Leaderboard

Popular Content

Showing content with the highest reputation on 04/15/19 in all areas

-

I think I spent rather too much time getting this to work again. I still haven't dug up a suitable crown, but it is running, all of the corrosion is gone, and the crystal is not too shabby. I popped it on a period correct band. So what was so interesting about this little Timex you may ask? Well it turns out it is just as ancient as I am, since it was produced in 1964. It had pretty much everything wrong with it. Covered in interesting (and no doubt mildly toxic) blue and green corrosion. It had no crown (but the remains of a stem), wouldn't wind, wouldn't run, couldn't move the hands You name it.. However in between a few household chores including having to nip out and purchase and replace a Venetian blind who's plastic supporting beam decided to shatter in to a million pieces bringing the whole mess crashing down on to the window ledge (and destroying a glass vase of flowers in the process), this afternoon, I tore it down, cleaned it, replaced a few bits and eventually got it running nicely. I've included a picture of the new blind, just so you can admire my handy work. It still needs a little bit of cosmetic work, (though that hair at 8 o'clock is now gone I assure you), but given that its age, I think we can forgive that, unlike the original window blind, which was only produced in 2015. Somehow I doubt if the new blind will last any where near as long as the watch.4 points

-

3 points

-

PaulnKC, I went through the same thing a number of years ago. The device that worked the best for me was definitely a microscope. Low power loupes have a decent range of focus but as the magnification increases the range of focus decreases. At 20X any head movement will throw the watch movement out of focus. Since the microscope lenses are fixed in a frame, you can examine parts at 40X with no problems. Also, your eyes emit vapor which will fog up the loupe. I would vote for the microscope hands down. david3 points

-

2 points

-

I dislike to clean anything with diesel fuel. It's greasy and smells bad. And in the US isn't even cheaper than petrol.2 points

-

Blue steel can't be cut with a jeweler's saw but can be filed. That used to be how they checked the repivoting exam for clocks back in the day- saw bites, fail, file doesn't bite, fail. The commercially available blue steel bars watch and clockmakers typically use is very hit or miss. The nomial size is often way off (not such a big problem), and the heat treatment can vary between too soft, uneven, or sometimes actually ok. I have some and use it for pins and such. For staffs, stems, pinions- anything from steel- I use oil hardening steel in its annealed state. The standard in Switzerland is Sandvik 20AP, probably not so easy to find in small quantities elsewhere. In the U.S. O1 would be the closest thing (and is a fine steel for watch parts). Parts get hardened and tempered after machining, with generally the last 0.01mm or removed in finishing for bearing surfaces. For a staff I cut everything right to size except the pivots which are a good 0.10mm oversized, and I leave the taper for the roller table straight and oversized. After heat treatment, holding on the now straight roller diameter the top pivot is brought to 0.01mm over final size, the surfaces polished, rivet formed. Flip around and do lower pivot, roller taper, polish. Finally finish pivots in jacot. Heat treatment is a little different than most books or schools teach. I use an iron tube welded to a long thin bar. These are actually CO2 or N2O cartridges from selzer or whipped cream bottles with the neck cut off (about the size of the first two digits of an index finger). This gets filled about 1/3 with fine wood charcoal powder, parts go in, filled the rest of the way. The whole thing is torch heated until glowing orange, then the contents dumped in oil. The parts fished out with a magnet, and they are a nice grey color and very clean. After cleaning off the oil they are blued in a pan of fine brass filings over an alcohol lamp. With the above method there is rarely any deformation of even long thin parts, and no pitting.2 points

-

Hi everyone! I'm a mid-fifties chap from the Isle of Wight, and I finally got round to getting a bit of a watch hobby (oh okay, obsession) going quite recently. As a result, I've been buying movements and inexpensive automatic watches, with a view to collecting and modding/servicing them myself. I am just at the very beginning of getting a feel for working on such a small scale. I really enjoy watching and listening to Mark's videos, and pretty much all I know about the workings of watches so far has been informed by his tutorials. Today I accidentally amused my granddaughter by replacing the hands on a movement so that the hours and minutes didn't work at all; she christened it "Popsie's Nonsense Watch"... I look forward to continuing to expand my knowledge on forums such as this one.1 point

