Leaderboard

Popular Content

Showing content with the highest reputation on 04/01/20 in all areas

-

4 points

-

With all due respect to both gentleman above.I just clean in place, these independently driven minute wheels and save yourself a headache. Regards4 points

-

3 points

-

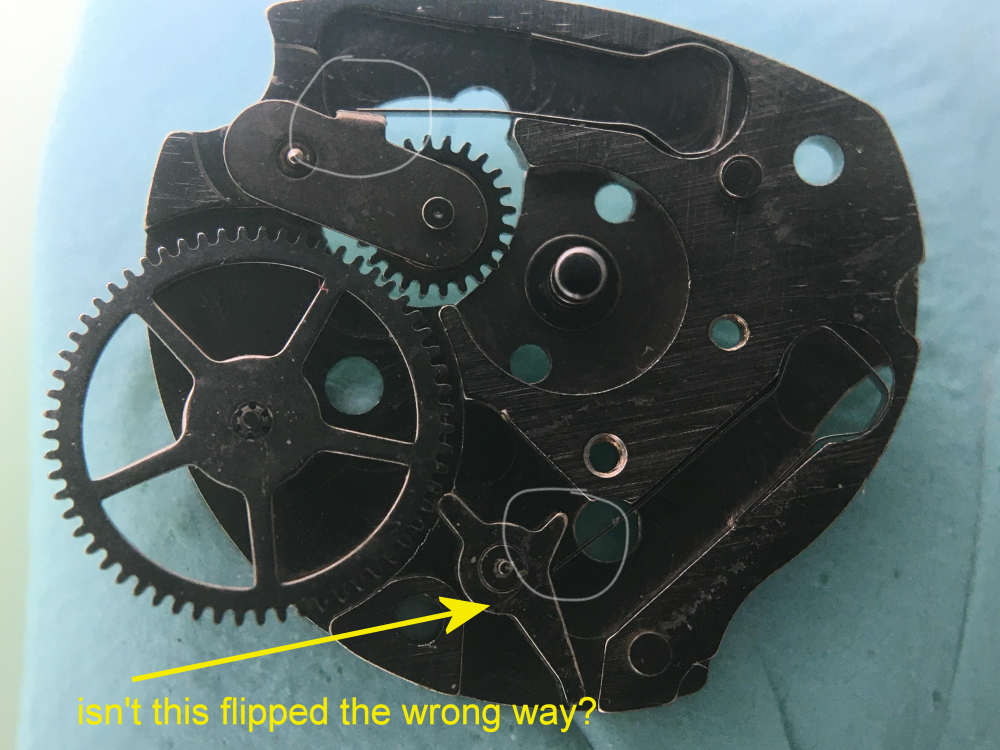

When I read your subject title I thought this was going to be something to do with social distancing!!! The wheel on the top of the plate (which drives the center seconds pinion) is a friction fit onto an extended pinion that comes through the plate, a bit like a sub second pinion goes through the main plate. There is a specific Presto style remover (mine is Bergeon 30638/3) for removing this wheel but it can be done with levers or even razor blades. The key thing is to ensure that the wheel is lifted vertically so that there is absolutely no bending force on the pinion as it is very brittle and easy to break, otherwise it should be relatively easy to remove. Reassembly is also easy, especially if you have a staking set.3 points

-

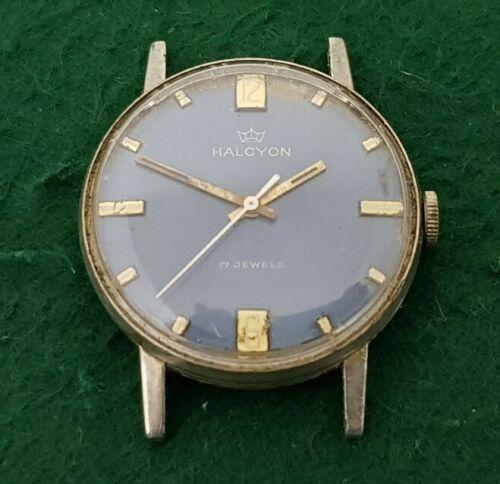

Hi FLwatchguy73, Same here. I have 2 Seagull 6497/6498 movements waiting for exercising stripdown, oiling and rebuild. I will do this while repeating course level 2. After that I will make watches out of them for more birthday presents. I also have a Swiss Unitas 6498 on hand, I am keeping it to make a B-type pilot's watch for myself. Here's the watch dial:2 points

-

2 points

-

Its a 1970s gold plated Caravelle "Set-O-Matic" automatic with quick change day today. It arrived without a crystal, and therefore the hands and dial are not perfect, but they responded well to a little TLC. I'm slowly working my way through the prospective 404 club candidates I picked up a few months back. This one came in at exactly the magic 404.2 points

-

Not only you're late to this thread, but your chastising intervention is very out of place. Leave to us (Italians) the right to tell things as truly are in our country. Including correcting others when necessary, even if that will sound "patronizing" to your mannerism. Leave to us, the ones emotionally and practically affected, to decide the tone that we take to each other. Spare us your misplaced lecturing. I will take as you are the one which missed the encouragement to be respectful, or at least silent on this grave matter. If you have an issue with that, the report button is top right of every posting. I have my meals distribution shift today a 3pm. But no matter how spent, have all a nice day, stay safe, stay united.2 points

-

2 points

-

2 points

-

2 points

-

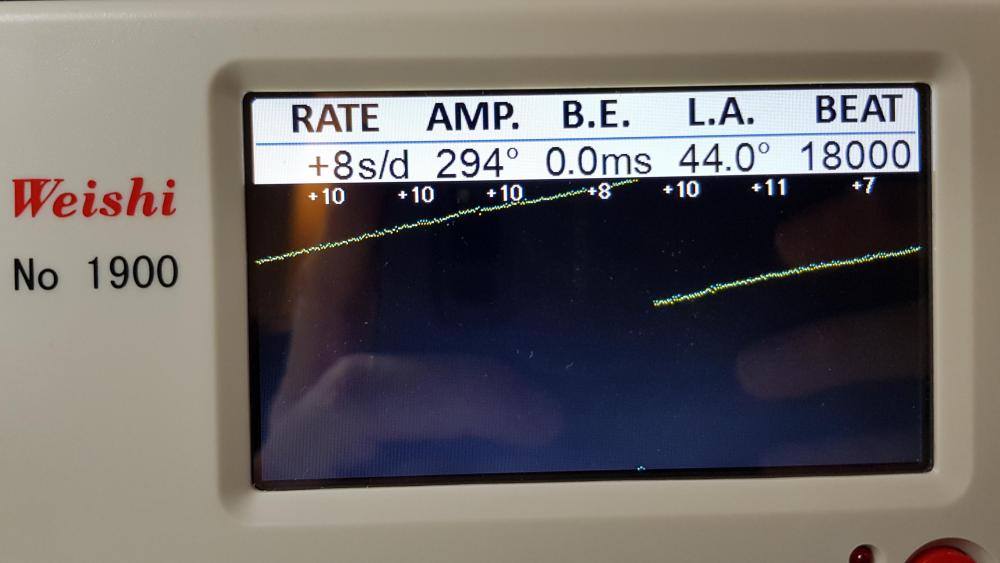

So, while I am waiting for the new case clamps to come. Let's test and adjust the timing on the Weishi. Before regulation the beat error was okay but dial-up it was running quite fast. I adjusted the watch for now to about +8sec/day. I will repeat the regulation after final assembly. Next steps: a) fix the movement using case clamps & screws; b) shorten the winding stem; c) regulate the movement (again); d) fix the wristband to the watch; e) test-run the watch for a few days to verify that its running fine! - to be continued -2 points

