Leaderboard

Popular Content

Showing content with the highest reputation since 03/25/25 in all areas

-

Hi all, I did ad the Google Adsense program to this site quite some time ago in order to attempt to reduce some of the costs of this site - which it did. I never did enjoy the look of the site clustered with ads and all sorts of tricks Google plays in order to garner clicks. In fact I hated it. Yesterday I decided to ditch Google Adsense and remove all ads from the site with immediate effect. I hope this will help to make the site more enjoyable and, hopefully, even faster loading.20 points

-

Hi guys. @VWatchie Those images are self hosted (not hosted on this server). Do a look at the page source and you will see this. I’m afraid, I can’t have control or backup images not hosted on this server. ( They seem to be served from here: https://qehvsw.bn.files.1drv.com/) This server is backed up fully every night and the database is backed up and versioned every hour, all stored off site on Amazon S1 platform. It’s hard for us to lose data. Ive got a huge overhead of space on this particular server the site is served from so no worries there Sorry all for lack of response so far, I have been extremely busy and am embarrassed to say that priorities had to be set in place for a while. Be assured that i’ve got constant monitoring and alerts should the site be in an extended problematic state (down etc) and work on these issues if they arise.12 points

-

That’s a nice idea, But i’m committed to providing this site as a gift to the watch repair community as my thank you for my incredible life i’ve had in this business. Ive done well and unless my financial circumstances change then i’m more than happy to foot the bill. If circumstances do change then be assured that I will make an appeal. For now, I’m comfortable with the way things are and I am extremely delighted to remove Google Ads from this site and to stop Patreon, it feels like a major step forward Sorry, I missed your reply, I got blinded by another poster in this thread. Yes - I can confirm that I have always seen WRT as a not-for-profit website, and therefore - not a business as such. I’m lucky and have done well in my life due to a decision made in my teens to start a watch repairing apprenticeship which has sustained myself and my family for many years now. Consider this my small way of paying it forward. Ive been committed to keeping the site alive on a technical and financial level for over 10 years now and I have zero plans to change that. Thank you for your kind words by the way. And as for your wish - nobody can control what happens in life, if something happens to me I have things in place with my family but I’m just not comfortable talking about my personal business - I wish a certain person would respect that, but i’ve calmed down now - i’m only human11 points

-

11 points

-

In tandem with my last post regarding the removal of Google Adsense on this website - I have also decided to fully self fund this site as a gift to the watch repair community of which I’ve been a member of, and have benefited from since being extremely lucky to gain an apprenticeship back in the late 80s. Well, that means that I have also closed down my Patreon account - or, to be clear, stopped all future transactions on my Patreon account and this is with immediate and permanent effect. not to mention, but I will, I really really do appreciate the contribution all my patreon and PayPal supporters have provided over the years, you guys have been absolutely awesome and helped to keep this forum alive and available for those who might not be able to afford the payments. again, from the bottom of my heart thank you.10 points

