Leaderboard

Popular Content

Showing content with the highest reputation since 04/18/25 in all areas

-

Hi all, I did ad the Google Adsense program to this site quite some time ago in order to attempt to reduce some of the costs of this site - which it did. I never did enjoy the look of the site clustered with ads and all sorts of tricks Google plays in order to garner clicks. In fact I hated it. Yesterday I decided to ditch Google Adsense and remove all ads from the site with immediate effect. I hope this will help to make the site more enjoyable and, hopefully, even faster loading.20 points

-

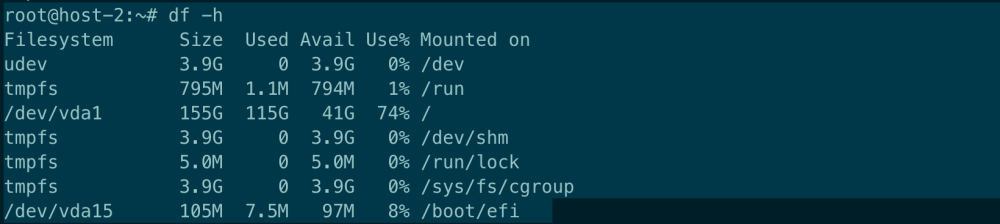

Hi guys. @VWatchie Those images are self hosted (not hosted on this server). Do a look at the page source and you will see this. I’m afraid, I can’t have control or backup images not hosted on this server. ( They seem to be served from here: https://qehvsw.bn.files.1drv.com/) This server is backed up fully every night and the database is backed up and versioned every hour, all stored off site on Amazon S1 platform. It’s hard for us to lose data. Ive got a huge overhead of space on this particular server the site is served from so no worries there Sorry all for lack of response so far, I have been extremely busy and am embarrassed to say that priorities had to be set in place for a while. Be assured that i’ve got constant monitoring and alerts should the site be in an extended problematic state (down etc) and work on these issues if they arise.12 points

-

That’s a nice idea, But i’m committed to providing this site as a gift to the watch repair community as my thank you for my incredible life i’ve had in this business. Ive done well and unless my financial circumstances change then i’m more than happy to foot the bill. If circumstances do change then be assured that I will make an appeal. For now, I’m comfortable with the way things are and I am extremely delighted to remove Google Ads from this site and to stop Patreon, it feels like a major step forward Sorry, I missed your reply, I got blinded by another poster in this thread. Yes - I can confirm that I have always seen WRT as a not-for-profit website, and therefore - not a business as such. I’m lucky and have done well in my life due to a decision made in my teens to start a watch repairing apprenticeship which has sustained myself and my family for many years now. Consider this my small way of paying it forward. Ive been committed to keeping the site alive on a technical and financial level for over 10 years now and I have zero plans to change that. Thank you for your kind words by the way. And as for your wish - nobody can control what happens in life, if something happens to me I have things in place with my family but I’m just not comfortable talking about my personal business - I wish a certain person would respect that, but i’ve calmed down now - i’m only human11 points

-

In tandem with my last post regarding the removal of Google Adsense on this website - I have also decided to fully self fund this site as a gift to the watch repair community of which I’ve been a member of, and have benefited from since being extremely lucky to gain an apprenticeship back in the late 80s. Well, that means that I have also closed down my Patreon account - or, to be clear, stopped all future transactions on my Patreon account and this is with immediate and permanent effect. not to mention, but I will, I really really do appreciate the contribution all my patreon and PayPal supporters have provided over the years, you guys have been absolutely awesome and helped to keep this forum alive and available for those who might not be able to afford the payments. again, from the bottom of my heart thank you.10 points

-

WRT feels like a second home to me, and I’m sure I’m not the only one. That’s why we care so much about making sure it’s seen as something bigger than just Mark and us users. Companies don’t rely on one person, no matter how great they are, because life happens. You know — don’t put all your eggs in one basket. When I started my own business, I lost a lot of gigs because clients worried what would happen if I got sick. Teaming up with a competitor to cover for each other made a huge difference. Right now, WRT is the company, and Mark is our brilliant, irreplaceable consultant. It would feel a lot safer if there was someone who could step in if needed. That’s my only little wish. Otherwise? Nothing but love for WRT and everyone here.7 points

