Search the Community

Showing results for tags 'restoration'.

-

My latest repair/restorations — running super strong. I’ve done like 2 dozen of these repair/resto this year alone and generally put them back on eBay to try to recoup costs. I like these so much I might just keep them for myself.

-

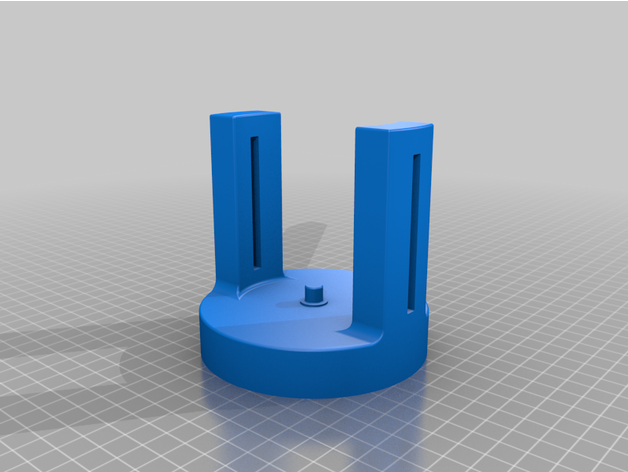

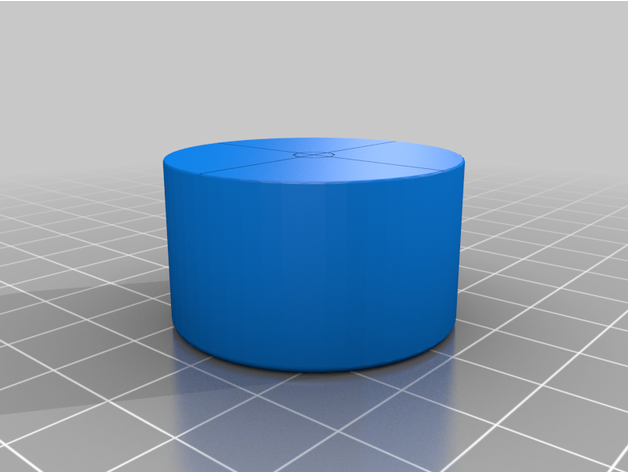

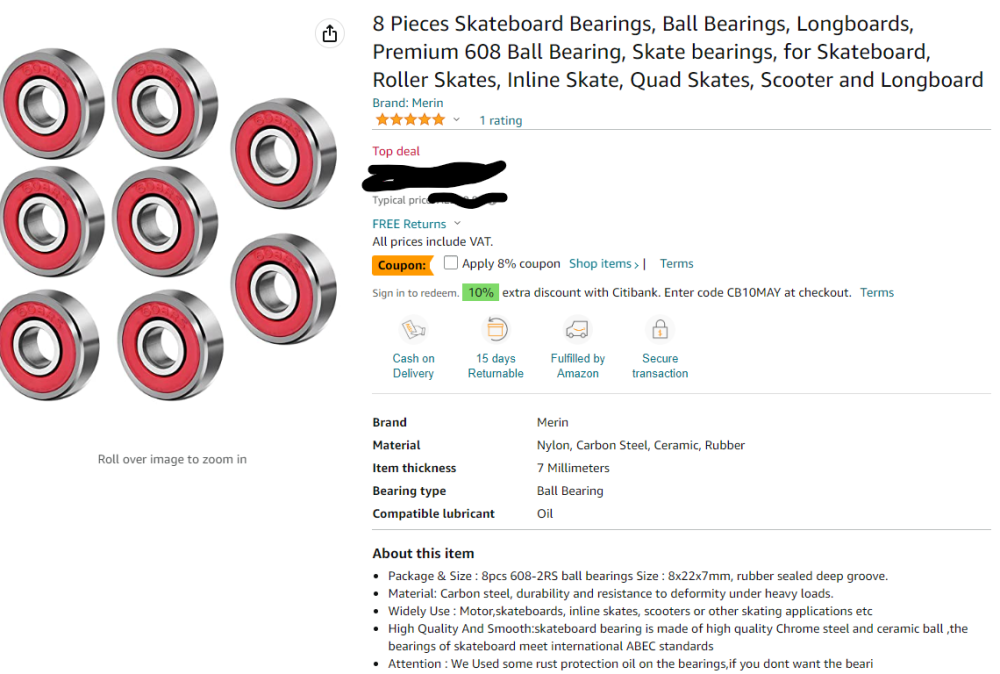

God day, I have designed a 3 part jig for adding a sunburst finish to a watch case restoration available here: 1) Jig: 2) Anvil: 3) You will need 1 of the the following bearings: Here is an example (not my watch) of the type of finish this tool is designed to achieve on the case of the watch: Summary A tool to add a sunburst finish to a watch restoration. you need to add a bearing (see Below) to the anvil and then attach this to the jig, this should allow you to turn the watch 360 degrees. Then using a needle file (sideways) in the groove(s) you can apply a sunburst in a sawing motion as you turn the watch. Details of bearing to be used: Skateboard Bearings: 608-2RS ball bearings Size : 8x22x7mm, rubber sealed deep groove. Available on amazon

- 11 replies

-

- 1

-

-

- case repair

- sunburst

-

(and 1 more)

Tagged with:

-

Hello watch bangers! Its been a while because I have decided to change my project schedule a bit but nevertheless, I bring you my most recent watch! This Report will be focusing on my work on an old Citizen watch with a Miyota 8200 movement! Next to the usual service features such as crystal replacement, lubrication and cleaning, I will also be talking a little about dial feet repairs since this watch needed one! Nevertheless, for you lazy people out there, here is the 4k fully commented video on Youtube: Overwise enjoy the read! Arrival status: Here is the watch when it first arrived on my work table Here is a list of what is wrong with this poor old watch: - Missing front crystal and dirty case back crystal - Detached hands - Misaligned dial - Non-Running movement So as you can see this is quite alot of work, but we will be covering all of this and the result definitely are worth it! Disassembly: 1.Removed the detached hands to protect them and screwed open the case back. 2.Removed the case, the dial spacer and the dial ( which had no dial feet attached anymore) and strapped the movement into the holder. 3.Took off the golden day wheel clip and the day wheel. 4.Unscrewed and removed the date cover to reveal all the setting subsystems. 5.Removed the date wheel by releasing tension on its little spring. 6.Took off the date spring and the two quick date and day levers. 7.Off with the canon pinion and the minute and whole wheel. 8.Removed the stem setting system ( Yoke and setting lever) as well as the translation to the canon pinion ( the two translation wheel and their cover). 9.Finally removed the clutch to complete the front side disassembly, well except for the balance jewel! 10.Flip the movement and remove the Rotor. I was really lucky and had a green gilden rotor on this miyota 8200! Loved the look of it! 11.Removed the complete balance. Loved the cool contrast of the round balance shape to the square jewel cap! 12. Undid the pallet fork bridge and lifted both of them away. Pallet fork jewels looked good under x20 magnification. 13. Unscrewed the brutalistically designed main bridge and took it off to be able to dig into the inner gear works. Took off all the gear leading from the escapement to the mainspring and moved on the to the ratchet system. 14.Removed the ratchet system and moved on to the Mainspring barrel and winding wheel which where both removed. 15.Here,I came to the final sub bridge where I removed the sweeping second pinion . 16. Lastly, I removed the final bridge and the underlying wheel which went through the mainplate. With this 99% of the disassembly was done! You can see all the parts (Around 75 I think) assorted in my sorting box! Mainspring As always, I did not have a spare mainspring at hand not did I plan on getting a new one so we once again go to servicing the mainspring! Unwound it out of the barrel and it came out pretty decent, maybe a few small nicks and unevenness but nothing major! After a manual rub down in lighter fluid and alcohol and the following lubrication of its whole length and the barrel insides, carefully wound it back inside to get this result: Cleaning Since I have decided to just keep going with the manual cleaning method, It is the usual process! A good soak in lighter fluid followed by a rinse in isopropanol alcohol. I of course did not include the balance or the pallet fork into this methodology since the alcohol could dissolve the shellac used in the jewel adhesion. I just gave them a good lighter fluid bath! Lubrication All the lubrication I used: Moebius 9010 - Basically All jewel bearing Moebius 8200 - Mainspring lubrication and barrel bottom and under the barrel lid. Moebius 8217 - Mainspring barrel grease Moebius 9415 - A miniscule amount on the palletfork jewel tips Moebius HP 1300 - Slower moving contact points such as: Metal barrel bearing, canon pinion and hour pinion sides Molycote DX - Heavy contact points mainly in the gearless setting system. Reassembly: Just follow the disassembly steps and you should be good! Dont forget to clean and lubricate the balance shock jewels. I haven't really taken any pictures of that process but they will be coming in the following reports! Here is one right after I did the whole process: Dial feet Repair: Now dial feet repair was quite a big issue for me since I always buy used watches and their parts online. And very often I would be super enthusiastic about a lovely looking dial that I snagged just to get it and realize that the dial feet are snapped off. And since I dont like glueing dial and not even mentioning the fact that glueing dials on watches withd ay/date complication being basically impossible anyways, I had to find another way. After some research, I decided to go into the field of resoldering the dial feet onto the dials. Now this has alot of variables which decide if it works out without ruining the dial ( dial material, print, cover, thickness etc..). I went onto my balcony and used a little tools holder, solder, copper wire, safety goggles, soldering paste to solder the copper wire used as a replacement to the dials again. Here are a few pictures of the balcony: And here of the “fixed” dial, even though the back does look absolutely demolished. You dont see that side though hehe. I wont write down the whole process here but I probably will do a more in depth one on a separate post in the proper forum. Timegrapher Test: After everything came back together, it was time to test my work on the good old timegrapher! Here is the result right after reassembly without any regulation: And here it the watch post-regulation: The low Amplitude is probably a mixture of the mainspring not being replaced and not being wound fully! Im also not very satisfied with the slight background noise with is visible on the graph ( just because I like my lines neat and straight haha). Oh and I regulate the watches to their best performance in two position. So once dial up and once dial down. Everything else really is outside of my skill, ressource and patience level xD Final Results So here are the final results of the restored watch! I did end up buying a fitting original citizen stainless steel bracelet but I did not have the chance to use my works camera to capture pictures. Anyhow, the pictures of the watch still look great to enjoy the view! Conclusion So in conclusion, working on this watch was a nice experience! It was cool to show you guys the movement since this was the last movement of a 6 watch lot which I finished off! I loved the brutalistic but kind of aesthetic design on the parts so shout out to the people at Miyota. Im writing this up last minute since im going on holidays tomorrow and I havent done anything in terms of packing or cleaning so i'm sorry for the shallow and short finish! Hope you guys enjoyed the write up and hopefully the video! Criticism, comments, tipps and anything else really can be put into the comments below! Enjoy the next weeks and see you watchbangers for the next watch!

- 1 reply

-

- 3

-

-

- citizen

- automatic watch

- (and 5 more)

