Search the Community

Showing results for tags 'chronograph'.

-

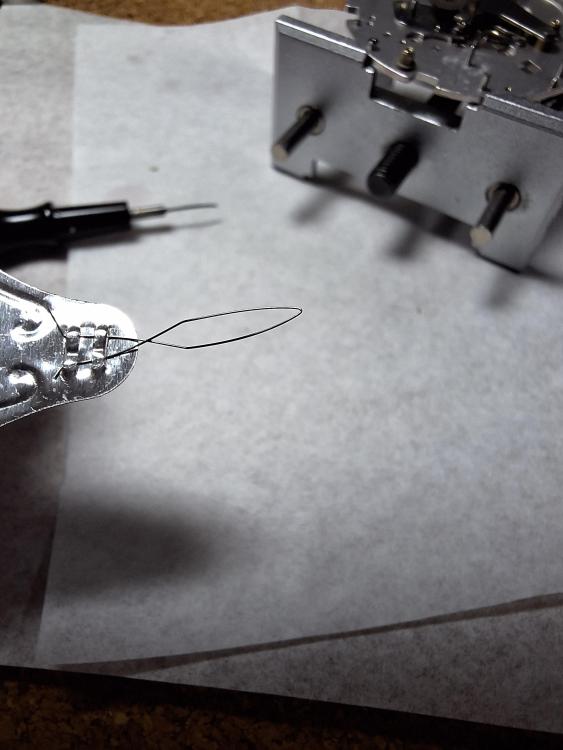

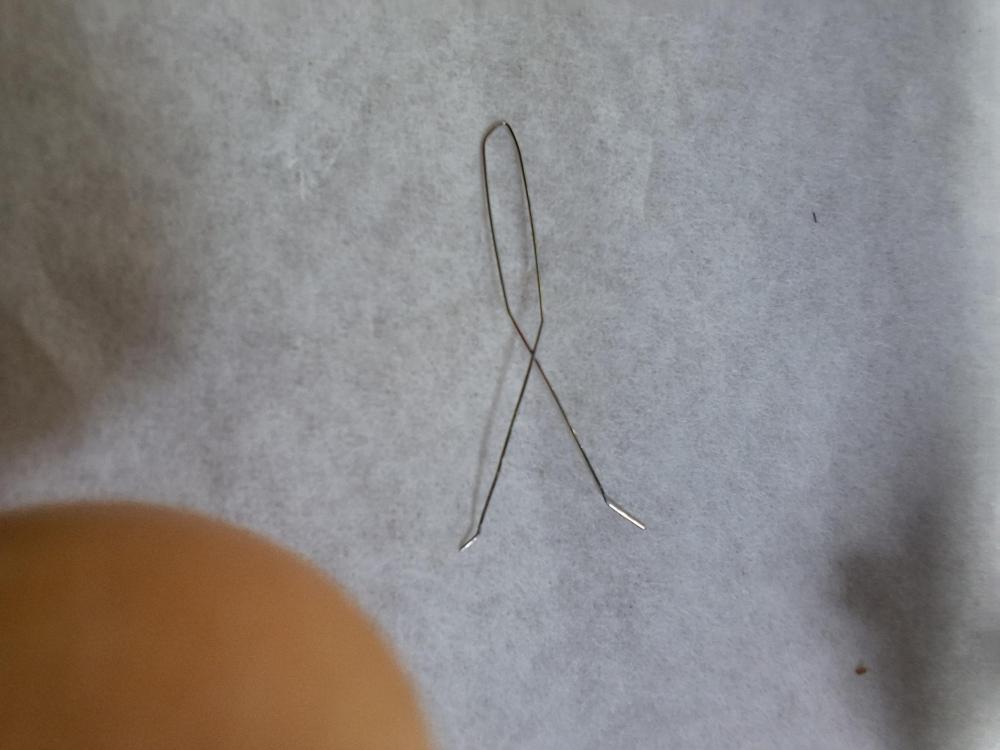

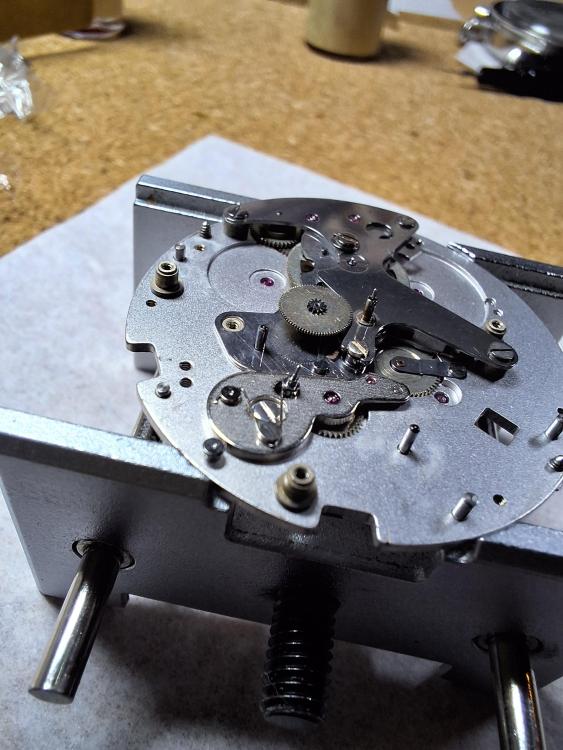

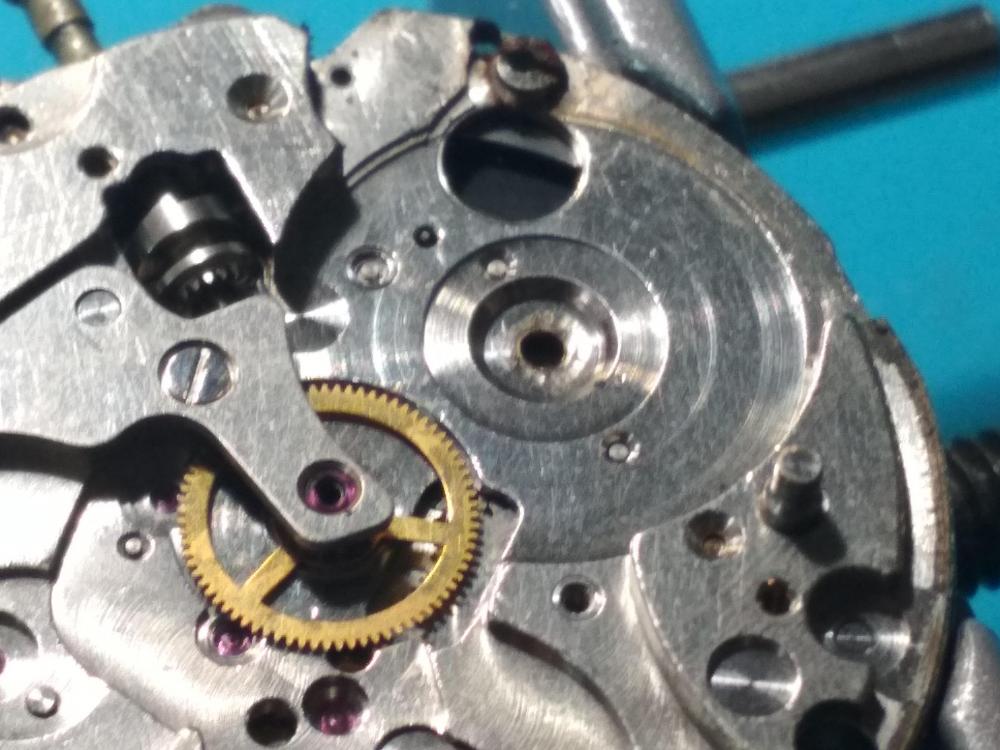

Hello and good day to all, I’ve had some difficulty with my Omega Speedmaster reduced overhaul, Cal 1141 with the Dubois Depraz 2020 module. I overhauled the ETA 2890-a2 last year but didn’t do the chrono at that time. Recently the pushers were sticky, and I decided to overhaul the module. *disclosure” I am not new to watch hobby, but still don’t have a sonicator. I used lighter fluid to clean the Dubois module and followed Mark Lovic’s excellent reassembly procedures—No problem with reassembly. The watch runs fine without the chrono engaged. The chrono starts but stops after about 15 seconds of running. I disassembled again and this time cleaned with Kleen strip low-odor paint thinner. I was extra careful during rebuilding, but still managed to lose the second pinion friction spring, (part 471 60.131 in the Omega 1141 technical sheet). That’s right I lost the spring. I looked for it, but I have carpet and so I gave up…moving right along. I know it’s impossible to get the DD module parts unless you buy a whole module from somewhere, but I discovered that needle threader is a good gauge and thickness to make a spring, so that’s what I did. After cutting and bending it seems to fit quite well. I continued the reassembly, and the watch runs fine, but once again when I engaged the chrono, it starts but stops after about 15 seconds in the same way it did before. I don’t think the homemade spring is the problem. What do you think it is? I suspect I need to clean the movement better as I don’t think the DD module is very forgiving of any drag once the power is transferred into the DD module. I welcome any feedback.