-

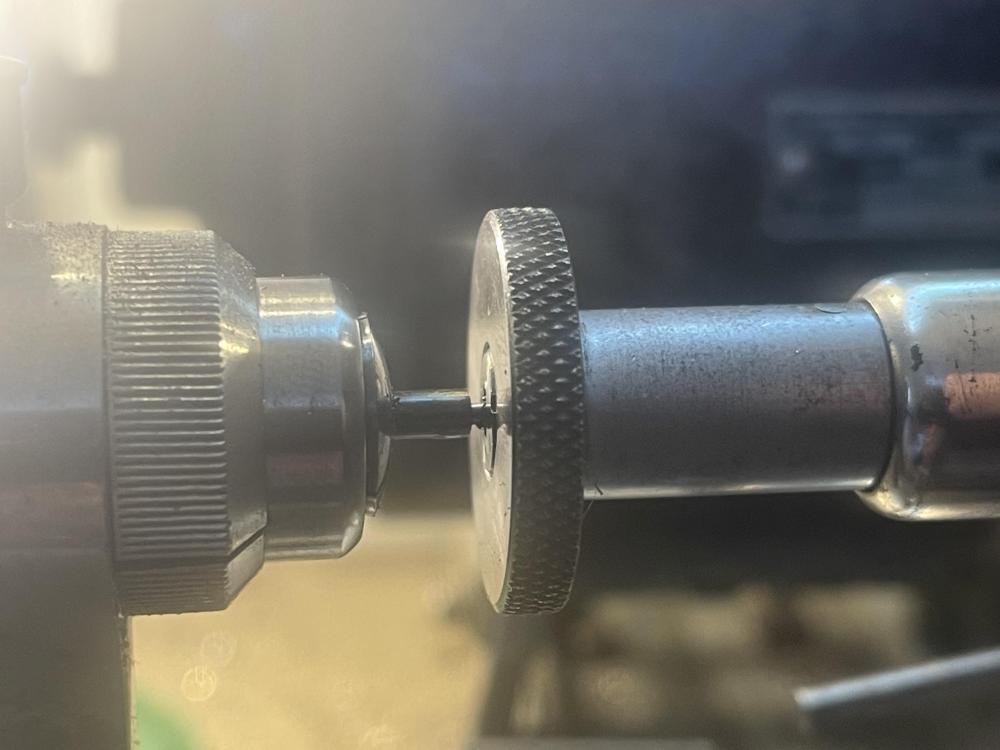

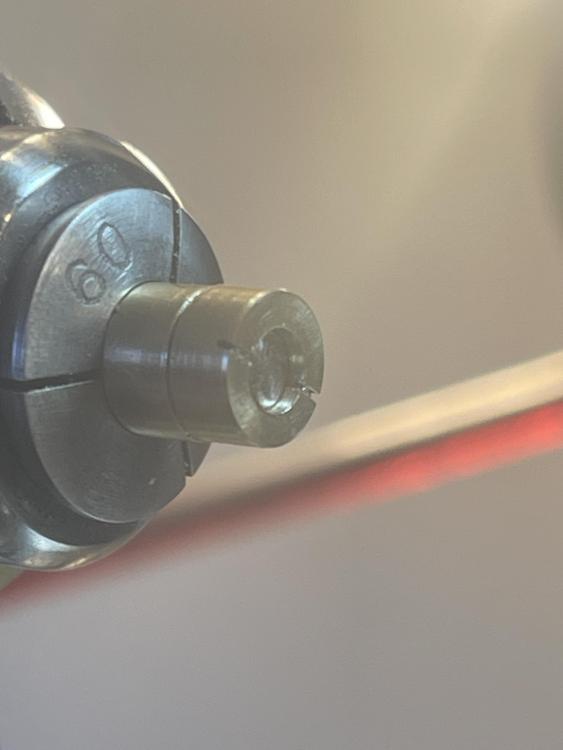

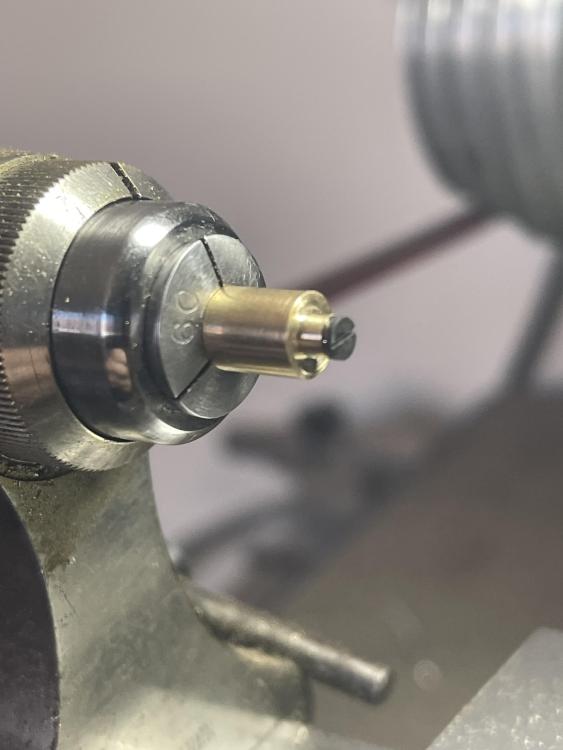

I recently repaired this movement but the screw for the ratchet wheel was the wrong size and it was bugging me (pic 1). I tried to find a replacement but I couldn't match the head width and tap size, so I decided to make one. I wasn't sure of the tap size for the screw, but it looked to be either 1.0 or 1.2 so I made a test screw out of a brass bar, with a matching threaded hole on the other end. I didn't photograph this but you can see the bar in picture 4. I settled on a size and proceeded to cut a steel bar down to length. I softened the bar first to make it easier to work with and the cut it to size, using the chart on my tap and die set for reference Once cut I set up the die in its holder and used my tailstock to hold it straight while I created the thread. Once the thread was cut, I tested it using the brass bar Happy with the diameter and thread I cut the screw off the bar and then twisted it into the bras bar to use it as a holder, for securing it in the lathe to protect the thread I made a face cut to clean the head up Next step was to make the slot. I currently do not have a table saw for the lathe so I was going to have to use a saw. To keep the cut straight and centred, I made a jig out of a piece of brass bar by drilling a hole big enough to slot over the stew, with a slot in it to guide the saw while cutting the slot on the screw head I then cut the slot with a fine saw (I forget what they're called, pin saw?). Once that was done, it was ready for hardening and tempering and then a first polish from 800 grits to 2000 on the lathe. The picture below is just before the first polish. Once I got it to polished with 2000 grit, I removed it from the lathe and then polished it with diamond paste and a Dremel, using the brass bar to hold it. (this turned out to be a really useful tool) Finally, it was ready to go into the movement. I am pleased with the result. I should have made it flatter to match the crown wheel screw better but, overall, it is a vast improvement on the screw that was in there. The main thing I took away from this was how useful the brass bar was, not just for testing the thread but as a holder in the lathe, for cutting the slot and for handling when polishing. No trying to hold it with tweezers or a vice. It was a really simple tool to make and really worth the 10 minuets or so to make it and cut the threads. The slot guide was a huge bonus because it worked much better than expected.10 points

-

Firstly i think you need calm down, and secondly you need to understand that Andy is trying to help you. A picture tells a thousand words, supplying us with a photo explains more than you can tell and is standard practice. I can't ever remember anyone arguing over it.8 points

-

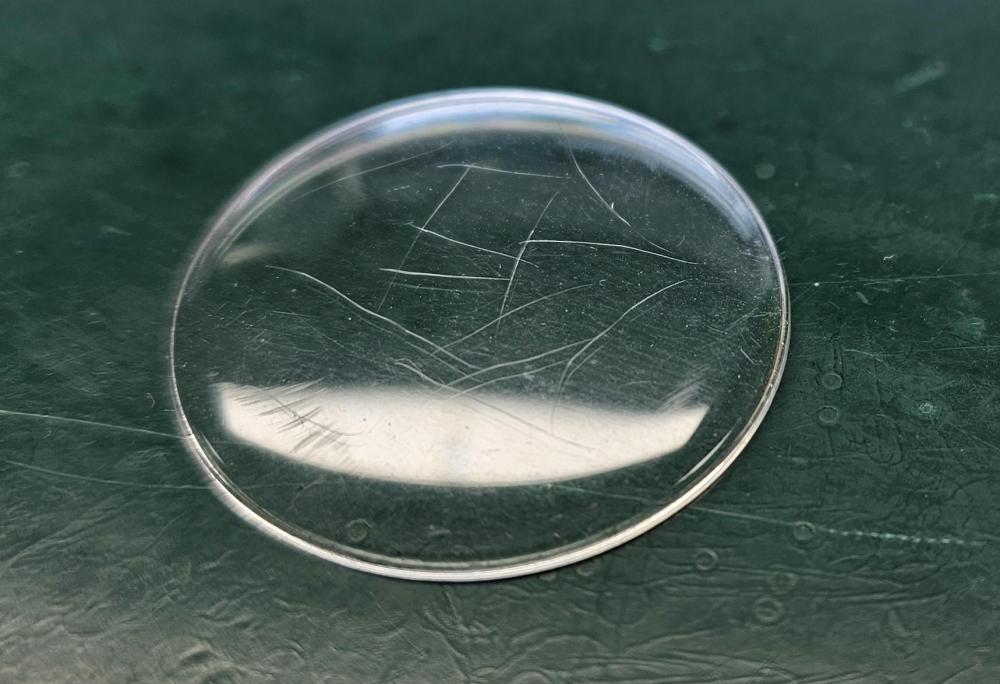

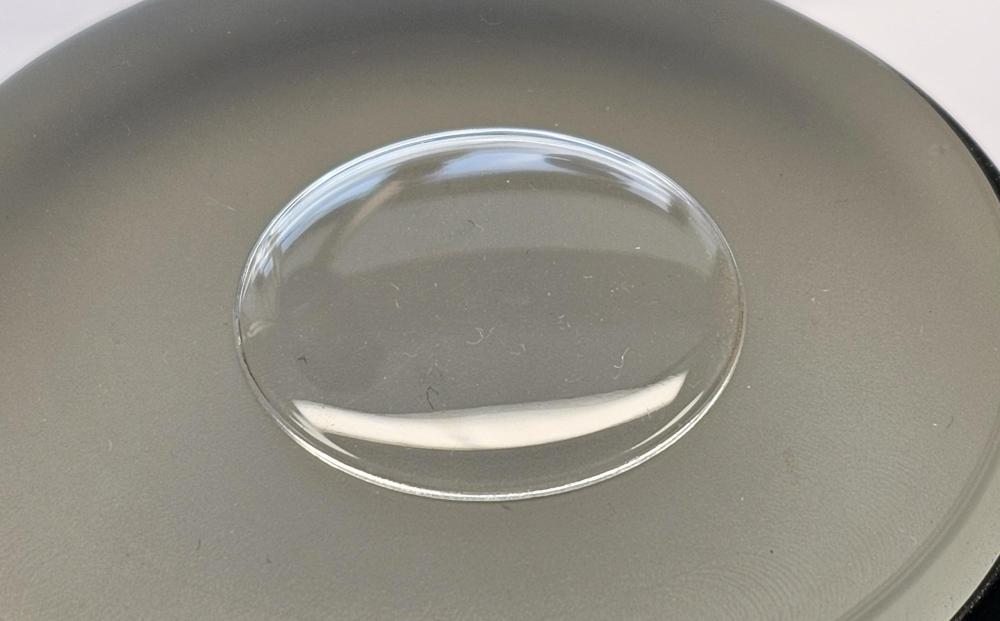

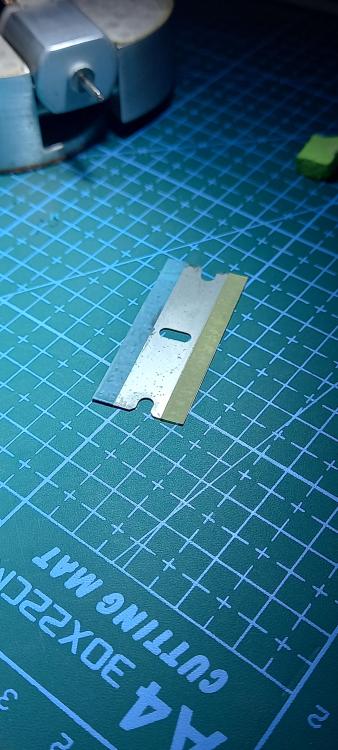

OK guys, This is a bold statement, but I think you all need to throw away your Polywatch! I've just scratched up an acrylic crystal with a blade, then gave it a good going over with 1200 grit wet and dry and finished it off with the Autosol acrylic polish by hand with a microfibre cloth. @RichardHarris123and @Neverenoughwatcheswere spot on suggesting using this stuff. The results are damn good as you can see from the before and after photos. Just in case some might think I put it on a watch cushion to make it look better8 points

-

One I just finished today, L. Audemars pocket minute repeater with chronograph. The case is in great shape, so I'm laying the destruction at the hands of the last watchmaker. I think they clamped it tightly in a movement holder and squeezed the hammers, but still kind of a mystery. Maybe the bare movement hit the floor? The damage: New arbors both hammers (both pivots gone on both- the plate pivots are like 0.60mm) New lift pin one hammer New bridge jewels both hammers New weight repeater escapement fork New banking pin for repeater escapement eccentric Repivot 4th wheel (3.70mm long) New staff I managed to get jewels in the original rub-in settings, so overall I doubt anyone down the line (except you guys) will ever know. Beautifully made watch.8 points

-

Just had in a very nice thin Patek pocketwatch. Came in for a staff; found out it had a random staff installed along with a random roller table- it didn't even engage with the fork. And best of all, a tooth was broken off the escape wheel. It was extremely lucky that I had an escape wheel in my stock that was the correct diameter, also found a roller table that was able to be modifed and work very well with the fork, and made a new staff. Darn thing runs great now- around 270 flat, 30 degree drop in verts. At least the former watchmaker did no permanent modifications.8 points