-

My first watch was a Timex as well and recall getting it on Christmas, maybe 1965 or 1966. No idea whatever became of it. Maybe I actually restored it all these years latter without knowing. The sprite will always be smaller than a Mercury or any other of the made for men series. BTW: here is the 64 Marlin out for a ride on the wrist. Although not quite as interesting as a window blind, I added some "eye candy" to the photo for artistic impact!1 point

-

Well... I tried contact cleaner and rinsed with blade oil on Seiko 6309... It worked well... Especially the rust residues...1 point

-

1 point

-

Hi The enclosed PDF's are from Witschi training bulletins and explain the tic/toc issue with the escapement regarding the sounds picked up on their timing machines. They may be of some use to you in understanding the action of the fork and impulse jewel on the roller Witschi Training Course (2).pdf Test and measuring technology mechanical watches.pdf1 point

-

i would place a lathe at the top of the list of things to buy to work on watches. vin1 point

-

As a few members on the forum recommend, pencil eraser works very well to brighten up tarnished hands. Every dial I have touched, with the exception of dusting off with a blower, I have regretted touching.1 point

-

Hi, the visible wear is more than normal (should be zero). But much more likely is a very weak release noise on one side, that is missed by your timing machine: it triggers on the next, higher impulse. Frank1 point

-

I started by getting a few of these kinds of job lots on eBay and starting a scrap collection. And just have fun with them. I've actually never touched a pocket watch. I jumped in at the deep end. Sometimes you find really cool things in these job lots that you end up wanting to restore. It's addictive!1 point

-

Do the best with having cheap Chinese movements... They are on eBay or AliExpress... You can be a professional with these and Mark's videos only for $400... This is my personal cost but I don't think it would be changed so much for anyone... Then you can try on Seiko and Citizen movements like me... You can also find cheap chronograph movements on eBay for $120-130 ...1 point