- 6 replies

-

- chronograph

- dubois depraz

-

(and 1 more)

Tagged with:

-

I'm looking for any instructions for this watch to reset everything after a battery change. It's some complex series of presses on the 3 pushers and 1 crown but I can't remember the sequence and I've lost the instruction sheet that I had. Any help would be appreciated

-

Hi all, I picked up a lovely Heuer chronograph pocket watch with a Valjoux 61 single button chronograph movement. I didn't notice when I bought it but the pusher which should sit within the crown is missing. The pusher within the crown pushes down two pins which you can see in the pictures, the pins then push a sleeve which sits over the crown, this then actuates the start, stop and reset of the chronograph. Unfortunately I have no idea where to find a replacement... anyone have any ideas? The dimensions seem to be quite different to old pusher pocket watch crowns. The crown is 8.0mm in diameter, the tube diameter is 3.1mm and the cavity for the pusher atop the crown is about 3.9mm Thanks in advance!

-

- heuer

- chronograph

-

(and 2 more)

Tagged with:

-

First of all my apologies for not having documented the disassembling, but the watch arrived in a terrible condition and I stripped it down right away to get rid of all that dirt. If you have worked on some watches yet and think about entering the chronograph world with a 7734 let me give you 3 advices: Do it! The 7734 is a solid construction and not too complicated. Take your time and watch all the 6 parts of Mark's Venus 175-service on youtube. Of course the Venus is a column wheel system, but the basic movement is very similar and also on the chrono layer you can learn a lot especially about lubrication: https://www.youtube.com/watch?v=EI3T-IR3AgM Download the 7734 service manual. A lot of information here: https://strela-watch.de/valjoux-7734-7733-7736-technical-documentation/ Here we go. Some 8200 for the barrel and the new mainspring goes in (got it from cousins - what I'm gonna do after Brexit? ). The complete barrel. Some D5 for the arbor. Putting in the wheels and the bridges. Lubrication: 9010 for the escape wheel and the second wheel, D5 for all others. The keyless works. 9501 for the stem and the gears. D5 for the wheels and the lever axis, 9501 for the contact points of levers and springs. The click spring. D5 for the click and the crown wheel, 9501 for the contact point of click and its spring. Finally the ratchet wheel goes in. The pallets go back in, no lubrication for the pivots. Lubricating the balance jewels with 9010. The balance back in. The escape wheel and the pallets got epilame so I let run the movement with dry pallets for some minutes. After that 941 for the pallets (work from the dial side through the window). Now I start with the chronograph. First the bridge and the spring for the levers go in. Fly back lever goes in with some D5. Operating lever, again D5 for the axis. A little bit tricky, you must upline the integrated spring with the upper lever first (9501 for the contact area). The second pictures shows the final layering. The sliding gear goes in, D5 for the lever axis, no lubrication for the wheel! At this point I forgot to put in the minute recorder runner (no lubrication). You should install it here, later its going to be more difficult. The blocking lever (D5) returns. Some 9501 for the contact area to the sliding gear. The blocking lever spring. Be very careful, this one isn't just a flyer, its a damned Lockheed SR-71 Blackbird. The friction spring (gets a drop of 9010). The chronograph runner and its bridge (9010 for the long pivot and the jewel in the bridge). The minute recorder jumper, no lubrication. The hammer. D5 for the axis, 9010 for the lever ends that hit the hearts, 9501 for the contact areas to the sliding gear, fly back lever, operating lever, jumper. The hammer cam jumper. Before installing the clutch give 9010 to the pivots of the coupling wheel. D5 to the lever axis. The spring. 9501 for the contact point. Finally line up the driving wheel with the coupling wheel and the chrono layer is complete again! The dial side. Some 9501 and the cannon pinion goes in. Hour wheel with D5. The dial rest with its 3 screws. The date indicator. The date indicator driving wheel with some D5. The jumper with D5 to its axis. As there was no lubrication described in the manual between disc/jumper or disc/wheel and the parts looked well polished I didn’t lubricate. It works - let’s see how long. The guard with 2 screws. Finally the spring. The dial comes back and is secured with its 2 screws from the side. While disassembling I put the little hands into seperate trays to prevent mixing them up. Now I turned the crown in the setting position exactly to the point when the date switches and put on the hour hand to 12. Positioning the chrono-hand exactly on zero was that tricky that I forgot to take a pic. New springs and gaskets for the pushers. Unfortunatly I’m not good in restoring cases. So just refreshing the brushing a bit and some cape cod work. The movement back in the case and secured with 2 screws. A new gasket for the caseback and here we are. Thank you for watching.

-

Hello! I am planning to service this watch soon. The only information I can find online is a parts catalogue from cousins UK but I was wondering if anyone had an actual service manual for the Venus 170? I want to make sure I do everything in the correct order and oil only that which is essential. I'm hoping to find one similar to the landeron service manuals available online. Failing that, would anyone be able to indicate which screws are the eccentric screws on this movement? That would go a long way in helping without the use of a manual. Thank you for any help you can give!

- 3 replies

-

- chronograph

- venus

-

(and 2 more)

Tagged with:

-

Beginner horologist here. I attempted to overhaul my first chronograph. I followed the manual from cousins to the tee from what I can tell, and everything is working great EXCEPT the chronograph will only start, and when I hit the bottom button to pause, it automatically resets to zero instead of pausing before a second click to reset. What would cause this? I've been scratching my head since it essentially works perfectly otherwise. Any help would be great appreciated!

-

Hello, everybody. I wanted to share my restoration stories that I have done for a long time and thrown into my archive. First I discussed the Atomic Mars 71 Brand using Valjoux 7734. As it was seen, scratch and dial is broken. To begin with, I tried to brush the Case as Brushed and make it the first day. If it is decorated, I polished and re-painted the indexes (with acrylic paint). I usually do this in three layers so that the paint is not deleted in a short time. I replaced the case buttons and tubes with aftermarket buttons. Since the condition of the dial was in very poor condition, I had it re-painted. The quality is not so good. In Turkey, unfortunately, not doing the job well. Caliber 7734 (Valjoux) is a special and robust mechanism for me. With good maintenance and lubrication, you can reduce deflection values up to 3-4 seconds per day. I added a short timelapse video about it :) As a result, such a result came before us. Thank you Taskin https://www.youtube.com/watch?v=XKH6yTKUfpM

-

Hello everyone. I have a really sad story and I am a complete amateur. I am a machinist for a living so I thought I would give a crack at making a frankenwatch, however it did not go as planned and now I have a movement with subdials that don’t work and a whole lot of parts and money invested and I don’t know what to do. I need the help of a professional. The donor movement was a NOS, new old stock, and was running perfectly, however I messed up almost everything attempting to make this watch. I will happily ship all of the parts needed to complete this watch and pay for any repair that need to be made and for the return shipping. I need the help of a professional how can repair and assemble the watch with the parts and return it to me. I will pay for everything, the labor, replacement parts, return shipping, I just need someone’s help. Details about the project: movement: valjoux 7733 dial: vintage NOS angelus chronograph dial case: custom machined case crystal: plexiglass

