Leaderboard

Popular Content

Showing content with the highest reputation on 04/18/20 in Posts

-

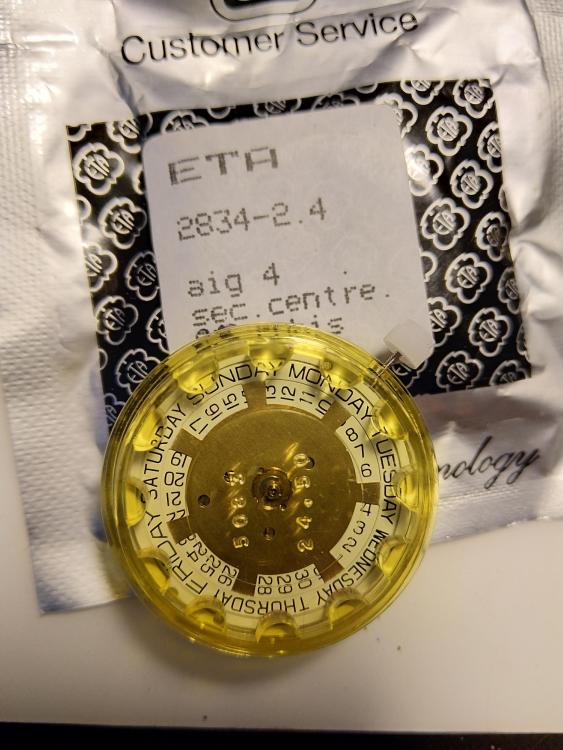

Hi there. from Jules Borel , ETA 2836-2 DATE DIAL, CURVED 02557.2836.B .You can put a 2836 date disk on a 2824 but cannot put a 2824 date disk on a 2836 .The 2824 date disk part number is 2556 and 2836 date disk part number is 2557.The 2836 one is more versatile of the two, being able to fit both movements, but on a 2824 it will not change instantly like the 2836. Hope this helps .Or you can send it of to dial restorer.Here is a link to the date disk http://cgi.julesborel.com/cgi-bin/matcgi2?ref=e[bHYJ3 points

-

2 points

-

2 points

-

Showing off the two most recent resurrections. The Casio is a 2005 vintage and was mine that I purchased new. It was my everyday watch until the battery quit. I tossed it in my tool box and proceeded to forget about it for 10 years. Fast forward to 3 days ago and my youngest son was organizing said toolbox for me and discovered it. I picked up a lithium battery and it came to life with zero issues. Remarkable honestly. I polished the Crystal this morning as it was a mess. It's supposed to self adjust the time with a radio signal I believe. Should give me another 5+ years of reliable service. The second is my most recent eBay purchase, a 1959 Timex 100 Beyonet / Darwin (depending on who you talk to). It looked ok in pictures but was missing the seconds hand and was stated to be a non-runner. Par for the course for most of my timexes, it was sluggish and stalling from dried lube, but nothing was broken. Gave it a good clean and lube, scrounged up a period second hand and gave the Crystal a good polish. Looks quite the treat. Scruffy Casio after 10 years bouncing around in a toolbox. Much better! Once neglected, revived and beautiful Timex 1002 points

-

Perhaps that pallet fork arrangement can’t put enough force on the impulse Jewel to get a high amplitude. I do however have a RR grade Elgin that is full plate and has excellent amplitude. My wife is still looking for Unicorn Poop. Sent from my iPhone using Tapatalk Pro2 points

-

The best approach would be starting with a broken American pocket watch because it's big 16 size is ideal. Broken so you don't care what happens to it but you can practice taking it apart and putting it together. Initially want to learn how to use your tools and get a feel for taking apart and put it back together preferably without destroying too much. Then you can move on to the Chinese clones of the 6498 or 6497 because they're cheap. Your clone preferably should be new as you want a running watch. You then practice taking this apart and putting it back together each time verify it still running. Then once you complete that you can start looking at a watch to repair and initially I would look for a watch that is more of cleaning then actual repairing. Often times people want to start with an actual project watch something it's broken they're going to fix it because after all watch repair is supposed to be easy. The problem is without the skill set to successfully disassemble and reassemble, watch accidents happen but they often go unnoticed by the new person because you don't know what you're looking at or what you're looking for. This then means the success rate of fixing a broken watch is very poor and leads to frustration.2 points