-

1 point

-

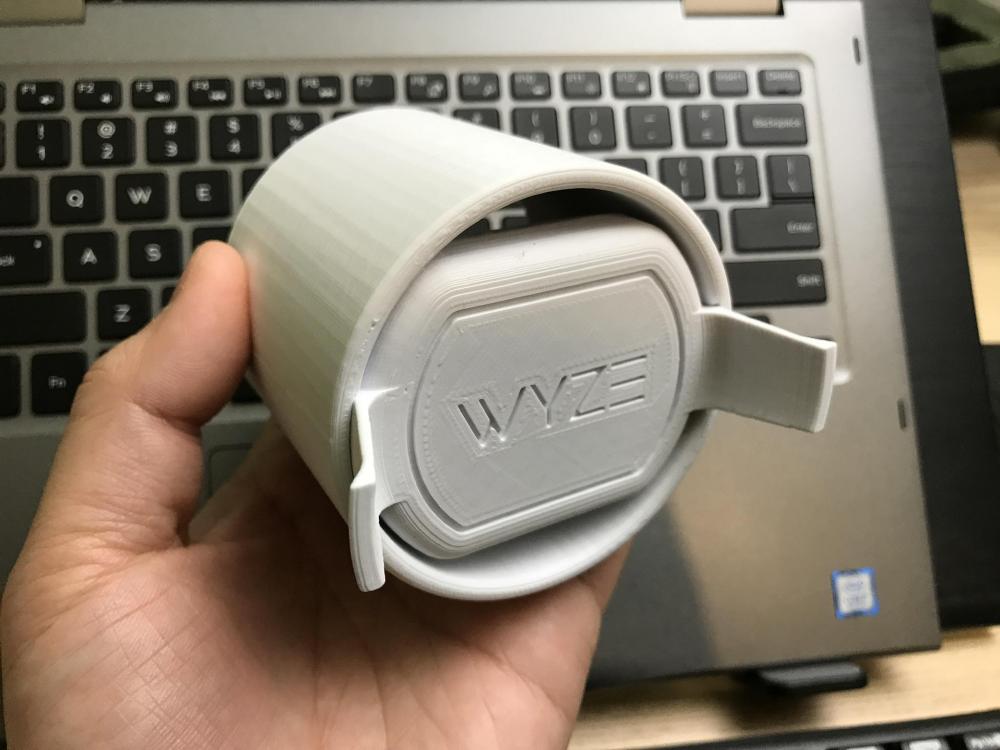

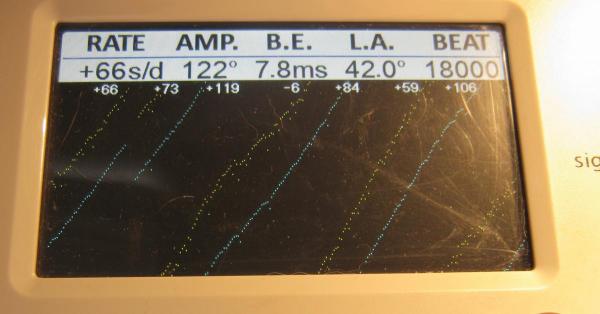

Dear all, I’m Darak Chen from Seattle, WA, you can call me Darak(same pronounce as Derek), very happy to find this professional community, before I found here, I always posted some deep questions on Facebook, like ”Why my timegrapher measurements have big divisions?”, show the measurements data but nobody had replied to me, for sure I repost the same question here, if you know why, please reply, thanks. I’m an electronic engineer, work at a tech company in Kirkland, WA as a product engineer, I have hardware engineering and manufacturing background, so mechanical watches are very attractive to me, I got my first Seiko 5 when I was 18 from my mom as a birthday gift, had it for a few years and the apple watch came out, so I got the first gen Apple watch and gifted the Seiko 5 to my cousin. Four years later, two months ago, my apple watch wasn't holding the charge for a whole day anymore and I missed my mechanical watches, so I got a Seiko SARX055, love the frosted dial BTW, and got some watch tools like a basic watch kit to adjust the bracelet, a timegrapher to regulate the watch, and I found myself really enjoy to work on tiny mechanical stuff. And now I’m really want to learn about watchmaking, watch a ton of YouTube vids every night about watchmaking, it’s so interesting. As a product/hardware engineer, I also start making my own watch winder, I’ll attach some photos and video, it’s still work in progress, using a very affordable Wyze Cam Pan parts and I designed the watch holding part, will start design the enclosure soon, the final product will be a watch winder with a security camera function, everything is 3D-printed for sure. I’m pumped to join the professional community, if you have any questions please let me know and thanks for your time. Darak 2820E31B-CC59-4153-A6E9-4EE0AC187DE0.MOV1 point

-

Ahh... Yes, now I see what you mean! Thanks very much for taking the trouble to explain that eezy, and for the link too. That's great - I'll get one of those ordered and give it a try. You really can't have too many incoming packages from Ebay in this hobby...1 point

-

1 point

-

Very good pic and video, and congratulations on your first balance refitting. There is nothing to complain about the hairsping, raw timegrapher data including amplitude, position deviation or anything else. For completeness post a timegrapher picture next time, as you test more watches you will see that even if running fine, not all present an equally clean pattern on the instrument. But when they do one is even more pleased, as I was with the divers which I prepared for sale yesterday.1 point

-

Great job cleaning it up.. do you have a case ring for it? I have a similar watch and the case ring was cheap white plastic hacked up to fit. Works but not pleasant to look at. Anilv1 point

-

I have considered an old pocket watch conversion project but one thing stops me - nickel poisoning! Most old pocket watches are nickel or if you pay more, silver or maybe gold. I doubt if you would want to potentially destroy a gold watch though. If I wear a nickel watch, within the hour I have a severe rash all the way up my arm and within a couple of days it starts to bleed. Takes about a month to clear up. I think I am an extreme case though.1 point

-

Nevermind, I got it on about the 12th attempt. Never had such a problem before; perhaps this watch just doesn't want to live.1 point

-

Nice , Clean , Classic....Interesting lug design . How about a pic of the back so I can take a gander at the band attachment . Thanks , Louis1 point