-

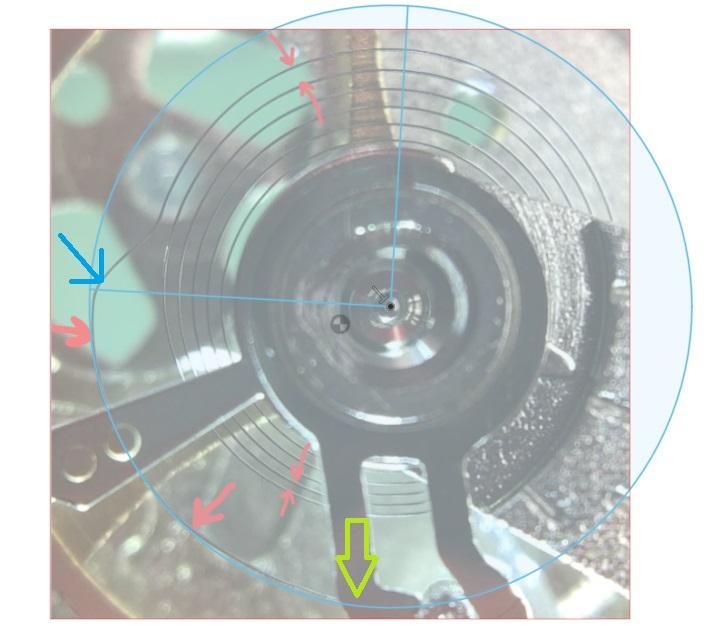

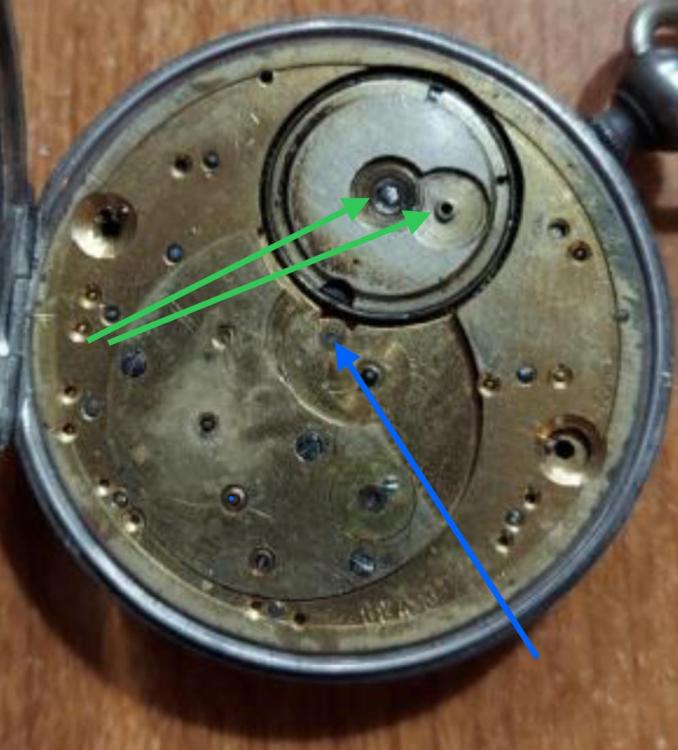

MIke's on the right track. For errors in the round, you make the correction at 90 degrees to the maximum error. You can see the regulator curve is pretty "on", but I would still push a little at the stud where the green arrow is. This will bring the hairspring a bit closer to center, but will also worsen the fact that the regulator curve is already favoring the inside of its perfect radius on the other side of the regulator pins. You could reform it, but you would reintroduce the out of round condition. For me the quickest and best fix would be to twist at the blue arrow, which happens to be at one of the bends that transition from regulator curve to hairspring body, and happens to be at 90 degrees to the max error.8 points

-

WRT feels like a second home to me, and I’m sure I’m not the only one. That’s why we care so much about making sure it’s seen as something bigger than just Mark and us users. Companies don’t rely on one person, no matter how great they are, because life happens. You know — don’t put all your eggs in one basket. When I started my own business, I lost a lot of gigs because clients worried what would happen if I got sick. Teaming up with a competitor to cover for each other made a huge difference. Right now, WRT is the company, and Mark is our brilliant, irreplaceable consultant. It would feel a lot safer if there was someone who could step in if needed. That’s my only little wish. Otherwise? Nothing but love for WRT and everyone here.7 points

-

7 points

-

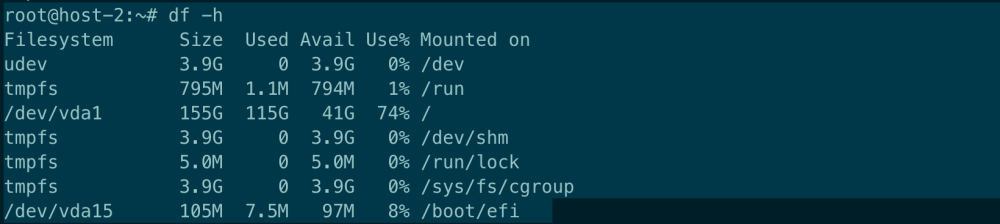

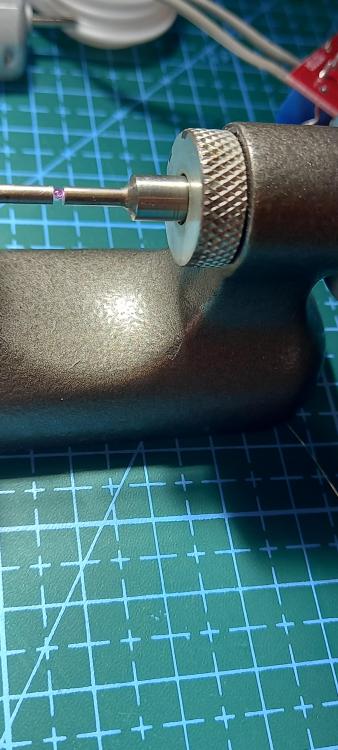

I want to show others how you can modify the inner diameter of a hole jewel. For this movement, I have a high grade Waltham that has it's pallet fork jewel broken. Sure, I could order a new jewel, but I have a large assortment on hand. To start, you'll need to remove the old jewel, if yours is broken. Find a jewel that is the required thickness and OD, and one that has an ID that is smaller than the pivot it will match with. Now there is a few ways to modify the jewel. You can place it in a jewel chuck, or you can mount it in it's plate, and then center the hole on the lathe. I for some reason have never purchased jewel chucks, so I have it mounted in its cock, and that is mounted in a face plate. For widening the hole, you also have a few options there. You can use a piece of thin wire that is charged with diamond paste, or you can turn a piece of hardened steel to fit the pivot. I have done it both ways, and I haven't had much luck with the wire method that Daniels demonstrates. When making the steel burnisher, turn it on a slight taper. The end of the rod should protrude just past the back of the jewel. Then, with the rod mounted in you tailstock, add some diamond paste to it. I purchase diamond powder of varying micro size, and then mix it with a bit of oil to make the paste. With the headstock turning roughly 1-200 rpms, advance the diamond charged steel rod into the jewels hole. Retract it every second or so to keep it even. Little pressure is needed, but the paste will work its way off the steel rod, so it needs to be reapplied often. I like to rotate the tailstock spindle while I do this as well, advancing and retracting the spindle to continue cutting the jewel. This isn't a fast process, but should only take you 5 minutes or so. You'll notice in the beginning, that it seems like the steel rod is advancing quick quickly, but this is due to it also being polished and shaped by the diamond paste. It will eventually confirm itself to the jewel hole shape, and it will be less noticeable that it's diameter is being reduced. You may be thinking, isn't the steel much softer than the sapphire jewel? Won't the steel be the only thing that's being removed? And you'd be right to a point. But the steel becomes charged with the diamond paste, embedding it into the surface. After you reach the point of the steel rod conforming to the jewels hole, little diamond paste is added from then on. Below are some pictures of how I have it set up. Here is the setup with wire. I don't really like this method. And here is the setup with a hardened steel rod7 points