-

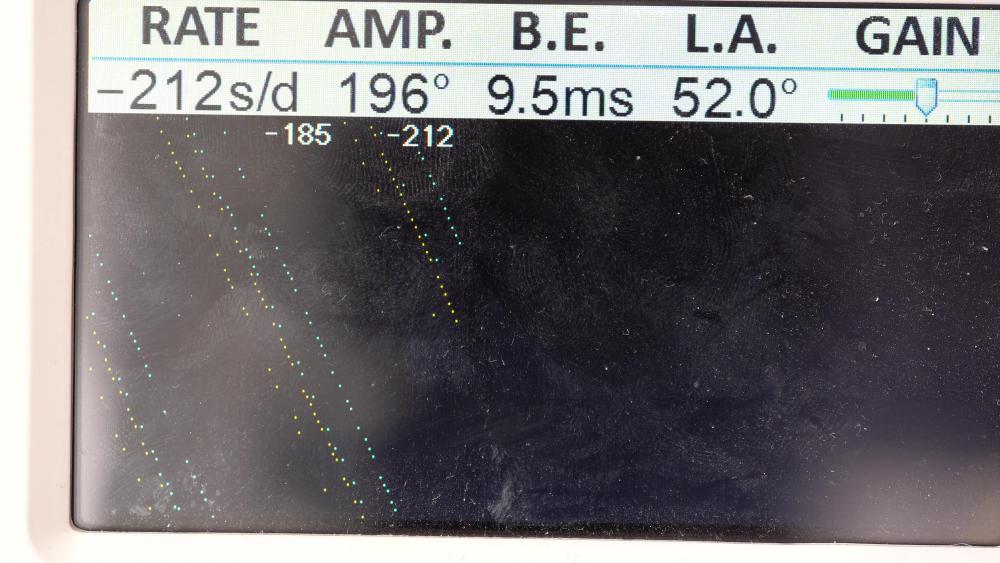

Hi Watch bangers! I did actually make it a personal goal of mine to present a watch every week but real-life caught up and ive been busy helping people move around haha. Bit nevertheless I am a week late but have another beautifull watch and project report for you guys! This watch was one of a few which I presented my Mother for her birthday to let her decide which one I should fix for her. She chose this vintage Seiko 4206A which I got from Ebay and so I sat down and got to work. Now I bought this watch online because I was really surprised at the remaining quality of the original dials and how there where still so many of them. After purchasing one and reading up a bit online it turned out that this movement line was particularly prone to behave irrationally or to repair so I kind of messe dup but nevertheless, I faced my challenge! The watch on arrival: Disassembly 1. Remove the watch case by unscrewing the back and removing the stem 2. Remove the Watch hands 3. Release the Dial feet from the back with the small levelr at the 10 and the 4 Position I think and remove the dial. As you can see it is in pretty good condition and has a very pretty sunbust effect. There is a slight stain though around the “ Automatic” text which left me kind of clueless since it is a metal surface and I wouldn’t really know what would stain it in such a way. I decided to leave it be to minimize the risk of further damage. Heres a close up picture: 4. Remove the Day clip and the Day wheel underneath it. This revealed a very interesting sping-like swan neck system for the day-wheel quick set system. Never seen that before! 5. Then remove the Day wheel spring and the 24 Hour day turning wheel. 6. Now you can unscrew and remove the main setting cover plate and the attached date wheel. 7. Take away the ( im not sure what this part really is called) but it is part of the quick set system which hooks into the second clutch wheel. 8. Now remove the Date Spring and lever, the bottom day wheel and the hour wheel to remove some more from the front side. 9. Remove the one translation wheel and the setting system sub cover which also separated the two clutches. 10. And finally take out the clitches and the yoke, setting system to completely disassembly the front side. Now you can turn the movement so we can work further on the back side. 11. Remove the Rotor 12. Take off the Automatic module 13. Remove the Winding wheel Y ratchet. I did try to remove the winding wheel in the first run but for some reason the screw did not watch to budge so I left it in for the picture. Off camera however I eventually did make. 14. Remove the elegant arching balance wheel. I was really surprised to see this in this kind of movement since I thought that this kind of design was only present in really high end watches. Interestingly enough the 4206 B however has the classical one winged balance. 15. Remove the Pallet fork system ( sorry for the blurry focus) 16. Take off the main bridge and and the small spring attached to one of the screws. 17. Pick out the Barrel, its ratchet and the 4th and 5th wheel. Interestingly enough the gears wheels have as many holes in them as the number which is kind of cool! 18. Now focus on the little winding module on the bottom right. Remove the translation wheel, the spring and the small bridge to take it out completely. 19. Almost done! Take of the final bridge which holds down the 6th wheel and the escapement. 20. And finally remove the 6th wheel and the escapement wheel. With that, we have completed the disassembly of the Seiko 4206A. Cleaning For cleaning im still sticking to the good old hand cleaning method. So this means that I let the individual parts marinade in lighter fuel for a while before giving them a scrub and rinsing them of in Isopropanal alcohol. I was thinking about dipping my toes into the ultrasonic cleaning branch but im unsure what fluids to buy and what parts I cannot drop into the cleaner so I think ill stay with what works at the moment. Additionally im broke haha. Mainspring service Now as always I did not have a spare Mainspring at hand so I removed the spring by hand and checked it out: As you can see it is / was absolutely disgusting haha so I gave It a good rub down in lighter fluid and isopropanol and the paper used for that was absolutely nasty in the end, see for yourself: However, I did clean it nicely I think and lubricated the spring with Moebius 8200 and the barrel wit Moebius 8217 before winding the spring back in carefully. After closing the barrel I did a mainspring wind test with the winding wheel and it had tension on it so it seems like I did a decent enough job. Lubrication Moebius 9010 – All jewels aside from the pallet fork jewel pivots Moebius HP 1300 – For parts which turn a bit slower. Between the arbour and the watches wheel, the barrel pivot in the main bridge or the metal pivots for translation wheels for example. But that’s just my personal tase Moebius 8200 – Used to lubricate the mainspring Moebius 8217 – Braking grease for automatic barrel wall Moebius 9415 – For the tip of the pallet fork jewels. Molycote DX Paste – Any strong friction contact points. So the setting and winding system basically Reassembly For the reassembly of course you just follow the above given steps and pictures from the disassembly backwards. Ive been thinking about making reassembly pictures as well, it would make the report way more comprehensive and would show more difficult nifty parts for example shock and balance jewel lubrication. However it would be way more annoying to take the pictures and it would cost me a lot more time. What do you all think? Timegrapher Test Okey, so once I’ve cleaned everything it was time to put my work to the test and I strapped the watch into the timegrapher. And this is the catastrophic result: This was the start of the snowstorm like reading which followed. It couldn’t really pick anything up and I was just devastated. Because I did not have any replacement balance on hand, I was desperate and opted to measuring the Rate my eye and stop watch. As you can think, this did not end up well so I ordered a lot of a few spare movement to butcher them for the balance. After placing in the 4th replacement balance however, I managed to get a decent reading. The Amplitide could be better, but this is the way I left it in the end haha. Final Results: After the timegrapher drama I closed the back up and attached a basic rubber strap for testing purposes. And from here on its basically B-Roll pictures! Here is a comparison of the movements size to my pinkie finger! And here the final satisfying shot: So yeah all in all a stressful but also fun little project which I could conclude by gifting the watch to my mother. I was very surprised to see the winged balance as well as challenged by working on a movement of this size but in the end I managed! I hope you all enjoyed reading this and that the guide may help other hobbysts or even professionals ( haha who am I kidding) in the future. Any comments, questions or criticism is of course welcome! If you guys would like the full commentated 4K Macro video of the whole process, ive uploaded it to my Youtube channel here and it would bring me great joy if you would watch it! And so as always watch bangers... Stay safe and healthy and till next time!

- 3 replies

-

- 2

-

-

- watch repair

- walkthrough

-

(and 2 more)

Tagged with:

-

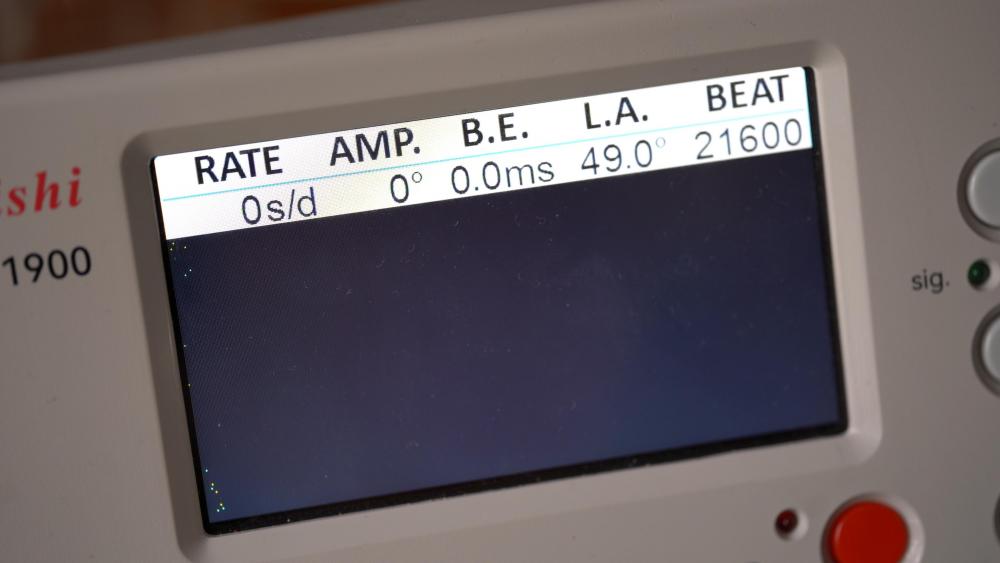

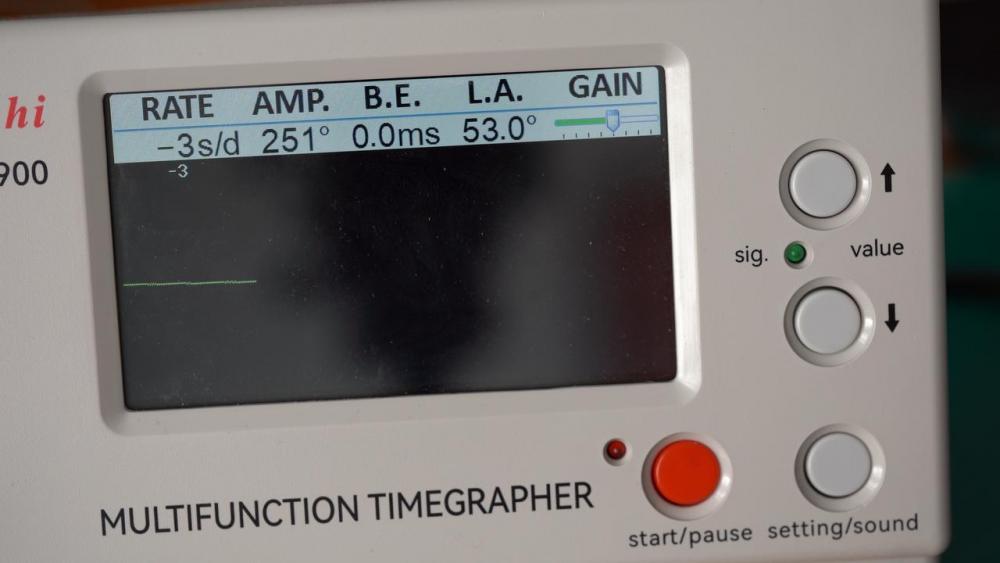

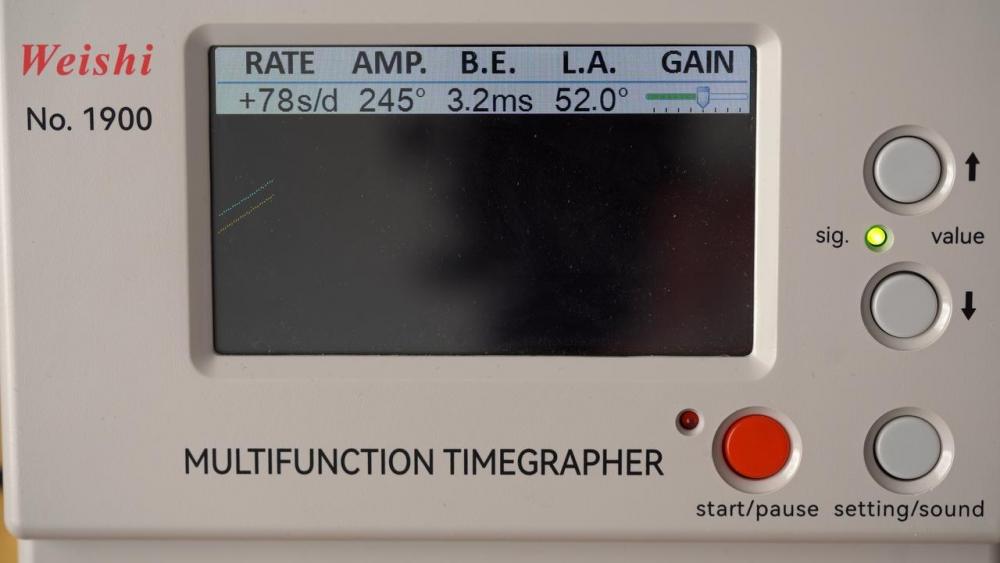

Seiko 7009 Report Hi dear Watchbangers, and welcome back to another little report from me! This week I am keeping in my set deadline and delivering my next project on time haha (not like last week).I know there probably have been a million reports, reviews and video on this but hey, it’s a classic; so this weeks watch is: A Seiko 7009 with a fully lumed up dial! I was super lucky to have found this, since at the time of purchase, I only found the pattern and colour scheme interesting and suddenly, this dial is just glowing up during night! So yeah, as always here’s a link to the commented 4K YouTube video for the lazy readers out there: Lets get into the written report then: Arrival status So this is how the watch arrived after I ordered it on Speedtimerkollektion and it seemed in pretty decent shape. The case was still in a nice condition, the original signed Seiko strap as well and the glass only had a minor little chuff so no need for replacement there. Interestingly enough the watch did not move a second for the first few weeks of me having it but started working again once I was filming for the above-mentioned video. Disassembly 1. Remove the caseback. 2. Remove the Stem by pulling into second position and pressing on the revealed lever to release it. Then remove the case. 3. . Remove the watch hands. They seemed In very good condition with me so no repolishing or reluming. Yay! 4. . Remove the Dial by turning the lever knobs at the dial feet, on the back side, releasing them in the process. The dial texture looks super organic and it makes sense since it is fully lumed! I used a little new makeshift dial container here for the first time to store the dial! 5. Take of the Dial spacer ring. 6. Remove the Front clip folding down the Day wheel by user something thin and sharp ( a cutter knife for example) and follow up by removing the day wheel. This day wheel was in English/ Arabic, which I found really awesome, and it also looks great so Ill be keeping that! 7. Unscrew the day wheel spring. 8. Unscrew the front cover plate and take that off. 9. Remove the top part of the 24 hour wheel by unscrewing the screw holding it all together. 10. Take away the rest of the 24 Hour wheel, the hour wheel, the cannon pinion underneath and the date spring. 11. Then remove the day quick set lever and its spring and the translation wheel from the setting system. 12. Move on to the setting system cover, the yoke and the clutch lever. 13. Remove the cluth and optionally the stem (if its inserted). 14. Lastly unscrew and remove the large metal arch which goes around the movement and hooks against small metal pole. With that, you have completed the disassembly of the front! Turn the movement in the holder so we can work on the back. 15. Remove the rotor and the balance wheel so that no further harm could possibly happen to it. 17. Remove the Pallet fork bridge and the pallet fork (this is ideally in an unwinded state, if there is power, please unwind the mainspring first). 18. Now you can unscrew the winding wheel and the ratchet wheel for the mainspring. 19. Unscrew the main bridge and remove it to reveal the gear train! 20. Remove the small clips holding in the automatic winding mechanism to completely disassemble the main bridge. 21. Remove the Mainspring and its ratchet spring and the complete gear train. 22. Unscrew the secondary small bridge. 23. Remove the final wheel underneath it to fully disassemble the complete watch! Congratulation!! Cleaning Cleaning as always is the hand cleaning method. Let the parts marinate in some naphta and then brush them if necessary. After this treatment I rince the parts of with Isopropanol alcohol to get rid of the previous cleaning fluids and left-over residue. I did however do some searching for vintage cleaners and what not but they really are expensive, around 200 Euros. And while that is a worth while investment, im not really sure if I want to and even can spent that money on something that ill only be using a few times a month at most. Well it’s a dilemma haha. But im also thinking about putting jars with cleaning fluids into ultra-sonic cleaners but I’m not sure if the jar walls are too thick for the ultrasonic waves to be effective. Mainspring Service As usual, I did not have a replacement Mainspring so it came down to servicing the mainspring. Upon opening the barrel, the spring seemed in decent condition, maybe a bit dirty but no visible physical defects. The barrel lid however did show signs of wear, so that place would get some well needed lubrication. Here is is unwinded and the back in its serviced barrel before closing it up. Lubrication Moebius 9010 : All jewels except for the pallet fork jewels Moebius 8200 : Mainspring lubrication Moebius 8217 : Breaking grease for mainspring barrel wall lubrication Moebius HP-1300 : Lubrication for slower turning/moving parts. On the barrel arbour for example. Moebius 9415 : Lubrication for pallet fork jewel teeth Molykote DX: Grease for heavy contact points. Mostly for the front in the setting and winding system for example. Reassembly Just reverse the disassembly Process above. Don’t forget to lubricate the balance and shock jewels and reassemble the main bridge correctly. Timegrapher Test So after cleaning and lubrication, I slapped the watch onto the timegreapher to see if the whole process did anything at all. Here it is preregulated: And post regulation within acceptable parameters. Im very happy about the Amplitude since this amplitude was the highest I have ever gotten in all of my projects! Final Results Concluding Fotoshoot strapped and lumed up again: Conclusion: All in all, restoring this old Seiko 7009 was really fun! Despite me not having the spare and clean replacement parts to replace all parts with visible damages and wear, I still managed to get the watch running in good condition again. Also the very unique and rare dial adds to that and Im happy that the light brushing with th Q-Tip did not damage the Lume on the Dial. Sadly, since the dial is a bit older (70s I would say), the fully charged lume on the dial does not hold its glow for very long and I have no possibility to relume the dial. Either way, Im happy if it even shines a little and yeah! Was a cool little project to work on! So if you guys have any comments, questions, criticism or suggestions/tipps, please write me or put them in the comments! I hope you guys enjoyed reading or the video and stay healthy! Till next time Watch bangers!

