Leaderboard

Popular Content

Showing content with the highest reputation on 07/10/20 in all areas

-

Ricoh 61 finally completed today. Feels great. Love the winding sound, Zip zip zip. Sent from my Moto G (5) Plus using Tapatalk4 points

-

I had a need to safely remove a C clip holding in two pusher buttons and thought I would share my method on the forum. I had a spring bar removal tool with a solid pin on one end and a scalloped forked end on the other. I placed a small bit of rodico on the bottom side of the clip and turned the C <- gap facing up. As you can see in the picture, I simply used the forked end that was the perfect gap to push off the c clips. I installed by getting the clip in place, C gap facing down, and used a #200 flat screwdriver blade and carefully pressed down to lock in place. I used the case wall to keep the c clip and push button slit in line. Don't attempt to push the c clip back on with the button pressed all the way in, use the wall of the case to help keep the clip straight in line. Hope this helps someone.2 points

-

I would check it again, look at the timegrapher pattern, and even at the sound waveform, because likely the spring is touching. In any case a 70 years old watch is always a great candidate for servicing.2 points

-

I've got quite a lot as well.. I'll start off with this Timex quartz diver, which cost £1.99..... Before.... And after.....2 points

-

Even if I don't have much interest in electronics, I love Mr Carlson's Lab, he makes everything look so easy! I am posting this because there may be some similarity with clocks in this video, beginning g few seconds after clicking below. And what I was thinking is that 3D printing some of these parts could really make a difference.2 points

-

Hello, There's a book in German which can be used for identifying movements, Das Flume - System , (Rudolf Flume). Mine is a 1963 print of the 1958 edition but I suspect there are older editions which are more relevant to earlier and (particularly) pocket watch movements. It's in sections - upto 1947 / 52/ 57, along with escapement type and is further divided.. you can look in the relevant age section and count the holes in the little plate which retains the keyless works, and work your way up in diameter - there's a picture of each movement with the under dial view. I have checked but this movement is a bit early for my edition.2 points

-

2 points

-

1972 Timex Marlin. This is a bit of an experiment. Having discovered that some (all?) of the ingredients of the secret sauce in Moebius Classical Oil "8000" are light mineral oil and neetsfoot oil, I decided to see what would happen if I brewed my own. This watch was treated to a 80%/20% mix of scent free hypoallergenic baby oil and finest saddlers neetsfoot oil. The former can be bought by the half litre bottle and is intended for oiling delicate infants. The latter I picked up a litre of from ebay and is meant to be used on equestrian tack. In total I paid the equivalent of around $12 USD for the lot, which should make roughly 600ml of my open source watch tipple. For comparison 600ml of genuine Moebius Classical Oil "8000" would set you back around $3540 (and last you approximately twenty life times). I mixed up enough to fill a 50ml hand sanitizer bottle, as for some strange reason I seem to have rather a lot of them kicking around these days. I chose an 80/20 mix for no other reason than it looked about the right colour. The watch was serviced, and lubricated in the usual manner, and so far nothing has exploded, and I haven't had a visit from the Swatch finder general. As a side note, it also appears to be keeping good time (for a 1972 Timex), keeping perfect pace with the Timex Big Q on my other wrist (which has NOT been similarly adulterated), so the viscosity is in the right ball park. Note: I am in no way advocating the use of random lubricants on precious time pieces, but this did seem like an experiment that was worth doing. I may make up a batch with a whiff of Chinese Molyslip knock off, as I have about 200ml of that sitting here crying out for a similar bit of probably unwise fun. EDIT: I forgot to mention, the strap (which came from another basket case watch) is also fairly ancient. I used the neetsfoot oil neat on that, and it has brought it back from a hard, cardboardy and twisted mess, to a supple, clean, wearable and comfortable piece of leather. If nothing else, I do now have a plentiful supply of leather softener.2 points

-

Hello, As a 'Newbie' I'm browsing the net to discover technics , guidelines etc. on my new hobbie. I found that document from US war department dating 1945 about : 'Ordnance maintenance for Wrist watches' ...as you'll notice it's also an introduction manual for vintage watches, and some american watch models Looking at it, I thought to myself how lucky we're to have internet and online courses ... P.S : name of the attachment, is the official document name in US army archives TM 9-1575.pdf1 point