-

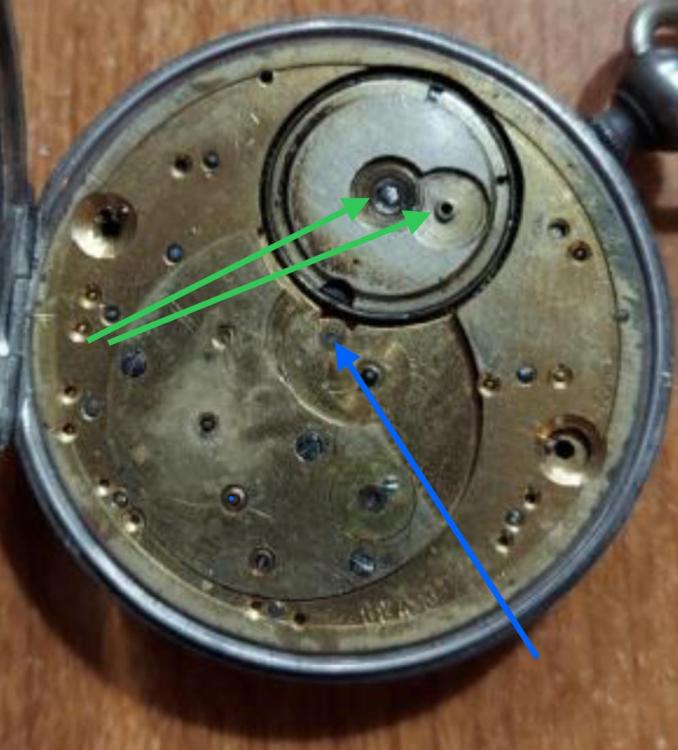

The movement looks like a lepine movement in the Locle style, with a tangential lever escapement, with decorative engraving. Without engraving, the movement would have looked something like this : The blue arrow points to the click, which appears to be missing from your movement. Without a click, it will be impossible for the mainspring to retain any power when wound. The “Echappment A Ancre” means the watch has a lever escapement. There is some damage and missing parts on the dial side. The blue arrow below indicates where the cannon pinion, centre wheel arbour and the pin that runs through them has snapped off. The green arrows indicate where the Maltese cross style stop works should be. Best Regards, Mark6 points

-

Note the 8992 is 850 pounds for a liter. I think this is really for industrial settings like they say, where it would be used as a final bath in a 20,000 buck cleaning machine. I use the 8981. That is excellent- I don't often get to see a serviced watch 5 years later, but when I do I expect to see pretty much the same oiling on the balance jewels as when it went out. I think at that area, being essentially sealed, it really should remain fairly pristine for likely 10 years. It's why some makers go to the trouble to use cap jewels on the escape wheel as well- not so much for friction reduction, but to keep the oil longer where it really counts.5 points

-

I have only been a member for six years & I have found this a very friendly forum although I don’t have anything to do with watches not because I don’t like watches but because I have gout in both hands so my dexterity isn’t very good, I restore torsion clocks & occasionally other antique clocks also at 72 my eyes are not what they used to be, that is why I only post on the clock forum & the lathe forum mostly . As others have said Mark it is much appreciated that you are willing & able to do this. very many Thanks Dell5 points

-

This is indeed a unique site and members including myself genuinely care about it. All we want is the site to continue.5 points

-

Often times the belief is when you're making small parts you Need a small lathe like a watchmaker's lathe to make small parts. But for gear cutting its oftentimes better to have something bigger. Then realistically you might end up with several things not just one machine for everything. Depends upon your machining skills and the equipment you have. This is where having a slightly bigger equipment allows you to make all kinds of things where if you have a tiny equipment you can not really make bigger stuff it's very awkward. Then indexing is all kinds of ways to do indexing a very popular way is with the stepping motor a worm gear like at the link below https://www.ebay.com/itm/191714031261 What's interesting with something like this is you can micro step at end up with basically a infinite quantity of indexing. But you still have to build some things. For instance here's an interesting YouTube channel and an interesting video. His watchmaker's lathe is a little bigger than what I'm typically used to for watchmakers lathe. As a rather interesting cross slide and notice he makes just about everything. Then he gets the indexing something purchased surplus but it's basically just a worm gear stepping motor his has way more hands-on control but it does the exact same thing as the one up above. Then if you read the description of the video is in a shop of creative people to build all kinds of nifty things like the stepper motor controller etc.4 points

-

As the question is about indexing, see this video. The quality is bad, but You can see how my setup for wheel cutting works and how the indexing is done. The index disk is just printed on paper. Otherwise, as it is seen, I use minilathe for the purpose of watchmaking and I find it more convinient than regular watchmakers lathe4 points

-

WW is 50mm exactly. Levin, Derbyshire, Leinen, Boley Lorch and I'm sure most others making machines based on the WW standard are all 50mm. Marshall/Peerless are 2", or 50.8mm height. Many lathe beds are slightly relieved in the center, so it could be possible to swing something a little over 100mm. More likely is the auctioneer had measured with a tape measure and called it 4" when it's like 98mm.4 points

-

4 points

-

4 points

-

Hello Mark, thank you for the ad removal , like JohnR725 , I appreciate any revenue from such would be helpful. This is the one forum which encourages conversation and social interaction and in that sense it is unique All the others I frequent can be a little intimidating and answers some what terse some quite rude. I think on here we try to do justice to your site in keeping with your principals. In my opinion it is like no other. The contributors behave and act like gentlemen and ladies. And long may it continue to be so.4 points

-

4 points

-

I’m having a hard time seeing exactly what’s going on, even when I zoom in as much as possible, but it kind of looks like the hairspring has gotten itself tangled up. How does the spring look when you place the balance cock on your balance tack? Tangled?4 points

-

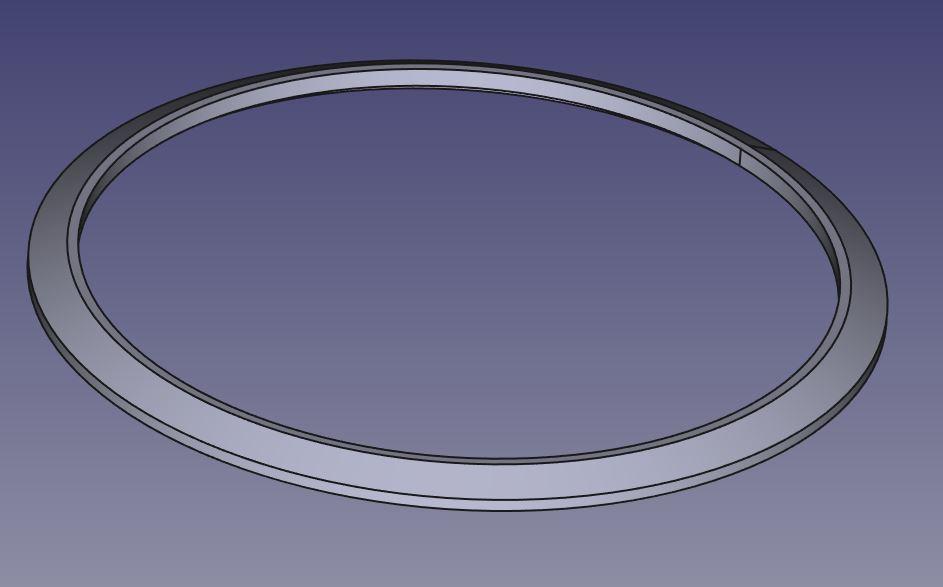

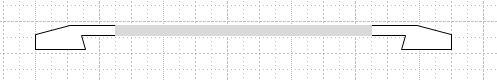

My drawings are not to scale, BTW. Here is the FreeCAD illustration of what was printed. It has been very helpful to hold the printed bezel in my hand to get a sense of scale. My plan over the next few days is to get some fender washers. They come in a nearly ideal thickness and and OD that is close to what I want. I will make a precision arbor to hold the washer in my lathe to turn the outside dimension. Still pondering the best strategy for the inside cut.3 points

-

It's difficult to tell, but my guess is it just looks like it has a bezel. Once you have removed the movement, you should be able to tell. Either way, I think you should be able to press out the old crystal from the inside as long as you have a die that properly supports the bezel around the crystal. So, take it apart first and then assess if any additional tools or actions are needed. Let us know how you do!3 points

-

I plan to continue this thread until done. I received the watch today. My first step was to make measurements. Here they are. Here is an image of this model watch retrieved from ebay Here is my sketch of the bezel profile that I need to make. No dimensions yet as I am pondering that. Question: Should the bezel grip the crystal? The crystal is already gripping a lip of the case. Here is a prototype I 3d printed just to get a sense of what i am dealing with3 points

-

Ahhh, yes. I hadn’t thought of that. I’ve serviced quite a few of these and the first time I didn’t realise it was a ships strike pattern! Ha ha, confused me totally until I realised.3 points

