I purchased Moebius 8217, breaking grease for the barrel wall. The whole service was a quite long process for me so I will just get to my point. On the cleaned barrel wall, I applied thin layer of 8217 thinking that too much would not do any good. Then I placed the mainspring and applied 3 drops of Moebius 8200 before closed the barrel cap. After I had assembled the watch, I tried winding it. It wound well but I could hear the mainspring slip in side the barrel when I felt some tension on the crown as I was winding. I know that automatic mainspring slips along the barrel wheel but never experienced such 'obvious' slipping sound. I guess the timegrapher tells that service was not that bad but I just don't feel right when hand winding the watch. Is it something wrong in the barrel? May be I should have applied the 8217 more thicker? Thanks for always helping me out.- 15 replies

-

- lubrication

- automatic

-

(and 1 more)

Tagged with:

-

Hi all, I'm new here, but have been watching the videos on YouTube for a while now, and used them to educate myself on the nature of mechanical watches. Thanks for the great videos Mark! You helped take the mystery and fear out of these works of art.

-

Hi, I have a Rotary Monza I am fixing up. I disassembled the barrel and removed and cleaned the mainspring. I secured a copy of the parts list and it shows that as well as the mainspring, there is also a Brake Spring (part 775 on the picture). What is it, and do I really need it? Certainly Cousins does not sell it. I googled AS 1902 brake spring and ONE result came up of a Russian watch forum discussing this item. Apparently it is thicker than a normal spring and it seems to have some sort of bent over feature on it. Can I just make one using the old mainspring? If so, how long should it be? Is it really necessary? https://translate.google.com/translate?hl=en&sl=ru&u=http://forum.watch.ru/showthread.php%3Fp%3D5196915&prev=search ROTARY Monza AS 1902.pdf

- 3 replies

-

- automatic

- mainspring

-

(and 1 more)

Tagged with:

-

Hi all I just recently finished servicing two Omega Speedmaster Reduced (equipped with the ETA 2892-A2 coupled with chrono module Dubois Dépraz 2020) for a couple of friends and both watches are having the same issue. I'm an amateur and just service watches for family and friends. The automatic work is not fully winding the movement and both watches are stopping after 6 days of use. Very curious that the two watches are showing exactly the same behavior!! I have tried everything and I'm not being able to get the automatic work to wind the watches for long period of time without the need to give it a manual wind. What else can I do? People wearing the watches are quite active and don't have the same issue with other automatic watches. See below a measure of the timegrapher for 6 days of wearing the watch without manual winding (except for first day): Rate Amplitude Day 1 (full manual winding) +20 299 Day 2 +13 280 Day 3 +7 261 Day 4 -23 238 Day 5 -12 211 Day 6 Stopped Some info regarding the service: - All parts were carefully washed and carefully oiled as per ETA technical chart - Replaced mainspring with new one ordered from Cousins (GR25341X). I measured both new and old mainsprings and they are they are the same - Replaced reversing wheel with new one ordered from Cousins - Checked the oscillating weight and bearing and all seems fine. There is not looseness and it all seems very aligned and in place - Oiled the oscillating weight bearing with 4 very small drops of Moebius 9010 on 4 of the metal spheres (don't have much experience on this one, hope it is ok) - All the automatic work seems to work perfectly when I manually tested the rotation of the oscillating weight with the movement out of the case Only thing I did not replace yet is the bearing of the oscillating weight. I'm reluctant to do so since current one seems to be just fine and I don't to want spend money for a part that seems to be just fine. What else can I do? Many thanks

- 31 replies

-

- eta2892-a2

- eta2892

-

(and 1 more)

Tagged with:

-

Hello! My first question / project as a new member: I have a watch with a Ronda 4438, or perhaps 4439 automatic movement. The rotor has considerable play due to wear. I have been unsuccessful at finding information about the proper rotor removal method. Referring to the attached photo - I have identified the two stake marks at the rotor hub, but I do not see any retaining components or clips (perhaps the component that I marked with arrow?). Any guidance would be much appreciated! Cheers, Neil