-

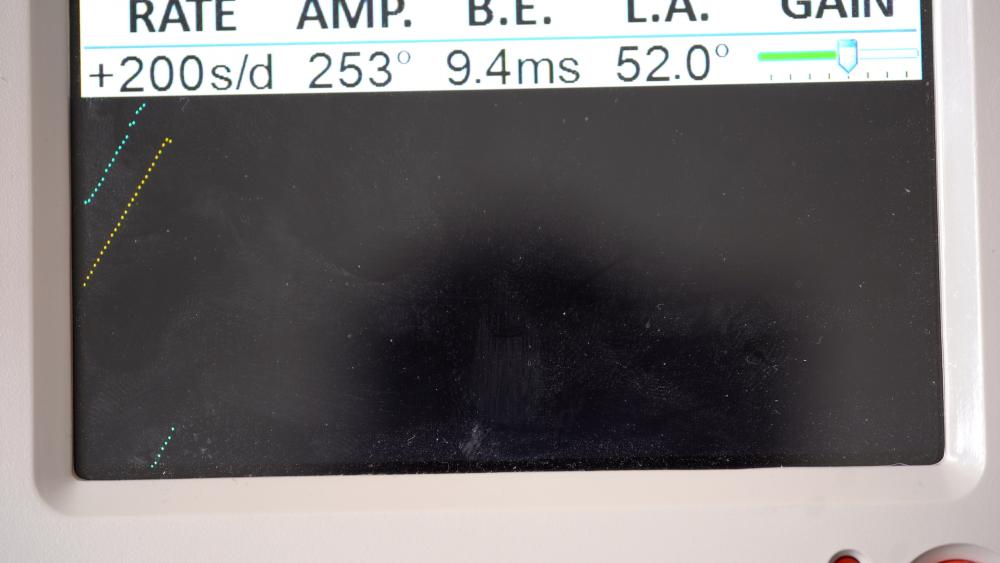

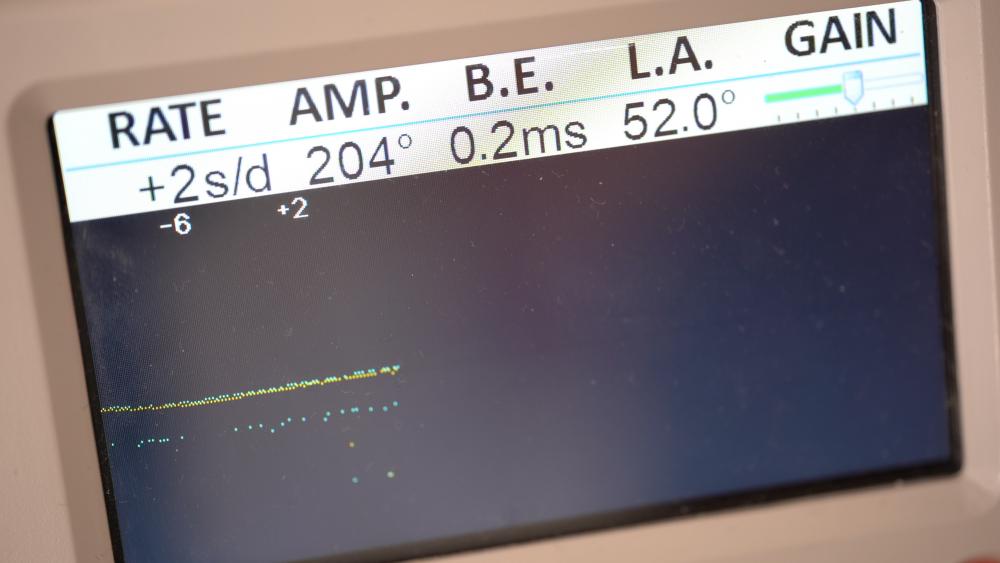

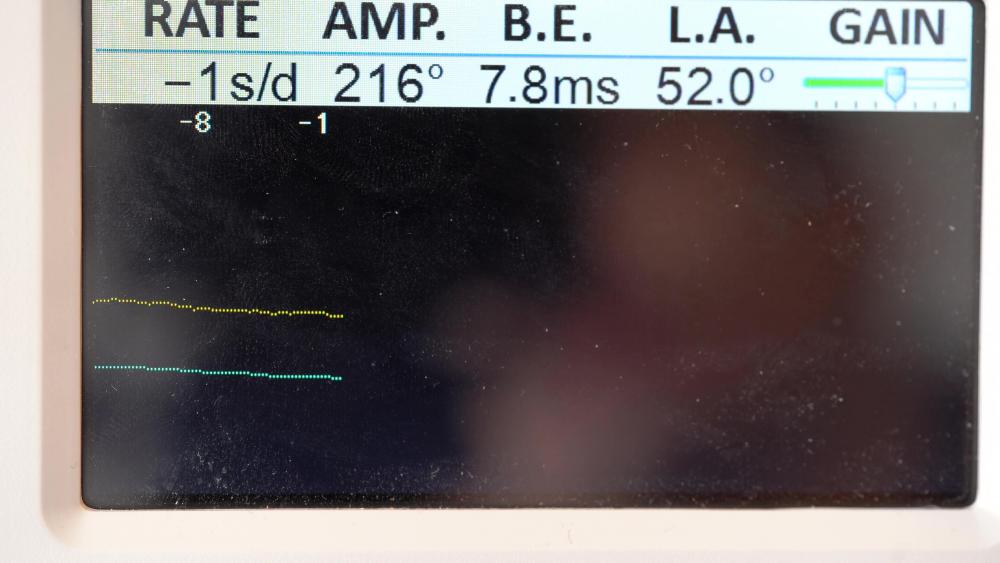

Hi everyone! This time I'm back again with a little something which turned out to be something of a hybrid project. I had repaired and planned a video on a Junghans watch with the 93 movement caliber to give to my younger brother ( which young adult doesn't need a nice looking watch) and had it all set out, planned and executed. The only downside was that the dial was slightly discolored on the right side due to bad cleaning on my part. Here you can see what I mean by that: But I happened to be at a local fleamarket on the day when I wanted to finalize the video and surprisingly found the exact same model! Even though the crystal was pretty scratched up, I was confident that the dial was in a good condition so I bought it for 10 Euros. And yeah, it looks like I hit the jackpot: So.. I got lucky and changed the dials in the end. But enough rambling around and here is the actual process of working on the watch movement: 1. Removing the movement from the case. This movement was from the “trilastic” model line of junghans and it got its name from the tri-legged support beams which held the movement inside the case. Just pop those up and remove the movement. Fun fact: While checking the inside of the caseback for marking I found one from 1981, thats so coooool! : 2. Remove the hands and and then the dial by unscrewing the dial feet clamps ( Forgot to take Pictures sorryyy) 3. Strap the movement into the holder and unwind the watch if needed. Then I removed the broken watch stem. 4. Remove the blued ratchet and the click spring 5. Remove the hour wheel, minute wheel, canon pinion and the very interesting looking yoke and its spring. 6. Then remove the clutch and flip the movement. The leftover lever will be released from the backside later on. 7. Remove the balance wheel and the pallet fork system. 8. Then remove the two screws holding down the mainplate and lift that. You can go ahead and unscrew the screw in between as well since that will release the left over lever on the front side. Do the same for the mainspring cover. 9. Remove the gear train and the mainspring And that's about it with the disassembly! Now moving on to the whole cleaning, lubrication and servicing part! Mainspring service: This Mainspring was something new to me since it had a very interesting arbor! Instead of the traditional small arbor inside the barrel, it extended outwards and acted as a lid and a wheel at the same time. While this is definitely cool, it also brings some negatives such as faster exposure to dirt and etc with it im sure. It looked fine so I just recleaned, lubricated and reinserted the whole thing: Lubrication: Here is a list of lubrications I used Moebius 9010 - All jewels Moebius 8200 - Mainspring and barrel lubrication Moebius HP 1300 slower moving parts such as canon pinion Moebius 9415 - Pallet Fork hooking jewels Molykote DX - Gearless works and high contact/friction zones (Front side only really) Oh and of course don't forget to clean and lubricate the balance shock jewels! Reassembly: Just reverse the disassembly steps or watch (no pun intended) the video for a step by step walkthrough. Timegrapher Test: Before Regulation After Regulation: Now i'm very happy that the rate is so much better. The amplitude can definitely be better however I would blame the old mainspring for that. The one thing that puzzles me really is the Bear Error. I've tried virtually every combination on the balance but the beat error does not improve. Maybe something is wrong with the hairspring? Final Result: After attaching the more aesthetic dial and recasing the watch and adding the straps, these are the final result pics: I must say I'm very happy with the whole process! Of course there were some up and down moments like when I destroyed the balance ( don't even ask) and had to get a replacement and such things but it all worked out in the end did it not? I was not sure how the beat error and the lower amplitude were going to show themselves while wearing the watch so I did a test wear for a week and the time only deviated by a second or two so I'm relieved! Now I apologize for the lack of pictures for a smooth documentation, I forgot and yeah, the rest is history. However, I have uploaded another fully commentated video so If you want explanations, more information or just a smoother experience go check it out: https://youtu.be/ZDXKiNnrmMk Any criticism, questions, comments and tips are always welcome and i'm happy to talk to you all! Hope you enjoyed it and until next time! Stay Healthy!