-

1 point

-

1 point

-

1 point

-

With nothing to loose and everything to gain, you could most likely fix it yourself. It looks like a Timex viscount from 1979 though others with more expertise can probably be more specific. They are pretty robust and relatively easy to repair. The things that tend to break are the click spring for the winder, but yours winds, the winder stem/crown, but yours is complete, and the balance pinions but this is a Timex v-conic movement, so this is not such a common issue. By far the most common thing that stops it from running, however is neglect. It probably needs a good clean and lubrication, and since this is not a high end delicate Swiss movement, but could be more accurately described as a Dundee mantle clock for the wrist. It is possible to "service" it by carefully giving it a bath in watch cleaning fluid, or even in this case, lighter fluid, followed by lubricating all of the pinions, re-assembling and adjusting it. There is a bit more too this than I describe, but that is roughly what is involved if you decide to attempt to service it yourself. You will need some watch makers screwdrivers, a movement holder, some good light and magnification a small container to give it a bath in, and a lot of patience. A professional watch repairer would probably charge more than the replacement cost of the watch, to service it, but that might not be a problem if the watch is of sentimental value. So are you feeling brave/foolish enough to attempt to fix it yourself, in which case JerseyMo, HSL, myself or any any of the Timex fans can probably guide you through what you need to do in more detail, or would you prefer to leave it to the experts, in which case, I'm sure someone here will know a reliable watch repairer who can service it. I only do this for fun, so I don't service other peoples stuff I'm afraid. If you decide to fix it yourself, this could put you on the path to slightly addictive but very rewarding hobby.1 point

-

1 point

-

1 point

-

Well, progress to SMALLER watches. The dirty little secret is that mechanical watches are actually NOT all that complex of machines. What they are is TINY. A pocket watch movement will be ~50% larger than a wristwatch movement. So it's easier for a beginner because the parts are larger.1 point