-

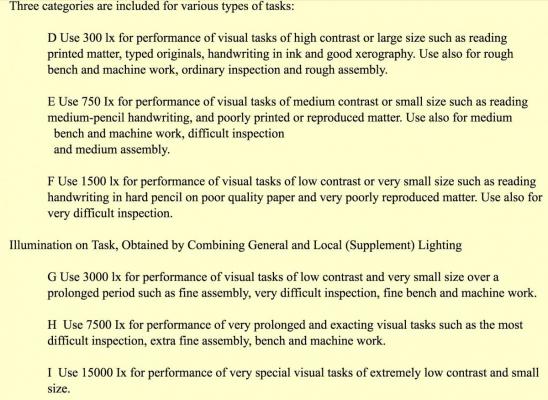

Here's some information on the output of the Cousins LED light as measured by a lux app on my IPhone. This light is fitted with two rows of LEDs that can be both individually selected and dimmed. The readings were taken with my phone 10" below the light as this is the height I have it when working on watches. I also measured the light colour temperature at the different settings. One row low setting 1,240 Lux ......... 6600K colour. Two rows low setting 3,960 Lux ......... 6000K colour. One row high setting 5,450 Lux ......... 6300k colour Two rows high setting 20,800 Lux ....... 5600K colour To give an idea of how it compares with the Cousins small portable fluorescent desktop lamp that I have currently been using. At the same distance of 10" it gave 3,170 Lux .......5600K colour At a distance of 5" it gave 30,600 Lux ....... 5600K colour although there was a bright hot spot with rapid fall off at the side. This was the the distance I have been using, and it was a nuisance as it often got in my way. This has been the best improvement I have made regarding equipment this year. Please remember that these tests are for guidance only as I have not used specialised equipment. I hope you find the information useful. Here's some information on recommended lighting.1 point

-

Hi Cecking through my workshop laptop I came across these PDFs and thought they might be useful to the members new and old alike. I have several more and will post later. Cheers Witschi Training Course.pdf TZIllustratedGlossary (1).pdf handbook_of_watch_and_clock_repairsa.pdf Test and measuring technology mechanical watches.pdf1 point

-

1 point

-

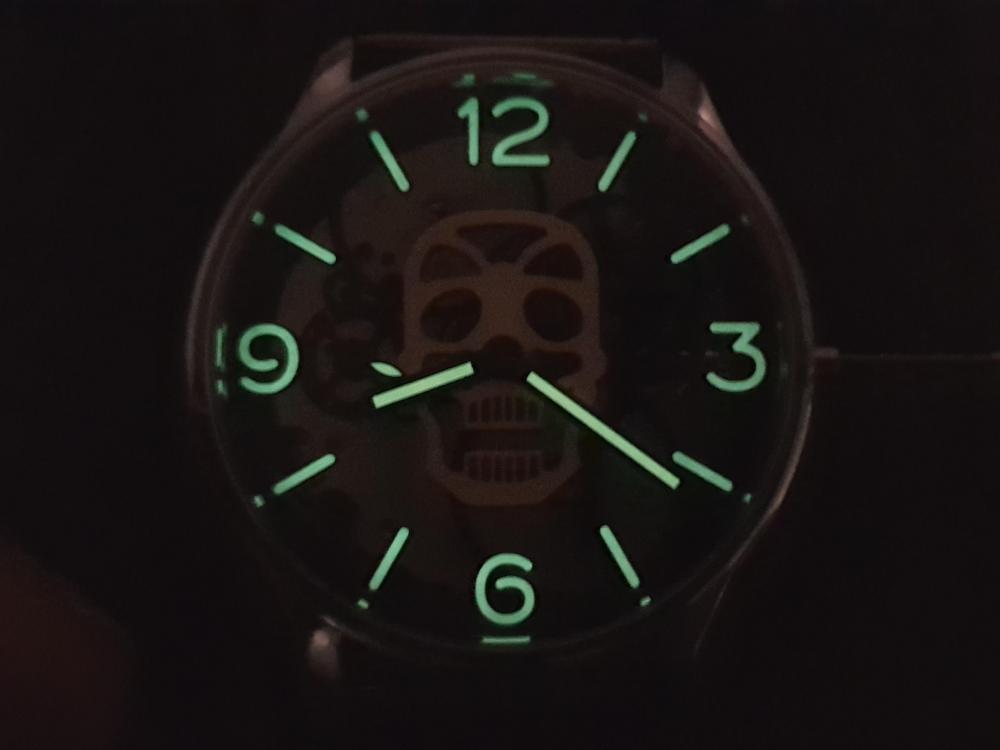

My first is a Panerai homage. All Chinese parts and I love it. The next is completely custom Frankenstein. Swiss movement, American dial, Chinese case and a Russian strap. The sub second hole had to be elongated because a 12s Elgin pocketwatch second hand does not quite line up with the 6498 second.1 point

-

I'm quickly becoming a Timex Electric addict. Learning to service these. Easier than citizen Cosmotrons and Seiko Elnix, but fiddly to get the balance in with that magnet and contact Spring and pallet fork all fighting me! Only the fixed magnet versions with the crown on the rear. First tear down to remind me how to put it together.1 point

-

They look fair, who made it one probably can see when you strip it down , a while ago I posted a stripdown of a cylinder movement maby that can help you on the way..1 point

-

1 point

-

1 point

-

https://gearhead.engineering/the-cylinder-escapement/ this link gives a very good explanation of how the cylinder escapement works.1 point

-

1 point

-

1 point

-

It Is indeed a cylinder movement(no fork) the escape wheel operates directly on the balance staff (cylinder) which has cut outs to arrest the wheel, locking and unlocking basically the same as the fork/pallet.1 point

-

1 point

-

1 point

-

Evertite crystal are very nice . Have used them on some Chronographs with same kind of chapter ring. They are hard to find here in Europe. And think they are of better quality then Sternkreuz If you are in USA check tiptopcrystals out. They could be opened? https://www.tiptopcrystals.com/1 point

-

I've had a few of them over the years. The inner chapter ring is a distinct feature and was not used often by Timex.1 point

-

The hairspring looks correct but I think the hairspring stud could be pushed in a little deeper. The overcoil appears to be very low and might be touching the other coils. Turn the watch edgewise and use a small torch to illuminate the hairspring and watch it 'breathe'. Also check that the hairspring is horizontal.1 point

-

Yankeedog is suggesting that you replace the entire movement inside your watch, as you mentioned than the hands don't spin when the battery is in. This suggests that there might be a problem with the electronics or mechanism. A new movement is quite affordable (around £13). Rather than attempting to fit all the pinions back into the train bridge. I would say assembling the gear train of a quartz watch can be more frustrating than a mechanical watch. Then chance of damaging the pinion of the plastic motor rotor and 2nd wheel is very high. So, heed yankeedog's advice and replace the entire movement.1 point

-

This is incredibly helpful! Thank you! I ordered a ET, but it sounds like the DT will work too (a look more rugged). Esslinger is closed, but casker is processing weekly... Thanks again!1 point

-

By coincidence I 've just noticed these https://www.cousinsuk.com/product/click-springs-wristwatch1 point

-

What can I say, Hoprfully it will run happy. Is this fhf 70, if so, except set spring, I have plenty of spare parts in case you came to need any. Keep safe pleeeease.1 point

-

I think you’ve missed my point entirely. Be nice to each other. If you have to say something then express it as an opinion and not fact, otherwise you will start to sound like Donald Trump.1 point

-

Tempting, I must admit Joe especially if you do not have the correct tools. However checking to see if the pivot is scored will not be possible so I would remove.1 point

-

Thanks for all your quick responses. Nucejoe, I’m just concerned that by not separating, I’m unable to easily lubricate the jewel holes after cleaning. However, I don’t have a presto tool (I have an old Star No.230 tool I use instead). Maybe an excuse to buy the required tool though! Thanks! Sent from my iPhone using Tapatalk1 point

-

1 point

-

I agree with Marc use a presto tool specific for this job. Looking at your pics measure before and lift the wheel from the underside (would be best if poss) so as not to distort the other wheel. The key to this job is a very straight lift. Also when re-stalling a straight push putting the wheels to the same positions on the arbour .1 point

-

Be sure and safe when broaching a little at a time, a good way of checking that you have a good fit is to test the running of the wheel, with the wheel fitted tighten the other plate, spin the wheel and with the plates in you hand move you had to different angles, the wheel should still spin it also is a test for end shake, if the wheel doesn't stop you know that when its all together it is going to correctly run, If it doesn't you know you will need to remove a little more. As they say practice makes perfect. It will be nice to see the photos after you have fitted the new bush if you can take a photo of both sides of the repair, we can look and if we think it is not quite right we can advise you, if it is good which I'm sure it will be we can give you a thumbs up. Unimat lathes are always for sale on Ebay, start about £250.1 point

-

That would certainly cause the symptoms you describe. The click spring should be one piece, yours has broken. It also looks as though the head of the click screw has sheared off too. You will need to remove the shaft of the screw from the plate and replace it for the click to hold in place.1 point

-

You can slow it down by adjusting the timing screws Sent from my iPhone using Tapatalk Pro1 point

-

Where do I start? In no particular order, here are a 'few'........ There are more........1 point

-

Another day, another basket case. I'm not even sure what the movement is. The nearest I can find is a Bleno Sonceboz ES 55 It was completely jammed up solid when it arrived, but after a hydrocarbon bath and a little TLC, it looks somewhat better. The silver seconds hand that it came with didn't actually fit, so a little artistic license was applied. Also the crystal that it came with was the wrong size, and glued in place, so that needed to be sorted too. The case needs re-finishing, but given the value of the watch I doubt if it is worth the effort. It is now running nicely though, so perhaps if i tun out of other tasks in the next few weeks, I may have a crack at nickel plating it. It wont win any beauty contests at the moment, but it does have character, and of course.. a blue dial!1 point

-

Me having the right tools is a bit like that Morecombe and Wise sketch with Andre Previn: “ I am playing all the right notes, but not necessarily in the right order.” Just substitute tools for notes.1 point

-

You can make a burnisher out of a hardened piece of steel by “making” it, which is to abrade one surface. Itv just needs to be harder than the pivot itself. If it was me then I personally wouldn’t bother on a clock like this unless the pivot surface looked rough. You’ve got the tools needed to do the job satisfactorily for a clock of this caliber in my opinion.1 point

-

I think in this thread you had a fair amount of warnings on not to alter things unless you absolutely had to and you knew the reason(ing) for doing so. The good news is that it's a cheap movement and therefor the outcome doesn't really matter. It may become a big success or a small price to pay for all the info you get and the learning curve to be gained. I've other project to do so I'm wishing you lots of suc61 point

-

1 point

-

If you cannot insert the stem then you could try using a screwdriver in the ratchet wheel screw, turn to release the click and slowly allow the ratchet wheel to unwind the mainspring by controlling the turning of the ratchet wheel screw. Easier to do if the movement is in a movement holder. Be careful not to apply too much turning (to release the click) as it may over-tighten the ratchet wheel screw.1 point

-

It's very normal; nearly every Vostok movement does that...... it's called the "poor-mans"-hack. Nothing to worry about and certainly not a reason to send it back or "fix"-it. These are great watches and unbeatable with regards to Value/price ratio. In fact they beat nearly all, if not all Swiss watches as for sophistication & design for the price. Just have a look at this link; what a fantastic piece of engineering for slightly over $40 !! ; https://forums.watchuseek.com/f54/vostok-2415-2416-self-winding-function-reversing-wheels-revised-5134701.html1 point

-

1 point

.thumb.jpg.3804117818d8ee542452ca064760f9bb.jpg)