Leaderboard

Popular Content

Showing content with the highest reputation on 05/25/20 in all areas

-

Hello, I finally got round to finishing an overhead drive for my lathe, inspired by pictures of a Schaublin example. I've yet to fit locking handles while I decide whether to go for press fit / threaded in / sliding handles.. and the MDF base is still in the testing stage while I get used to the ergonomics and decide on a way of locating it onto the lathe bench. The short belt was just a length to hand, and the WW headstock will eventually be replaced by another heavier-duty DIY spindle. I'm not entirely unfamiliar with lathe based gear cutting but my own setup is still a work in progress. Overhead Drive for lathe Hardinge Cataract gear cutting in progress A new ratchet wheel for a ladies fusee watch4 points

-

hi guys, my obsession is early Timex watches from the 1950s, 60s and 70s with a particular focus on 1976 birth year watches, Dundee made pieces and early 50s pieces. what attracts me to Timex is how disposable they were and how they shouldn't have lasted as long as they should. there's a UK connection and a wide range of mechanical pieces produced in 1976 when the quartz crisis was at its height. unfortunately i have the money but not the time to restore many of these pieces so for now stick with m24 (no date) restorations with others being helped out by the timex community on fb and ig. (@timetrope) my current challenge is getting date wheels on m25 movements back on. theyre tricky. and getting crowns to stay in place on m21/22 movements which im hoping some new antimagnetic tweezers will help with. if your looking to sell or trade pieces then my goal is to collect them ALL and even at 200 im short quite a few3 points

-

Not on these Seiko five which are built for simplification and ease of assembly. Just press out and replace with a generic crystal. No point in wasting time chasing original parts that even if found would cost more and be identical.3 points

-

I’ve always been really impressed by the lapping machines that are used to achieve flat faces and crisp on cases. Although I don’t do enough case refinishing to warrant the price of a machine, I though maybe I could achieve a similar result with something home built. The impetus to try came when I bought an Omega Chronostop. The case came with a sunburst case finish that was long gone and would require precise brushing. I figured I could replicate the multi-axis adjustment by using a telescope head. Found one on eBay for $125. Then added a 3 jaw Chuck for $50. My only issue was that I needed to adapt the two together. Because the stress won’t be so high I figured I could just 3D print some adapters and it worked perfectly! The great thing about the resin printer is that the resolution allowed me to actually print the threading! Because the case is a top loader, there was no good way to hold it properly so I printed an adapter to screw on the back. All ready to go: I am really happy with the results! The case has some dings that I wish I could laser weld but alas I can’t built one of those on the cheap. Lol. My next step is to find a way to fasten everything down so I get more consistent engagement with the sander and recreate the angles consistently between checking my work. - Craig2 points

-

2 points

-

If it were a construction site I'd be fired. An 8-hour day and one successful joint to show for it. I had to tweak the jig and lots of trial and error before I got my tools to behave. Having that behind me, the rest of the drawers will take far less time. So my 14 drawers will be box jointed just like this.2 points

-

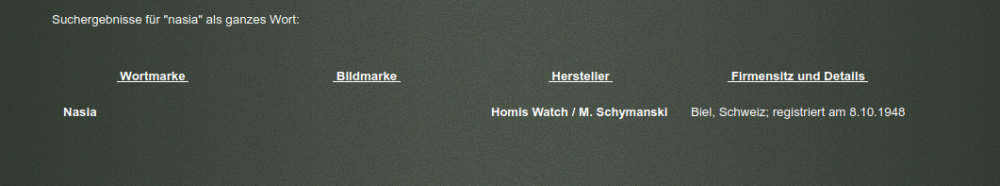

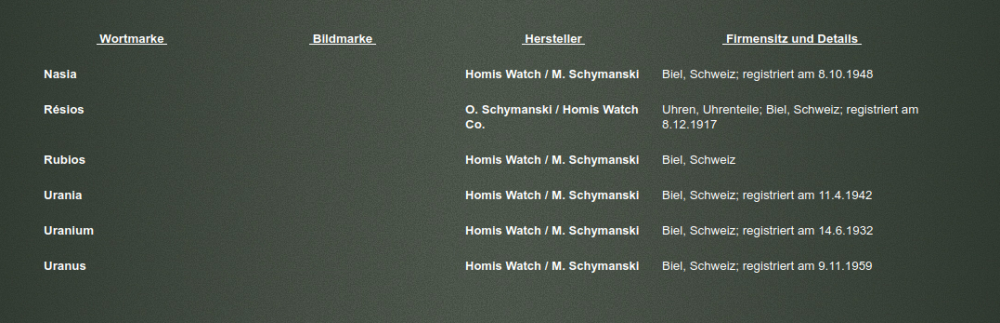

Monetary value may be low, but there is a bit of history associated with all of these long forgotten Swiss manufacturers. Source -> http://mikrolisk.de/show.php?site=280#sucheMarker https://en.wikipedia.org/wiki/Biel/Bienne -> https://www.europastar.com/time-business/1004089256-jewish-roots-of-swiss-watchmaking.html2 points

-

Some might have noticed I started a thread first about buying, then about making my own. A friendly cautionary tale to those like myself who are just getting into this hobby and like the wonderful pictures of benches on Amazon and eBay. It seems that all who sell benches, sell the one I purchased. I was reluctant to note the manufacturer, but it's necessary for this post. Doesn't matter from whom you purchase, just be aware of a few things. The drawer assemblies are laid with the back facing down. Since the drawers are shorter than the compartments that hold them, they are hanging from the false front. Gravity/age/dropping causes the false fronts to stay put, as the drawers themselves drop, splitting, splintering separating the drawers from their fronts. The layout is classic (from what I've been seeing) but the quality is simply not there. ALL wood is veneer, and the backs and sides could be split by a stern talking to. Some list the manufacturer, many don't. Some have a nameplate, some don't, but Grobet is the manufacturer and it seems these were made by the hundreds, boxed, and sit on warehouse shelves. Lastly, the wood is dehydrated and shrunk to the point where the typical hardware holes no longer line up. You can certainly fix this, but as my wife said, "You're putting that $700 desk back in the box." (That included shipping). I could have made this work quite easily, but the low quality of materials didn't warrant "fixing" it. Last word: do not buy a desk unless you can put your eyes on it. Mark Twain's quote comes to mind: "Beleive nothing of what you hear, and 50% of what you see." Larry.1 point

-

Hello fellow watch lovers, I have just completed a build from part sourced from various sellers. It turned out to be the best build for me yet and I have really amazed myself and the skills I had to exercise on this timepiece. I have impressed myself with this one and it is a stunner with a salmon dial. The NATO strap is very lovely on this timepiece. I apologize for the lack of details on this beauty, Enjoy1 point

-

Hi everyone! I made log of my activities with photos of my practical exercises for WR Course level 2. It's in the PDF file attached. I had some scary moments doing this. One of them was the balance cock that slid off the movement onto the table while dangling by the hairspring. Furthermore, I discovered that end stone jewels and shock springs also like to fly, causing lengthy search parties Cheers, Mark Watch Repair Course L2 v2.pdf1 point

-

hi folks, ive been collecting vintage timex for almost 2 years now having been bitten by the affordable watch bug and liking how ephemeral these pieces were supposed to be. ive around 200 watches in the collection which i wear on rotation new pieces come in weekly including some rare items like a Southampton chronostop, Emerson Fittipaldi rally watch, Bat Man and Superman watches take a look at my collection @timetrope on instagram1 point

-

And further to Nucejoe's remark It could be the Cannon Pinion being loose. It slips at calendar change time. When changing the time is the crown really easy to move the hands? Often a sign of a loose CP.1 point

-

The Bezel might pop off the case when you remove the crystal so be aware. The Bezel might be difficult to fit back to case if the gasket is hard....a little silicone grease might help ease it in. But.....If you support the bezel the crystal will come out Crystal is 290P02LN03 or 29mm generic glass crystal and you can measure the thickness. crown gasket is DB0055B01 generic is possible 1.75mm or 2.05mm not sure case back gasket is FH2980B02 or generic flat 29.8mm x 0.5mm might be fine try cousins for spares in UK1 point

-

The scuff marks on the crystal can be easily polished, or a generic flat one be fitted. You can desume the hands hole size from the movement used and get generic baton one. Again, it seems to me that all original ones need is a bit of cleanup.1 point

-

Hi Its not an insult to horology as the module driving it is usualy quite good (miyota) which is a cheap reliable watch movement, the problem is with the designers creating round the module some gross fashion statement which the public will buy because of the the name it sports, Ie Gucchi, Kelvin Klien etc. As Andy said WHY ?.1 point

-

1 point

-

The answer "yes" given above is substantially correct but incomplete and hurried. For example, on the very popular swapping to a SKX 200m divers, one cannot reuse the original stem/crown combo, so a new one must be bought. Then, one must reuse the original movement ring, as well the day disc. But you cannot count on carrying over the date wheel, because that changes across versions. I wrote about that many times here and on WUS, it should be easy to locate my postings for those that desire to gain full understanding and do a perfect job.1 point

-

That is absolutely normal, Seiko has produce this movement over many decades and in various factories in Asia, variations in finishing and lettering are expected. The advice to replace with a brand new NH36 was also a good one, then of course anyone does as he pleases.1 point

-

1 point

-

Thanks for the replies, it belongs to a friend and I have just replaced the battery for him. It seems to me to be a bit of an insult to horology.1 point

-

1 point

-

My exact listing is gone but the parts are: - Celestron Astromaster CG-3 - CME 2”/50mm 3 jaw Chuck1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

it's unfortunate that something that can look so pretty in a picture can turn out very poor. On the other hand it's an opportunity to make something much nicer. Like for instance when I'm doing this I'm looking at my computer and the desk I made so it fit the space that I had it met my requirements because I couldn't find anything that was suitable for a computer desk for me. As much as I like my watch bench I would really like modifications like it would be nice to have drawers on both sides of the bench. The entire left-hand side is open and basically it's wasted space. when you're starting out it seems like the bench is a vast open space but it's amazing how fast it gets filled up and then you run out of space.1 point

-

Picked up the Swiss case from eBay, brand new but from the sixties I believe. Unfortunately can’t source a 10 1/2 mechanical movement so fitted a Swiss Ronda quartz movement. The dial is a genuine 1963 uncirculated half penny which I machined down to .5 mm and then silvered. I made it for my wife's birthday who was born in 1963. She absolutely loves it Just normal dial silvering compound1 point

-

I like it! It's one thing for a watchmaker to make their own tools, but their own bench too?1 point

-

A classic Seiko quartz rises from the junk pile today. This was missing its crown and stem when it arrived, but otherwise it was in excellent condition, so I decided to trawl through my large pile of random stems to see if I had something suitable, and my luck was in. I then couldn't decide whether it would look better with a silver or gold crown, but settled on the silver one. Too much bling with the gold one I thought. Looking online, all of the similar Seiko watches with silver cases have silver crowns and gold cases, gold crowns, so I think I made the correct choice. A little bit of a polish and a fresh leather strap, and it makes a very handsome addition to the 404 club.1 point

-

If the mainspring unwinds back through the stem then the click may have failed. On these earlier longines the click spring is concealed under the barrel bridge. Loose screw - most likely you loosened the bolt screw to far and it has fallen out. Remedy - remove dial to reveal bolt (aka setting lever and hold static while you reinsert the stew again).1 point

-

1 point

-

Hi Mick I have attached a service sheet for you. If its a front loader it will have a split stem (two parts) and removal requires a straight pull on the stem to separate the two halves, and remove the glass you either have to remove the bezel ring and the glass or to have to pressurise the watch case and blow out the glass, depends on the case type. I have also attached some further info hopefully usefull Omega 565.pdf 7197_Omega 565.0008 BA Case (3).pdf Omega_Omega The-monocoque-case-for-the-new-Seamaster.pdf1 point

-

Hi as stated its a dollar watch. It is what is known as a fashion watch, purely for show probably a miyota 2030/35movement. Take Andys advice and have a coffee. 20 yrs ago you could get one of these free with 4gallons of petrol (gas) in the UK,1 point

-

1 point

-

1 point

-

Not easy to find parts to those Cartier (Piaget) 212P movements. Nice job filing that part, guess it is what it comes to with these ones.1 point

-

There is a US company called Sherline. They sell quality lathes and have 8mm lathe 3 jaw chucks with an adapter. I did a review on YouTube. Sent from my iPhone using Tapatalk Pro1 point

-

Hi There are probably more answers than tools available as to what constitutes a list of tools for watch repair, but here goes. A good quality set of screwdriver,the French screw drivers are good value for money, I you want the best Then its Bergeon but you pay the price, Likewise tweezers, there are good mid range tweezers, by Idealtek and others but the best are Doumont. these I wouldn't skimp on as they are the extensions to you fingers. They come in various styles and sizes and you will no doubt be advised by others as what to buy or what they recommend by way of sizes. Next is a good loupe (eye glass) again these come in various sizes and types X5 X10 X15 all determined by the focal length. Some are binocular Visors with interchangeable lenses. A good movement holder, you can get a good Bergeon movement holder around the £20 mark. Stay away from the cheap chinese ones they are cheap for a reason. I have attached two PDf's to get you started. TZIllustratedGlossary.pdf Oils_and_Greases_June_2019.pdf1 point

-

1 point

-

Hello All, A BIG thank you for all your messages and great advice and apologies for my delayed reply but it has been a very complicated week professionaly and not much time left for the hobby (A special thank you also for the very professional advice regarding the beers, well noted and will definitely be followed ). I'm proceeding with the dial removing today and will try to put your ideas to work and will report back later today ... keep figers crossed to save the dial. A few answers: Unfortunately not, as the dial is curved at the edges and "recovers" the movement not leaving any space for such intervention Same problem, if the fluid is below the edge of the dial I'm not sure there will be enough contact with the screws ... maybe I'll proceed this way after trying another method. I will try this method first - I think the advantage is also that, if I can get to see the bottom of the feet it will also facilitate the other method of drilling "over" the crews. Indeed, its just that I'm not sure I have the right tools (and expertise) to proceed with this method and not damaging the dial ... but I believe I might have no other choice in the end Thank you very much for this ! Thank you for sharing your experience and photos! And like I said, I will definitely follow the beer's advice (whatever the outcome ) Thank you but like I said before the dial is quite curved at the edge making it impossible to get the acid to reach the screws without risking to damage the dial ... Thank you for your advice, indeed I beleive this will be the kind of last action possible if all other less invasive methods fail ... Thank you all again for the great advices, I'll post later today or tomorrow with the results !1 point

-

Even the relatively simple movements like that one are feats of precision engineering, and very attractive objects in their own right.1 point

-

Hi Nice job and well done ,like most of us you find watch parts can take off at an alarming rate and disappear, When removing and fitting such parts its as well to either use rodico to hold them in place or work inside a large clear plastic bag that way is the part/parts take off they are retained in the bag. Get a large bag and cut the bottom off so you can get a hand in eiither end and carry out the required operation, then work outside the bag for normal operations,, Might save time and your knees.1 point

-

As mentioned, brand new GR mainsprings do not usually require lubrication. You have observed my videos on YT where I apply a little grease to automatic watches to the barrel wall. As has been mentioned above, this is braking grease. The mainspring also has an extremely light (and I mean extremely light) application of 8200 along it's length also. I do not film every aspect of what I do as some tasks are a royal pain in the rear to film. This is one of those tasks. Although I do cover this in the video course. The videos on YT are usually a 30 minute give or take condensing of a job that may last hours I cannot film everything. If you look hard enough you may notice many places seemingly not lubricated - this doesnt mean those friction points were not dealt with. My YT videos are there for entertainment purposes and whilst many find them extremely useful as a learning aid, they are not comprehensive breakdowns of a full service, that would make them hours long each., my course on the other hand is a full breakdown of all steps required to effectively service a watch. I hope this clears things up1 point

-

You may have noticed a few changes - I have removed the Gallery section and the CMS pages app from the site as it costs too much to 'rent' those modules with comparatively very little use by members - it just did not make sense to keep them going. I apologise if this inconveniences or annoys anybody but I think it is better to keep the core of this website to be a discussion forum. The WRT website is costing me a lot of money per month to run and I am making a few changes to help with that - there is a little income from eBay affiliate ads but not enough to cover the cost of hosting and some help from Patrons and for this we are very grateful. The site has over 30GB in uploaded media now!!! And the notification emails generated is quite high too - I have to use a separate company to handle this so that the site doesn't get email black-listed. One of these services suddenly and without notice stopped our service a few months ago and it was a few days before anybody even noticed (password reset emails were no longer working). I did manage to find a new email provider and things have been running smoothly ever since. Getting back to the uploaded media, as mentioned it's over 30GB and this covers images in topics going back several years. I do back this up every night and I backup the site database every hour in order to protect the content should we ever have a disaster I have a Synology NAS here in the office which has a full backup on and I also keep a backup offsite on a cloud service. I have also decided to use Amazon Cloudfront to host all the uploaded media. I am in the process of migrating this content over and you may notice broken images for a very short period during the migration. But ultimately this will maintain and even improve performance of the site. Anyway, all being said, this is a fantastic community and I am fully committed to continuing with it's administration, keeping our little corner of the net alive - Just a little update to let you know what's happening -1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point

-

What do I think. The three sub dials make no sense. The top left suggests state of wind or state of charge, but its a quartz, so this makes no sense. The top right has no designations on it? What on earth is it meant to be measuring. The lower one tells you it is Sunday, every day, so at least that one is correct once per week. The chapter ring suggests a 24 hr hand should be present, but it isn't, and finally, why does it say 8,6,4 between the 3 and 5 markers? Save your money and buy yourself a coffee, assuming they are charging more than the cost of a coffee for it.0 points