-

Wearing this one today, will post a new picture in the appropriate thread later.....2 points

-

As we say in Sweden... Ujujujuj. I would say those worn teeth is just a symptom of something else is going on. Just switching a part or two will probably just dampen the sympoms for a while. I would recommend a complete overhaul / service in this case and, in that process change the winding pinion and sliding pinion since some gears clearly are bad.2 points

-

Probably a waste of time because I looked at the link above that is a really good price for quartz movement and they supposedly check it out before they send it. Visually you can't tell if the quartz watch is going to run or not. You can put a battery in after you change the circuit and see if it works. But visually is not good enough Your supposed to do some electrical checks to verify that it indeed is running correctly.2 points

-

2 points

-

2 points

-

2 points

-

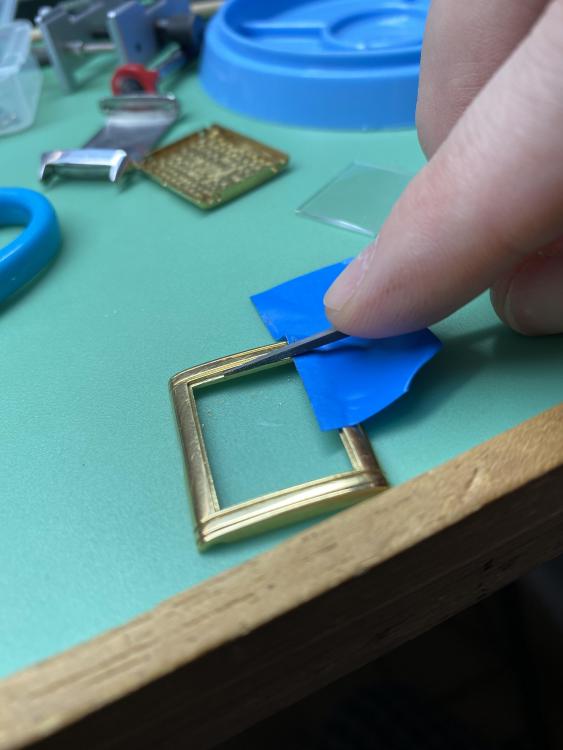

This turned out okay. I very carefully filed the curve down flat with an escapement file. It took me three hours because I was being so careful. It was hard to get the angle correct. But the file you can see in the picture did the job really well. The glass now sits flat and the watch is "upgraded" to accept flat bottomed glass. It just needs some UV glue and she's good to go. Phew!2 points

-

Hey All, a few of you have noted that you were unaware of the connection. But yes westclox did assemble Seiko movements into their cases. Much like Seiko sells bare movements to third party assemblers today. For your pleasure I have included a picture of the movement in the westclox recently posted in the watch of the day.1 point

-

A long video I put together that eventually has the cleaning of a vintage Waltham 15J Pocket watch. Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

1 point

-

Just bought the movement, excited for it to arrive in about a week. I will check back in then1 point

-

1 point

-

Reassembling the Tourneau 7750. Keyless work and Train of Wheels Click to view on YouTube1 point

-

I agree with @JohnR725. I started with American pocket watches - mainly Waltham and Elgin , as parts (and scrap movements) were easy to find. They are much easier to work on than wristwatches. I don't buy movement with less than 15 jewels. The problem is you will find plenty of broken jewels in the movements. The good news is, it's not difficult to find replacements (whether they fit or not, is another matter !)1 point

-

Well I don´t think finding that split stem for a monocoque like that will be easy. But somewere in the back of my mind I remember this being up here before, I think the go to man in this case would be Nucejoe. If it someone who would remeber this it would be him, think he showed a Logines Admiral in a monocoque some years ago.1 point

-

Jon, are you at EFHC? I was taught by Richard and Lalit many moons ago! Currently just do clock restoration with Francis.1 point

