Leaderboard

Popular Content

Showing content with the highest reputation on 08/17/22 in all areas

-

That's a problem with most Seiko service sheets, but I found one for the 7016 Seiko_7016A Color.pdf3 points

-

Is it just the barrel rotating on its own or are the rest of the wheels moving as well ? Barrel on its own, it's not meshing with the second wheel. Rest of the wheels as well, there is an issue with the escape side of the movement. Remember I am a beginner so probably missed something obvious3 points

-

This is a good article on the subject. The bottom line is be very careful when handling dials and hands you suspect are painted with radium paint. Wear a face mask and wear finger cots. https://www.wristwatchreview.com/how-do-you-know-if-a-watch-has-radium-hands/3 points

-

2 points

-

Hi everyone. I have been absent on here for awhile. Not by intention, just stuff. Friend across the road, working from home, has his morning meeting with his colleagues, then tells his wife, Kylie, he is going to have a shower. Yells to Kylie that he needs her. Kylie gets to him in the bathroom. He is lying on the floor and says to her that he thinks he was having a stroke. 16 hours later, Bill has left us. One thing that Kylie said in her speech after Bill's burial. "Live every day as if it were your last." Don't know who first said that, but it is oh so true. That and working with my mate up the road to make a Joe Collins spring winder. Also been investigating getting a 3D printer to make movement stands, tool holders, things for the lovely wife. I need to do something nice for her as she was none too happy about the clock from Darwin. Weathered that storm and the movement is now sitting on a block of wood after I removed the back plate to remove the first(?) wheel in the going train, the pallet Arbor the suspension spring and the crutch and then the first(?) wheel in the strike train as well as the fly. Then had a rather hamfisted effort getting the rear plate back on, but eventually got it all done. Did notice that the rear movement plate had at least four bushed pivot holes. While they are visible, distances have been kept correct as everything that I have turned moves quite freely. I am not sure if I have the terms correct for the wheels that I have removed. I have had a bit of trouble deciphering some of Mr. De Carle's pictures in his book. Anyway, this has enabled me to sit there and turn the going train easily as well as keeping light pressure on the strike train and I can see how the parts interact. I presume that it is the strike flirt that stops the strike warning wheel from turning. The hour wheel and the snail I have been able to work out. Beind the hour wheel is a small cam (possibly for want of a better word) that another arm that is attached to the strike flirt, runs on. It is responsible for a single strike on the half hour as well as releasing the strike warning wheel before the hour strike. I now understand how the flirt works with the snail and the rack and the gathering pallet to strike the hour. It is all quite ingenious really. I am fairly sure that the releasing of the strike warning wheel and its subsequent capture by the strike flirt occurs simply due to the larger cam behind the hour wheel that operates the strike flirt approaching the hour. If the warning wheel wheel was not captured, the clock would strike the hour several minutes early as the rack hook has released the rack as well as the gathering pallet at that time. When I get around to disassembling the movement to clean everything and then reassemble it, I don't think that I will be able to remove the clicks and springs for the two barrels. The parts look to be riveted to the rear movement plate. Anyway, that is where I am up to now. That and cleaning in our garage to make more space. Skip bin later and we are getting there. Hope everyone is well.2 points

-

Eyup. Here are 5 Timex watches that cost 23 quid in total so a little over the original 404 price budget. 3 waterproofs with snap on backs so thats non believable for starters. And if Andy's American strap a Timex to an outboard engine propeller, submerge in a large tank full of water and let rip advert is anything to go by then i dont think so lol. An unusual pink/orange dial hard edge cushion case and an m22 W.D.P Cinderella from the late 50s early 60s which my missus really loves and is going to restore herself.2 points

-

2 points

-

I finally got round to tidying up this rather beaten up Allwyn 21 jewel Automatic from the early to mid 1980s. I picked this up a couple of years back, and it was in pretty bad shape, with damaged hands, the remains of a smashed crystal, which had been superglued (badly) into the case, and a large collection of dirt and battle scars. It looks a whole lot better now, but there is still some evidence of the hard life it has lived. Allwyn were a competitor to the arguably better known HMT, and Titan Indian watch brands, producing licensed Seiko movement watches in Hydrabad. This is actually a licensed Seiko 6319A movement, and I believe the parts are interchangeable. One neat feature that makes it unique from the Japanese version is that the the day disk is in English and Hindi (Devanagari) script.2 points