-

Hi All, I managed to reshape the hairspring in my Ricoh 61 project tonight. I am absolutely elated that I didn't give up and was successful in the end. I managed to make some mistakes on the way but in the end I corrected them all. I used hand remove levers to remove the hairspring from the balance wheel. The tips were too thick and I slipped and twisted the hairspring at the collet. Job for another day before I attempt it again is to thin down the hand levers. To correct the above I placed the collet on a pin and used tweezers to press down on the inner coil opposite where it was twisted up (under a binocular microscope). Tweezers got dirty and I managed to transfer that to the hairspring causing the coils to stick together. I solved that with a quick dip in IPA followed by a quick dry. Best to try and avoid that in the first place. Outer coil had to be reshaped to follow the path of the regulator pin. That took me a while to sort out. I did review some Ricoh hairspring images on Google and eBay to give me an idea of how the outer coil should be and then followed the helpful videos on YouTube. Hairspring fitted back on balance, managed to position it so the jewel was 180 degrees to how it should be. Corrected this with tweezer tip in the collet slot while gently turning. What I would do better next time. Better lighting would be the most important improvement I could make. It would have been a lot easier I believe with good lighting. It was very tricky but I am a beginner. It was my first success with a hairspring reshape. I am 52 years old so a late starter. Hope this write up can help someone in future. Sent from my Moto G (5) Plus using Tapatalk1 point

-

There also could be a tiny foreign body interfering on the hairspring.1 point

-

I had to thank you for sharing this. Just what I was looking for to help salvage an old Pulsar Digital navitmer 358 chrono on which one pusher is fouled.1 point

-

1 point

-

Do you its history? Was it running Ok before? One of the other possibilities is wrong spring has been slapped on.1 point

-

Nicely done. I like what you did on the front to stop things rolling off. I don't do much wood working at the moment, but I do agree that there is something special about using hand tools. My shed workbench I hand planed it flat using a bench plane that I found at a swap meet that had a blunt blade and surface rusted sole that I restored. Using corundum powder with kerosene on a glass plate I trued the sole of the plane and using Japanese water stones honed the back of the blade to a mirror finish before I even started to sharpen the front. Quality tools are always a pleasure to use.1 point

-

Ah, so no the click is not on the rocker arm side unless I'm missing something. I managed to wind it without a stem by physically holding the rocker arm to engage the ratchet wheel rather than motion works and rotate the winding pinion with a screw driver. There is a visible spring on the dial side but I believe that may be the setting lever spring? Not sure, but it seems to me like what is missing from my winding/setting mechanism is 1) a stem and 2) a mechanism for switching position between winding and setting. Next time I will look for a more complete movement.1 point

-

You see the big screw in second picture( dial side) ? It is holding the rocker arm, rocks to wind position and to set position. You will find three gears mounted on it.1 point

-

You can always release barrel power through the fork, Remove balance and cock, fork bridge screw, insert a took pick in spoke of a gear to keep it from turning, lift the fork bridge and lift the fork out. Normally with the old rocker arm, you need to turn the crown towards winding to relieve torque on the clcik, release the click off of ratchet teeth and let crown free to unwind.1 point

-

Hi Daniel the ones put on site by OldHippy by Meadiafire are still active just use the search on the home page. If you cant find them PM me your email and I will try o send them that way1 point

-

1 point

-

Hello Daniel I think the BESTFIT books 1 & 2 would be a great help to you in the future. Old Hippy put them on the site some time ago under Meadiafire they can be found using the search function in the upper right of the home screen. I have just checked them out and are still working. you are able to down load both parts .a usefull reference. Also I am sure AndyHull did the same with an OCR version which makes searching for information easier have a search.1 point

-

1 point

-

Are you saying they gain the full couple hundred second just for the duration of the workout? Or are you extrapolating the amount of time gained during your work out to a day? If so around how many seconds do you gain just for the duration of the workout? The reason I suggested the test is to make sure it's just knocking and not any other problem like isochronism or hairspring sticking. If the rate doesn't fluctuate significantly before the movement starts knocking then your problem is that you're causing your watches to knock. If it does than it's another problem. If it's indeed only knocking then depending on how aggressive your movements are, the duration of your workout, and amount of seconds gained during workout it could be normal. Especially on higher amplitude watches if they are subjected to certain repeated aggressive movements they will knock and you will gain a whole bunch of time. All my watches gain anywhere from 3-5 seconds just from vigorously towel drying my hair.1 point

-

1 point

-

De nada! Glad I was able to help. Looks great too! Woodworking with proper hand tools is one of those "zen washes over" activities once you get your feet under you. Glad to have made the introduction! I went back and re-read what I posted up there, and I'm a little embarrassed... Work + baby + pandemic + everything else = frazzled! The phone conversation/texts followed that to a significant degree. I must sound like a broken record!1 point