-

If you dont mind me tagging something onto this thread of modifying jewels Cole. I had a little play at changing the outside diameter of one, no lathe required. I used a very small dc motor, the type that were used in Scalextric cars. I turned the very end of the 2mm spindle down to 0.8mm, then shellaced a 1.2 mm jewel and centred it while heating and running. Using the spindle directly minimises any run-out, that can also be futher improved by shortening the spindle, but for the 8mm sticking out, I couldn't see any at x40. Once mounted I used a 2000 diamond file on the side of the jewel , which quickly ground down the size. In the pictures you can see the outside edge is a little rough and chipped from the file. The jewel did polish up much better with some diamond dental strips. But as I was finishing up, I got a bit heavy handed.... the shellac gave way and the jewel flew . You'll have to take my word for the finish, though it did need some diamond paste ( on its way from AliExpress) to complete the job. The initial diameter reduction was rapid, at the last measure before it disappeared the OD was 1.13mm, which took less than 2 minutes. Now I just need to check in a mirror, I seem to have something in my eye7 points

-

7 points

-

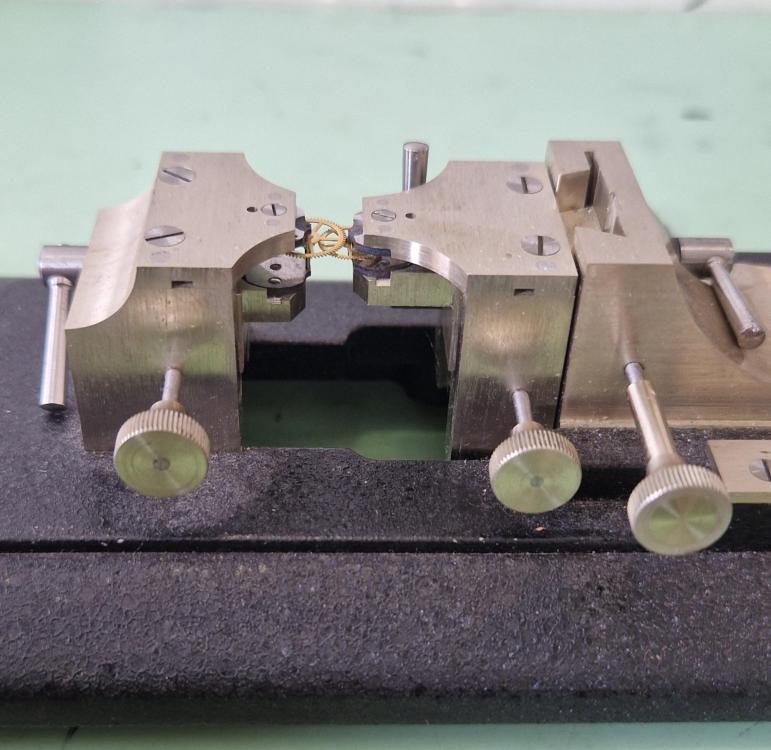

I really like this old tool. They are still made (Horia makes one), but this one has seen some serious use and still works great. It's a filing block; the center portion can be adjusted in height with the knob at the bottom, and the rim is glass hard. It lets you file small parts very flat and parallel quickly. The frame goes in a vise and allows it to pivot to further help keep the file flat. I don't use it often, and when I do I never use the frame, I just hold it in my hand.7 points

-

I think for the age of the watch and considering what it looked like previously I'd just leave it as is.7 points

-

7 points

-

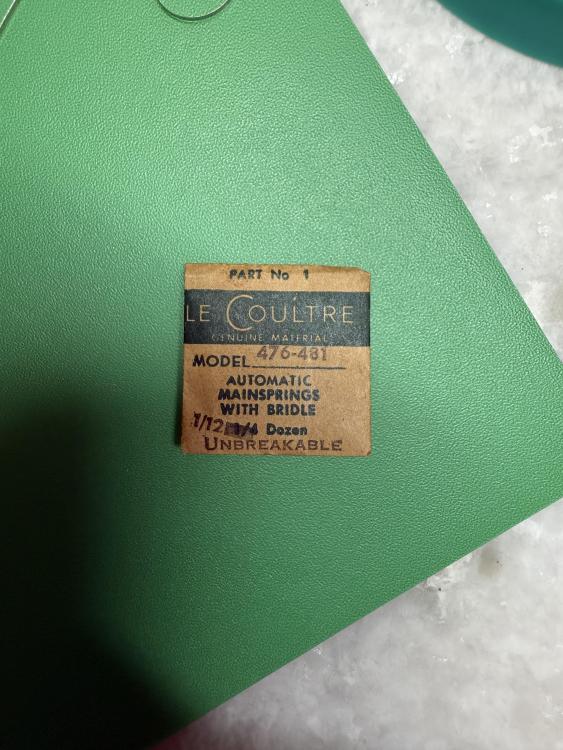

An update on my JL Powermatic- I found an original mainspring for this caliber- the one with the circular end…and decided to replace the GR spring I installed… …here’s the GR mainspring I installed then removed… …I don’t see anything wrong with the GR but on disassembly there was significant power remaining after it stopped naturally and I tried to remove any residual power via the (two) clicks. The power wound down quite a bit more after I pulled the pallet fork, like perhaps the 10 hours of reserve the indicator was showing. Perhaps it was a poor job of lubricating the barrel or some error with the clutch mechanism I did not detect during a careful disassembly… …now I’ve reassembled with the new original spring and the indicator easily synced with the spring power in the way nevenbekriev describes- full wind brought the indicator in sync then it read zero at stop. Thanks! …so unfortunately I cannot conclude for certain if it was an issue with the length of the replacement spring or a bodge of the first assembly… …Here it is with the restored dial and hands relumed…7 points