-

I thought I would compared to Rolex so I snipped out some other specifications. When you're looking at the chart you do need to find a watch comparable in diameter size as others have pointed out that will change things. You'll notice that your beating out there specifications you're much tighter than you really should be especially with a watch of that quality. When I'm reading this it's reminding me of clock repair typically by a watchmaker but not necessarily. But usually when a watchmaker looks at the clock things seem really sloppy and there's an obsession to put bushings in. Typically only need a bushing if the hole is no longer is round. No matter how sloppy it is if it's still round that's the way it was made. So then obsession with bushings you can end up with clocks that will not run on the weight there designed for because it's just too darn tight. So yes if you get carried away with getting your tolerances super super tight you're going to have a running issue in the watch. Especially if the watch was manufactured with more liberal tolerances that requires greater spacings possibly bigger hole diameters for pivots.2 points

-

Here's a cutaway with close ups of the two ends. The sideshake is 0.01, which is about right for a 0.15 pivot (this size). If the arbor is under tension, it will generally want to tilt- like when you try to wind the watch with the wheel train in but haven't put the bridge yet- everything tilts . With a very small but existant endshake, the shoulders of the arbor can touch both flat surfaces of the two jewels at the same time. With a little more endshake, as the tilt is restricted by the pivots, it will become possible for one shoulder to touch one jewel (and is almost certainly the case 99.999999% of the time), but both shoulders can't contact both jewels at the same time.2 points

-

Hi guys, I'm working on a watch with a T-end mainspring. The mainspring still looks good, so I cleaned it and wound it into my mainspring winder. The problem when I put it back into the barrel is that I cannot get the T to fit into the cutouts in the barrel and lid. I tried aligning it by looking through the barrel cutout and placing the T there before ejecting the spring from the winder, but it still moved. I assume that if I simply put the lid back on and assemble the watch, the spring will align itself when it is wound, but that would probably damage both the spring and the barrel. How do you gurus do this? -- Best regards, Stian1 point

-

1 point

-

If you look at the big crack does the crack go all the way to the center hole? Has it damaged the center hole? If you look at the balance staff is the pivot scored from the result of running in a cracked Jewel? In vintage pocket watches you will find flaws and things that look like cracks. But if you look at the hole itself it looks smooth and shiny it's not a problem. Yes pocket watch staffs typically come in several sizes of pivots for the exact same staff number. Then of course the balance hole jewels will do the same thing. Which means you usually stuck having to measure something you can't just look up and find the exact one your watch Is using. Then of course there was also the problem of variations over time because of manufacturing changes. That's more of a modern watch repair question. In the case of this watch the Jewel settings will only fit other Illinois watches. It be nice if you give us the size of the jewel setting that would speed things up considerably. I have a link to a pocket watch database if you like is sometimes a give you parts listings but not today this one is a listed. Then snipped out an image from the 1923 parts catalog problem is it's 1923 new watches made after that so it's not listed at all. I sub another image of another reference book and basically you're still stuck with you have to measure the jewel setting to see which one it is. Then you have to measure the balance pivots to see which hole size you need. Because as far as I know there was never a listing of the exact part that your watch would need. https://pocketwatchdatabase.com/search/result/illinois/51523341 point

-

Looks exactly the same has mine. Mine has been a real workhorse. My heater works, but it is slow. Running the ultrasonic adds as much heat as just using the heater The only tip I have is to make sure that there is plenty water in the tank when you run it, as I believe if you run it when dry the transducer may overheat, as it uses the water in the tack to cool. (see above). Cheers!1 point

-

Had a look in Marshall and Swigart but couldn't find the size. In Swigart in says that pivots come in various sizes - which is my experience of these types of watch. Unless you can measure the pivot very carefully with a micrometer - though it's not recommended. A better way would be to find something (old pivot?) that fits the top balance jewel correctly, and measure that.1 point

-

There are many different ways of fixing these movements to the brackets inside the cases of these clocks . I's seem some where the screws are about 3 inches long with flat round brass heads. Others just held in place with pins. Could be they don't belong to that clock.1 point

-

1 point

-

1 point

-

1 point

-

Hi I suppose its quite likley they are not from the the clock and were put in or left in at some time.1 point

-

No diag be conclusive without full inspection of the barrel, arbour ...etc. Regs1 point

-

With some luck you will find an genuine service guide for the similar predecessor Rolex 3185 in the www. Best is to search Youtube for an appropriate service video. The differences in the caliber design between genuine and fake are minimal. But be aware that the material and build quality is significantly lower. Up to now I had two Chinese movements on my bench and had to deal with a broken screw head in both cases. (see personal message!)1 point