-

1 point

-

yes I'm going to be extremely disappointed with you if you do not throw away all your lubrication's when they expire. Then if they don't have an expiry date their incredibly old and should have been thrown away years ago. I was at a lecture once where the professional watchmaker Jeff was talking about upgrading & replacing your lubricants. I thought about it realized I hadn't bought any new oils in quite a few years? So armed with $200 cash I went to the material house. I think Debbie was amused because normally watchmakers cry about the price and I said I had $200 and I wasn't concerned about the costs I wanted to replace all my lubrication's. unfortunately the HP oils were relatively new and only in the large bottles the same size as a bottle D5 at five times its cost. So this means I have roughly $200 of miscellaneous lubrication's and another $200 of two types of HP oils. Then I thought about it for a while decided that at least at home I have zero intention on ever replacing these oils unless the bottle runs out which based on the consumption of the previous oils I was using is extremely unlikely especially the HP oils I will never go through all of that. Everything at home is for personal use I have zero intention on ever upgrading my oils. If something nifty new comes out I might buy that maybe or I might buy a lubrication for amusement sake but at home I really wouldn't worry about the expiring dates of synthetic oil. My understanding from the watch companies is that there is concern about each time you get oil out of the bottle there's a risk of contamination. That's why supposedly Rolex has all of their lubrication's in syringes so there's less contamination issue. Then you're supposed to replace the oil in your cups on a very regular basis so all of this becomes irrelevant because you go through your oil in a lightning fast speed if you really did that. My personal recommendation for lubrication is stay away from natural oils as I have a shorter life time even though the indications were they were much better lubricants at least while they were lubricating. The staying with synthetic and mineral oils or whatever with long life find whatever you you like and go with that. with modern cheap timing machines you can now check your performance and because are your watches you can check your performance over years you'll figure out eventually what you like what you don't like what works and what doesn't work go with that. Except if you make poor lubrication choices on an automatic for instance a lot of times the automatic mechanism will suffer and might disintegrates from use. this tended to be a more common problem with earlier automatics it didn't have jeweled bearings and to some degree this is all irrelevant if the gaskets in your watch disintegrate and moisture gets in. Rust and any form of lubrication is a really nice grinding compound.1 point

-

this is a unfortunate problem for a lot of horological lubrication's zero specifications. At least with moebius you can download their tech sheets to look and see if there's any natural properties in the lubrication and see the shelf life. then yes as we discovered another discussion may still have natural substances and those lubrication's have a much shorter shelf life. then regarding lubrication I'm attaching an Omega document helpful hints for lubrication. Omega 8645_WI_40_rules for lubrication cousins uk.pdf1 point

-

I would expect over-winding a manual watch is fairly common, but what happens then would depend on how the mainspring is secured in the barrel. There are many different types. I'm guessing that you have the Swiss tongue end, which looks like, when wound too tightly, might bend and deflect the spring as you describe. A different style might simply break under those conditions.1 point

-

Apart from Cousins, I often get my mainsprings from here : http://www.obsoletewatchandclockparts.com/770-mainspring.htm1 point

-

Dont mean to keep bumping this thread but i just though id report back and let you know i tried the mainspring suggested by WatchMaker and it worked a treat. It was a near thing, but it hooks without adjustment and now the watch is working well. Thank you a great deal.1 point

-

Standard Seitz jewels are sized in 0.01mm hole increments up to 0.20mm, from there they go in 0.02mm increments. In industry makers would order jewels from specialist makers, to whatever size they wanted. In general the outer diameters would correspond to normal 0.10mm increments but the hole sizes could be anything- one common size I see is a 0.25mm hole, which isn't in the Seitz offering. What are your actual pivot sizes? Thankfully, at 0.20mm and up an extra 0.01mm of wiggle room usually doesn't affect performance. Do any of the suppliers have a 22/120 and 32/160?1 point

-

Reference picture of Ricoh 61 balance showing the terminal curve shape that helped a lot. Sent from my Moto G (5) Plus using Tapatalk1 point

-

I do keep a selection of jewels, but sometimes do have to order them. The last time I ordered, I had to get one size larger for the outer diameter and then broach to fit. Sometimes that can be a good thing as the old hole may not grip tightly enough on the “same” size jewel as the original.1 point

-

Are you going to route a little 'trench' across the front edge of the top to catch anything that trys to roll off the front? Coming along nicely.1 point