-

Crystals usually come out the front. The way that yours has cracked makes it likely that you won't be able to remove it without breaking it. This wouldn't be a disaster but it helps if you can measure the diameter of the old crystal to inform what size new crystal to order. To get the old one out you could simply push it out from the back with your thumbs, although a more elegant solution would be to use a crystal lift or better still, a press. You will need one or the other to install the new crystal anyway, and if it is a tension ring crystal it will need to be a press.1 point

-

Hi Patrick, welcome to RWT. Really interested in seeing your eclectic collection....1 point

-

1 point

-

Another interesting HMT joins the low cost crew today. An HMT 'Ambedkar Centenari' 1891-1991 – A.B.Ambedkar Centenary. This one uses a manual wind HMT 0231 (Citizen 200/1802 licensed copy) caliber. The odd spelling of Centenari appears to have been how these left the Bangalore factory. There are quite a number of similar examples on line. The (later?) quartz version uses the "Centenary" spelling. There is always the chance that the dial is after market, but it looks to be genuine, and for what I paid for it, I'm not going to loose any sleep over worrying on that score. This one arrived looking immaculate, on as new unworn strap, although it was made in the 1990s. If you are looking for a simple watch to practice your servicing and repair skills on, these HMTs are perfect. Expect to pay around £10 to £30 for a good clean example, and under £10 for some of the "franken dialled" Mumbia specials (which make a good source of HMT/Citizen 020X and 180X spares if nothing else). This one cost a mere £3.20 plus postage, which was surprising as the commemorative and interesting HMTs usually sell for much more. There appears to be a bit of a cult following for these watches developing on line. They may never reach the stratospheric prices of an Omega, but they will probably never be as inexpensive again as they are now. The postage was almost as much as the watch I might add. The listing did state that it was an "AUTOMATIC" but that is par for the course. I've seen quartz watches listed as automatic, so you have take that description with a pinch of salt. I expected it to be what it was, namely a manual wind. If you hunt around on ebay, then for little more than a cup of tea and a sticky bun, or some other pre-lockdown treat, you can bag yourself a quality manual wind licensed Citizen movement to practice on. This one is running a little weak with a swing around 200 degrees, so I'll give it a quick clean and service. If you take care with them, you should be able to dial them in to +/- 10 sec per day fairly easily. The balance is a relatively sturdy, if utilitarian construction and there is no simple way to adjust the beat error, so adjusting that takes a little more delicate fiddling to get it down to acceptable levels. They do however seem to run reasonably well even with a relatively large error though, and many of them appear to have left the factory that way.1 point

-

I always get my students working on a big ETA 6497 copy. It's about 16.5 lignes in size, so pocket watch territory. In fact it originally was a pocket watch, which got turned into a wristwatch. You can pick them up under the name: ST 36 or ST 3600. They are a Chinese copy of a Chinese copy, as Seagull originally copied the ETA 6947, but the Seagull will cost about £150, as opposed to the Parnis ST 36 which will be about £45 - £70. They are remarkably good, except the escape wheel pinions are really easy to break and the lyre springs will ping out very easily.1 point

-

Turned out to be a nice little project for you , and some old style watchmaking exercise too, great work!1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

To be honest, I use a few methods but still read the other answers to see what is currently popular.. I always take a moment to think about which way is likely to be the best for the watch at hand. Back when I was starting out there was one hairspring which got warped when lifting the balance while hanging from the bridge (after the first which was destroyed on my first parts movement), and it put me off doing that in future. For a long time I got to grips with lifting the balance and bridge as one with the tweezers providing support rather than any real grip. It wasn't until a few years ago that I got the courage back (partly while going through some repetitive practice disassembling and reassembling a movement, getting bored) after watching someone lifting the balance out with it hanging by the hairspring, that I started to re-try and use that method. On the newer watches it can often work, particularly as these generally have light weight balance wheels. Sometimes I have unfastened the hairspring stud in place, then lifted the balance bridge away first, and I've occasionally used (with tweezers in both hands) the method of supporting the balance from underneath rather than gripping - while holding and lifting the bridge with the 2nd set of tweezers.. I used to be particularly dexterous. Realistically, the best thing is to try a few methods and see what works the best for you.1 point