- 2 replies

-

- angelus

- vintageangelus

-

(and 5 more)

Tagged with:

-

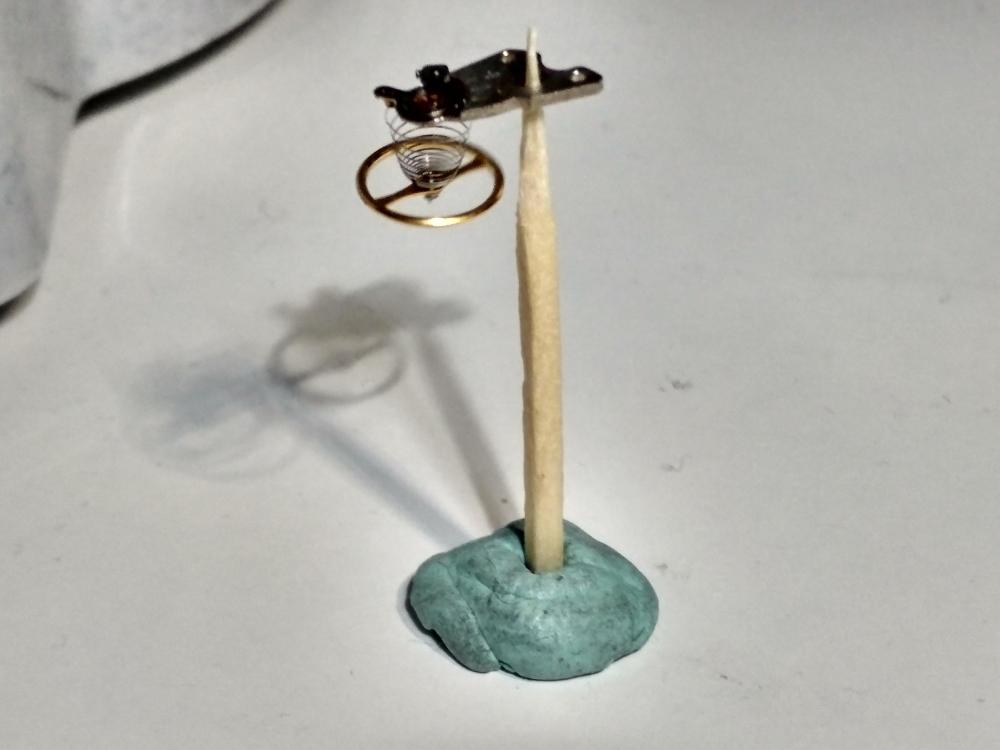

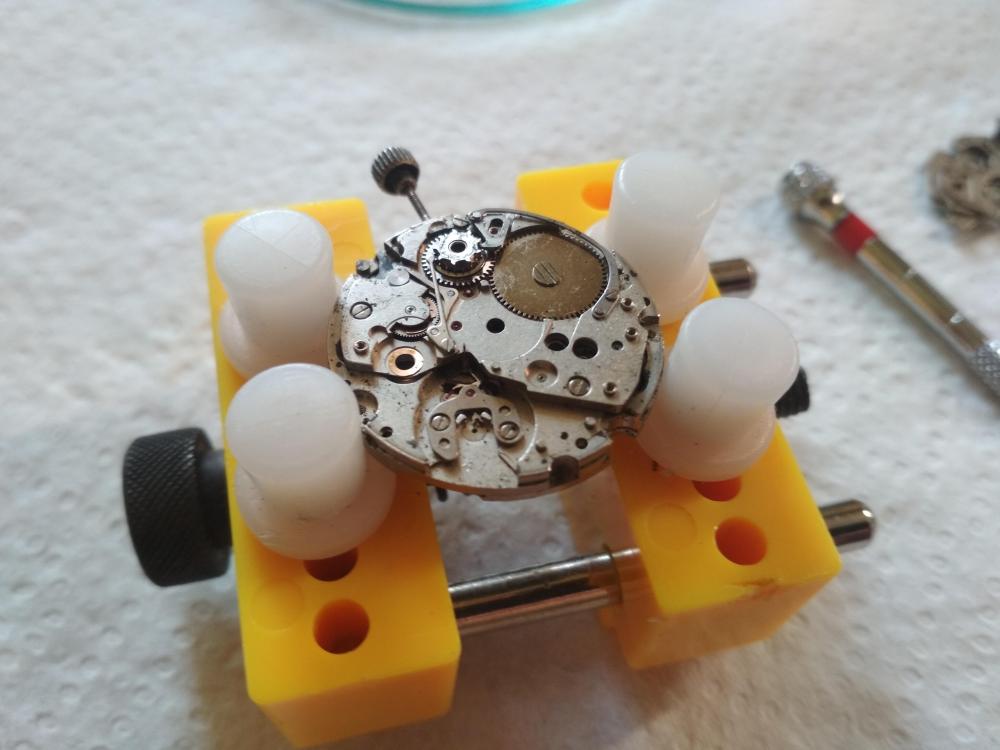

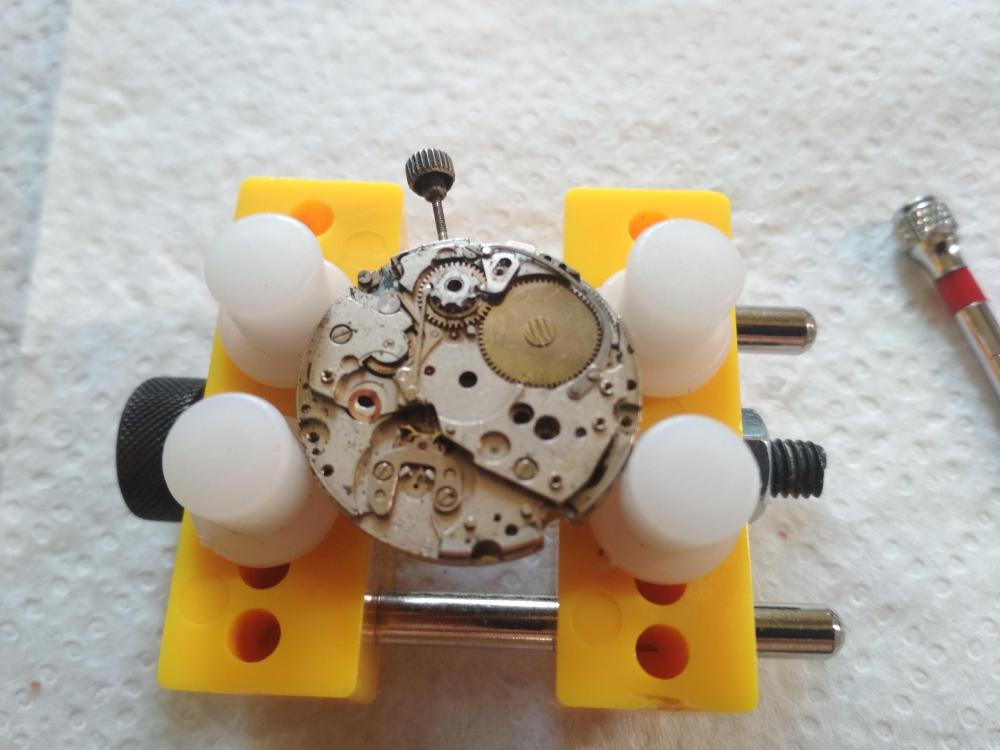

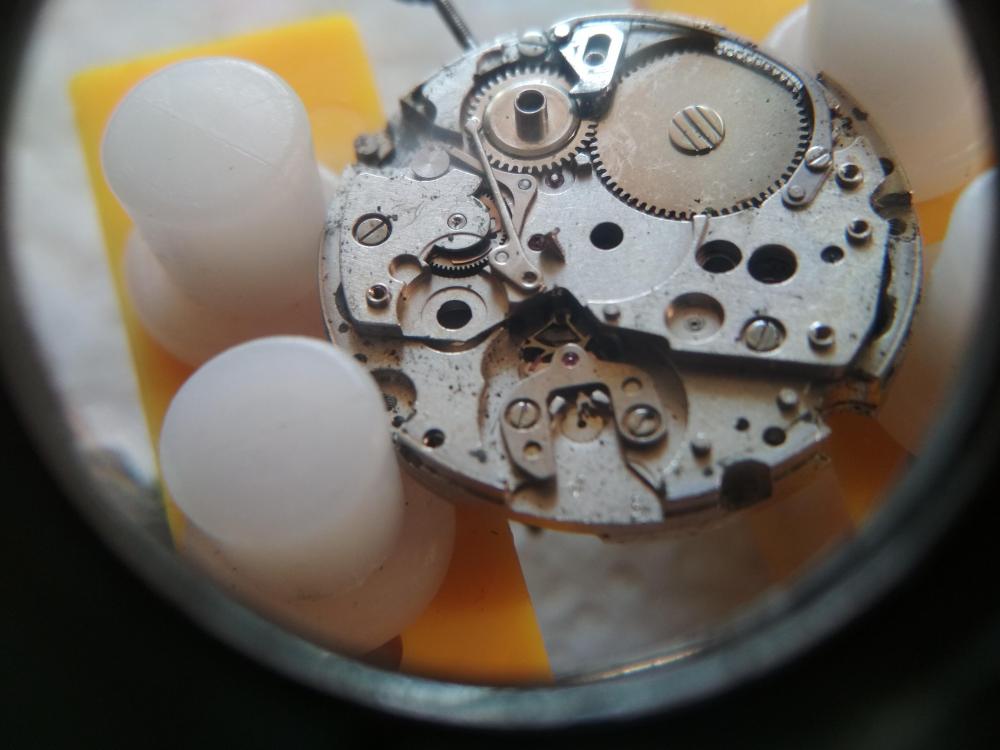

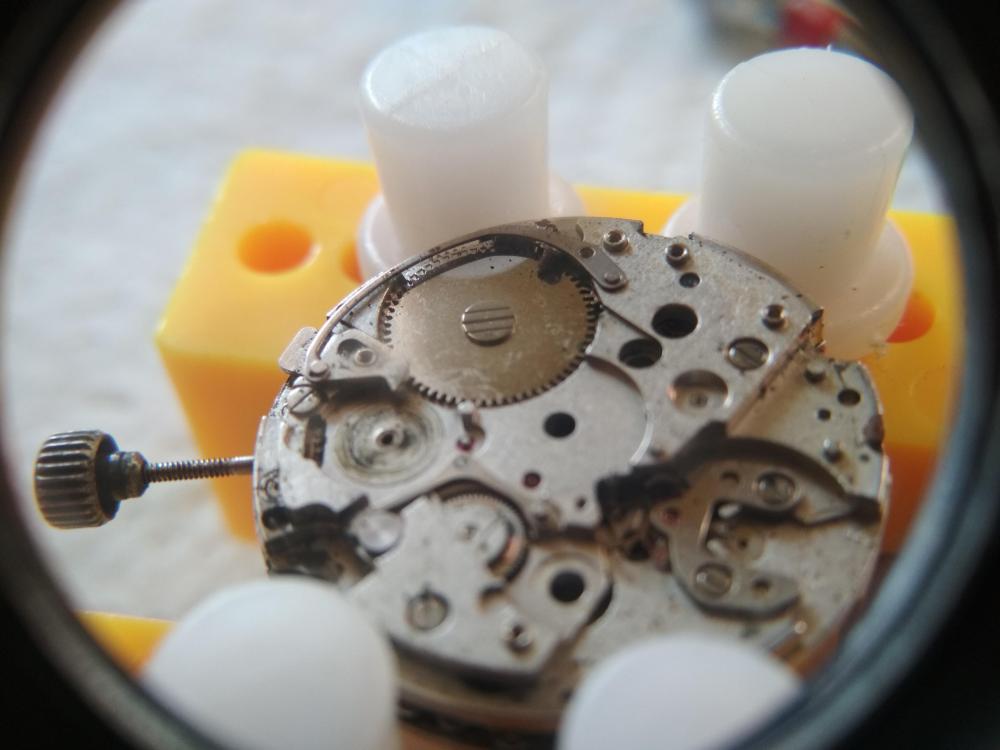

Hello guys, I want to show you my lately restoration project. This time it was a Seiko 7015-8000 with blue dial. Watch came to me in very poor condition. As you can see on photos the case was scratchty, crystal was totaly tarnished with deep scratches. Everywhere was dirt, gunk and mud...yuck. Movement was running and stopping with very low amplitude. After opened the caseback I wasn't suprised - it looked like as case - dirt and signs of wear. Rotor was loose and fall out the case. When I take off the crystall I saw dial which had faded Seiko logo, some scratches and hands which lost their lume. Next step was strip down the movement - everywhere dirt and dry old oil. Time to cleaning bath Look at this - it's my temporary balance wheel stand - I suspect that from temporary it will be permanent. It does job well. After cleaning it's time to assembly movement. Now it looks better - maybe not pristine but clean and shiny. New oil here and there and movement starts to run. Now it's time for bench testing before install it to the case. Meanwhile I took care of the case, dial and hands. Case got some