-

The movement looks like a lepine movement in the Locle style, with a tangential lever escapement, with decorative engraving. Without engraving, the movement would have looked something like this : The blue arrow points to the click, which appears to be missing from your movement. Without a click, it will be impossible for the mainspring to retain any power when wound. The “Echappment A Ancre” means the watch has a lever escapement. There is some damage and missing parts on the dial side. The blue arrow below indicates where the cannon pinion, centre wheel arbour and the pin that runs through them has snapped off. The green arrows indicate where the Maltese cross style stop works should be. Best Regards, Mark6 points

-

Here's another old tool that doesn't get used much, but has saved me many hours and headaches when it has been. This is a depthing tool, but quite special. The depth can be set (or measured) very precisely with the micrometer to the right, with a direct reading of the actual center distance between the wheel and pinion. It originally came with a set of the little plates in the slots to the right that take the pivots (first pic), most of mine are missing but they can be made when needed. The section that takes the right hand wheel can be adjusted in height. And it can be set on a profile projector if needed to check things. This one is marked Tripet, but most I have seen are marked Hauser. All of them were made by a small company in La Chaux de Fonds (can't think of the name now).6 points

-

As a retired dentist, I've drilled into a lot of stuff, including elastomeric substances. I had drills that turn as fast as 400,000 rpm and as slow as 1 rpm. Rubbers don't drill very well. They tend to distort under pressure and the hole will end up... not very nice. Watch this video first. Rubber is better cut with a blade than drilled with a twist drill or abrasive like a diamond drill. In the above video, a brass rod was used but your case, I think a large bore stainless steel hypodermic needle would work better. Maybe a 1.5mm needle. Cut off the sharp tip and file the inside surface of the tube until a sharp, cutting edge is obtained. Then mount the needle in pin vise and bore the rubber by hand, constantly checking that the bore hasn't drifted. You might need several straps as guinea pigs before succeeding. Hope this helps. And please treat everyone with respect and dignity. Shalom.6 points

-

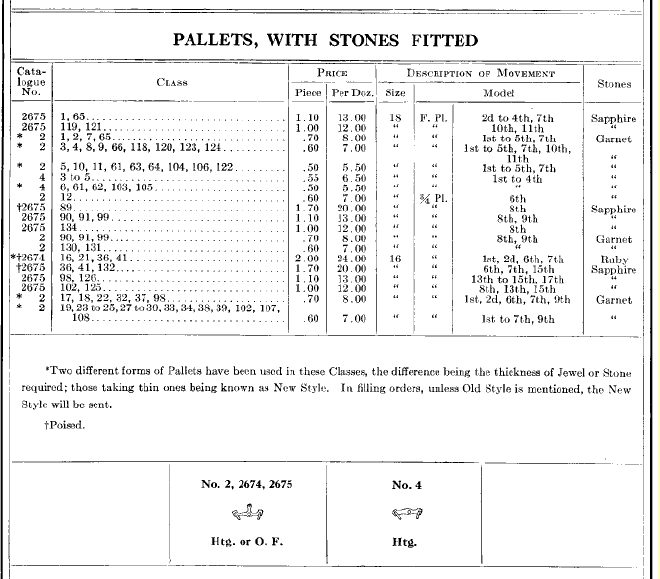

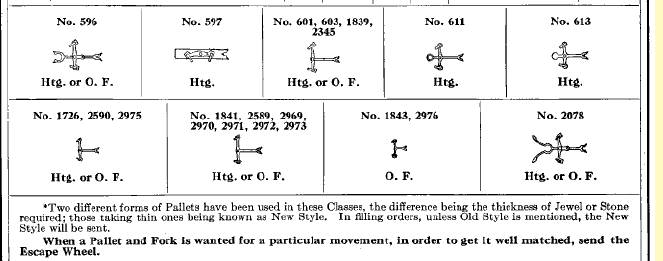

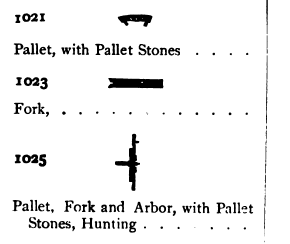

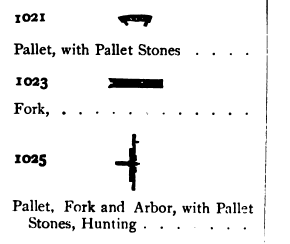

It's hard to help out when you get such a general description like this. Which is why I always ask for photographs model number is oh look we did get a number much much farther down. One of the problems with early American pocket watches will be lots of parts variations. Your pallet fork is a number four which on the parts list has an X indicating that it has variations. Then the parts book really sucks because it doesn't show the entire pallet fork and yes other than the modifications with file that does look like the right pallet fork. Oh and of minor confusion on the part book notice the reference to class? Sometime in the mid-20s Elgin change their entire parts system before this they used a class system. So in other words a 335 is equal to a class of 105. The pallet fork section actually covers several pages with lots and lots of drawings a pallet Forex. On the second page of the section we see another one of those forks were we can see a better example of the entire thing. Interesting description for a pallet fork the kindergarten design well I learn something new every day. Plus it could be worse like let's look what Waltham did with their kindergarten design pallet fork Yes this is one of the 18 size Waltham pocket watches notice how you get the pallet with stones and you get the separate fork? But for quantity a pallet forks there are two of them? That's because the open face in the hunting have the gears arranged in a different fashion and the pallet stones have to be on the right side. So even if you find a donor watch to steal a pallet fork from you may have to disassemble and reassemble it so the stones are in the right direction. Then I can't remember which company uses two screws to hold the assembly together and that allows you to adjust the depth of the pallet fork. If that wasn't enough things for somebody to screw around with like banking pins you can have more things to screw around with.6 points