-

I have this problem with my Vostok Amfibia. Originally before I used braking grease in the barrel, it didn't have this problem. I haven't tried cleaning out the barrel and using normal grease. I should really do that and post my findings.1 point

-

Hi I have not worked on a huge amount probably under 40, and mainly Seiko and Citizen and a TAG and have never felt or heard the mainspring slip on any of them. I got the impression when I asked about it that the slip is so gradual that it should not be detectable. Given that I have not don't that many and am quite new at this dont take what I say as correct, await a more knowledgeable reply1 point

-

Same here. If the pivots dont fall into place within a minute or so i start to put a couple of screws in. I use pegwood to lightly hold the bridge in place. If the pivots are still resisting i do closedown one screw very very lightly after i have one pivot in position. The screw closest to that pivot and then gently position the pivots in place one at a time working away from the screw and closing it down just a touch at a time until all the pivots are in the jewels. Then test free running of the train before the last nip up of the screw. I only do this if i am having real trouble locating the pivots and i also stress that the screw closed down is done a fraction at a time. I do have an extremely light touch which helps. My missus says i have anyway1 point

-

Hi Bruno . I have quite a few watches from the 30s up to the 50s that have radium lume. There are differences of opinions on this subject. Somewhere here is a chart with radioative danger levels of materials we encounter during general living. Radium lume did seem rather low in relation to what is hazardous to us and within certain guidelines of exposure. That being said if incorrectly handled and disturbed risk would be higher. Any dust inhaled and absorption through your skin an obvious danger. The British MOD did change dials to a safer Tritium lume dial on their mil spec. watches after the second world war second as and when they were serviced . It doesnt stop me working on watches with radium but i am extra careful and do wear a face mask as a precaution. The risks though are entirely your decision. People can smoke heavily all through their life without any cancer scares others get away with very little. Some research on the subject will help you decide.1 point

-

You live and you learn. We've all broken pivots at one time or another. I also start two screws and then manipulate the wheels to get them in the jewels. One thing to watch out for is not to lift your finger off the bridge without first screwing the screws home... reason being your finger (even with cots) may lift the bridge away slightly as you move them and dislodge the pivots from their holes. If you need to remove your finger, use a pegwood to hold the bridge down. Anilv1 point

-

1 point

-

Yes if all else fails this is the best way. There are still other options you can sometimes measure the staff and from that size alone figure out the watch or replacement staff or you can do it with the Stamm sometimes. I once identified I got really close by just measuring the stem and looking up the sizes of that. But by far the best is somebody gives us the diameter the movement from the dial side because in pictures the watches all look the same size and nobody's going to waste their time looking up somebody's mystery movement if they can't help us and give us the diameter. Then of course we need a picture of the keyless components and then we can look up or try to. There is a problem though in that they do not go back to the beginning of time and they don't go forward to the end of time and this watch is probably too old but it doesn't look super alts there is a possibility but I do know in the bestfit book for instance it doesn't seem to have every watch ever made even for the time span that these books were in existence.1 point

-

Hi Willow, were these screws loose in the case ? You have picked up a nice clock there, weight driven Vienna.1 point

-

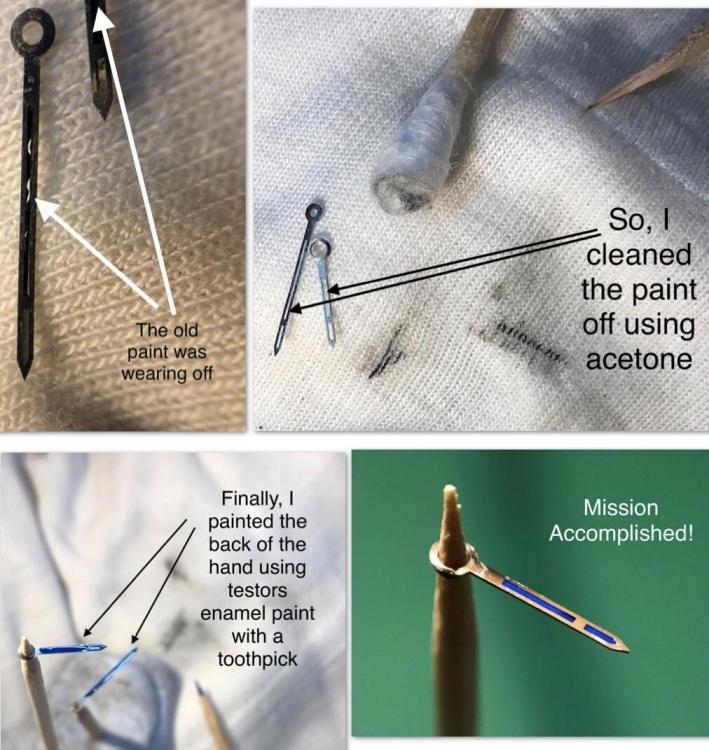

Hi with a 1.2 you may be able to get it to fit it all depends on how much metal there is on the donor hand, but in cases where there is no alternative it is best to give it a try.1 point

