Search the Community

Showing results for tags 'lubrication'.

-

Well here goes. At my work wrist watches are forbidden so I dug up a vintage no name pin pallet pocket watch out of my collection,so if I damage it all OK. I stripped the movement out of the case cleaned it in the ultrasonic wholus bolus. Put it back together. And experimented with oiling all pivots and pin pallet with only mobius 9415. D5 on the mainspring and 9415 on time setting mechanism. Well 3 years later it is still running perfect. Here is some photos. Tomorrow I will relume the hands with Superluminova. Mmmmmmm. I never set the time and have kept it wound seven days a week for 3 years as an experiment. Once I am home back on goes a wristwatch. Has anyone else done a lube experiment. I must admit this old German movement is like a tractor.

-

Hi Fellow People, Im reaching out as I’m currently learning all I can about watchmaking, and am working through the BHI distance learning technicians course, with my exam booked for May. I will need to service a quartz watch as part of my practical exam, and am learning about watch lubrication. A few months ago I found a great article that covered the technique for dipping and collecting the right amount of oil on the oiler, such as the speed and angle of the dip, however, I now can’t find it anywhere, no matter how much I search the internet Does anyone have or can point me in the right direction of instructions specifically on oil collection on the oiler? As you will know there is lots on the actual oiling process but not the oil collection process. Any help would be greatly appreciated. Thanks Bethan