-

1 point

-

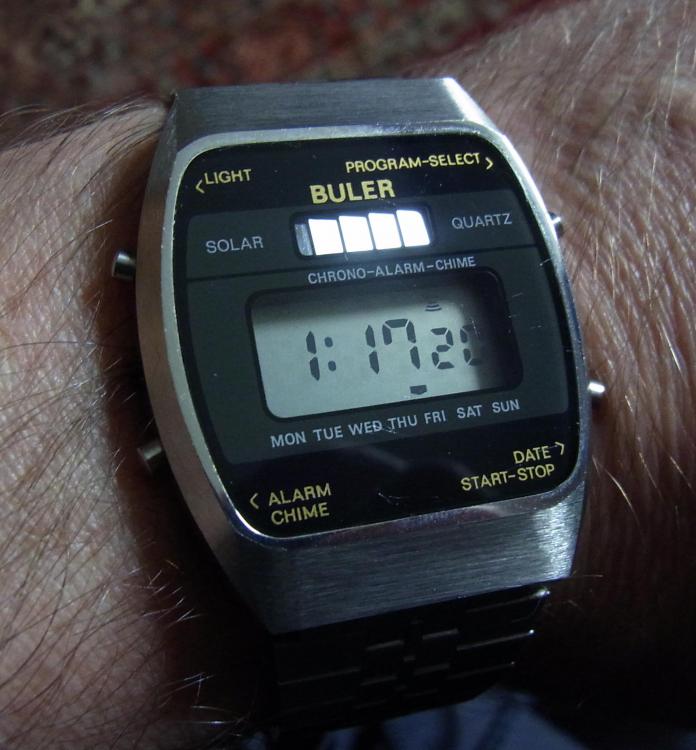

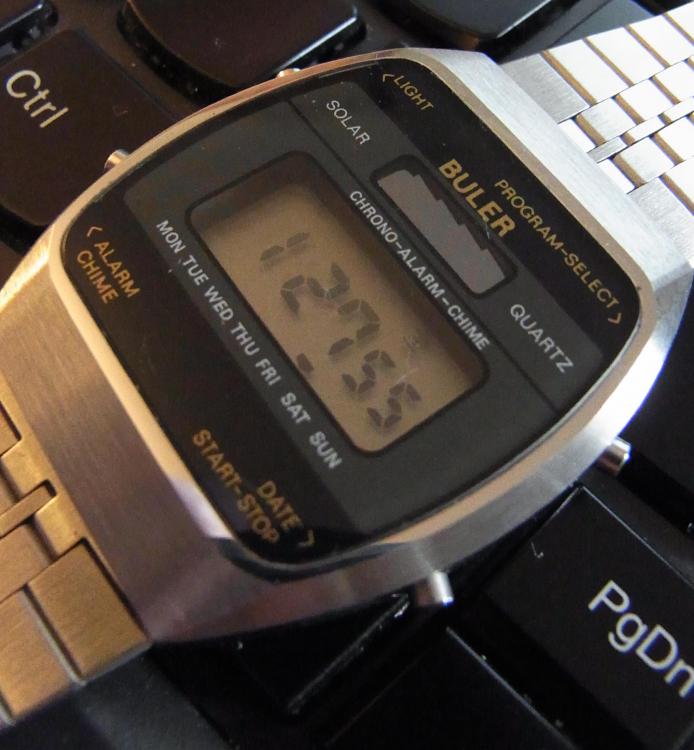

\ Buler Solar LCD Chronograph Alarm (3091-9003), circa 1978. This was presumably meant to compete with the likes of the Seiko LCD Solar Alarm Chronograph A156 produced the same year. It has all the look and feel of a quality watch, entirely stainless in construction. Very different from the 99 pence "Hong Kong specials" that you could pick up from a filling station a few years later.1 point

-

Use leather to protect the arbour when using pliers, seeing its brass you could have also gently heated it the expansion would have been enough to make it very easy to remove.1 point

-

The problem with these small movements is that each time you manipulate things, you get close to disaster. And it's a game of numbers. Cheers. .. well put sir! Sent from my iPhone using Tapatalk1 point

-

Stopwatches are different then regular watches for hand removal. Usually with stopwatches the hands are not removed but the dial is removed with the hands. The hands are friction on with extreme force to a tube that on the backside has a heart shaped cam. So basically the hands go on spring-loaded cannon pinions with a heart-shaped cam used for resetting.1 point

.thumb.jpg.e131d813a90c7e94b4e5307732555715.jpg)

.thumb.jpg.c7a2e4cdf52d1d9777294e5a2f056f61.jpg)