-

Hi Mike, I did, thanks. Found this clip that was really helpful: It says Seth Thomas but it's actually the same Hermle I've been working on. I'd had it working correctly all along but hadn't noticed that the lever with the sprung end stops the hammer a bit short of the bell on the second ding at the end of the half-past sequence. If only I'd put the bell on when testing, rather than just looking at the hammer, my ears would have told me it was working, even if my eyes didn't!3 points

-

I, too, am a fan of L&R, so I will continue to use it. About half the cost here in USA as your locale. Even so, it is expensive, but so is everything else in this horological world. I don't take expensive vacations, so horology is where I splurge!3 points

-

Thanks Mark for this update. I was a little down last week when I read rumors about the future of this site - very glad to hear that you are committed to keeping this running! I know from experience of hosting my own stuff that most of the time it is a breeze but once in a while there are whole evenings spent making stuff good again. I would be happy to help out on a site support ops team if you wanted to set that up (or have me help set that up)3 points

-

Did you watch the whole video? Once Alex has set the stud, he first corrects the best error, then checks that the hairspring coils are breathing concentrically, then turns the stud to centre the hairspring between the open regulator pins. He then checks that the regulator can traverse the terminal curve without disturbing the hairspring. A correction is needed, which he performs. He then reinstalls the balance and re-centres the hairspring between the regulator pins, and verifies that the regulator traverses the terminal curve without disturbing the hairspring. Finally, he demonstrates how to close the gap between pins. He then recaps the whole process, fleshing out more detail. If you follow this process, you have correctly set up the regulator pins, and are ready to set the rate of the watch. If you are interested in learning more about the effects of the regulator pin spacing on positional rates etc, you can read any literature regarding regulator pins. The etachron system makes adjusting beat, centering the hairspring between the regulator pins and adjusting the gap between the pins very convenient, but the same rules that apply to old style regulator pins apply to the etachron system. This video explains the basics : I hope that helps, Mark3 points

-

Thanks, Mark. That's the kind of reassurance many of us wanted to hear! Yes, life is unfortunately unpredictable, and it would be a shame if the many dedicated WRT: ers became stranded if, god forbid, something happened to you and WRT stopped working.3 points

-

3 points

-

an investment in assortments most likely from a seller like Ebay will be a good choice, I have seen several this month already sold, or a donor if your supplier does not carry something suitable....3 points

-

This is the old/first(?) way for making a mainspring for an automatic. "Evolution-wise" it is an logical first step forward from a standard spring. Usually these are indeed replaced with a new spring with an integrated/fixed bridle. Lubrication as you would do with any automatic. Added: I can also imagine this construction was originally made to achieve some safeguard against "brute force" handwinding...?3 points

-

Thank you. I was informed it was a cheap worthless Lack watch from India. It’s in a small mens watch looks to be around 1930 odd Cleaned the movement and it’s going really well. Keeps good time. This is a great site. Mystery solved. I’m obliged.3 points

-

If they don't give enough movement individually then just bend a piece of wire or rod so you can depress them together.3 points

-

Wow! What a great gift! You, Mark, has been a blessing to the watch repair community and has inspired a lot of watchmakers and hobbyists, including me. More power to you!3 points

-

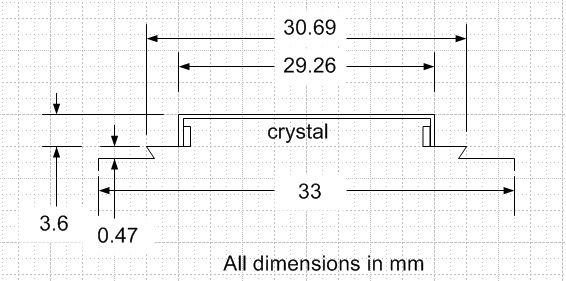

Welcome to the forum. The sticking could be corrosion of a build up of old oil. Not sure what you mean about not being able to find one with the same dial as the movements come without a dial. As with all posts, photos will help along with where in the world you are for sourcing parts. Here's the selection available from Cousins here in the UK.3 points

-

3 points

-

The screenshot was poor https://www.mikrolisk.de/show.php?site=280&suchwort=A&searchWhere=trademark&searchMode=exact&id=33 points

-

3 points

-

Agreed. There are many different automatic winding mechanisms, each with their own quirks wrt. lubrication. Access to the specific service instructions is the ideal. Otherwise, ask here for advice on the movement you are working on.3 points