- 4 replies

-

- 6

-

-

- restoration

- walkthrough

-

(and 1 more)

Tagged with:

-

Just a quickie When my dad died 7 years ago my mum gave me his old Riquartz watch that she gave him for their 25th wedding anniversary in 1981. It was in a sorry state. Dad had worn it solidly from that day to the day he died. The case and case were badly scratched, the original strap lost, the day date mechanism jammed (broken as it turned out). It had been left neglected for the last 7 years. With a bit of patience and good fortune I located new-old stock movements and crystals. For a well worn 41 year old watch I think it's come up rather well after a strip down, polish and careful rebuild and new movement. I think it's good for a few more years. Before and after photos below. I can't wait to show my mum. James.

- 5 replies

-

- 5

-

-

- ricoh

- restoration

-

(and 1 more)

Tagged with:

-

Hi I've just acquired a Seiko 7T94 0BS0 Quartz Chronograph for clean up and restoration. It is scratched and filthy but otherwise fully functional. It has a black coated bezel into which the crystal is embedded. There is a tachymeter chapter ring under the crystal sandwiched between the crystal and the body of the watch. I assumed I'd be able to prise off the bezel to release the chapter ring to allow me to clean and polish the case. The I can't seem to remove the bezel.. but the chapter ring is slightly loose. I'm uncertain if that is how it was when I received the watch. I think it's held in place by the movement. If that bezel is removable I'd like to get it off so I can thoroughly clean and polish the case... and touch up or re-coat the bezel. I'm at a bit of a loss. I can't see a way of pushing it out from the inside as the channels for the pushers and stem intrude into the watch body. Photos below. Thanks in advance. James.

-

Hello, everybody. I wanted to share my restoration stories that I have done for a long time and thrown into my archive. First I discussed the Atomic Mars 71 Brand using Valjoux 7734. As it was seen, scratch and dial is broken. To begin with, I tried to brush the Case as Brushed and make it the first day. If it is decorated, I polished and re-painted the indexes (with acrylic paint). I usually do this in three layers so that the paint is not deleted in a short time. I replaced the case buttons and tubes with aftermarket buttons. Since the condition of the dial was in very poor condition, I had it re-painted. The quality is not so good. In Turkey, unfortunately, not doing the job well. Caliber 7734 (Valjoux) is a special and robust mechanism for me. With good maintenance and lubrication, you can reduce deflection values up to 3-4 seconds per day. I added a short timelapse video about it :) As a result, such a result came before us. Thank you Taskin https://www.youtube.com/watch?v=XKH6yTKUfpM

-

This is one of my first watches. I own it for more than 40 years and I stored it for years after it fell and the crystal snapped. Seven years ago I decided to restore it . I went for two or three watchmakers for an estimate but In the end I decided to do it on my own. Had to Redial/Relume, find a new crystal, gaskets, hands, bezel spring and movement overhaul. Took me a while and finally finished it a few weeks ago. I’m very pleased to wear it again (though I’m not planning to dive with it) The original watch looked like this: There was a lot on my list: There were scratches on the dial and the black lost its depth, The lume was in bad shape (though the lettering was better.) The hands were missing, and I had to find something that resembles the original hands (“Hens teeth”) The Mineral Crystal broke long ago and I had to find crystal and gasket(s) The rotating bezel had to be polished and repainted. The bezel click spring was missing. The crown gasket over the years became black goo and had to be replaced. The crown tube gasket was missing (I didn't know it at this point) The movement was in fair shape, but has to be serviced. As I wrote I decided to do it all by my own after I received several estimates from watchmakers (I guess this was my intention from the beginning but I didn't have the know how nor the confidence.) Took this as a project and had to dig for information. Since there are few versions of this watch I had to find the right info. Some restored a similar but not the same version and I had to dig for the right info. The dial: I sent the dial to Robert Miller at international dial company. He told me he has the original dies for the “professional” sub (The orange sub) for this watch he had to change it to sharkhunter. (this was seven years ago, now I see the company changed its location and website) You can compare the before and after. The Hands As the original hands were lost, and there are no originals to be found.I Found very similar ones at Yobokies. This sub uses Eta 2472 movement (aka doxa 118), which uses the same hand size as seiko. Yobokies (and dagaz) sells seiko mods, one of them is the soxa mod or axos mod which mods the seiko to look like the doxa sub. The ”soxa” hands looks very similar to the sub’s hands. Since they were meant for slightly bigger dial, I had to shorten the seconds hand. I was also happy to see that the lume color on the dial and hand were the same. The crystal and the crystal gaskets. Since the crystal broke years ago I had to find one that fits. I was a little bit confused from what I saw on the net until I realized there are few versions of the sub. In the synchron sub for example (A later version of this watch- from the time synchron company purchased doxa) the crystal is a thick flat mineral glass. It is inserted from the front and held by a thick visible orange gasket. In this version the the crystal is a stepped glass, 3.6mm thick approx, it is inserted from the back of the watch and held by a screw in retainer ring, with no visible gasket. Because it is not manufactured anymore, some watchmakers produces a close clone by bonding two flat crystals in different thickness and size. This guy on the bay produces this crystal by copying an original one(as he said). He posted it as a “DOXA SUB 300T Sharkhunter” crystal unaware of the various possible versions for this title. At the time I wasn't sure it will fit mine, so I made one using the watchmakes method by bonding two crystals to one using ultraviolet curing bond. At the same time I was looking for a fit gasket when I stumbled on a post in this forum . Now You can’t see the original post’s images, but in this image (from the post) I found that the Crystal was held by two (probably the same) gaskets (the gaskets on the center of the image). Ordered some gaskets in various possible sizes and choose what fitted best. The gaskets fits the inside of the watch and around the wider bottom side of the crystal. It is all held by a screw-in retainer ring. (bottom left ring in the image above). Can’t tell if this was the original design, and I didn’t make any pressure test (yet) This is the crystal and gaskets I used: The rotating bezel At the time I didn't notice the bezel has polished and brushed parts, so I polished it all, and colored the marks and numbers using nail polish lacquer. On the luminous dot I used epoxy glue mixed with luminous powder. It was one of the first things I did on the watch and left it as is. The bezel spring Had to create a new bezel spring following this post. I used dentist's 0.8mm stainless steel wire but I wasn't sure what of the exact wire girth, so I ordered from AliExpress various wire sizes. Made this spring. It's not perfect but it's doing the job. The crown gaskets The original crown gasket became black goo long ago. Couldn't find any information regarding this screw down crown. The closest design I found was Rolex twinlock crown . From the shape of the crown and tube I assumed the possible sizes of both case and crown gaskets. I ordered some possible gaskets sizes and used the ones that fitted best. I added even one more gasket around the case tube to imitate the Rolex triplock (obviously unnecessary...) The Movement In this watch doxa used the Doxa 118 movement - a slightly modified eta 2472 movement. The movement had to be serviced. On some point on this long period I decided to service it on my own. It was the most intimidating part of this restoration because I had to learn this from zero. Bought some old movements on the bay for cheap, bought some required tools and started to take them apart and rebuilt them again. After I gained some confidence I did it on the doxa. I made some damage but found the right replacement parts (One of my discoveries was that movement springs tend to fly and disappear while flying…). It took me longer than I thought. For couple of years I left it in the box, but the covid19 period gave me little time to get back to it and finish the job. more to do Need to regulate the watch, probably after I will build a proper timegrapher mic. Maybe pressure test: just to check how waterproof is it. I’m not planning to dive with it. Bor bracelet: maybe yobokies. found this on alibaba but minimum order is 200… Thanx Gabriel (This was also posted on Watchuseek doxa forum few weeks ago)

- 2 replies

-

- 5

-

-

-

- doxa 300t

- diver watch

-

(and 1 more)

Tagged with:

-

Hi fellow watch enthusiasts, I hope you are keeping safe & well. Having tinkered for a while, and completed the second of Mark's on-line course, I'm taking the plunge and undertaking a full dismantle, clean and reassemble of an old 1960's Tissot Seastar. As a result I have two questions, if I may. I read somewhere, that I should not subject the pallet fork to the harsh cleaning fluids, as it may damage the delicate End Stones. Is this accurate and correct and are there any other components that I should not put in the harsh cleaning fluid..? In addition, I've managed to secure a NOS replacement main spring. I'm assuming that as its been sitting around for a good while it will need lubricating. It there a method of lubricating the main spring without the need to unfurl it from the temporary housing it comes in, or once inserted into the barrel..? Many thanks Phil

-

I mentioned to a friend that I'd been tinkering (mostly unsuccessfully) with watches (all Timex #31 movements) and he offered me the chance to try and fix his father's watch, which is a Sarcar from the late fifties. Nasty band missing a buckle. All kinds of crumbly blue-green patina/corrosion. Crystal (doesn't seem original) pretty well scratched up. After cleaning the band with saddle soap and leather restorer, polishing the crystal, and scraping as much crud off the case as I could, I opened it up to find quite a pretty interior, though something way beyond anything I've ever opened up. Seems like the mainspring is taking a load, but nothing is moving. From the looks of it, I think I can pop the stem out and remove the movement, allowing access to clean the face, but I'm not sure if I should even begin anything more. The case cover has some dates on it, with the most recent service looking to be from '68 (his father died when he was very young and he's probably never had the watch serviced himself). My comfort level says just clean everything up and point him in the direction of getting it serviced. But another part of me is thinking that going a few screws deep isn't going to hurt anything and I may learn something in the process. Just document along the way. It's not like my Timex where I could lose a piece and have a back-up...

-

Hi, I will be working on restoring Perrelet James Cook Antarctica. For those who may not know the brand, Perrelet takes its name from Abraham Louis Perrelet, the inventor of automatic watch movements back in late 1700. The brand, however, did not survive through the turbulent times, and was only re-activated in the 1990s. And that's when Perrelet James Cook Antarctica was born. I would say that the Perrelet timepieces from the late 1990s and early 2000s seem to be the most beautiful to me. I think the case design and the dial are timeless, hence my personal affinity to the brand. I already own a two-tone Perrelet Tempest and spotted this Perrelet Antarctica on eBay with some visible damage to the dial and hands. I pulled the trigger and here I am trying to restore it. Also, the bet with the size of the bracelet did not pay off, and I am currently trying to source spare links from Perrelet - what a pain. I already contacted the authorised distributors in the US, the UK and Germany, but apparently everyone in Switzerland is on holiday now! As you can see, the dial appears to be water damaged, but the markers are fine. Additionally, the front rotor (the trademark of Perrelet watches) appears to be discoloured in places, which after some inspection seems to be due to stripping of the nickel (or possibly gold) plating on steel rotor. I will be nickel plating soon (using brush technique) and will share pictures soon. I have managed to remove the markers and strip the dial from its colour. I am however unsure whether the original colour was achieved by chemical treatment or painting - the colour seemed to be completely resistant to varnish. It could only be removed by gentle polishing. There is still some left over in the ridges. I am unsure how to proceed from here. I would like to get back the beautiful blue finish on the dial. I already purchased an airbrush, but I have difficulty in choosing the right paint for the job - I would like to preserve the sharp look of the ridges without putting too many thick coats. I would greatly welcome any advice on what paint would be the best for the job, and how to prep the dial (assume roughing slightly with 1500 sandpaper would do fine?) Alternatively, is it possible to achieve such deep, aquamarine blue colour by electroplating? That would seem like an ideal solution? Hopefully, all the sweat will pay off. I will keep updating the thread with progress as I go. Happy to answer any questions on my work so far.

- 9 replies

-

- 1

-

-

- perrelet

- restoration

-

(and 3 more)

Tagged with:

-

Hi Everyone, Recently I have become obsessed with ana digi watches from the 1980's! I really dig the style for some reason. I was looking on ebay in the low price ranges and I found this little nugget for the princely sum of $5.70 - the shipping from Peru was an inflated $20 AUD - so I got away with it for under $30. It came well packed in a little padded envelope. It was missing the back, had severe damage, but I didn't see any rust stains on the back. A view from the side It is a Seiko H127A-5000 - the year could be between 1979 and 1980 - there is a little bit of info around the internet. The case back will be an insanely rare part to find so I may have to CNC mill something or potentially 3d print a plastic back. That is if I can get it working. The Crystal is trash. I've tried sanding it, will wait till I have some crystal polish - I haven't had much luck polishing mineral crystals. A new crystal is around $35 - with OEM Seiko writing. I removed the movement and soaked it in WD40 to loosen all the bolts. It was too seized to attempt opening. The LCD panel/dial has a crack in it. The sub assembly appears clean, the zebra strips on the LCD were a bit gummed up but cleaned up. Happily the analogue movement was turning over freely, it wasn't ticking - but likely due to so much grit and much on the contacts. The only corrosion was on the rotor, and some of the non important chrome plated parts. I've soaked them in shellite. Cleaned with blutac and then inspected under microscope. Everything appears fine. It is a very high end movement with 8 jewels and all metal parts - it would have been top of the line back in the day. Very tiny parts. The main circuit board is out - my it looks complicated. Simple plain jane movement - nothing fancy: It's all inside: The bridge is off and the rotor is next to the movement: Cleaning the case: Tonight I have finished cleaning everything - I have put it into my movement parts tray - awaiting some time after work tommorow. If anyone knows how the LCD works please let me know - is the display in the top dial section? Or the next layer down? There is a white mirror presumably to reflect the light off the screen as this is the black model version (there were two models). Parts look pricey and rare - I've found a dial panel NOS - also crystals online. May have to look for circuit board if its fried - Can't find any bracelets - may have to go non OEM generic steel band. Goal is to get it running - if its not running - atleast to be a show piece in my cabinet. More soon

-

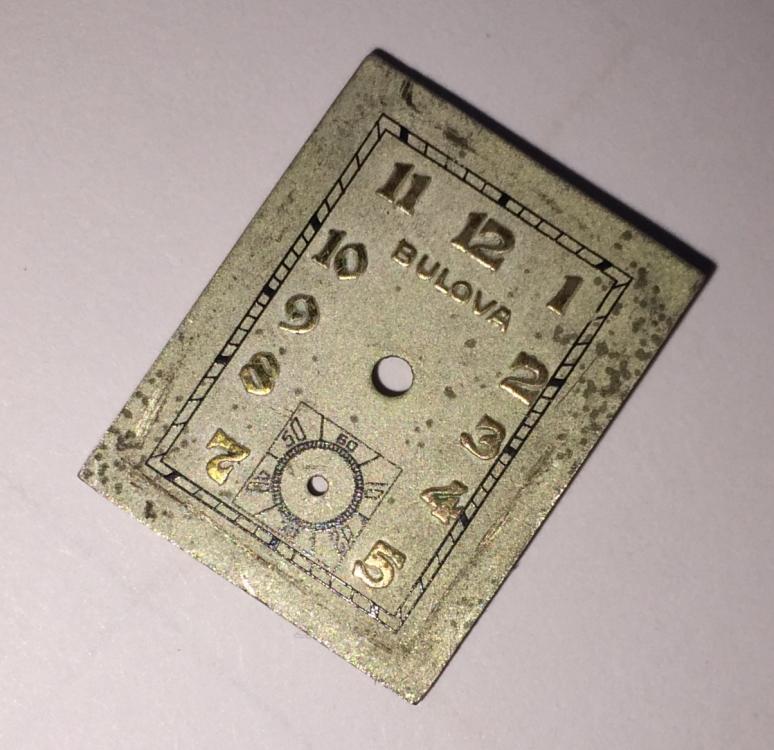

Hi all, I got kinda jealous when I read a bunch of posts about people using Photoshop or InDesign to mock up dials and print them on decals etc... I mean, I know the real way to refinish a dial is to send it to the professionals, but I've been wanting to try to make some of the cheap and cheerful Bulovas I do be a bit more presentable before I wear them... Been wanting to try some diy approaches, but I always get stopped by the first task: removing the dial markers / indices. The few posts I've read about diy dial restoration speak about using a pin or tweezers to push the dial markers out from the back... but the vintage Bulova dials I see have totally smooth brass backs with no sign of marker feet or anything... so how do the dial refinishers remove them? Are they riveted on somehow? are they held on by varnish or something??? Anybody know? Here's a pic of the kind of thing I'm talking about - hopefully someone out there knows how the dial people remove these little markers (and replace them)... inquiring minds want to know