-

Old American pocket watches are relatively easy. I'd actually suggest starting with two size 12 Elgins made between about 1918 and 1935 as this is probably the least appreciated size (cheap), the quality is actually pretty good, capable of good timekeeping, pretty easy to wear, and while not the largest of watches, they are reasonably large to work on. There's also plenty written about these watches. On the downside, most parts have to be taken from other watches unless you've got access to NOS parts. Balance staffs are available for some but not all vintage watches (I haven't checked for these), and donor watches (as with all watches that age) need to be carefully selected from the same design / similar grade - vintage watches were often made in batches. If you know an old watchmaker, there's a decent chance they might have a few AS parts watches / movements 19-22mm in size. Those aren't valuable, and they're not too bad to work on (excluding decades of potentially being exposed to poor servicing/ stripped or broken screws, etc. I once got a partial carrier bag of those movements for £10 from an antiques fair. The new clones are also sensible choices, I believe (I don't have much to do with modern or new watches) it's possible to get complete balance wheels quite easily and cheaply for some. If you choose one you can customise then it's possible you can build your own watch how you'd like it.1 point

-

Welcome aboard Patrick. Related to your passion for 20's and 30's watches, I'm currently on the hunt for a square, rectangle, cushion, barrel or tonneau shaped watch from that exact time period up to the early 50's. I have my eye on a couple specific models that I find very appealing. Anyways, great to have ya!1 point

-

1 point

-

Woah you are fast and talented! Wonderful. Could you please post a picture about all 4 sides or from the other three corners too (not sure if it makes sense)? If nothing else we could thank this silliness around us the time we can spend with out family and hobby. Congrats!1 point

-

YES! I looked up dial spacer on the internet. Then looked down and saw the same part staring at me from the parts tray. Somehow this beginner forgot where it came from and assumed that it was a second movement spacer. I've lost track of the times forum members have saved my feeble attempts. Thank you all! Charlie helpless in Maryland1 point

-

Pocket watches are easier to work on as they generally lack date complications and are larger in size. Spare parts are costly and sometimes hard to find, so ideally getting two movements of the same caliber to make a good one out of the two, saves on spare parts expense considerably. Finding a watch with a spare/scrap may require a good search but offers many advantahes instead. I hope this helps.1 point

-

1 point

-

1 point

-

I am a bit unconventional in my way of doing things and I'm always looking for a product that I can 're-purpose'. 3M Auto Rubbing Compound is a 3k grit compound that is used to remove fog from auto headlights, but it is an excellent product for watch crystals. I've used it for a long time and never use anything else. Buy one bottle for about $12.00US and it'll last a lifetime.1 point