polishing work - not to much cause I didn't want to loose the sharpness of edges. That is effect: Dial and hands got new lume - I am not perfect in this work but I still learn to do this. Additional the seconds hand was repainted to orange color. I didn't change the crystall but i just polished it with waterpaper and on the end polish paste. Effect suprissed me. Time for the pleasant work - putting this all pieces together into the watch. VID_20190927_195610.mp4

-

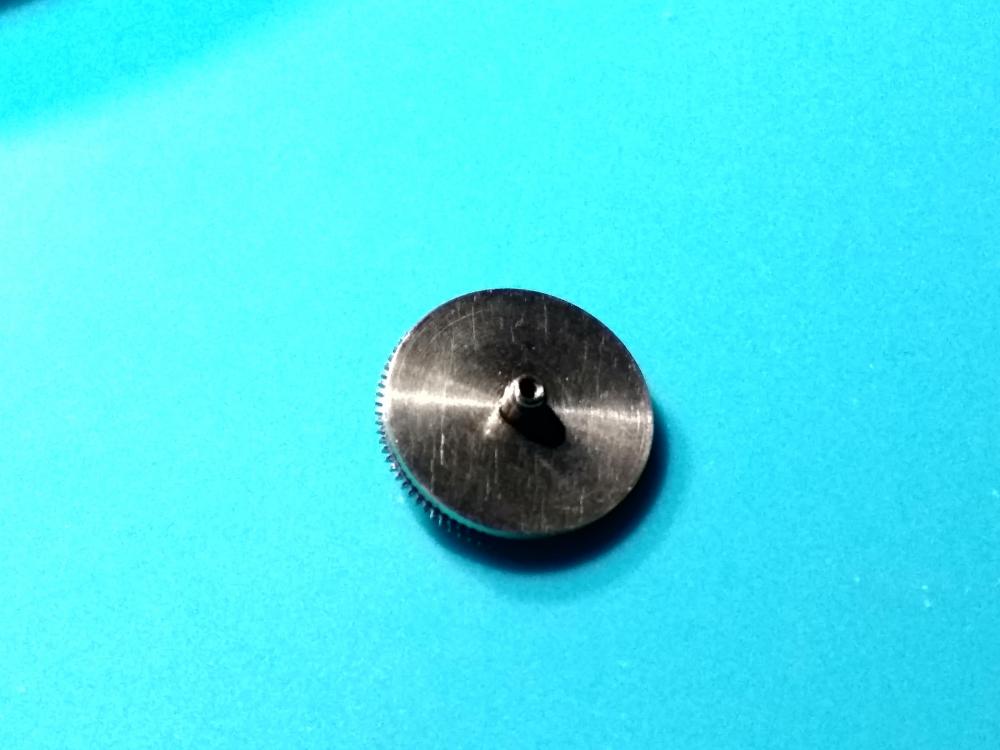

Hello everybody,I open this thread to archive works on Citizen 8110A Bullhead. I purchased this watch in poor condition as You can see on the photos. Cause I have serviced few chronographs in the past I decide to try restore this watch. Maybe is not ractional from the economical aspect but we do this because we love it So let's open it. Hands are in good condition (required repaint and relume) but the dial has broken legs and tachy scale is faded :/ I think it's really hard to find orginal and there is no gold aftermarket replacement - sad. Look at the movement. Gosh, what a dirty place It needs good cleaning and oiling. But the biggest problems are this. Broken post on main spring bridge and missing rocking bar core and screw in gear train. I need to find replacement.While I'll be working on movement the case and pushers are send to renew - putting new gold plated coat Stay tuned