- 10 replies

-

- dial

- restoration

-

(and 1 more)

Tagged with:

-

So I picked up this bad boy on eBay from someone in Spain. It's pretty messed up cosmetically, and missing a heeled bush and a removing punch. Considering all that, I definitely overpaid, but oh well. I don't know how rare these are to find on eBay, so I just decided to grab it. I scraped off all the old flaking paint and found a very similar color paint at Michaels. Not a very professional job and you can see some brush strokes, but all in all it's much better. I know the colors look off in the pictures, but that's a camera white balance issue. In real life the colors are very similar... a completely unattractive greenish gray oatmeal. Why Bergeon used this color I'll never know. Carefully removed the rust from the metal plate with steel wool and very very fine sandpaper. Did the same with the punches and bushes which had a nice coat of oxidation on them, then put them through the ultrasonic like they were watch parts. The original chrome plating had worn away on the top knurled nut, but not to fear! I busted out my little Caswell "Plug N Plate" kit and used "copy chrome" (real chrome plating is dangerous and pretty toxic apparently, but I can't see much of a difference between old chrome plate and Caswell's 'copy chrome' - looks about the same). The biggest unknown was if I could find replacement punches / bushes and yep! I just ordered them from perrinwatchparts.com... they were super expensive. I definitely overpaid for these, but again, oh well. I just wanted the tool to be complete. So ta da! I now have a Platax tool. I'm going to break out one of my many Bulova movements with a broken staff and experiment with using this tool on the poor thing. I don't know the I really needed this tool, per se. I have a nutcracker - type roller remover which works pretty well (I might have broken a few staffs by squeezing a little too much, but those staffs were broken anyway), and I have the little K & D balance remover tools for my staking set. I don't see how the Platax tool would be so so much better than the K & D tool, and I'd imagine any objections or concerns about the K & D tool widening the hole in the balance by using force instead of cutting out the old staff would also apply to the Platax tool, no? It also uses force to drive out the old staff while keeping the balance arms pinned. So maybe I didn't strictly need this, but when it popped up on eBay I couldn't resist, because I want to be able to follow along with what Mark does as closely as possible... and I'm still so new at doing this. So, now I have a Platax tool, a complete 'inverto' K & D staking set (got for under $100, go eBay!), and just picked up a Seitz Jeweling tool (ouch, that was too expensive). I am now wondering what other real watchmaker specific tools you need to have to be able to deal with most, if certainly not all, the issues you find on vintage watch movements ??? I mean, I'm not going to buy an old mechanical watch washer and put it in my one bedroom apartment in manhattan, not going to happen (at least, not if I don't want my husband to divorce me ). So I make do with a tiny, cheap Chinese made ultrasonic machine. And obviously, I'm not going to buy a lathe either, for similar reasons (space constraints, expense, plus wouldn't know how to even begin to use it)... but I'm wondering if I've covered almost everything else? In terms of being able to make watch parts, yeah, that's the holy grail. Living in manhattan comes with many advantages and disadvantages. The disadvantages are obviously space constraints and expense of living. But the advantages are there are lots and lots of resources. In fact, there are a few "Maker Spaces" in the city, which are co-ops you can join and you can use their tools, like CNC mills, CNC lathes, 3D printers, 3D scanners etc etc... you can join these co ops for not much money, and they teach you how to use the tools.... I know that the consensus so far is that 3D printing watch parts won't work, because the machines are not accurate enough on such a small scale. But the CNC lathes? The CNC mills? Could they do micro-machining, in theory? It's something to think about. I think I'll create another thread about that sometime. Maybe I can pick up some good tips. Anyway, hooray for overpriced watch tools! They are so much fun!

-

Okay, for those who notice nitty little details (as I think most watchmakers do) I am aware that the hands need to be corrected. My only excuse was that when I got around to putting on the hands it was towards the end of the day and I just wanted to case the thing and see how well it kept time. Haven't had the time to go back to it. Anyway, I titled this entry the way I did because it indicates something I love and the reason I entered watchmaking. For I found this watch in an old box (of old remnants thrown in free with some things I bought at a trade fair), lens-less, dirty (inside and out) with a broken mainspring. I replaced the lens and mainspring, gave the movement a good cleaning and did as much restoration of the dial as I could do with the primitive methods at my disposal; dial restoration being an art requiring far more time to master than I've so far put into the craft, but someday I hope to get better at it. As I said, the watch was in sorry condition and I felt sorry for it; as one might feel towards a waif on the streets, I decided to take it in some months ago as a practice piece. I mean, it literally had "cobwebs" in the movement; some kind of moldy stuff which I've seen in a lot of long--neglected timepieces. I put it through the cleaning machine and was pleased to see how it had brightened up and its quality began to show through--like a chronographical David Copperfield or Pip. I removed the remaining dirt with pegwood (Peggotty!) and Rodico and carefully oiled it. I was gleeful when, after final placement of the balance, the piece started to tick like a newborn baby come into the world. I, the parent, felt jubilant and, so far I haven't been disappointed as it is keeping good time, living up to expectations. I wear it regularly and someday maybe I'll come across a stray strap--lurking even now in some forgotten recess--that will do it justice. The watch is a 17j Elgin, with a gold plated case, as you can see. I haven't taken the time to look up the movement to see when it was made, but my guess is pre-WWII (any thoughts?). Would this have been a ladies watch? It's a bit bigger than most at that time. An unusual feature is the sub-seconds dial at 9 o'clock as opposed to 6 or 3. I may return to it someday when I am more skilled but it's still a joy to own.

- 1 reply

-

- 2

-

-

- elgin

- vintage watch

-

(and 1 more)

Tagged with:

-

Some of you already know that I bought myself as a birthday present, and to celebrate the birth of my first daughter, a Landeron 248 based Chronograph to restore / fix, and that I thought that it was a redial. Here the thread about it: Apparently it is not only the case ot a simple redial (albeit with a wrong dial which was adapted) but what I would define as "watchmaker's botchery", since the dial itself was fixed to the case with 2 screws (and from the front side...):

- 23 replies

-

- 1

-

-

- aftermarket dial

- repair

-

(and 4 more)

Tagged with:

-

Thought you guys may be interested in my latest project. full write up on my blog, but a few pics below Started from this.. to this.....

- 1 reply

-

- 7

-

-

- watchmakers

- pad printing

-

(and 2 more)

Tagged with:

-

Dear friends, This small centenary pocket watch of my collection came to me without a crown as you can see. This is a pity, since the mainspring and balance test as working and everything else seems to be in good condition. The stem sits correctly inside the sleeve and can be adjusted to two positions (winding/time setting). I have taken some measurements in case any one has a spare crown of the correct size: Crown (base): 4.6 mm. Sleeve (outer diameter): 3.36 mm. Stem (length): 9.44 mm. Thread (length): 1.72 mm. Thread (width): 1.14 mm. Square end: 0.99 mm. This grandpa-watch really misses its old ticking days! Please have a look in your spares. Thank you in advance!

- 8 replies

-

- Pocket watch

- Illinois

-

(and 3 more)

Tagged with:

.thumb.jpg.1c8520451ecd2671931a2b087658480f.jpg)