-

It technically can go straight in without the thicker piece of metal that acts as the hook, although the end that is left is not a hook as it hasn't been flattened or rivetted or spot welded to make the hook strong enough to use, so it would more than likely snap when near full wind. The heavier piece of metal that does actually hook on the barrel wall puts force on the end of the mainspring in a different way. The force is directly on the bend on the end of the spring which can handle that force. In this way the bend on the end of the spring isn't trying to open up, as if it were fitted directly into the barrel1 point

-

Nice CAD work. VWatchie, also remember that Nickelsilver probably also modeled those parts in theoretical perfection. All dimensions spot on, lines that should be parallel are, all angles are accurate without internal filleting or external rounding, concentricity or T.I.R. zero. Which is all easy to draw, very (impossible) to obtain. Watch parts (even "cheaper" mass produced watch parts) are probably closer than most but will (on average) deviate from print. That's called acceptable tolerance. If you don't want to hand fit every part in every assembly, you assemble using fixtures adjusted for parts assuming the widest possible "acceptable" deviations. And as Nickelsilver said, while under torque is not the same thing as when it is free wheeling. Shane1 point

-

Hello all--new here--Retired airline pilot--------My question is-- How does the bezel attached to the case---I have a replica Rolex yacht master found--I have no idea who made it--but I decided to change the bezel face, so I removed the bezel---it is a rotatable kind----- There was a hole for the spring click--but none was there---that's ok as you can rotate either direction----but---now the bezel was a little hard to pry off----but now can't get it to attach to the case --sloppy loose---What held it to the case ? It doesn't just snap on over a lip like some watches I had---real Rolex for example-----What is that slot around the inside of the bezel for ? Driving me crazy to figure it out---any help appreciated--Thanks SAMe1 point

-

Any clicking arrangement does not influence how the bezel is held to the case, which invariably is snap on. Check that the bottom of the bezel is all the way down to the case, if it was very tight to remove will need a good case press to be put back.1 point

-

Hi A picture of the underside of the bezel and the front of the watch would be helpful in determining the problem. On some bezels there is a wavy flat spring that fits under the bezel and then the bezel snaps on , the spring prividing the tension for the bezel. There are others in which there is a small hole in the case with a spring and a bearing (a Biro ball is some time used as a replacement) which detents on the underside of the bezel. thanks1 point

-

These are are snap on indeed. If your fake doesn't really, that just demonstrate its poor quality.1 point

-

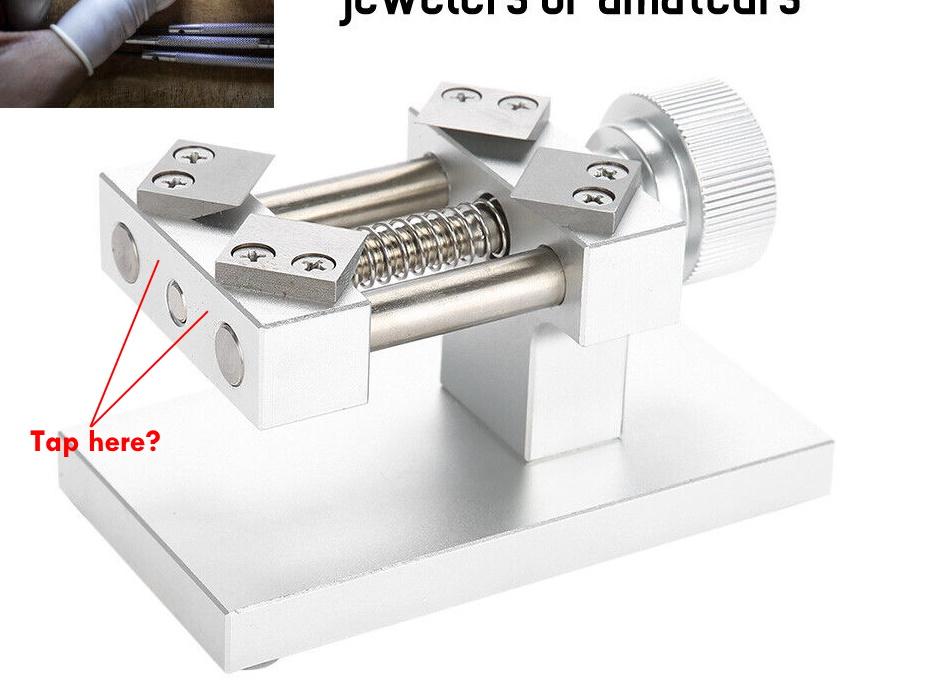

I have the Chinese version and it works fine, I would recommend placing a plastic bag between the watch and the claws to reduce the risk of marking the case or bezel1 point

