Leaderboard

Popular Content

Showing content with the highest reputation on 05/17/19 in all areas

-

I just completed my first project - (nearly, as described below) full service of this Elgin Sportsman. I polished the crystal and cleaned a whole bunch of gunk out. It's mostly complete - I have a new main spring for it that justbarribed with the strap (I was waiting to pay shipping once). I've given it to my wife and she chose the strap herself. Sent from my SM-G960U1 using Tapatalk3 points

-

Perfect fitting ...and i just can say it is a superb watch ! What say you? Послато са SM-J600FN уз помоћ Тапатока2 points

-

About 20 years ago I came across my dad's old straight razor, a Sheffield made Taylor's Eye Witness. It was just the blade and dad had relegated it to cutting quill pens for calligraphy. He once told me that he considered one of his greatest achievements to be successfully shaving with it on a moving steam train just after WW2 without any blood loss. Anyway, I made new scales for it, honed it up and gave it a go, and was mightily impressed. I have since managed to accumulate around 30 of the things along with a couple of vintage strops, and they are regularly used as part of my daily ablutions. However, for speed on workday mornings I use a DE razor. I have 2 of them, a 1950's Gillette Aristocrat, and a 1920's Gillette #77 set open comb (the only 2 piece Gillette ever made), and they get used in equal measure. Using Wilkinson Sword blades they are about the best shave I've ever had after the straight. As for saving money, my entire shaving inventory has been sourced from car boot sales for a total cost of about £40, and that includes 25 unopened packs of NOS Wilkinson Sword blades. Vintage Gillettes are now very collectible. I have managed to pick up a good half dozen at car boot sales over the last couple of years, never pay more than about £2, clean them up and straight on ebay. The one piece TTO's and adjustables always fetch good money, and mint boxed Aristocrats reliably get well over £100.2 points

-

I have a crystal lift like that, made by Vigor. It works, but seems a bit sketchy at how it grabs the edges of soft plastic with sharp metal. I'm sure that it puts scratches around the crystal even if you can't see them without magnification. Plus, it's always a pucker-factor 15 to get the crystal's diameter decreased enough to get it inserted. But since I don't have the proper Longines wrenches for monocoque cases, it's all I can use.2 points

-

I disagree with the premise.It has one use.so it is not useless..It would more correctly be called the least useful watch tool.2 points