-

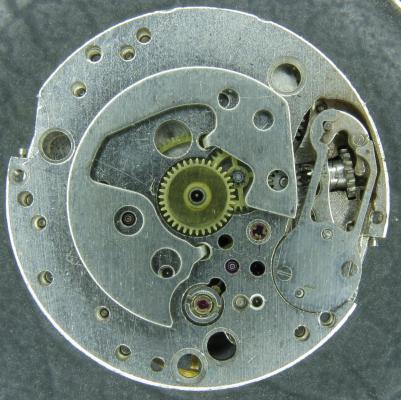

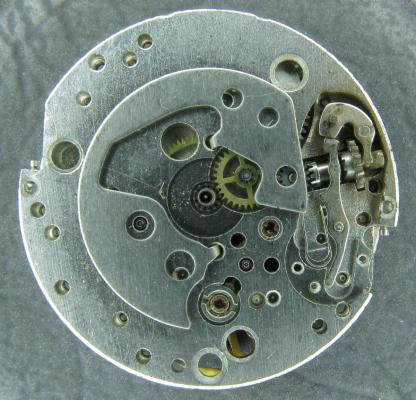

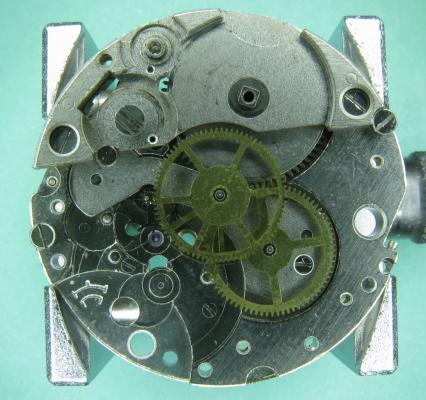

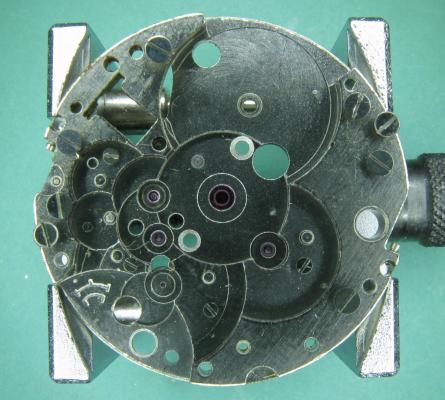

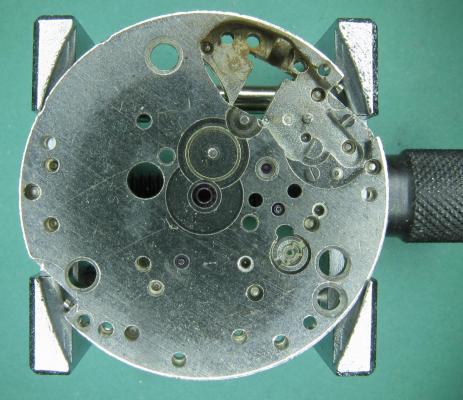

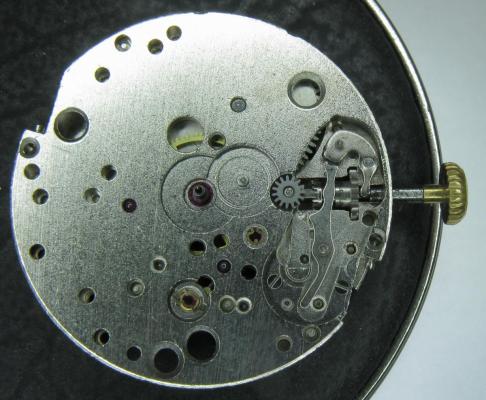

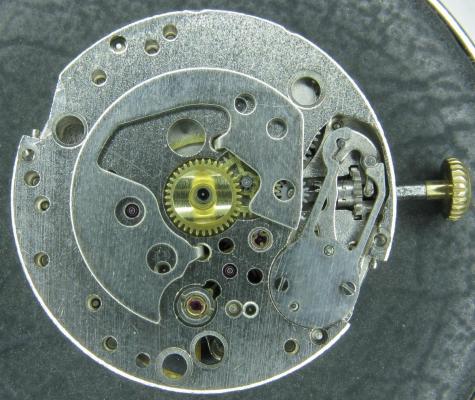

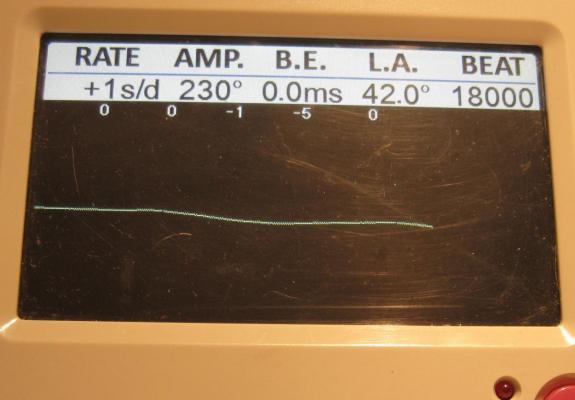

Just before Christmas I sold (through the good offices of eBay) an absolutely immaculate example of a 19 jewel Sekonda hand winder. I was a little sad to see it go as I don't think I am likely to see another in as good order for some time, and having just serviced it it was running like a champ but I couldn't justify holding on to it. Well, shortly after it had arrived with its new owner I received a message through eBay from the buyer. Huw had contacted me to say how pleased he was with his new acquisition, and did I service watches? as he had another example of one of these that was a little stiff in the winder and gained about a minute per day, and he felt that it maybe could benefit from a bit of a spruce up. I have done quite a few of these so am reasonably comfortable with them so I quoted a price and accepted the commission. A couple of weeks ago Huw's watch arrived so I thought I'd do this as a walk through. Looking well used but not abused, Huw had explained that he bought this not too long ago as a stop gap whilst his other watch (a Sekonda quartz chrono) was out of action with battery issues. First impressions are of a watch that has seen a lot of wrist time in its (probably) 40 years. The Timegrapher trace confirms the rate at roughly +60s/day, and confirms that a service is long over due. With the crystal out of the way the condition of the dial is actually rather good. The shadow to the right of the 7 is a lens fault on my camera, not the dial. With the back removed there is plenty of dirt speckled around the whole movement and everything is bone dry. The good news though is that it doesn't look like anyone has messed anything up inside. You can see the spring clip retainer on the escape wheel end stone (a bit like Seiko Diafix but not quite as clever). You can also see corrosion to the back of the bezel, this watch spent a lot of time on some ones wrist. With the movement out of the case the reason for the stiff winder and all of the dusty crud in the movement is brutally apparent. The outer end of the stem has started to rust causing it to bind in the case, and the resulting rust powder is thick on the inside of the case. These cases are a bit prone to this kind of problem as there is absolutely no attempt to seal them even against dust, let alone water, so even sweat on a hot day can seed the beginnings of a corrosion problem. With the dial off the press fit retaining plate for the motion works is exposed along with the keyless works. There's that little end stone retaining clip again, and the Raketa version of Incabloc on the balance. The rust doesn't seem to have got this far. With the set bridge out of the way though there is a hint of rust in the keyless works. Ouch!!! Just in time me thinks!! Balance and cock removed and the hairspring looks to be in good shape apart from the terminal curve which is off concentric. That will need to be sorted or the regulator will distort the hair spring as it is moved. Here also is the shim that Raketa are fond of using under the balance cock to adjust the balance end shake. A bit further in and plenty of gunge under the ratchet and crown wheels. Train bridge removed to reveal the train layout and a sub-bridge for the 2nd wheel. The main plate stripped with the screws