-

6 points

-

6 points

-

6 points

-

Never throw away anything with good jewels. Odd wheels? You can practice pivot burnishing in the future.6 points

-

Never ask anyone into watchmaking what to keep! As Andy points out we probably all have an aversion to getting rid of potentially “useful “ things natural born hoarders and tool collectors, every single one of us Tom6 points

-

This is how the hairspring looks now after I manipulated it according to @nickelsilver's instructions. It once again looks just like it did before the accident. A huge thank you to all of you, but a special and heartfelt thanks to nickelsilver for the illustration and the accompanying pedagogical explanation, which—just like always—is world-class! The first thing I attempted was to adjust the slight indentation in the terminal curve just below the curb pins. I probably didn’t succeed completely, but I also didn’t want to tamper with it unnecessarily, as every adjustment carries a certain risk. Here are the tools I used. I held the spring in place with the tweezers right at the bend (at the blue arrow in nickelsilver's illustration) and then gently stroked the part of the spring that lies between the terminal curve and the main body of the hairspring, using the oiler, repeatedly in the direction of the arrow. I did this in stages, checking the shape of the spring after each step. I took my time and continuously monitored my breathing, and kept my shoulders relaxed. After eight years of working on watches, I know that when things go wrong, it’s usually because you feel stressed and tense. I also had to manipulate the hairspring slightly at the stud in the direction of the green arrow (in nickelsilver's illustration), as the spring was making slight contact with the curb pin. However, I made this adjustment as close to the stud as possible. Fortunately, things were not as bad as I initially feared. In my first post, I mentioned that the balance cock jumped at least ten centimeters into the air. In reality, it was probably no more than two or three centimeters—but it felt like a meter. And like my heart stopped. What likely saved the situation was that the only part mounted on the main plate at the time was the balance cock—no other components. In other words, there were no other parts for the balance wheel to get caught on. Before I begin assembling a movement, I always install the balance assembly, chatons, and cap jewels first to check the free movement of the balance wheel. It was right after doing this, when I was about to remove the balance cock, that the accident happened. I must say, I feel very encouraged and inspired after this “little” operation, so once again, a huge thank you!6 points

-

Mostly, and to maintain a constant pressure on the hole, and to keep the rod aligned Yes I use the same technique on balance pivot holes as well. This is just what is currently on the bench for this type of repair. The smallest I've done is 0.09, but It should scale down, although I haven't done a 0.07 hole yet. I have some sapphire rod, maybe ill cut a slice off and see how small of a hole I can make someday. I would someday like to start a YouTube series on lathe work, from basic gravers, to making your own jewels and threading attachments. But I'm swamped, have roughly 35 watches in the backlog.6 points

-

On an automatic watch, I always time it at totally full-wind and not wait up to an hour, which I would if it is a manually wound movement, because the movement is going to spend most of its time when worn with the maximum amount of torque in the mainspring, thus being at its fullest wind. If it is a watch movement such as a Rolex 3135, the isochronism that has been designed into the movement makes no real difference if it is timed at full wind or an hour off that, as the rate is going to be pretty much the same even hours off a full wind. I have found, especially on vintage automatic watches, such as Omega 500 and 700 series autos, that if you fully wind the watch by hand just before the mainspring slips you may see a reading of 260 degrees, for example. Once the auto module and rotor is fitted and you give the rotor a bit of a spin on top of the full wind, so the watch movement is always at its fullest wind, you might be surprised to see a jump of 20 to 30 degrees, bringing it to 280 to 290 degrees, which in my experience is more a real world reading, as the watch is going to remain there more than being just off full wind, even by a few minutes. I'm not disputing what you are saying about leaving it 15 minutes to an hour before timing it, I'm just giving my experience of working primarily on vintage automatic watches and seeing this idiosyncrasy many times. In fact, if you fully wind an automatic watch and put it on a timegrapher at full wind and then turn the winding stem to put a bit more torque on the mainspring, you will probably see the same phenomena of the increase of amplitude as I have described. I have an Omega 751 on my bench at the moment which this is happening to. Full wind gives me 250 amplitude. Full wind with the rotor on and turned gives me 270 degrees6 points

-

Note the 8992 is 850 pounds for a liter. I think this is really for industrial settings like they say, where it would be used as a final bath in a 20,000 buck cleaning machine. I use the 8981. That is excellent- I don't often get to see a serviced watch 5 years later, but when I do I expect to see pretty much the same oiling on the balance jewels as when it went out. I think at that area, being essentially sealed, it really should remain fairly pristine for likely 10 years. It's why some makers go to the trouble to use cap jewels on the escape wheel as well- not so much for friction reduction, but to keep the oil longer where it really counts.5 points

-

This is indeed a unique site and members including myself genuinely care about it. All we want is the site to continue.5 points

-

So this was something I bought a few years ago. I've always been interested in how hairsprings work, and pretty good at the manipulation of them from day one, mostly because I have rock steady hands and very good dexterity. Watching guys hands on the UTube flutter around when working on hairsprings.... makes me wonder whats going on ? I may be just very lucky in that respect. This isn't the better, more expensive Luthy, but it works lovely. I have only used it once to check a hairspring's frequency, something unnecessary, as a timing machine can do just that, but it was accurate compared against. I guess these things were a timesaver, after pinning a new hairspring to a collet, something I might never do, but probably will5 points

-

I suggest if you don't like a simple response from someone trying to offer help then you go elsewhere.5 points

-

Here’s a tip for those of you who occasionally use a smoothing broach—for example, to smooth out the bearing for the barrel arbor in the barrel bridge. Mount the smoothing broach in a pin vise. It greatly increases efficiency, ease of use, and control. I was genuinely surprised by how much of a difference it made. So much so that I felt I had to share it.5 points

-

Not sacrilegious at all. Repurposing redundant objects I always consider a good thing , somthing that may well have been put in the tip has another useful life. May I suggest maintaining the horological theme use it for displaying your watch collection . Somewhat fitting for the old clock case.5 points