-

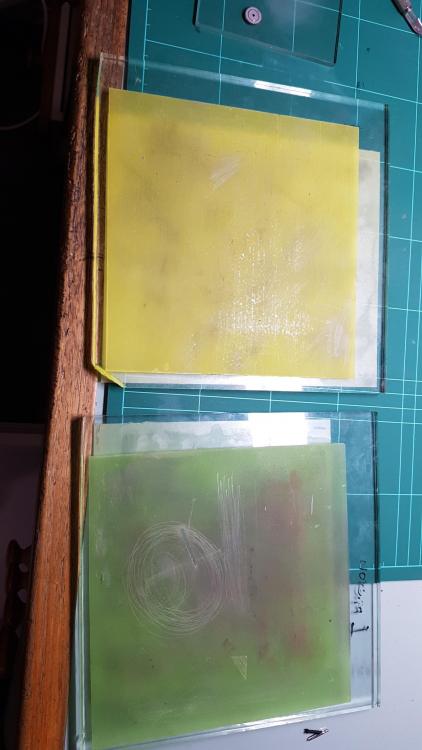

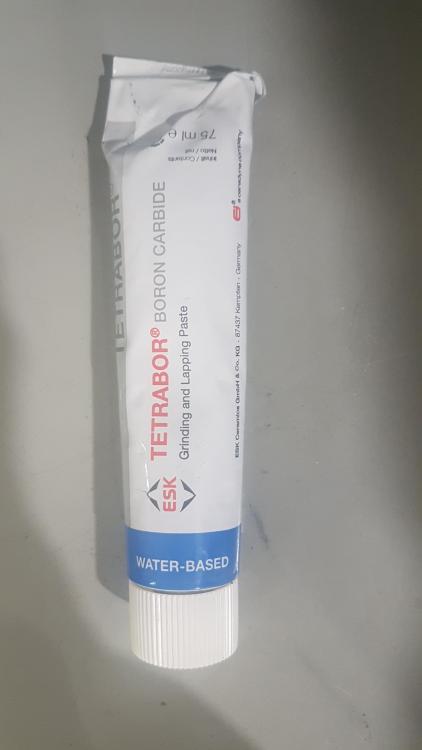

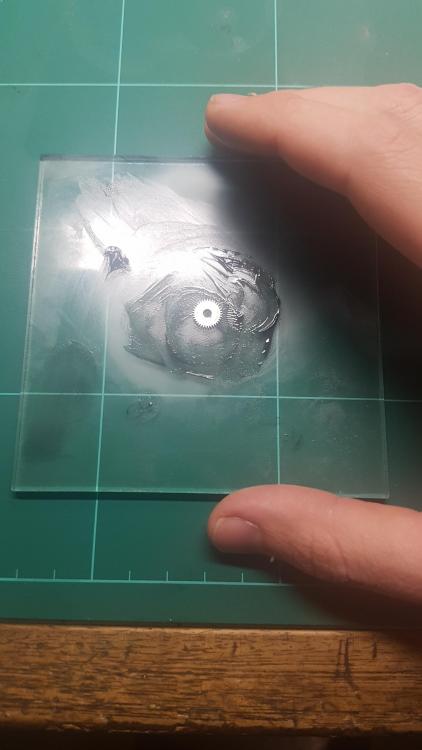

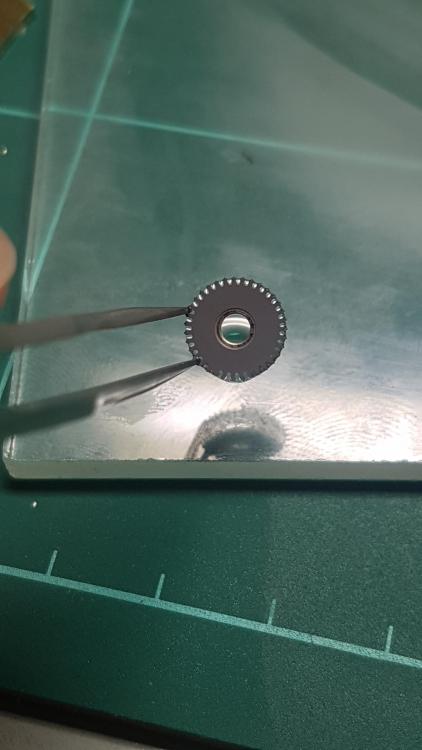

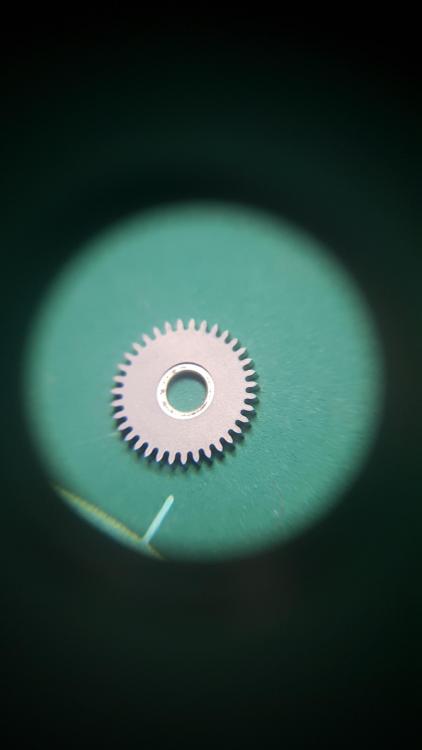

Hello All, This is my first post so I thought I would show a little finishing technique I learnt a while back. It basically turns the ratchet or crown wheel into a matte/ frosted finish. It was popular back in the day with some high end companies and still looks good in my opinion. I'll run through how it's done and try answer your questions as best as possible. What you need: 1. glass plate 2. Micron paper in various grits. 20 and 12 will do. 3. Tetrabor 800 grit/ mesh 4. Ultrasonic or cleaning machine 5. rodico First thing first, you have to flatten your ratchet wheel. To do this I use some lapping paper on glass. I start on a 20 micron and rub the ratchet wheel with my finger in a figure 8 pattern or circular or however I feel. (we arent trying to achieve black polishing flatness) If you are worried you can set up a jig to hold the ratchet wheel. but I often find using your finger will suffice. Once happy, move onto a 12 or 9 micron and do the same. At this point it is imperative to clean the wheel so that you remove all the grit from the paper that may be stuck between the teeth. So chuck it in an ultrasonic or your cleaning machine. Next place some tetrabor onto your plate, no need to add oil or water. place wheel onto plate and start rubbing it in. Generally it doesn't take to long no longer than a min or so. Doesn't hurt to check the piece to see how the finish is developing. if you want to check you can dab it with rodico, very carefully to remove the tetrabor. Do NOT wipe with a tissue or anything, this finish scratches so easy its crazy!! you can always chuck it through the ultrasonic (carefully) to see how the pattern is going. Its the checking and chasing that one last scratch which takes up the most time. The slightest bit of dust or dirt on the glass plate will scratch the wheel. You can always blue the wheel after, it comes out with an interesting tone when blued with this finish. This technique is fairly hard and does take some time to get good at, because it's just so easy to scratch and because of this scratches stand out against the matte surface. I'll try answer questions as best as possible. I try and post interesting stuff on Instagram regularly at least 3 to 4 times a week. obr_horology is my account on insta. its just time consuming to post (slow at typing) I plan on doing a youtube video in the coming weeks to better explain it. I learnt this from Henrick Korpela. Check him out if you haven't heard of him. He also writes in the AWCI and gives away a lot of info. Thanks O1 point

-

1 point

-

You may be on to something.... The click spring can be managed after putting the cover on and not tightening the screw. There are parts sticking out that can be pushed until the click catches onto the wheel. For the other spring, I just noted that the cover is thinned out at the edge where the spring is sitting under. Might be enough room to push the outer leg of the spring in with an oiler until it goes into the recess...? Will try when not so tired. Bad idea to end the evening with a spring flying into space .... Not the most brilliant design this one though... Sent from my iPad using Tapatalk1 point

-

Normally anyone who used to work on a certain caliber, should have bunch of scrap balances, from which a good impulse pin can be removed and reused. I don,t see that as anything unusual, The problem is proper removal and installation which requires staking set and some skill, So as long as you got a good HS and the matching wheel , the rest is what used to be routinely done at repairshops. Another wheel is not a good option. Hardly any demand for parts to such old pieces so they are cheap.Once we know the right one, I think I should send two just to be on the safe side. I guess many diferent size staffs of similare shape we made for various calibers. I got a feeling this is one of those instances you see an old piece which gives a feeling of the golden days and you feel good bringing it back to life. I enjoy seeing you see the job through for that feeling and is truely worth it. I had no idea I could get this poetic. regards1 point

-

I nominate the 3D printed mainspring winder that I printed and tried yesterday which successfully butchered a Seiko 7019A mainspring for me. At least that spring wasn't in the best fettle to begin with. Back to winding in by hand unless someone wants to donate a spring winder set?1 point

-

According to balancestaffs.com, The closest would be rego 148, correct you are153, 154, 148, 1149 linge 13.5 . I forwarded the pic you posted to this retired repairman just by the looks he says he got the staff but not the impulse pin and added looks like you can use an impulse pin, looks damaged. To get the exact right staff, we now need a friend with micrometer. I,ll dig in my bag of tricks for possible complete balance, don,t even know if spare ones were marketed. Next I,ll check your birthday date. Regards1 point

-

Check the price. If it is left handed, it will be at least three times the cost of a right handed one.1 point

-

I grabbed the crystal with the claws, then held the lift tool between my knees and gave the movement plate a playful tap with a plastic rod and the useless tool I mentioned above. Not the most subtle method, but very reliable for sending the watch in to orbit, and you do need to do that at least once a week, or you 'aint trying hard enough. Second try worked like a charm, and the movement, crystal and movement plate parted with the case quite nicely. Something makes me suspect there may be a better way of doing this.1 point

-

Is that a Left or Right Handed Hammer? Sent from my iPhone using Tapatalk Pro1 point

-

just used my crystal lift on a friends roamer(question posted earlier!) and it was a doddle both off and on.mine is a Liberty made in india,a good price and quite solid.does the job well.also use a crystal press when needed.both handy to have.B1 point

-

The dial frankly looks too good for a franken. If it is, find out which backstreet shop in Delhi did it, I may need to pay them a visit.1 point

-

I was going to nominate one of these... ... but I believe there are a few people who use them to 're-allign' Timex watches. Sacrilege to my eyes. Using it to 're-alligning' an overpriced Daniel Wellington, or maybe a dime store quartz possibly I could forgive, but not a Timex.1 point

-

I've just used both the lift tool, and the crystal press, in the process of fixing a Timex. They are a little tricky to get right, and they don't work well in every case, and I did manage to drop the movement on the floor due to my ham-fisted efforts with the lift tool. I wouldn't say it is *THE* most useless tool, but perhaps one of the most tricky to use, and not appropriate for some crystals. Popping the crystal out is often much easier with your thumbs, but obviously you can't do that with a front loader.1 point

-

You can tilt the movement out once you remove the crystal.Them stem would be in two pieces, a sort of male/female arrangement. The part attached to the crown being split.With the movement slightly tilted rotate the crown, feel for the spot where the split is perpendicular to the case, it will be obvious to you when it is as the movement will have the most tilt. It should then tilt out pretty easily.1 point

-

1 point

-

I use mine regularly, as vinn3 states on vintage watches. Just used it the other day to fit a 14.4mm crystal onto a late 1950s ladies Certina. That's the smallest crystal I've fitted and it was nearly at the limit of my tool as I just have the cheap Anchor brand one, but it has worked every time I have used it.. You also need the small base for holding the crystal for the tool to work though, this makes the claw grip the crystal just off the base of it so you can drop the crystal home whilst still compressed and then release the tension and it just expands into place.1 point

-

As far as the project is concerned noirrac1j can answer, its his baby im just providing the additive manf part. I use all Autodesk products. Fusion 360, Inventor, they also have a powerful slicing app. Ive found that a lot of the end result of a print job depends more on what happens at the beginning. Noirrac1j-i have some new filliments on the way. One is supposed to print completely smooth. As soon as they come in ill run a couple samples and send them up. Sent from my SM-G950U using Tapatalk1 point

-

What's the book? Its easy say, near impossible to do without a lot of special equipment. I believe the manufactures used special angled fixtures of their contrivance. I'm not sure there is a bigger machining challenge than getting a bi conical section mating to another to a high standard of finish and accuracy. but, imo, the starting point is whats the symptom/observation. If its just some very light scoring that might be taken out with fine stones (Arkansas or red ones, are ruby something)?1 point

-

1 point

-

1 point

-

It has no quick set that I could find. I cant figure out how to set the day. Sent from my SM-G965U using Tapatalk1 point

-

Hamish, At some point a person has to conclude that a tool functions adequately for the job or it does not. Selecting a designer label tool seems to be an easy way to select quality but unfortunately things do not always work out that way. Does a SNAP-ON wrench really tighten a bolt better than a CRAFTSMAN wrench? Does a BERGEON case opener open watch cases better than the Chinese case opener? Is a BERGEON watch winder a better tool than the Chinese made watch winder. Is a BERGEON lathe more accurate than a DERBYSHIRE or a LEVIN LATHE? As most people tend to think that a highly advertised Swiss tool with a designer brand name is a superior tool, they will never be happy with actual reality. When the issues are researched it becomes evident that the BERGEON case openers and watch winders are made in China and the DERBYSHIRE and LEVIN lathes are far more accurate than the BERGEON lathe. The BERGEON lathe is manufactured by a company called DIXIE, which is owned by a Japanese company called MORI SEKI. The next question is, Is a BERGEON lathe adequate for watch work? The answer is yes. I own one and it is a fine machine. I also own a Chinese made Sincere lathe and it is also a fine machine. The BERGEON and SINCERE machines have cone bearing spindles and have accuracies limited to that particular bearing system. That said, both machines can make parts with enough precision to be used in a watch. I also have both BERGEON and HOROTEC screwdriver sets. Either type of screwdriver is able to remove watch screws. As long as the screwdriver blades are of good quality the rest is a personal preference. david1 point

-

@noirrac1j Nice to meet you too. For the case back are you just going to use some metal plate or will it also be 3d printed. I have a spare ronda movement in my parts draw I will have to have a go at making a case for it. This thread has really got me excited about the possibilities.1 point

-

We tried on edge which would put the grain running in the preferred direction but result in more support and face up with non preferred grain and less support. These were printed on a flashforge finder which is fairly basic. Weve upgraded to a dreamer which should yield better results with more mat options. What printer are you using?? Sent from my SM-G950U using Tapatalk1 point

-

did you need to print it with supports, for the inner shoulder ? My printer is pretty basic, but your results are encouraging.1 point

-

Noirrac1j's designs pictured here were printed in PLA. The printer used was a single head with no heated chamber so the mats are limited. Grain direction is obviously a factor. Our new set up has a dual head and heated chamber so we will be using dow's new water soluable support material and we have abs polycarb and many other options including impregnated materials. The final product will look much cleaner. Sent from my SM-G950U using Tapatalk1 point

-

I could make one. Sent from my iPhone using Tapatalk Pro1 point

-

I seem to have gone auto panaramic, sorry for triple pic. Give any dimension you can access. I am highlh likely to come up with exact right staff.1 point

-

Most but not all of my all Roamers are housed in a “brevete waterproof” case which pushes through from the front with a little pressure from the thumbs, no tools required to get to the movement. I can't say that yours is the same but a clearer picture from the crown side i.e. picture 4 & 5 should allow confirmation if yours is of a similar design. Sent from my moto g(6) play using Tapatalk1 point

-

Your case looks like ones that are used by Wittnauer and Longines, among a few others. On these you have to "blow" the crystal through the case tube after removing the crown. It should be a two-piece stem that has to be pulled smartly, perhaps with a set of nipper pliers. If the case is karat gold, you should be extra careful about where the jaws are levering. But that's how I've pulled them out of Wittnauers with such case. Usually there will be an engraving on the back that says something like, "Use 1260 wrench". These squeeze the crystal to remove it, rather than having to blow the crystal with a syringe. I don't see it on yours, so maybe I'm missing something. Good luck. Looks like Watchweasol beat me to the draw. But they do say the same thing, in essence..1 point

-

Hi Bernie If it is indeed a monobloc case the stems are usually split stems and the crown and part of the stem clips out allowing the removal of the movement, and access to the second part of the stem in the watch. Some require some force but be careful and pull straight so as not to damage the stem and not too much force and damage the keyless work. one method is to use top cutters and a piece of tough thin plastic between the cutters and the button to protect if from marking1 point

-

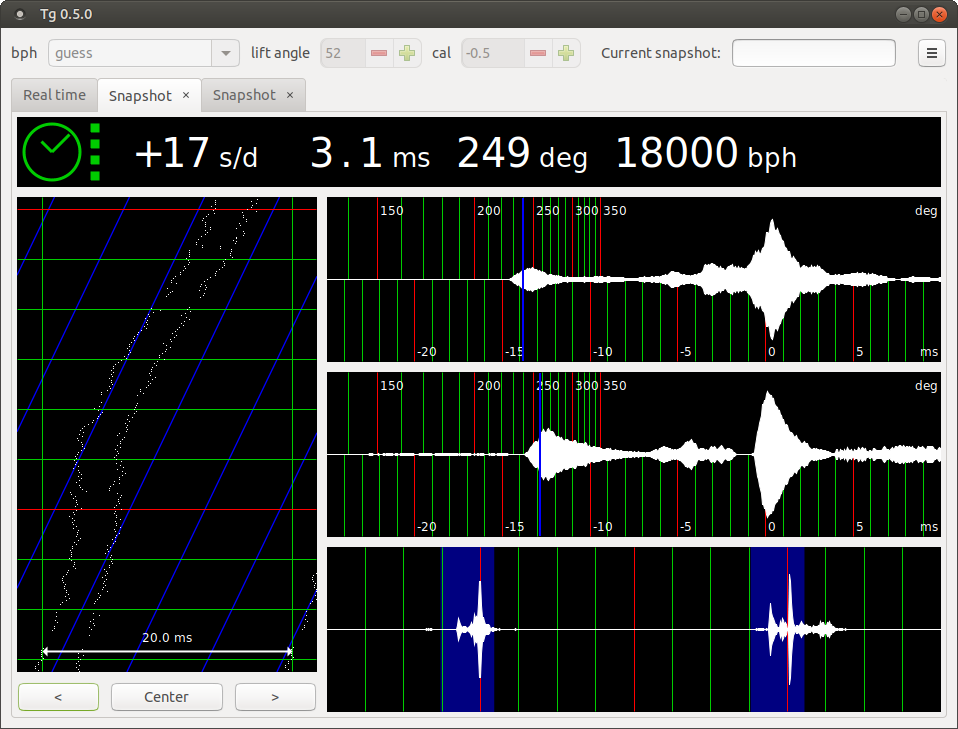

Today I have a Ruhla/UMF "Falux" branded pin lever based on a late variant of their Caliber 24 design and produced in the GRD around 1978. The movement looked familiar, and indeed is very similar to a Saxon branded Ruhla I restored at back in november. I found a couple of nearly identical versions of this dial on line, with Saxon and other logos. It runs reasonably well, but the balance objects if I try to get the beat error below about 3ms, so there is probably a little wear or eccentricity issue there. I didn't delve any deeper as I suspect it might not be possible to improve on the results owing to the somewhat rudimentary nature of the balance. It whirs away at a somewhat pedestrian 18000 bph with an almost cartoonish and very audible tick-tock, but has kept pretty reliable time over the last day or so. Edit: Given the spec of the movement, I think this particular one is well within spec. Escapement: Pin Pallet Escapement with a Safety Blade and Roller Balance Spring: Temperature Compensating Accuracy: +240 sec/ – 120 sec/day Number of Beats per Hour: 18,000 Diameter of movement: 24mm Height of movement: 6mm -2 to +4 mins per day. That is a pretty big target to hit.1 point

-

1 point

-

My father recently asked if I would service his wrist watch which he bought from the NAAFI at RAF Akrtiri in Cyprus during his national service days. The watch came to me as ticking, but the oil on the keyless works had gummed up like tar, making it almost impossible to wind without fear of doing some damage. Anyway, here are a few before and after photos. Sent from my iPhone using Tapatalk1 point

-

I picked up a couple of NOS watch bands a while back. "High quality French real leather" apparently, or if you put the embossed wording on the back (semelle croute de cuir veritable) in to Google translate.. "genuine leather crotch sole", which sounds more like something you might expect to find strapped to your wrist in Madam Sin's basement of correction in some dark corner of the Quartier Pigalle, than a quality French watch strap. Some day machine translation will improve no doubt, but I rather enjoy it the way it is. The "crotch sole" bands were in new condition, but dry as a stick, so a little leather rejuvenation was in order. I popped one on to replace the XL strap that was on this Lorus quartz, so it is a much more comfortable fit, with less excess strap flapping in the breeze.1 point

-

1 point

-

Five Goats? how could you go wrong ?You probably paid a chicken and a pig to get it.1 point

-

Crum’s. I had no idea you were practising on something like that. I do not want to burst your bubble but a basic watch makers lathe with collets would be a good investment, that’s if you intend to make parts for watches.1 point

-

Well put David. What you have stated is the advice I received when I purchased my watchmakers lathe. One tool I find really useful is a "tip over rest" which I have not seen supplied with a mini lathe. Making balance staffs I find really difficult with only a couple of successes and that is after converting existing staffs. Lathe work is a whole new skill but well worth learning.1 point

-

I was advised that the ideal is to have both. Unfortunately I just do not have enough room.In my opinion for watch repair the watchmakers lathe but for clocks the mini or bigger lathe.1 point

-

For the high precision required for making watch parts I would recommend a watchmakers lathe. If buying second hand try to ensure all is correct regarding condition. A mini lathe is indeed a very handy tool and good for the likes of model and clock making, but does not generally have the higher precision required for watches.1 point

-

My email signature at work is - "When all you have is a screwdriver handle, everything looks like a nail" Some may recognize it as a takeoff of on another saying, "When all you have is a hammer, everything looks like a nail" So, not only the wrong tool for the job, not even using the tool appropriately! I came up with this when I was bashing away with a screwdriver handle at UPS case that had a bloated battery inside. Didn't have a hammer, or even better a nice pair of the right sized pliers, or best some sheet metal tools!. None of which are usually used for a battery replacement. So, for a one off, you make do with what's available. If, however, sheet metal work was something that I was going to do regularly, I sure as heck would invest in the appropriate tools, and "cheap" or "expensive" has nothing to do with it. Sometimes brands can be a guide, but I don't find that to be very true any more. Country of origin has little to do with it. I'm only interested in the "quality" or effectiveness of a tool, and the best way that I can explain that is that a quality (hand) tool disappears, it becomes an extension of you that you don't notice. With poor tools you are always aware of the tools, there is always some little gripe that demands attention, either before it is ever used or as you are using it. For instance, I went ahead and bought a set of the screwdrivers that Geo sometimes recommends. Well, sorry Geo , but in my subjective opinion they suck. They are not any better than my old Radio Shack "precicsion" screwdriver set, not as good as my cheap Bestfit set, and even the non-ball bearing Horotec screwdrives blows them out of the water. I bought one of the Horotecs just to see if I could tell the difference. And yes, oh boy could I tell the difference. That's why I'm saving my pennies for a Horotec set. At some point you will probably find me beating on the top of the no-name screwdrivers with the handle of my sledgehammer trying to free some stuck doodad out of a rusted hole. Cheers!1 point