put back in their respective holes. I do this so that screws don't go missing in the cleaning machine and I always know which screw goes where. The stripped main plate dial side. And then with the balance reinstalled (minus jewels) ready for the Elma. After a thorough clean everything is ready for inspection and reassembly..... ....starting with the balance jewels. This is when I check and adjust the hair spring for flatness and concentricity, eyeball the beat, check the end and side shake on the balance, and that everything swings freely. If you leave it until later there is too much other stuff in the way. Once I'm happy with it the balance/cock assembly comes back off until later. There is still a little work to do in this pic as the coils are still not quite concentric. The main spring re-lubricated and back in the barrel. This maybe could have been replaced but it wasn't too bad so went back in to help keep the cost down. Barrel, barrel bridge, 2nd wheel sub-bridge, and train back in place. Pallet fork and bridge installed. You can see the exit pallet poised ready to receive a drop of 941 on its impulse face. Walking the pallet too and fro then distributes the oil to the escape wheel teeth. Drop in the balance and away she goes. The cleaned up and de-rusted keyless works go back in.... ...and then the motion works and cover plate. Dial and hands back on, and ready to re-case. Again, to help keep the cost down I didn't replace the crystal with a new one, however, the original was just a little too deeply scored to easily polish out and there was what looked like a very small fracture. So a quick scout through my spares box and I found a second hand replacement which has cleaned up nicely. And the proof of the pudding ... as they say!! At 230 degrees the amplitude isn't anything to write home about but it is a significant improvement on the starting point. A new mainspring would almost certainly help this up into the high 200's (on the watch Huw bought from me I seem to remember it was 300+), but 230 is certainly usable. It is otherwise a nice clean trace with minimal beat error. It has been running for a week now in which it has gained just under a minute, so after a final tweak to the regulator it will be ready to return to Huw. I like these movements a lot. They are well designed and well executed, and capable of excellent results if looked after. They also seem to turn up quite frequently at the boot fairs. Unfortunately though, the lack of any attempt to keep moisture out of the case does mean that they quite often suffer from corrosion issues, and the relatively low cost (both when they were new, and when they turn up second hand) means that they are often used as a beginner watch smiths practice or learning watch, with the resultant butchery that many of us have dealt out as part of our learning curve. It's a shame in many respects, but then we all have to learn somehow. When you do find one that has survived unmolested though they are very well worth looking after. My thanks to Huw firstly for buying my watch, secondly for asking me to help this one to keep going for a few more years, and finally for allowing me to post his watch on here.1 point

-

My progress. (I play guitar = long nails) So i still need to cut the gap and thread it. It is tempered blue steel so what is the simplest way of softening the tread end before taping/dyeing the stem. Sent from my iPhone using Tapatalk Pro1 point

-

Here is my very first stem with this stuff. Is tempering needed? Or good to go? Still need to cut threads Sent from my iPhone using Tapatalk Pro1 point