-

Hello there watch fix fans. Here's (I hope) an interesting one for you. I have this beautiful small ladies 'Fero Feldmann' Swiss-made watch - it came in a bag of "used and to be repaired" watches. From what I can see, the mechanism seems in very good working order. Just a slight shake and it goes and goes. There is no strap, but that is not the issue here. The problem is the stem and/or crown. As you can see, there is definitely no crown. But I am wondering about the stem. The watch does have its case and edoes have, as you can see, a hole where the stem and/or crown will/should fit in. There is something which appears to be some kind of part-stem at the 3 o'clock position. Using tweezers I can pull it out and push it back in quite freely. A very small screw on top holds this "stem" in place. I think you can see, in ths second photo, how this "stem" attaches to the rest of the movement. Clearly I need to attach a crown. BUT what about a stem? A stem extension? Or one of those crowns which has an extended stem-like attachment which should fix onto this current "stem" in this watch? Yes, the watch face is somewhat scratched, and the minute hand is a little bent at the top. You may say it is not worth my while trying to get this fixed. But I just SO MUCH like this little watch and would LOVE to give it life again! It clearly IS still "alive" - though I'm not sure if it is a mechanical wind-up or an automatic. The latter of these seems to be the case - as I said earlier, a little shake and the mechanism goes and goes. PErhaps with a little oil (and lots of encouragement) it can be made good. So my main question - what kind of stem/crown to attach and how to do it?

-

robisi automatic How to repair automatic watch?

aqeeliqbal posted a topic in Watch Repairs Help & Advice

Hi watch lovers <3 i got a Robisi automatic watch. It accidentally fell down on the floor and its glass got detached which i attached again but after some time i realised that the Synthetic ruby gem was missing from it. Therefore it lost its balance and it stops time to time. How do i fix this?- 6 replies

-

- automatic

- automatic watch

-

(and 2 more)

Tagged with:

-

Good day all, this is my first post so please excuse my limited knowledge of watches and repairing them. I have a Seiko 5 model number snk805 that I recently bought overseas that has stopped working. It seems like the watch is not being charged even though the self winding weight is spinning as normal. The watch is still on warranty but since i bought it overseas it would be difficult to have shipped back. Basically what I would like to know is if it is worth attempting to fix it myself or would it better to take it to someone trained. I do have some experience with working with watches but i have never attempted to fix an automatic mechanism. Thanks for all the help.

-

Hello, I have a similar problem like this topic: but my watch is a Maurice Lacroix PT 6158. It is a automatic watch. and recently my problem seems worse. I tried to wind the crown towards 12 more than 30, but it doesn't help, and make the thing worse, the watch stop moving immediately, until i shake the watch, and it start moving a little bit. and stop again. (The watch used to be really good, and can hold for 2 days straight) Like the other guy, i am using it regularly from 7am - 10pm. Every morning I wind the crown 5-6x to make it works until noon. and sometimes it does not working. the only things i could notice: 1. the circle movement (I don't know what is it called) that i can see on the back side of the watch move really slow. not as fast as it used to be. (I am using it for more than 4 years now). 2. if i put the watch down with diagonal position: the crown touch the table, the watch will be able to hold for about 3-6 hours. IF, i put the watch on the table, and the crown does not touch the table (again, diagonal) it will take less than 1 hour until the watch stop. IF i put the watch down (Horizontally), the crystal touch the table. the watch will stop move immediately or in less than 1 minute. Can anyone help advise me what I should do? i wonder if it could cost so much to repair it? or just need some oiling things? Thank you so much.

- 5 replies

-

- automatic

- automatic watch

-

(and 3 more)

Tagged with:

-

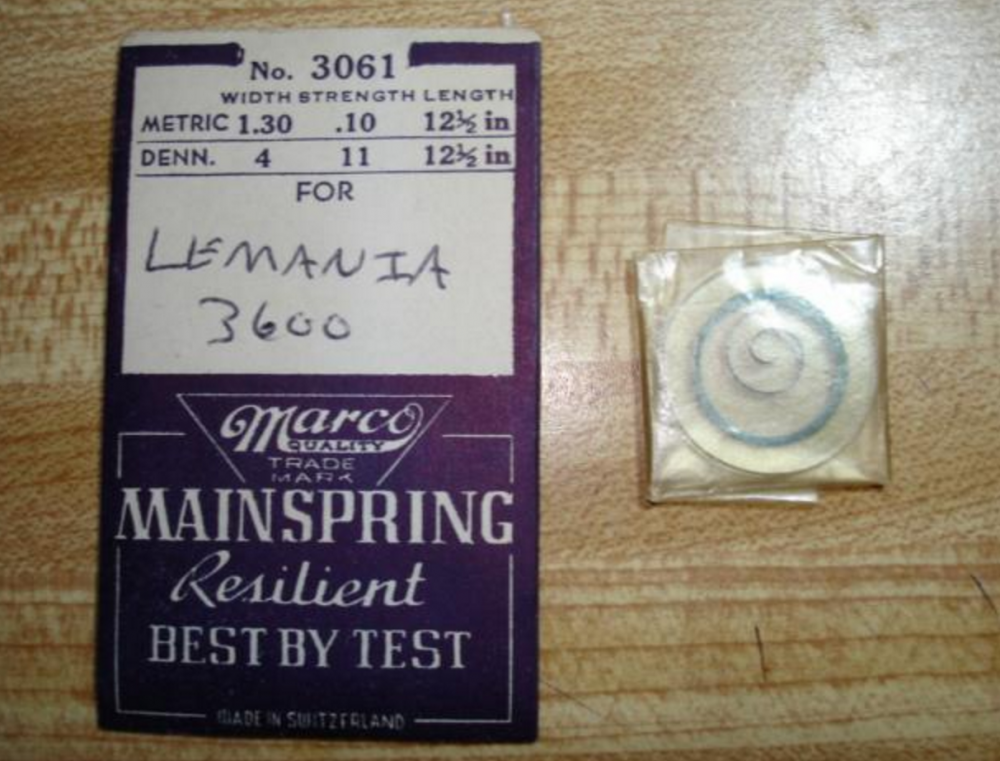

Hi All, I’m a Lemania collector and as a hobby I try to service some watches myself. I still have a lot to learn and currently i’m a bit stuck with finding a decent main spring for a Lemania cal 3600 (automatic). Here’s my problem: I ended up with 2 different specifications for a Lemania 3600 mainspring based on the following pictures (see attach). Maybe the Marco one is less reliable because it has a hand written specification instead of a printed one….? Now, there is a wide variety of auto mainsprings available here: http://www.ofrei.com/page_112.html and here: https://www.cousinsuk.com/category/mainsprings-by-size-watch-pocket The thing is that they all differ on at least one of the specs. I can imagine that the width is crucial, otherwise it will just not fit, but other things like length, is some margin allowed there? For example instead of 12,5 inch is 12 or 13 inch also ok? If i have to choose, which specifications are more important, for example strength is more important then length,..…? Would be nice if somebody could give a good hint to a mainspring to would fit in a cal 3600 .… Thanks! Gert

-

The oscillator, or something, in my automatic wrist watch seems to be greatly affected by outside temperature (summer vs winter). It seems to run fast in the summer, and even faster in winter (The manufacturer said they could adjust it). Q: Is this difference with temperature normal/possible? and Q: What would cause this? [a poor choice of hair spring material (stiffer in cold = higher rate)??? a poor choice in lubricant???] Thoughts? As an Engineer, I like to understand causes and effects. As far as my watch is concerned, I will be surprised if there is a year round fix. -E-

- 3 replies

-

- automatic

- hair spring

-

(and 4 more)

Tagged with:

-

I just purchased a Waltham Selfwinding watch marked B-251K on the inside of the case back. First of all, it is marked 25 Jewel on the face and 17 Jewel on the rotor, which I found odd but its nothing I haven't seen before, and that's where the trouble started. The watch runs, and runs very well. However, the rotor is wobbly and loose that it contacts the balance wheel at times in its travel. The rotor does not attach with a screw, but rather with a sort of sliding clip. I am no watch repairman, more of a tinkerer who has opened and successfully repaired and maintained a watch or two in my life. I'm beginning to think this might be the wrong rotor, but it appears to be a perfect match, even drops in perfectly, but it is so loose it practically falls out. Ideas anyone?