-

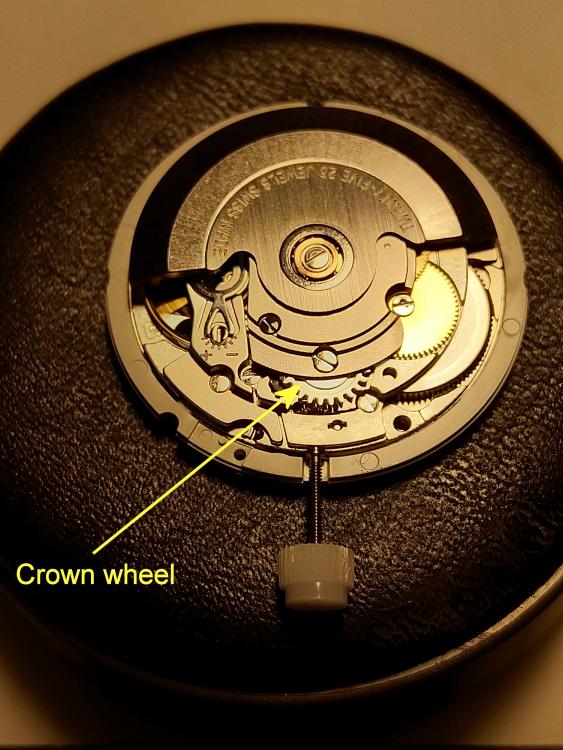

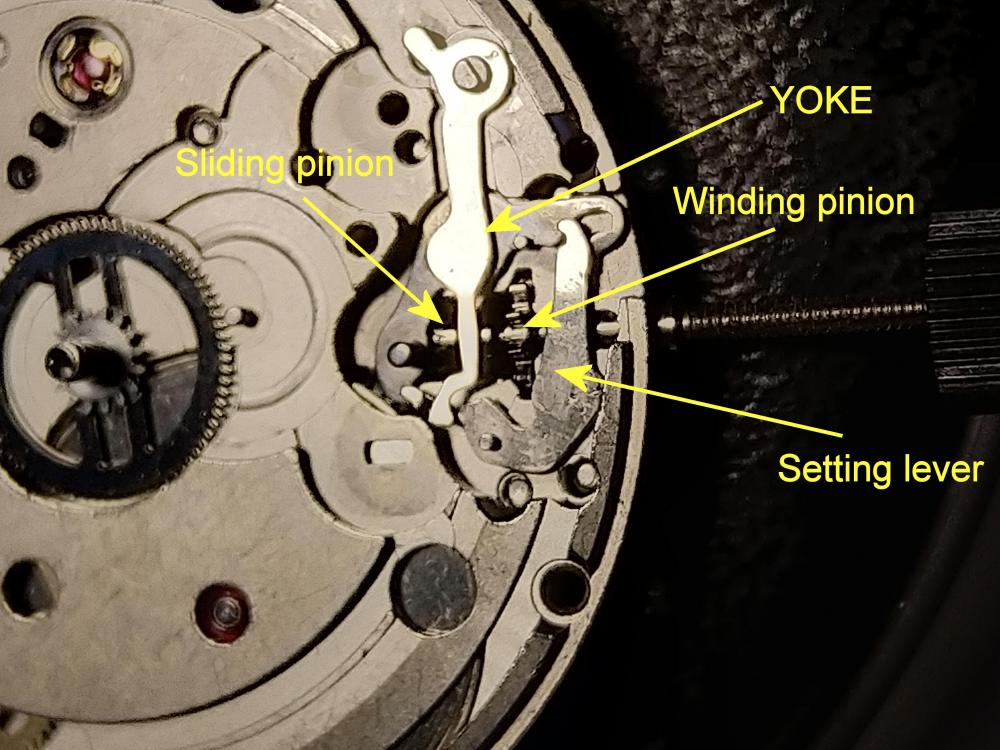

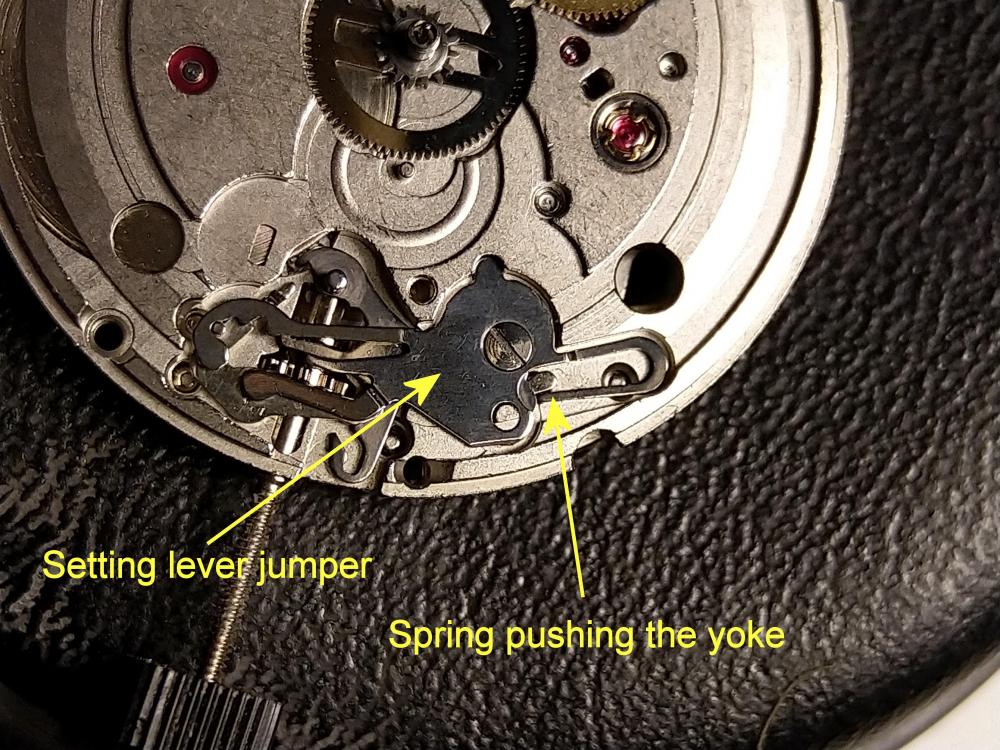

The ETA 2834-2 is a quite straight forward robust based on the 2824-2 movement. To pinpoint the issue you first got have to have a little understanding of the basics of the keyless work. I got the movement ready so lets go.. First, the crown wheel. It's not too hard to see if the crown wheel is worn down it is quite exposed. The crown wheel is driven by the winding pinion, you can see the gears interact here. Since I don't want to stripp this movement down, I have prepared with an appropiate victim, just like the TV chefs. Here you see the parts involved with the winding of the watch and setting of day and date, We got the sliding pinion, this is what is pushed forward to set the day and date, when pushed forward the winding pinion get released. The yoke is pushing the sliding pinion forward when it is affected by the setting lever. As you said the date and day is ok so the yoke must be in place. To wind the watch the setting lever must push against the winding pinion. Both these have angled gears where they interact which makes the winding possible when turning one way but makes the gears not grip when turned in the other. So one of the culprits here could be worn gears on the sliding and winding pinion, On a "normal" older movement you would have a yoke spring but on these movements that is integrated on the setting lever jumper. Sometimes the spring gets dissengaged from the yoke at the point the arrow is which makes the winding waked. If everything is okay that spring is what pushes the sliding pinion against the winding pinion. So the second fault could be here. The third and last fault could be lack of lubricant, dirt on the winding stem or it is damaged. But I think a watchrepairer checking these simple things would make a wonder on your watch.1 point

-