- 18 replies

-

- 1

-

-

- automatic

- chronograph

-

(and 2 more)

Tagged with:

-

Hello! Could anyone help me with some more detailed information (service sheet, manual, etc) for a russian chronograph Molnija 81322? It was (and still is, from my knowledge) used in MIG 21 airplanes. Two links that I've found: http://www.abbeyclock.com/photos/mig.html http://www.cockpitclock.com/MOLNIA%2081322.html Thank you, Bogdan

-

I have a UG Tri-Compax from the 1950s or 60s (Calibre 281): The chronograph (centre) seconds hand can’t turn past 58.5 seconds and the whole watch stops ticking/working (nothing moving/turning in the movement). However, when the reset pusher (4 o’clock) is kept pressed, it enables the seconds hand and watch to move/tick again. The reset pusher is released when the chrono seconds hand reaches 60: the watch resumes ticking and the hands move until the chrono seconds hand reaches 58.5s again. The process is repeated. It has been noticed that if the watch is held face down then the reset pusher “procedure” doesn’t always work (i.e. the watch does not resume ticking/moving). It’s usually necessary to turn the watch over and try to press the pusher a few times in order to make the seconds hands move again. The 30-minute sub-dial at 3 o’clock has stopped working, too. If the chrono is not activated, then the watch seems to run properly. What do you think is the problem? Thanks for your insight!

- 5 replies

-

- chronograph

- ug

-

(and 3 more)

Tagged with:

-

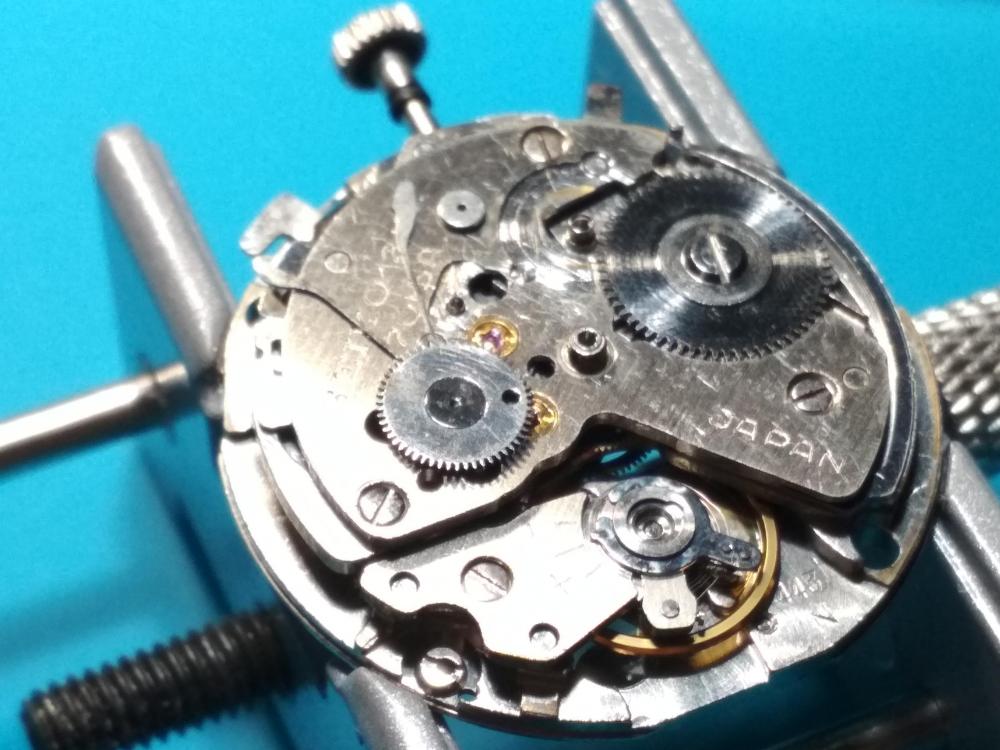

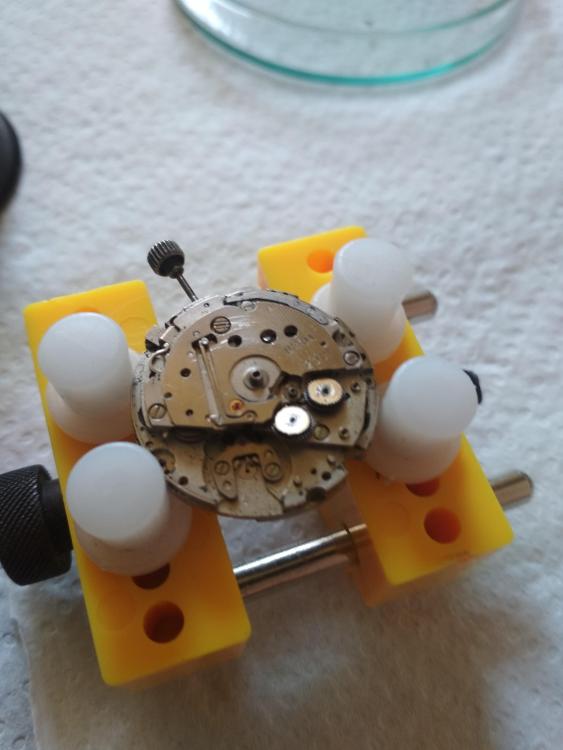

Hello, I started new project - Citizen 67-9119. It's seventies chronograph based on 8110A movement. Watch came to me as "fully working in great condition" As you can see there isn't crystal. The one which was here had chip and wasn't set properly in bezel so when i turned the watch it fall on the floor and broke. As you can see dial is in quite good condition, only it needs to be relumed. Hands needs to be repainted and relumed too. Movement works well but it is too speedy ( +3 min/24h). Chrono buttons work properly, only the hour counter stops at "3h" position so I must to take a look here. I striped down the watch and disassembled movement. There was some much oil everywhere so the cleaning is required.

- 25 replies

-

- 3

-

-

Hey everyone, I cant find out how to get this drown off and I've tried everything. The Miyota JS25 movement says PUSH and points to a hole which I've learned means this is where you press to reease the crown but I still can't get the crown out no matter which position the crown is in. I first tried with the crown all the way out then with it halfway in, then all the way in and haven't been able to get it out, please help.

-

I wish I had more projects to report on but things have really bogged down lately as I continue to bite of more than I can chew. I'm in the middle of three long term projects (the Favre Leuba Bivouac going on year three) and am running short of workbench space. I'm in the middle of changing out the engine in my wife's Mini Cooper too (that's another story but if you own a Mini- be sure and replace the timing chain guides!) and that has really eaten into my "fun time". I thought I'd bring this one to the board for comments before I'm underwater- it's an old Gallet from the 60's. Do you think it can be salvaged? We clearly have some water damaged however, the seconds hand will move if the crown is given a little pressure. Water entered in through the chronograph buttons and the pendant tube. I haven't tried depressing the buttons- I think that would just lead to bits snapping and rust moving about. I'll need a new stem for sure... The dial actually looks quite good. I wonder what it looks like underneath though... It's not terrible, but it's not great either. Most of the rust damage is concentrated in the keyless works. There's a bit of damage to the hour recording mechanism... That's as far as I've gotten thus far. The screw for the Operating Lever is rusted tight and is now being treated with a bit of penetrating oil. Once removed I can pull the second pusher button out and remove the movement from the case. I'll know the full extent of the damage once it's in a pile of bits and pieces. This is an Excelsior Park EP40-68 movement. I've wanted to work on one of these for quite a while but couldn't afford a proper working piece. Excelsior Park parts are difficult to source though so I may not be able to bring this one back to life.