-

lubricating barrle wall for automatic movement

east3rn posted a topic in Watch Repairs Help & Advice

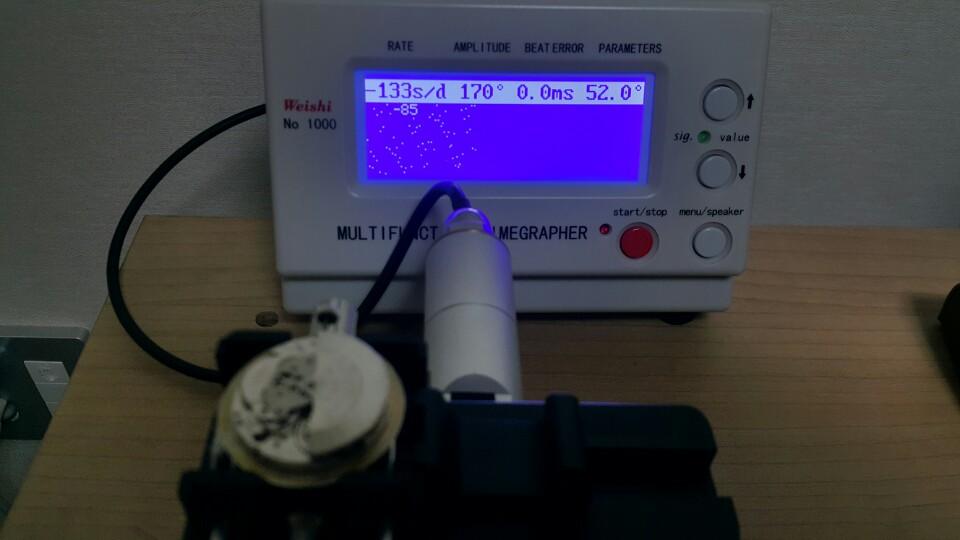

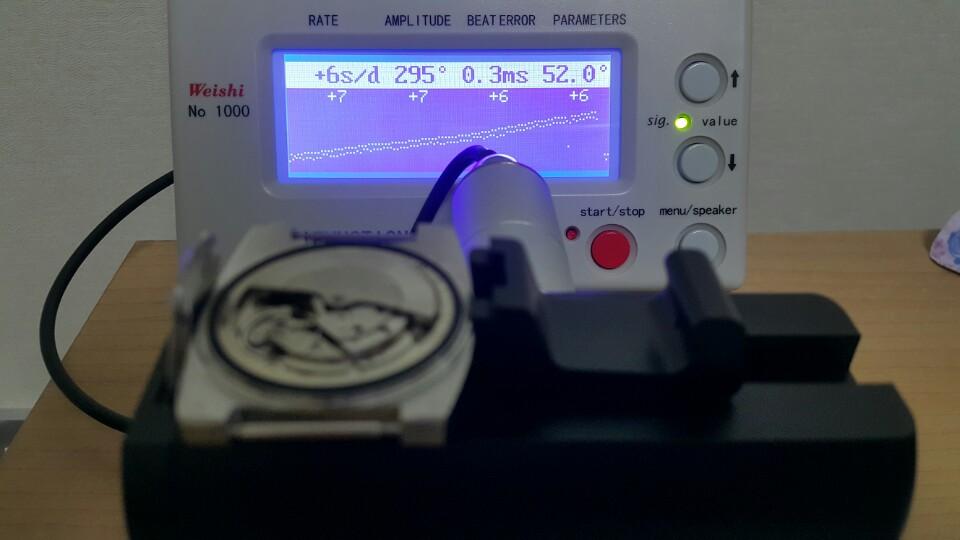

Hello. I recently serviced a PUW 1561 automatic movement. This was my first time servicing automatic movement and I am not confident on lubricating barrel wall. I purchased Moebius 8217, breaking grease for the barrel wall. The whole service was a quite long process for me so I will just get to my point. On the cleaned barrel wall, I applied thin layer of 8217 thinking that too much would not do any good. Then I placed the mainspring and applied 3 drops of Moebius 8200 before closed the barrel cap. After I had assembled the watch, I tried winding it. It wound well but I could hear the mainspring slip in side the barrel when I felt some tension on the crown as I was winding. I know that automatic mainspring slips along the barrel wheel but never experienced such 'obvious' slipping sound. I guess the timegrapher tells that service was not that bad but I just don't feel right when hand winding the watch. Is it something wrong in the barrel? May be I should have applied the 8217 more thicker? Thanks for always helping me out.- 15 replies

-

- lubrication

- automatic

-

(and 1 more)

Tagged with:

-

Hi Everybody! Henry Fried has in one of his books a little recipe for making a grease that one can use on the outer wall of the mainspring barrel in an automatic watch. It supposedly provides lubrication for proper slippage of the mainspring tail. Has anyone tried this? What is the proper consistency (Fried is not very specific about this because it was probably so common in his day)? Also how would such a preparation compare to Kluber P-125 which, here in the US is really expensive? I won't leave it here. I"m gonna experiment a bit with this and will let you know what I found. Just want to see what other's have found out. Thanks.

- 13 replies

-

- lubrication

- kluber

-

(and 1 more)

Tagged with:

-

I’m in the process of establishing a reassembly and lubrication plan for of what is basically my first automatic; a Vostok calibre 2416B, and I’ve come to the reversing wheels. As can be seen in the above pictures from the strip down, the teeth of the reversing wheels have blackened. It looks to me like they have must have been lubricated, or could it be that the oil that was once applied to the jewels has spread out over the teeth? So what do you think; should I lubricate the teeth, and if so what kind of lubrication do you think could be suitable? This movement is about 25 years old and has never been serviced. I know this for a fact as I know the original owner who bought it new. The watch is in great condition and was only worn for about three years when the strap broke and was then placed in a drawer. There it had been sitting until I got in my hands. It’s a somewhat rare Komandirskie, and for anyone interested here are some pictures of it and how it got into my hands.

-

This is a 2 part series from Oklahoma State University of Watchmaking on the correct use of Oilers. Oiling a movement correctly is one of the most important skills you need to master, and these videos give some excellent advice. Part 1 https://www.youtube.com/watch?v=eMJiX0MA-Wg Part 2 https://www.youtube.com/watch?v=rlMW5qMHaNc

- 7 replies

-

- 4

-

-

- Oilers

- Lubrication

-

(and 2 more)

Tagged with:

-

I am out of Lubeta v105 (for lubricating reversing wheels) and lucky me, cousins have just started stocking it. I am a happy bunny :) https://www.cousinsuk.com/product/oil-eta-lubeta-v105?code=O39844

- 2 replies

-

- lubeta v105

- reversing wheels

-

(and 1 more)

Tagged with:

-

I'm going to reassemble and lubricate my first watch this weekend. I've seen a few people on the web mention using PML Stem Grease to lubricate the keyless works parts. Is anyone here using it for this purpose? It's supposed to make setting and winding smooth and silky.

- 2 replies

-

- lubrication

- grease

-

(and 1 more)

Tagged with:

-

Hi All, I've been reading a lot on barrel and main spring lubrication and find two distinct "factions", those that lube the mainspring outside of the barrel and those that lube the main spring inside the barrel. I would tend to think that lubing the mainspring outside of the barrel is far more thorough and complete but wanted to know others thoughts on this if at all possible? Thanks in advance for any feedback on this!

- 11 replies

-

- barrel

- lubrication

-

(and 1 more)

Tagged with: