Leaderboard

Popular Content

Showing content with the highest reputation on 03/23/21 in all areas

-

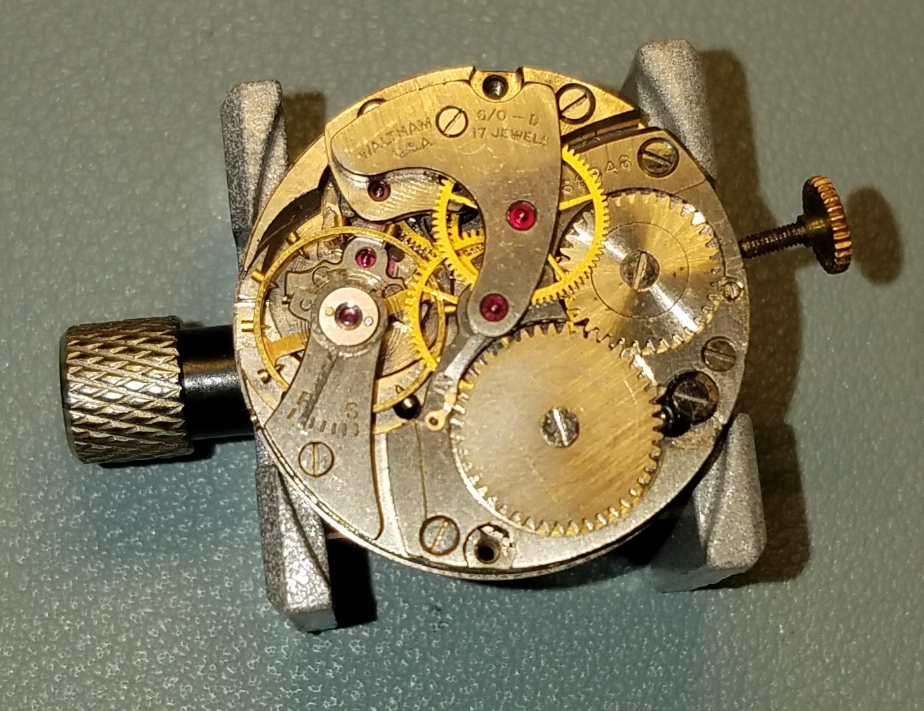

Oh boy this was hard. So I had an A-17 Waltham 6/0 military watch with a busted staff. The first one I ordered was incorrect. The second one I ordered was correct. I watched this WRT video about a dozen times: "Fitting a new balance staff to a vintage 1940s cyma www military watch" I read the Bulova training manual (fitting a balance staff) that somebody posted the other day. Once I was comfortable with the process, I dove in. Imagine that, just like on the video, the roller came off in two pieces. Removing and installing the staff went off pretty much like the video said. I used a truing tool to make some slight tweaks until I figured any more fiddling would make it worse. Then on to assembling the broken roller. I had taken pictures of the balance in all positions, so I knew how it had to go back together. Got it on, and examined under a microscope and was happy. Then I put the hairspring on without any issues. This is where it became incredibly hard. The way the hairspring is shaped (pretty odd), it was nearly impossible to get the hairspring into the regulator pins while getting the stud in place. At one point I thought I had it so I turned over the balance and cock to see how it hung. Something jiggled and the hairspring looped over the stud screw. Rather than take a chance of bending the hairspring, I removed the screw so that the hairspring would fall away. So, with the undamaged hairspring away, I had the task of getting that damn set screw back into the cock. With my dad's copious amount of tools, I found one that is like a locking tweezer with a round hole in the end. I locked the screw in this and had plenty of control to put it back where it came from! After much fiddling I finally got the hairspring installed with the stud in place and the hairspring properly installed in the regulator pins. Then, I put the balance back into the watch and it started ticking! Wow...what a great feeling. This took me about 3 1/2 hours (starting with a disassembled balance that I had started over a week ago).7 points

-

That is a Breguet Hairspring, basically it is superior to one that just spirals out. Have a read of these sites. https://www.buzzufy.com/blog/2018/09/24/the-breguet-or-overcoil-hairspring/ https://www.breguet.com/en/history/inventions/breguet-balance-spring3 points

-

3 points

-

2 points

-

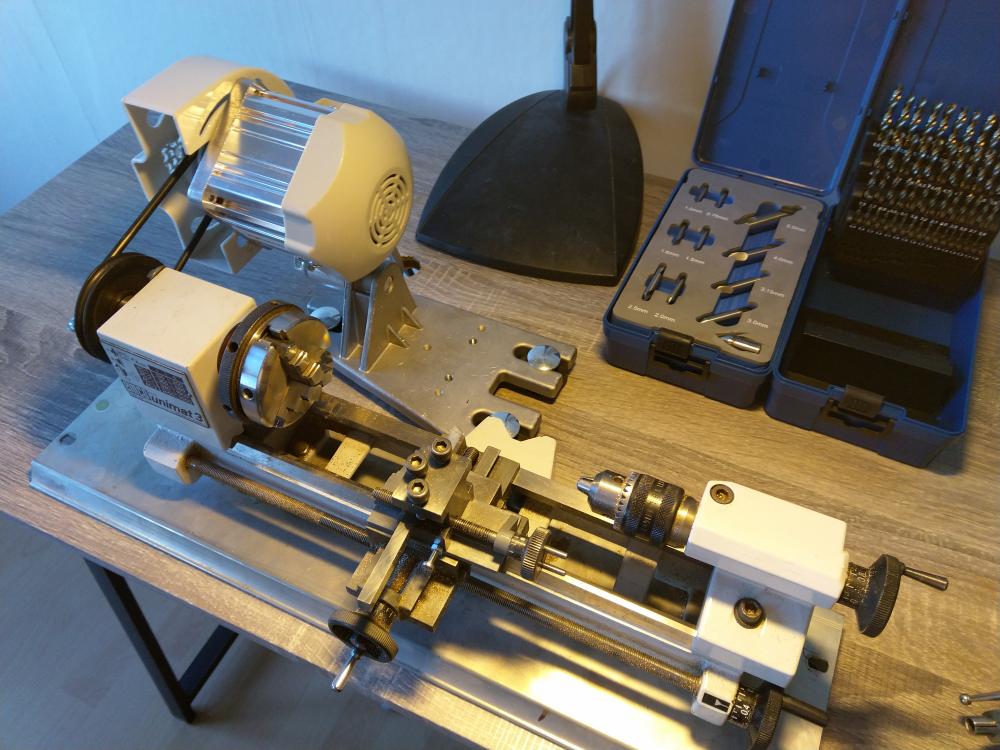

I'm probably not a good example but I make parts on my lathe pretty much every day for both vintage/antique and brand new (prototypes). I have a small 3 phase motor for my lathe with a countershaft; 3 phase power is ubiquitous here so no issue 99/100 I use two speeds, about 1500 rpm or 700. I use a cross slide for 99% of the work. Everything turned to size, +0.01mm on pivots which get finished in the Jacot after heat treatment. The little 3 phase is smooth as silk, there's a scope over the lathe, and a quick change toolpost on the slide*. I do use hand gravers, for cutting off balance hubs when restaffing, for cutting conical pivots and rivets, chamfering things sometimes, a quick retouch if the slide isn't mounted on a screw length etc. The slide is a massive timesaver. *the quickchange is a copy of a Dorian post, which I copied from a friend's when I was in school. It repeats almost without fail within 2 or 3 microns, spooky. Dorian stopped making it, but Horia makes a copy still. Worth every penny if you make your living with it.2 points

-

Have a look at this it tells you all you need to know. Just click on it.2 points

-

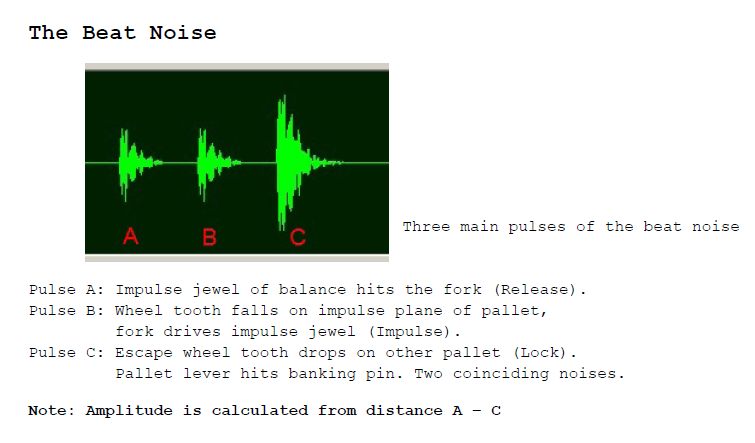

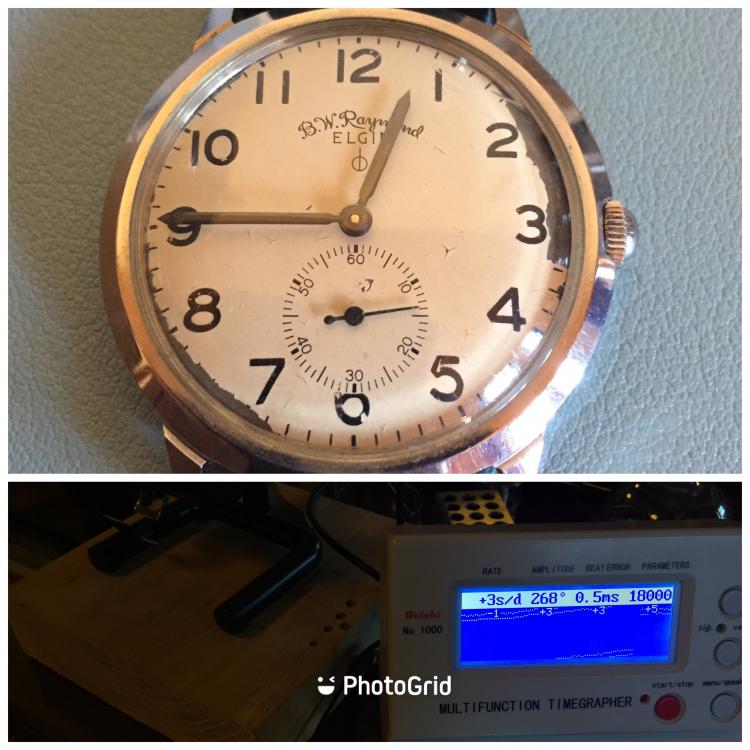

Answer is quite simple. The noise is too quiet with mov holder (for this TM). Tick noise consists of mainly 3 pulses, the first being by far the lowest (most times). If the TM misses the first, it takes the 2nd as start of escapement time, base of ampl measurement -> detected esc time too short -> amplitude value too high! Didn´t I explain that just recently? Frank2 points

-

Sharpening the edges on my Mark II gold case. Made a lapping collet out of brass. And 3D printed an angle base. Seems to work!1 point

-

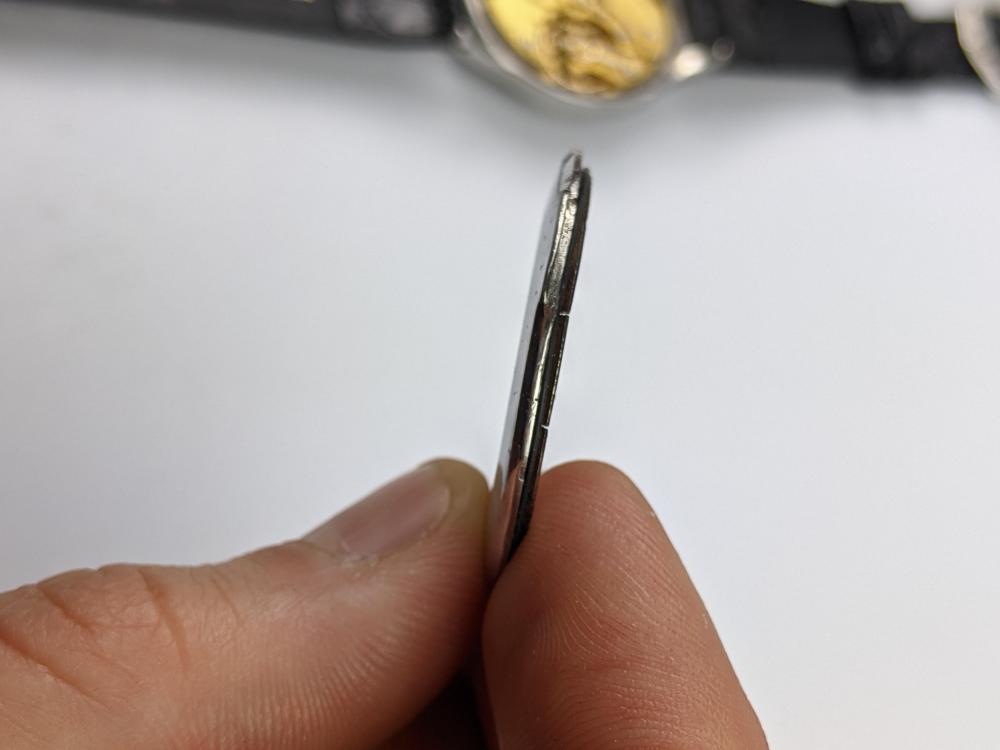

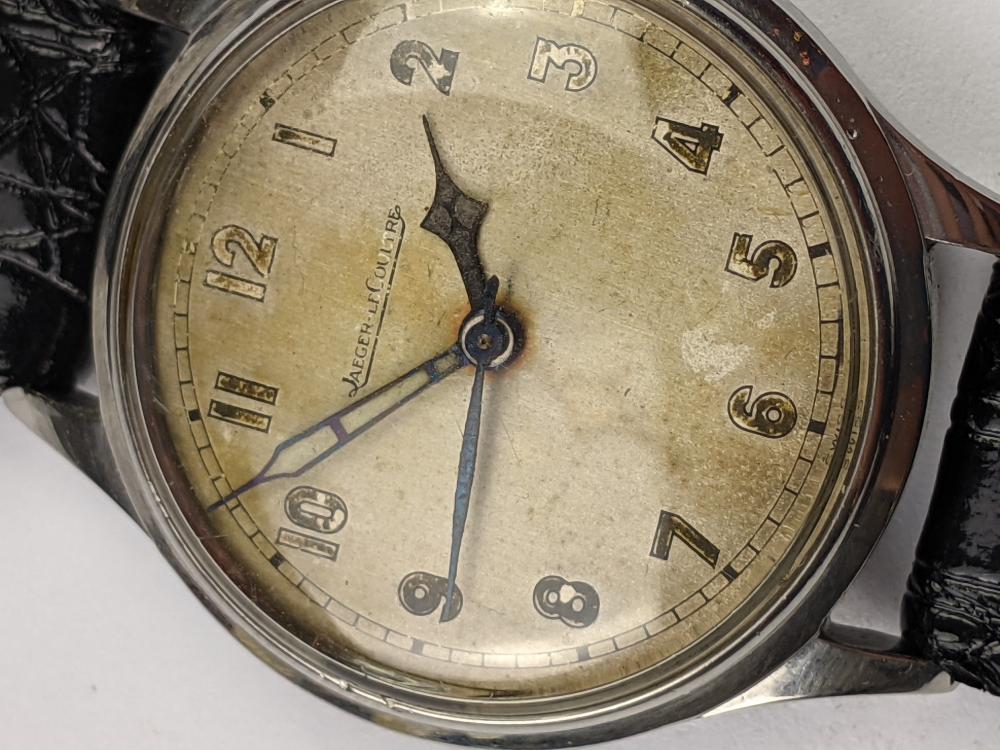

Hello! I recently acquired a Jaeger Lecoultre P478. There are two issues that I have. First, the snap caseback is warped so that it doesn't sit flush all the way around the case. It seems to fit well enough but there's still a gap which makes me wary. Is there a way to fix this? Second, the hands on it appear to be quite old but they don't look like other hands I've seen on the same model, could they possibly be original and I've just never seen one like this before or are they for sure replacement hands? Any help is greatly appreciated! Thank you!1 point

-

If you are going to work on vintage watches you probably quite fast will realize some parts is just not available any more, and one probably will turn a balance staff faster than waiting for one in the mail with some training. I noticed you said your problems would be over when getting the setup fixed, I would say your problems are just beginning when you get the lathe running, it sometimes just can be so addictive your better half have to pull your away from it at 2 am. So, they might just begin ?1 point

-

The Geneva style lathes I mentioned above which I run with the same setup is an 8mm Lorch and a 6mm BMC, even if the motor is slightly more powerful, I think I get good enough control to cut a cannon pinion or two, even made a new axis for an escapement wheel the other day. Guess I got a bit lazy with age and think new technology to control the revs is convenient, but I still think these rubber drive belts work just fine. I add a romantic picture of the babies too.1 point

-

Here's my latest entries into the 404 club. A nice little haul of Casio's costing me a princely sum of £3.09 each posted. Pretty tatty and grubby to say the least, not all will buff up, but I've had great fun tinkering with them. They all work now despite the battering they've taken. The one on the far left is my favourite, must be from the late eighties. It had lost it's beep. Though after about 10 mins over lunch it got it's voice back and proudly beeps away quite nicely.1 point

-

I would change the case gasket, Just to be sure its sitting properly in the groove and check the flatness of the case back on a glass plate. If its out of true using a light hammer and blunt punch gently reform the back.1 point

-

I have a Seiko sport diver where the previous owner had removed the unscrew case back without unscrewing it. A Seiko case back normally isn't particularly expensive to replace but I thought I would give straightening the threads out a go. I surprised myself and fixed it. I did it all with little hammer love taps and a semi blunt blade.1 point

-

Your is a watchmaker's lathe, so a powerful motor, belts etc are not important. Very different from even an baby lathe like HSL's, on these you want to cut steel and the standard motor is easily not enough, there are other limiting factors, I know a old machinist that says "for each one his own". See if you can get to turn a cannon pinion to fit precisely the minute wheel, using just a graver. That is the kind of work it is made for.1 point

-

@praezis; I know we digress from the topic and perhaps that's how a timegrapher works. You may be 100% correct, but it doesn't make a lot of sense to me. It would make far more sense to me if the TG would measure the time in between the 3 pulses and the next set of 3 pulses. The way you explain the workings (and therefor VWatchies problem), the TG would measure the speed (=time) with which the impulse jewel performs the unlock till the final lock over the duration of the lifting angle. This would mean that the higher the amplitude, the greater the speed of the impulse jewel. All well, but what about the beat error? If the time was measured between the last pulse, the lock, till the next first pulse, the unlock, that IMHO would also tell something about the amplitude and gives an indication of the beat error.1 point

-

I think sewing machine motors are good replacements, here is one of my “bigger” small lathes with a frequency controlled sewing machine servo motor (brushless). I use the original 5mm rubber belts for the EMCO Unimat 3 even if this is a 550W motor, it works just fine. I have the same rubber belts for my Geneva style lathes too, they are really cheap. Think they are just a 100mm in diameter rubber gasket.1 point

-

New main-spring? I wish I could come up with an answer to make your day ...... ? How about filming the balance wheel with your iPhone in slow motion? With a video editor you can slow the video down even further. With a bit of luck, keeping an eye on one of the balance wheel spikes, you can spot the difference between 240 and 300 degrees?1 point

-

I agree the movement on the mic directly is probably the right one. This is probably one of the significant differences between these machines and "real ones" at 15x the price, the real ones seem to have a bit more sophisticated circuits that filter things better. I'm sure John will chime in, and he has experience with both- I just have experience with Witschi and then numerous old paper tape machines, haha. I did have the add on meter for those to see amplitude though.1 point

-

As JohnR725 always says with timegraphers; rubbish in is rubbish out. The microphone receives a signal, passes it on to the processor and it's up to the software to make any sense out of it. It may well be that a movement, clamped in a movement holder and subsequently the combination is clamped in the microphone creates additional vibration or resonance (?) If that would be the case, the software may or may not correctly interpret the received data. Which one is correct? My two cents; as per design, the movement directly in the microphone. Do I know for sure: no I don't ?1 point

-

Well done @Endeavor and I shall follow this with great interest. It's a very beautiful time piece! I'm happy you didn't try to take that mainspring out of the barrel. Having an eight day power reserve I guess it could have taken your head off! ?1 point

-

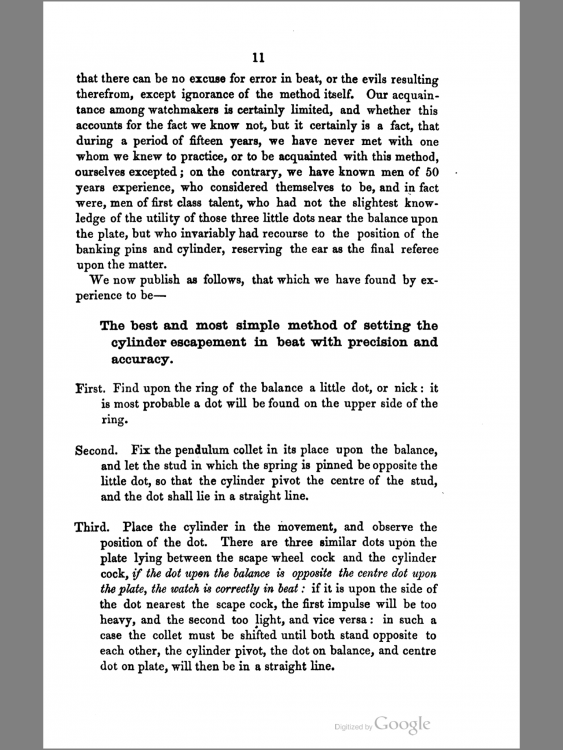

No, I'm not going to polish the brass parts. I know they have in the UK Horolene. For years CousinsUK was not allowed to ship it overseas. Now they are allowed, but with Britain out of the EU the EU Mafia authorities penalizes everybody heavily who does any business with the UK. Above the 80DKK (£9.25) and I'll get hit with £21 registration fee + import-duty; that is as a starter !! Now, each time I order from CousinsUK, it can only be small parts or split orders to stay below the £9.25 per order, but obviously pay the multiple postage extra. Above the £9.25 and I've to source the items somewhere else, against higher cost ! ??? So for now I'll leave the brass "as is", but thoroughly cleaned. I adjusted the platform already and there is only a tiny axial play in the contrate wheel shaft. Please remember that on top of my post I mentioned already that the clock wasn't running great. If the opening of the cylinder is "out of line", that may explain a lot(?) My question remains; what is the correct cylinder alignment compared to the center-line of the escape-wheel ? It would be very nice to know that ?1 point

-

I guess the articles Tmuir provided link to does explain some resason, here is what I figure, Some advantages; The diameter of overcoil gets increasingly smaller as you get closer the stud so hairspring moves less between regulator pins during oscilation, therefore isochronicaly enhanced , almost as good as free sprung. As you can see breguet hairspring allows longer length therefore bigger amplitude of oscilation. Both effect directly increase percision of regulation. Disadvantage, tall balance staff.1 point

-

Almost certainly an English fusee pocket watch made in about the 1870,s. Some have no makers ID,s1 point

-

I would try using a sharpened piece of peg wood and a rust remover fluid. Such as: https://www.cousinsuk.com/product/rust-removing-fluid?code=R14701 point

-

Getting those screws in is a real pain. My method is to use a very very small piece of rodico (or bluetac if no rodico), push the screwdriver through the rodico, engage the slot with the screwdriver and push the screw/driver back onto the rodico so the screw is held. The screw can then be fitted easier and once engaged the rodico can be removed. A dial dot also works but can leave adhesive on the screw which needs to be cleaned off. Plastic magnetism !!1 point

-

@KlassikerYes, exactly. With only one small point of light a reflection is easier to see. The more diffuse a light is the softer the reflection becomes. To super optimise this a penlight with a tight beam would be ideal.1 point

-

1 point

-

Well done a nice success story, quite an achievement I will have a beer on that one.1 point

-

1 point

-

1 point

-

Thanks for the info, Graziao. I will try to repair based on the lube chart you gave me. And I will share some Japanese watch repair experiences . I appreciate your cooperation. Jpwatch1 point

-

1 point

-

Well done for taking a step back and finding that screw-holding tool!1 point

-

Hi there Jpwatch , the 3130 is the same as a 3135 but without the date as your probably aware, so here is the lube chart for this movement. Hope this helps you. Maybe you can go over to the introduction section of the forum and introduce yourself, and share some Japanese watch repair experiences Graziano 392075043_rolexoilchart3135 (1).PDF1 point

-

It really helps to have access to one of many manuals for American parts and materials. You can find Marshall Handy Manuals, Swigert manuals, and many others here and there around the Internet. I consult the old Marshall parts interchange all the time. You'll also find old Waltham parts lists and mainspring charts online, too. Many parts suppliers (like Otto Frei) basically copy and paste the info from those books into their descriptions, and that would be a good place to start for American mainsprings. As for figuring it out, once you narrow it down to the brand and size you funnel into the specific model (a Waltham 16s Model 1908 in this case), and then you should see at least 1 option. Often you have a range of strengths available for models that varied in their jewel counts. For a Waltham 16s 1908, you could use those you mentioned or 2218. They vary slightly in thickness (strength) but are otherwise identical. As a related tip, Cousins UK sells new Swiss alloy mainsprings for many old pocket watches. If you download the Generale Ressorts pages from their webpage, you can get guidance for many of the common American mainsprings. Brand new mainsprings from them are often cheaper than vintage NOS ones from eBay.1 point

-

I was doing a file search On my computer for the version you have and it looks like I never had the short version before. It looked familiar but I'm guessing it's because it looks kinda like the longer version. What I like about the longer version is PDF page 32 talks about the microphone. Specifically the ways in the microphone and this is where I had found the reference that using a high pass filter and keeping it everything above 1000 Cycles and everything under isn't important.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

It was productive week with these 3 watches and getting them in working order. The Bancor AS1187/94 was the only one received that was running but needed a new mainspring and cleaning. The Elgin 730A wristwatch stopped and started and the pocket watch had a broken staff. The PW, Elgin grade 96, was a gift for my father. All running well now. Lastly, I made some cosmetic improvements to my staking set last month. The tools inside needed minor refreshing but the box had seen better days. Scraped to bare wood - poplar - stained and finished. before: after:1 point

-

You need what is called a chalking brush, you must always keep the brush clean and never use it for other things, you load the brush by chalking the brush and then brush the plates. It is a very old way of stopping brass from tarnishing. I dear say the chalk of today is nothing like the old stuff and how things change I bet it isn't even the same now as what I bought back in the 70's & 80's.1 point

-

1 point