- 31 replies

-

- 3

-

-

- chronograph

- water damage

-

(and 1 more)

Tagged with:

-

Hello guys.. Why my seiko speedtimer 7015 chronograph run smoothly when its day(morning till evening) But its stop and heavy when its time to changing the day date,whats the problem and how to fix it.. Thankyiuu

- 3 replies

-

- seikochronograph

- vintagechronograph

- (and 5 more)

-

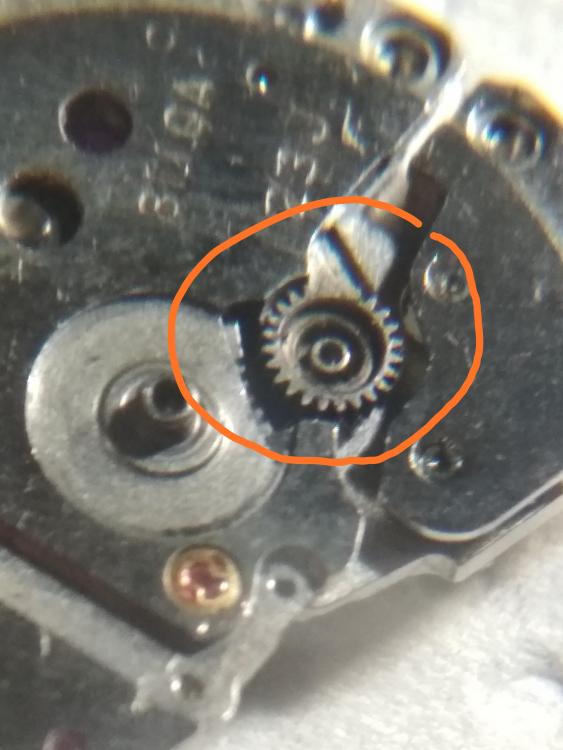

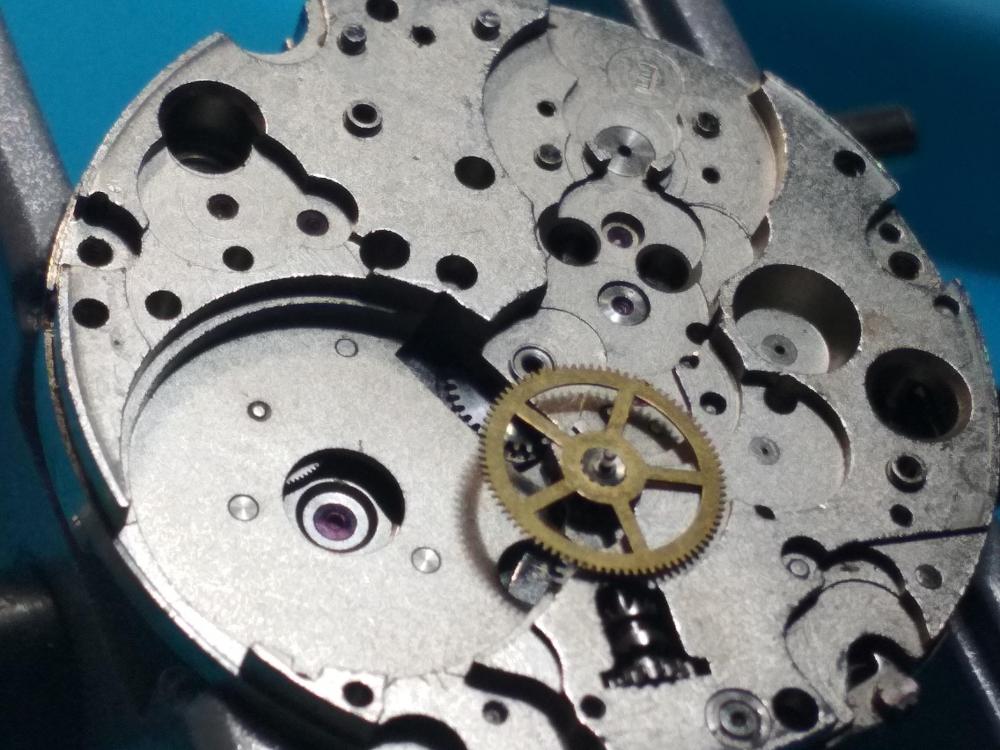

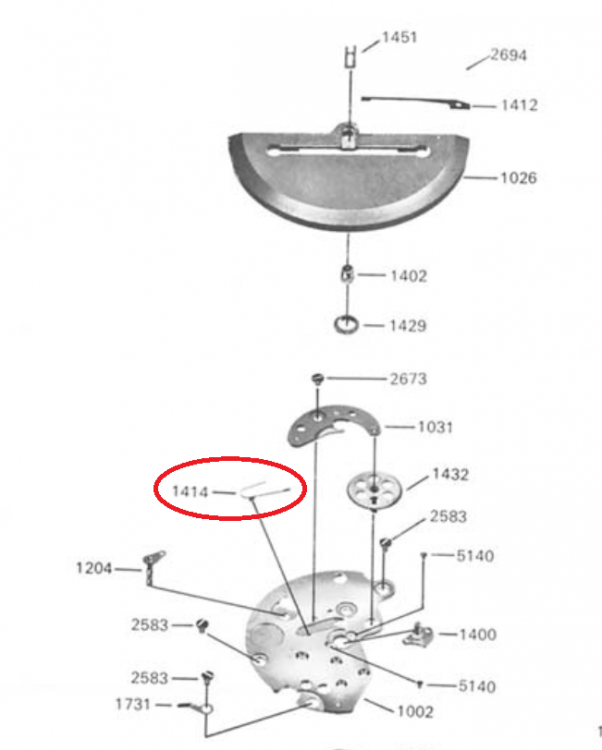

I recently acquired an Omega Speedmaster automatic from the 1970's that has the Omega 1045 / Lemania 5100 movement inside. Long story short- the previous owner tried to service it and made a mess instead. I've managed to source all the parts I think I need except one for the automatic works- the Stop Spring (part no. 1414). This looks like a part I may be able to fabricate but if the original is available I would prefer that. Unfortunately I've come up empty with my usual suppliers. Cousins is the one one who may have it, but it's Restricted which I suppose means you need to be an Omega authorized technician (which I naturally am not) to purchase. If anyone has a lead to follow I would be most grateful for your assistance. This piece is a proper mess right now but I think I'm close to bringing it back from the dead.

- 9 replies

-

- 1

-

-

- chronograph

- lemania

-

(and 2 more)

Tagged with:

-

I received this really nice Seiko 7T42-6A00 to service and the description was that the timer (yes, this particular 7Txx model has a timer also) was not working. After first inspection, actually I noticed that it had some more issues, among which the quickdate that was not working. I made a video presentation of this watch: I decided to strip down completely the movement since it apparently had never being serviced. A movement swap was just not an option... Opening the case no sign of damage was visible, although I did notice some very fine white dust, probably some acid liquid that had dried out. Removing the movement from the case, and inspecting it, showed indeed traces of dried up acid:

-

I just got my grandfathers Gucci 9300 Chronograph and I installed 2 new batteries. However, I cant seem to get the chronograph function to work properly and I cannot find any manual to help me get the watch back in working order. Any advice would be much appreciated

- 3 replies

-

- gucci

- chronograph

-

(and 1 more)

Tagged with:

-

Hi there, I've noticed that mostly analogue watches are discussed on this forum so hopefully posting about a digital watch is okay. I bought this M929 from a thrift store for $3 the other day in a non-working condition. After opening it for the first time, it was evident that a battery had leaked at some point - there was quite a bit of corrosive material everywhere. After giving it quite the clean using vinegar for the batteries crap and isopropyl alcohol for everything else, the backlight was again functioning, however, the LCD was not. There appears to be some sort of potentiometer on the back of the main module, although this looks exactly the same as the screws that held in a back metal plate so I stupidly rotated it for a while before I realised it wasn't a screw. I've roughly rotated it back using a reference photo I took before I dismantled it (below) but the best I can get is a very dim set of numbers that flash and are only visible if directly under a light and viewed from an extreme angle - and even then, it does this randomly. I'm not sure if the pot is even for the LCD, though. I've also checked all the other components on the board with a multimeter and there seems to be continuity at least, although measuring the pot leads to no usable number of ohms. Here's a bunch of photos I took. Hopefully, they can be helpful. Any help with the repair will be greatly appreciated. Here is what the watch looked like on first opening. You can see green/blue muck everywhere. Here you can see the extent of the corrosion on the buttons. This was even holding some of them in place. Vinegar made short work of it, however. A close up of the main module before disassembly. The flipside of the module. Corrosion was bad here too More disassembly and after cleaning Otherside. Note the pot at the bottom LCD, reflector and contact transfer things Close up of the LCD The plastic casing cleaned. There is still a bit of corrosion on those contacts but that is as much as I could remove. The flipside Reassembled after cleaning. Accidentally added some scratches from the screwdriver slipping, though. Whoops. Flipside The corrosion had actually eaten into the watches metal. Luckily the buttons were fine after being cleaned. The backlight.

- 6 replies

-

- seiko

- chronograph

-

(and 1 more)

Tagged with:

-

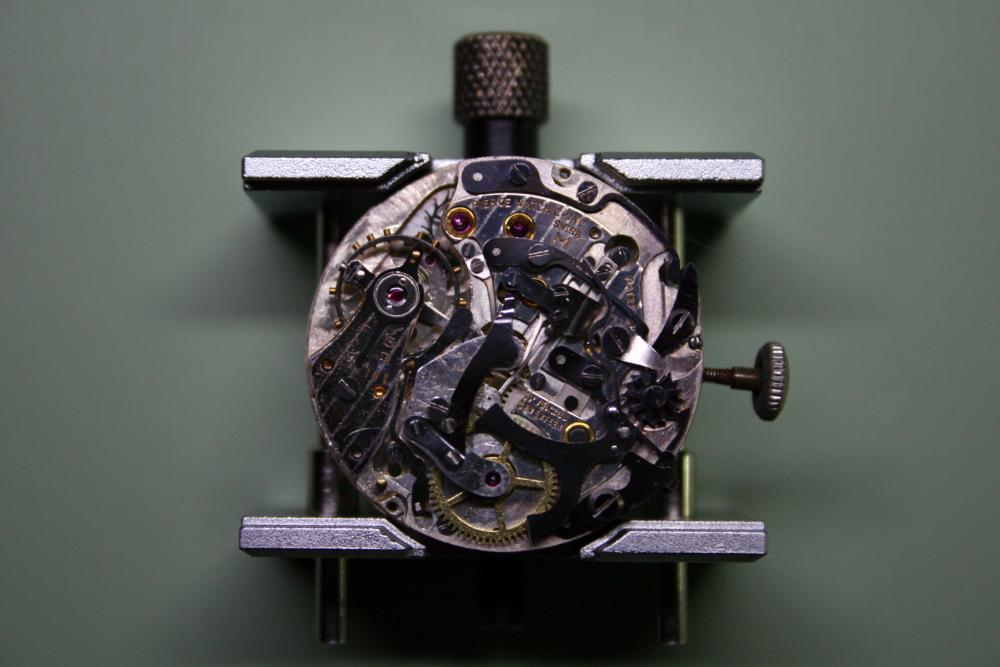

If anyone has happened to work on a Pierce chronograph with a waterproof case, I could use a little help. I'm in the middle of another Pierce chronograph restoration and this is the first I've had with a waterproof case. The case is missing the pusher buttons and stem tube, but I can see that the holes for all three are threaded. The holes for the pusher tubes have a small red rubber gasket inside and behind it there appears to be a compression spring. The hole for the stem also has a rubber gasket which is secured with a threaded ring. This is the first time I've encountered a waterproof case by Pierce and I'd like to return the watch to as close as possible the original specifications. The problem is that I don't have the pushers or stem and I do not understand how they were engineered. Naturally I can fit off the shelf replacements but I would like that to be Plan B. If anyone has any prior experience with Pierce's odd case please feel free to chime in. They had odd solutions to many challenges an I'm interested in finding out how they made their waterproof chronograph.

-

I've done a lot of Pierce Navigator repairs in the last year but this one was a bit special as it was the first I completed for someone other than myself. The watch is an heirloom and as such was received in much better condition than the those I've purchased off the bay. The bracelet was broken and would eventually be replaced and right off the bat I noticed that the sweep second hand was missing. The crown was also stuck in the setting position and therefore it was impossible to wind the watch. With the caseback off I could see that the chronograph staff and pinion had actually been removed sometime back. Also missing was the intermediate wheel which activates the minute recording wheel when the chronograph is engaged. My guess is that the rubber clutch for the chronograph had failed sometime in the past and the watchmaker simply removed the other bits as opposed to attempting a fix. I also noted a chip in the upper balance cap jewel. I've never seen a defect such as this before. With the dial removed, the normal accumulation of dirt and debris came to light. The setting lever snapped back into place smartly and with that I was able to check the timing. With the movement out I turned my attention to the case and pushers. The spacers for the pushers often become jammed inside the pusher button as the result of an accumulation of grime beneath the button cap. The springs, which sit between the spacer and the button, are made of stainless steel and generally hold up well over the years. I've discovered that a good soak in vinegar will usually free the spacers and springs from the buttons. With the pushers soaking I turned my attention back to the movement. As I said before, this Pierce 134 is in much better condition than those I've restored in the past. It's clear the owner has taken good care of the watch over the years. Generally I'll follow the Esembl-O-Graf (volume 15) in reverse order when disassembling a Pierce movement. I've done a few now and am getting used to the process. Looking the parts over I didn't find any that required immediate replacement so the only order placed was for a mainspring and crystal (in addition to the missing chronograph staff, pinion, and intermediate wheel). The old crystal was in fair shape but a little loose in the bezel so I opted for a new one. The damaged cap jew was chipped only on the topside and therefore I opted not to replace it. The parts were whisked off to the L&R cleaner and I turned my attention back to the pushers. The vinegar bath succeeded in freeing the spacers and springs from the buttons. I set the parts out for cataloging after cleaning and drying. At this point I'll also do any rust remediation. This movement was in fine shape but the levers for the chronograph did suffer from a bit of oxidation. The rusted bits were placed in a bath of vinegar for a good soak, then any pitting was smoothed using the Dremel tool or a rub on the Arkansas stone. The replacement chronograph staff, pinion, and intermediate wheel arrived in time for assembly. The staff needed a new clutch plate. In the past I've cut these out of nylon and although this is an adequate solution, it makes the final adjustment a lot more difficult since the nylon has so much less give than rubber. A while ago I began experimenting with rubber o-rings as a substitute. I use a rubber o-ring which had a thickness of 2mm. By sharpening an Exacto knife and lubricating it with a bit of watch oil I can cut through the o-ring with very little compression. This results in a disk that is thin enough and flat enough to use as a clutch plate for the chronograph. A punch I made on the lathe is used to place the center hole. Unfortunately since I made the o-rings before I began this service, I didn't have any images of the procedure. Assembly is straightforward provided all the gremlins have been discovered beforehand. The pallet, escape wheel, and cap jewels receive epilame treatment. The balance wheel is cleaned separately with One Dip. Put back together I noted a funky reading not the timegrapher. The culprit was a slightly bent pivot on the pallet. I replaced the pallet with one from my own stock and this resolved the problem straight away. I let the watch run overnight before beginning on the chronograph layer. It comes together a little slower as there are many more parts to lubricate and adjust. A missing sweep second hand can be a real problem with Pierce watches as the center post is 0.35mm (which is large). Fortunately I had a hand in my stock from a parts movement that would do- once I attached a post to it! I have some brass tubing that has an inside diameter of 0.35mm so I just needed to turn the outside diameter down on the lathe and rivet the post to the hand. Here I test the fit of the hand prior to painting. Once that was settled I discovered the post on the minute hand was loose also. A new post was turned on the lathe for it as well. Problems with the chronograph became apparent after fitting the hands. The culprit in this case turned out to be a damaged center jewel. This must have occurred during assembly as the jewel checked out after cleaning. Bad luck. The jewel is pressed in from the topside and so it must be removed by pressing from the bottom side (dial side). Unfortunately the jewel sits at the bottom of a long tube which required me to turn a special adaptor piece on the lathe for my Seitz tool. A replacement jewel was sourced from a donor movement and I was back in business. The owner decided on a replacement crown and a new strap and the watch finally came together. I have a bit of a thing for Pierce watches but at the same time I don't think it's much of a coincidence that the watches housing a Pierce 134 movement only seem to exist from the late 40's and early 50's as they can be a bear to get running right. In the end I was really pleased with this service though.