-

5 points

-

Some might find this idea useful. My son owns a bar, which is handy. If you have lots of different cork sizes like me ( I don't drink ) you can usually find one thats a good tight fit inside the case. If not , find one that's close undersize and bang a wedge down the middle of the cork to expand it, like wedging a handle for something. I also use corks for sittings domed acrylics on when polishing them. Stick a sponge on the cork end and squeeze the crystal over it. Like so.5 points

-

It's quite a lot of work to get it back to brass and replate with nickel. The finish you get on the nickel will be the brass finish you achieve - nickel does not fill any defects. So you need a polished finish with no defects. I plate with copper before nickel as it can be plated thick enough to fill pits and defects. But then I have to polish again before the nickel. You can do home plating quite cheaply, there are plenty of Youtube videos showing DIY nickel plating.5 points

-

So this is where I’m up to. Just using saliva and a piece of paper towel wrapped around a small plastic stick. It’s still not a thing of great beauty but better than it was! I’ll go over it again but it almost feels like all the staining is in the top layer of lacquer, so it might be interesting to try and remove that without destroying what’s underneath. Somehow .5 points

-

Some of those felt wheels are quite hard and take a bit of use before they wear and the Dialux covers all the surface. I use them with Dialux Green for scratches on stainless steel. For final polishing on all surfaces, I use the mini chamois wheels. They are excellent, robust, you can get them in to tight corners, and they will give a mirror finish.5 points

-

5 points

-

Keep everything !!! It's all usable. Reassemble it and zip lock it whole. A plate, a bridge or a cock might hold a jewel that you will want one day.5 points

-

I'd say just keep everything but I'm probably classed as a hoarder. If you come to work on either of these movements again the parts could come in handy.5 points

-

5 points

-

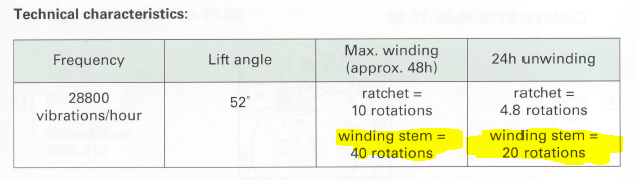

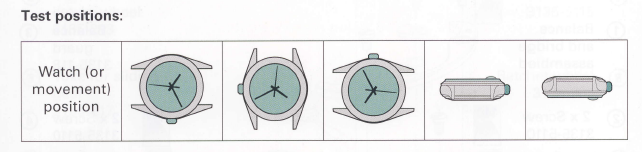

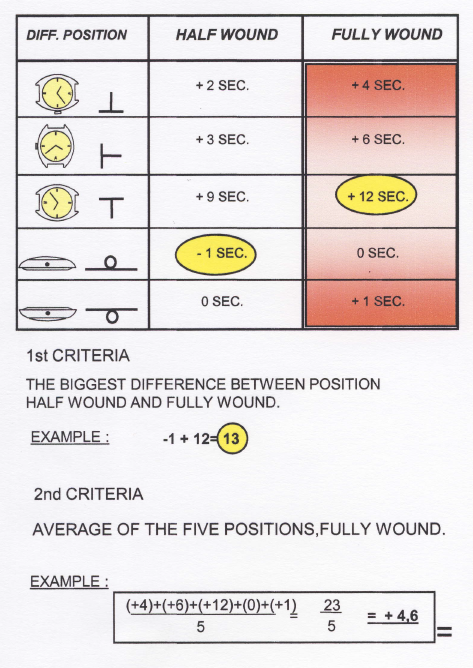

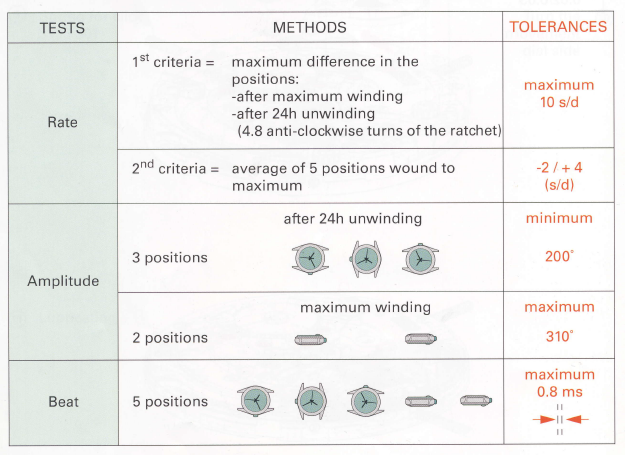

the answer for the question is no it will not help you. Adjusting the balance screw for regulation only works if you actually have a regulation problem. Attempting to regulate a watch for a problem that is not a regulation problem is not going to be helpful at all and will actually make things worse. not understanding how your Rolex works is going to lead to problems and confusions. let's look an example of a confusion and problem that you're having of lacking of understanding of what exactly are trying to do. Rolex has a procedure if you would like to evaluate your watch on the timing machine. notice in order to wind your watch all the way up to its maximum requires 40 turns complete turns of the crown. In order to reach the 50% minimum required for running of your watch it requires 20 turns. so basically you're not winding your watch up to get it to run at all and that's leading to confusions. you didn't say how fast the watch was two days later? In order to do a proper timing procedure you have to follow a procedure putting the watch on the timing machine and getting a result instantaneously is not a procedure. A timing machine shows what the watches doing at exact instant it's on the machine in that exact position wearing a watch means the watches moving around in a variety of positions which is why Rolex has a procedure. So in its procedure you're supposed to look at the watch on the timing machine in five positions then the procedure is to wind the watch all the way to the maximum. Do not place in the timing machine yet as the watch needs to run a little bit the settle down when it's wound to the maximum the numbers will not be quite right. So typically would wait anywhere from 15 minutes to about an hour. So basically 15 minutes would work well. then as you're rotating the watch around in the various tests positions you should allow about 20 to 30 seconds between rotating positions for the watch to stabilize and then let it sit on the timing machine for about 30 seconds to get your numbers. Down below is an example of the procedure. then the actual specifications for the 3135 is this5 points

-

5 points

-

5 points

.thumb.jpg.9385550d228113fa7b67d93c68b52d12.jpg)

.thumb.jpg.a6131757362d38af302ef12fe9e0e3f2.jpg)