-

I am old enough to remember the phrase “lies like a cheap Japanese watch” bit different now Tom1 point

-

ha! I don't feel so bad now because I do have the very same thing sitting on my bench and use it when my case blades don't work.1 point

-

No, I have not, so really great tip! Thanks, I'll try that! Well, that sounds like a really great tip! Thanks a ton! Anyway, just to make sure... And while we're at it. Should I go for this bezel remover from CousinsUK £100 (I live in Europe) or would a Chinese bezel remover £23 work as just as well?1 point

-

The 4 blade tool works great.... but not the way you think it would work. Initially I had problems with the 4 blade tool. It takes a lot of pressure on the knurled wheel to actually wedge under the beze and advance the bladesl. When having to use so much force, you lose tactile feedback. You can't tell when the blades are not engaged proper or when it has traveled so deep that it is touching the lip of the watch case. In any case, the risk of damaging the bezel, watch case or the tool is very real. The way I discovered to use the 4 blade tool safely is to use a small hammer to tap on the movable jaw of the tool. I first engage the blades of the tool into the gap between the bezel and the case and tighten it lightly. Then I use the small hammer to tap on the movable jaw. The small amount of backlash in the screw threads will allow the jaws to move forward. If there is any "give", you will feel the knurled screw loosen and will be able to tighten it a little more. Continue this tapping and tightening until the bezel pops off or the blades stop advancing anymore. If the blades stop advancing, it probable means that it has reached the lip of the watch case. In that case, you can wedge a thicker blade into the gap under the bezel and pry it off. I hope this helps.1 point

-

have you tried using a little heat say from a lighter or jewelers lamp to remove separate the cyclops from it's adhesive? I removed one using a soldering flame and it slid right off the crystal. A little One-Dip later and the remaining adhesive disappeared. correct-the tape is to protect from scratches. What i'm more concerned with is safety. my fingers and razor blades just smacks of a bloodletting for me. Case knives work best for me when removing bezels. it takes a little muscle sometimes but they work.1 point

-

Very old thread, but I hope that doesn't matter too much. I have a Chinese Submariner case and I really don't like the cyclops for the date and so I figured I could just replace the crystal. Anyway, I thought it would be a good idea to remove the bezel to get a better view of what needs to be done but I just can't get it off. I have the tool in the picture by @clockboy but the bezel just won't budge. So, I thought I'd get myself a 4-blade remover, but it would seem it's no guarantee for success. So, I too was thinking to get myself a stack of razor blades. But, what is the polyimide tape for? I would assume for protecting the case, but I thought I'd better ask. Any recommended videos or other instructions for the razor bade method?1 point

-

I need to see more pictures. There appears to be only two wires connected to the speed controller. Is that right? The speed controller looks like a wire wound rheostat. It varies from 0 to R ohms. R is probably in the range of 500 to 2000 ohms SWAG. Lowest speed when R is dialed in and fastest when 0 is dialed in. I am troubled by the fuse blowing. No setting on the rheostat should cause that, so even if it is damaged in some way causing 0 or R, it would not blow a fuse. However, if one of the wires is shorted to the case, then you might blow a fuse...and this is possible due to physical damage. I would unplug power and remove the rheostat and inspect it...post pictures.1 point

-

I am not about in which section you post. I rest my opinion that your secretive attitude is in contrast with the spirit of this forum in general.1 point

-

1 point

-

I too have hand wound a few mainsprings when the end will not catch on the tab on the inside of the barrel: bad engineering, not maintainable Sent from my iPhone using Tapatalk Pro1 point

-

I could have written your post word for word as that is exactly what I have found. Same tools, same results and same technique! :)1 point

-

I have a 4 blade bezel remover & I have never been that happy with it. It just does not seem to work as efficiently as I thought it would. I usually wind it in as tight as I dare without bending the bezel and then also lever either side of the 4 blazes & the bezel then pops off. I just wonder if the Horotech two prong is better.1 point

.thumb.jpg.c090a8faa25e47684f71c6de38836828.jpg)