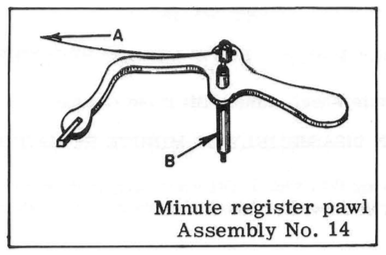

-

I thought I'd break this out as a separate narrative from the Pierce Navigator repair I posted here. Anyone who has done an old chronograph repair is aware of how delicate part 8270 (minute recording jumper) is. The Pierce 134 movement is put together quite a bit differently from your normal chronograph in that it has a vertical clutch arrangement as opposed to the laterally engaged coupling clutch found in the more common Venus and Valjoux chronograph movements. As a result of this uniqueness many parts, while functionally the same, are designed in a wholly different way. The Pierce minute recording jumper (pawl) is different from the typical jumper piece in that it is not a spring, but rather a pivoting lever which is held in tension by the thinest of wires. The wire needs to be manipulated in to put the jumper under just enough tension to hold the minute register wheel static until activated by the intermediate wheel. Too much tension will cause the watch to stop when the elapsed minutes are recorded, and too little tension will allow the minute register wheel to spin freely. Unfortunately it is not uncommon for the wire providing tension to fail after manipulation. Here I have a jumper in which the wire has broken and the jewel (well, actually it's just a cut piece of steel) has come lose. Initially I though it would be a simple fix to replace the broken wire. I used some 18 gauge electrical wire which was composed of several strands of thinner copper wire. Stripping the insulation off, I took a single strand of the copper wire and assumed it would suffice. Under the microscope it was evident that this approach wouldn't work. Even the smallest copper wire I could find was several times thicker than the wire I needed. Using the bench micrometer I measured the thickness of the broken wire at 0.05mm. To give an idea of how thin this is, I snapped a picture under the microscope of the wire next to a human hair. The wire is on top, the hair on the bottom. Armed with hard data I was ready to take a second shot at the challenge. Using the internets I found a company in the UK which could supply nickel wire in the same thickness. I placed an order, then added a couple spools of varying thickness just in case (and to make the product to shipping cost ratio a bit more reasonable). The wire arrived in due course and was exactly as described. I began my repair by knocking out the brass pin which secured the old broken wire to the pawl. A sewing needled was used to knock the pin out. The "jewel" was then replaced using a bit of shellac and a alcohol lamp. Now it was time to replace the spring wire. I cut a length from the spool and threaded it through the eye piece on the jumper. Naturally this was done under a microscope. A replacement pin was inserted to hold the wire in place and the excess was trimmed off using the scissors on my Swiss army knife (they seemed to be the perfect tool for this job). As you can see had two jumpers to repair: I'm very pleased to have been able to repair these parts as they can be quite expensive when purchased second hand; from personal experience I've seen the Valjoux and Venus jumpers cost between $30 and $120 USD which is quite a lot for a little bit of steel. Pierce parts can be hard to come by also. I currently have two Pierces in varying stages of repair so the jumpers will come in handy. On a side note I don't vape so I have no idea why tiny nickel wire is necessary for smokeless smoking.

-

A few months back, I purchased online this Breitling Navitimer for a fair price despite the fact that the watch was non-functioning at the time. I did this without seeing the movement which was a bit of a risk as there was the possibility the insides were rusted out, but the price was right and the I figured I could resell the case and dial if the rest turned out to be a disaster. Things looked bad when I received the watch as it wouldn't run at all and the pushers were jammed. I noted on inspection that the dial didn't sit flush either which caused me quite a bit of concern. Removing the caseback revealed one of the case screws had broken off and gummed up the works. Extracting the screw head brought the watch back to life and allowed the chronograph to function properly as well. Knowing I would need to extract the remains of the broken screw from the plate in order to properly secure the movement and seeing that the watch clearly had not been serviced in a while, I added it to my queue. It would be a few months before I would have time to work on it, but I must admit to being anxious. I don't often work with watches of this vintage that aren't terribly weathered but the dial and hands here were in quite good condition. Removing these gave my heart palpitations but with a bit of patience and caution I was able to get to the engine without damaging any of the paint. The video Mark posted earlier of a Navitimer service was a quite a help also as I was a bit stumped when it came to removing the bezel. The watch movement is a Venus 178 which is a fine manual wind chronograph movement that was produced in the 1950's and 1960's. Contemporary chronographs movements would be the Valjoux 72 and Lemania CH27. Disassembly was pretty straight forward. The chronograph mechanism is bolted piecemeal to the barrel plate so each lever needed to be removed separately. I would remove each spring first to release tension then proceed with the removal of the accompanying lever. Each screw was then returned to its hole so that I wouldn't mix them up later. Pictures were taken throughout the process for reference. The dial side received the same treatment for the hour recorder and keyless works. I had assumed I would need to dissolve the broken screw in a bath of alum in order to remove it from the plate but found this not to be the case. Once the barrel plate was removed, enough threads poked above the main plate to allow me to grab it with my tweezers and slowly unscrew the remainder. I have an old L & R machine for cleaning movements, so the parts were separated and packed in small baskets before undergoing a cleaning in the appropriate solvent and rinse. The case, caseback, and pushers were cleaned separately in small ultrasonic cleaner. Since the shafts of the pushers are not the same length I snapped a pic before disassembly for later reference. Following cleaning, each piece was inspected under the loupe before reassembly. I can't stress the importance of this step! Reassembly was the reverse of disassembly. I referred heavily to the images taken during the disassembly process and also used the published technical sheets and representative Esemble-O-Graf. Before reassembling the chronograph the base movement was completed and properly adjusted. Despite having already procured a replacement, I reused the original mainspring as it seemed to have quite a bit of life still in it. My assessment turned out to be correct when I placed the base movement on the timegrapher and discovered the amplitude was fairly high. This is not a problem I've had before but since the watch had a full wind I felt there wasn't much need to replace the spring with a weaker one. The beat error was initially on the high side (3.1ms) but a bit of adjustment brought that down. I suppose I would be remiss if I didn't point out that adjusting the beat error was difficult as there is no beat corrector and the Breguet hairspring sits so low that it's difficult to see the position of the roller jewel. Assembly of the chronograph mechanism is laborious as each piece needs to be checked for movement and properly lubricated before moving on to the next. I had inadvertently mixed up a few screws on the dial said which added another hour of labor to the job as well. The toughest bit was the actuating lever for the hour recorder- it passes from one side of the plate to the other and likes to fall out when you try to thread the screw to secure it. Otherwise reassembly went as I hoped- no parts lost or left over! I cleaned the dial and slide rule with a bit of Rodico. The slide rule is set in the bezel before the crystal is dropped in. A new crystal was needed as well since the original was damaged beyond repair. Lastly, a replacement case screw was procured to reset the movement and a crystal press was used to reset the crystal and caseback. I added a black leather band as the expanding bracelet wasn't really my taste. For my next chronograph project I'm hoping for a Valjoux 72 movement or perhaps an Excelsior Park EP40. We'll see what comes along though.

-

As pe the title, here a small comparison video of my Seiko Quartz Chronographs from the 7Txx series. Enjoy!

.thumb.jpg.21fef8a034b96c538aeb74080200021a.jpg)

.thumb.jpg.79ad121181594f35081614d0d9500df0.jpg)

.thumb.jpg.442640492ead5012aaa3e995af1f9b39.jpg)

.thumb.jpg.9095a8cd02c1e1bcf97b53fd03d1589e.jpg)

.thumb.jpg.659e45086cdb83afb64c371dfb284dba.jpg)