-

If at all possible, find a service guide for the automatic movements your work on, because the lubrication procedures may have different requirements or rely on oils you would not use in a manual wind train (in addition to the braking grease you mentioned). Some autos like older Seikos do not have a manual wind option, so the procedure of letting down the mainspring without being able to use the crown may require a screwdriver in the ratchet wheel screw and great care. Do you have an auto movement you were planning to start with?3 points

-

HWGIKE#57 Valex FEF 190 15 jewels Swiss lever full service and repair This one was waiting for a balance staff replacement in my cabinet parts and case cleaned up with a new balance staff and a 4th wheel as the original 4th wheel had a broken pivot for the off center second hand. I never attempted a balance staff replacement before however I received a Bergeon Molfres (i was hunting it for about 2 years) and with the help of it I managed to remove the old staff and riveted the new one in. It also received a new MS, crystal and the hole for the MS arbor was also tightened. With the new MS now it has an acceptable performance meaning that the amplitude goes up to 280 fully wound, has an acceptable beat error and I have the two nice lines but only dial up, dial down is not as nice and I could not figure out as why. I have the two lines but the amplitude is dropping to around 230 and the lines are a bit hairy. Both dial up and dial down the lines just go up and down without seemingly any pattern. I cleaned the movement two times, and then a 3rd time pegged out the main plate and train bridge holes but made no change. Both the HS collet and the roller table was too lose on the new staff... I did not count how many times I took the balance cock off to sort out the HS collet, the roller table and the beat error, somebody before me also shortened the HS by pushing it out a bit and it seems every time somebody is messing with the end of the HS the protruding bit is most of the time twisted bent etc. This one was probably one of the most challenging repair and service. I might take the new MS out and clean it lubricate it as I just pushed the new one in to the barrel from the retaining ring. Plus started to re-read the theory of the escapement and how to analyse the graph on the timing machine: Greiner Chronografic Record manual. I am also thinking to put the watch on a 24 hour long run with the eTimer SW it once helped me to figure out what was wrong with a watch. There is an interesting part of the Greiner record manual talking about the pallets and the end shake of the balance and pallet staff. Maybe this is my issue? Who could that possibly identify? After a few years now I am still without a clue how could watchmakers make parts I can only see with my microscope or how could/can they carry out complicated services impossible to do.. real magic..... .... ..... before I sent this post while the pics were uploading I had an idea, i was browsing the possible outcomes on the timing machine I had one for magnetism..... so I demagnetized the movement and it is not hairy now.... two really nice lines 0.2 ms beat error still a bit wavy, but a lot lot better..... argh....3 points

-

Heat from the wearer's wrist is causing internal moisture to settle on the glass. You could try putting it in a dehydrator for an hour with the back off3 points

-

With these battery clips , what I do is with a finger cot on cover the coil and release the clip that way if you slip you finger guards the coil, If you use the hole in the clip to hold the tweezers/probe all is ok. I think more coils are damaged by removing the snap backs without due care and clipping the coil, whick always seems to bl located at the pry point.3 points

-

I made a brass object sort of approximating the shape of a balance staff on my lathe (obvs learning), cleaned and reassembled a Timex M24 from a late 60's watch the seller said "needs new battery" and installed a NOS Elgin mainspring that showed up in the mail into an 1890s 6 size that had been waiting on the bench. To find it runs ++++ on the timegrapher, at a wicked 100° amplitude.3 points

-

It would help a lot to see a picture of the balance cock removed and on its back with the balance pivot in its jewel hole. From this view we can't even rule out the outer hairspring coil being hooked on or under the stud.2 points

-

Is it water moisture ? If so and you have good sunshine where you are, just put the watch under direct sun light ( Dial facing sun ) a few hours, sun light dries the moisture. Depending on the amount of moisture, lubricants in movement might have been ruined. No other source of heat is safe.2 points

-

Ahh the DD modules. I havent done one of these for about a year, but when I did it, I followed the service guide and got it within spec. Do you have this? Ive attached it for you and any others who might need it.Omega 1140.pdf2 points

-

i think this is true, once the back has popped off the case seam, a repairer must develop a habit of lifting the back away carefully without inserting anything sharp inside. I use a fingernail at the very edge of the back before the lip starts.2 points

-

The terminal curve of your hairspring might be distorted. If the curve is perfect, the hairspring should remain in the centre if the gap of the regulator pins when the regulator arm is moved along the entire curve. And adjusting the rate should not affect the beat error. However, reshaping the terminal curve is not easy stuff. Maybe at this beginner's level, getting the watch running is already a commendable achievement.2 points

-

2 points

-

2 points