I read your intro. My sister lives in Sac. Thanks for the welcome! My universe also thinks I'm an oddball. I like machines of all sorts, and have this odd notion that adding computers is cheating. By day, I work with computers and electronics. My best friend has a horological connection in that he built a new experimental resonator for the atomic clock at NIST that's 10,000x more accurate than the existing one. He thinks my tube amplifiers and pre-war woodworking tools are weird. I did get him into a car to wrench on though! I think you're onto something with the attraction to artisans and craftsman... A moment of personal revelation here (thanks for the inspiration!): the reason I have no real love for silicon probably has a lot to do the lack of artisanal craftsmanship. The engineers are mostly divorced from the final product. The devices are made by machines, and half-assedly slapped together by unskilled labor defined solely by price point... Certainly there are exceptions (and it's those exceptions that have me writing code today), but there's just no "soul" in a television set... There's a clear tie to the automotive world here too in terms of differentiating desirable classics from modern appliances, but I don't think this is the right crowd.1 point

-

Here are my watches. My favorite one is the 1954 gold capped Omega automatic seamaster cal 354, case 2767-1sc. It has been recently restored.It s a family heirloom. The Hamilton Khaki field 42mm is the watch that I wear daily. The Seiko Chronograph is the watch I put on when I am messing around. The new member of the family is the Wolbrook skindiver 34mm. it needs a new click spring but it looks good! I fell in love with the watch when I came across this new kickstarter project:1 point

-

1 point

-

1 point

-

1 point

-

I have a question @Geo. You clean the balance assembly put on the main plate and only at the end you take off the balance jewels and clean them separately. How are you sure that you sufficiently cleaned the balance pivots. I believe hardened oil and dirt could remain on it (between it and the jewels). This is why, if I had a machine, I would wash the ballance on the main plate, but without the jewels on. Thank you, Bogdan1 point

.thumb.jpg.51643a41f5b128c3bb1981272208295d.jpg)