Leaderboard

Popular Content

Showing content with the highest reputation on 12/20/20 in all areas

-

2 points

-

Yes I'm in agreement unless you've done something to the balance wheel leave it alone. It would only be if for some reason you wanted to make it better than the factory made it. But when you look at the manufacturing information you can see that trying to convert a lower grade watch to a chronometer grade watch isn't going to work because there's other things beyond the balance wheel that makes it a chronometer grade. I had a suspicion about this I gave you an epic novel and you are looking for? Perhaps we should look at the question differently or what is the real question? Learning watch repair is interesting how long do you think it takes to learn watch repair? If you answered a number anything less then forever you answered incorrectly. Yes there are people good at watch repair but watch repair is an ongoing learning process that will take forever. Unless you have a very tiny world then maybe it will occur faster. Real question here is not just watch timing but an evaluation of how you are doing for learning watch repair. This is why for beginners I always recommend a timing machine and a brand-new preferably Chinese clone of the Swiss pocket watch because it's cheap. This way can put it on the machine see what it's doing. Disassemble reassemble see if it still doing the same thing. If you start with a broken watch and it's still broken whose fault is that which is really what this question is all about is it not? As rewind to be using the timing machine to evaluate some of this you should establish a timing procedure. Ideally you should establish a repair procedure especially when you're learning. On the watch comes in you evaluated what do you think it needs for repair to run again? Write it down. Establish a timing procedure yes on a dirty watch if it runs time it. Write that down. Then proceed with the repair afterwords they can go on the timing machine again and because you are so eager initially I would've recommended timing again in 24 hours later but you probably didn't but now is the time to do. In other words timing when it's wound up and 25 hours later like the watch companies do. When you're all through it to repairs look at to do repairs agree with the original valuation? Now you're all done hopefully the watches running keeps time except you're not done?As your collection is probably relatively small this will be easy to do wait a month put it back on the timing machine see how it's doing as you get more and more watches you probably won't do it on a monthly basis but from time to time check your watches how are they doing are they still performing the way they were when you finish to repair. This is where you'll find out if that cheap bottle of used oil on eBay was a worthy investment or not. Or whatever else you're doing good or bad. Always interesting to look at your watch five years from now see if you can even see the lubrication on the watch for instance? Is it even running five years from now. Then I thought I'd throw in a few more pictures balance out all the text. Yes Omega really does have timing specifications of almost every single watch they ever made in modern history. But what if it's beyond that that's covered also so I snipped that out. If you looked at the manufacturing information above or even the timing image you can tell these watches are being timed and three positions so they are a better grade of watch. Then as a reminder there only evaluating for timing purposes which is why they only have one dial position. The watchmaker would've already checked the watch in both dial positions in very likely all the positions.2 points

-

2 points

-

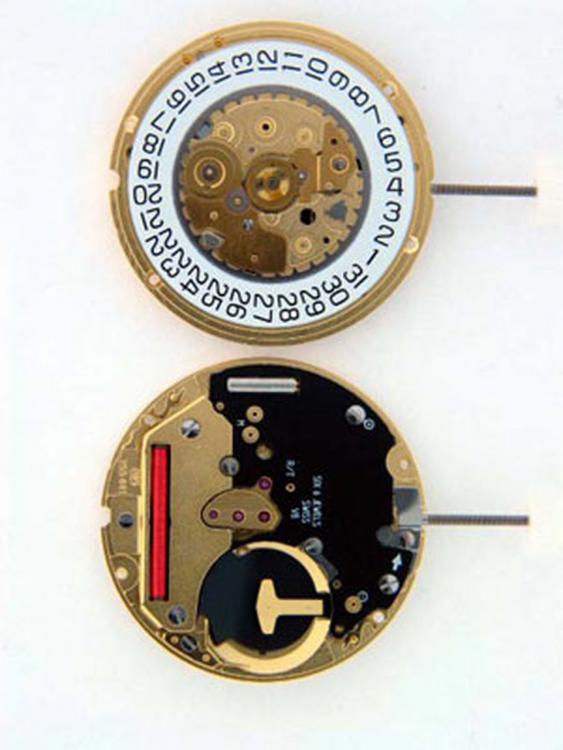

Yes, you have a Dubois Depraz module that's held on by clamps. The dial is fixed to the module with those screws. There is zero tech info on servicing those modules available though Mark does a vid on one version; but zero spare parts available. Most pros hate them.2 points

-

2 points

-

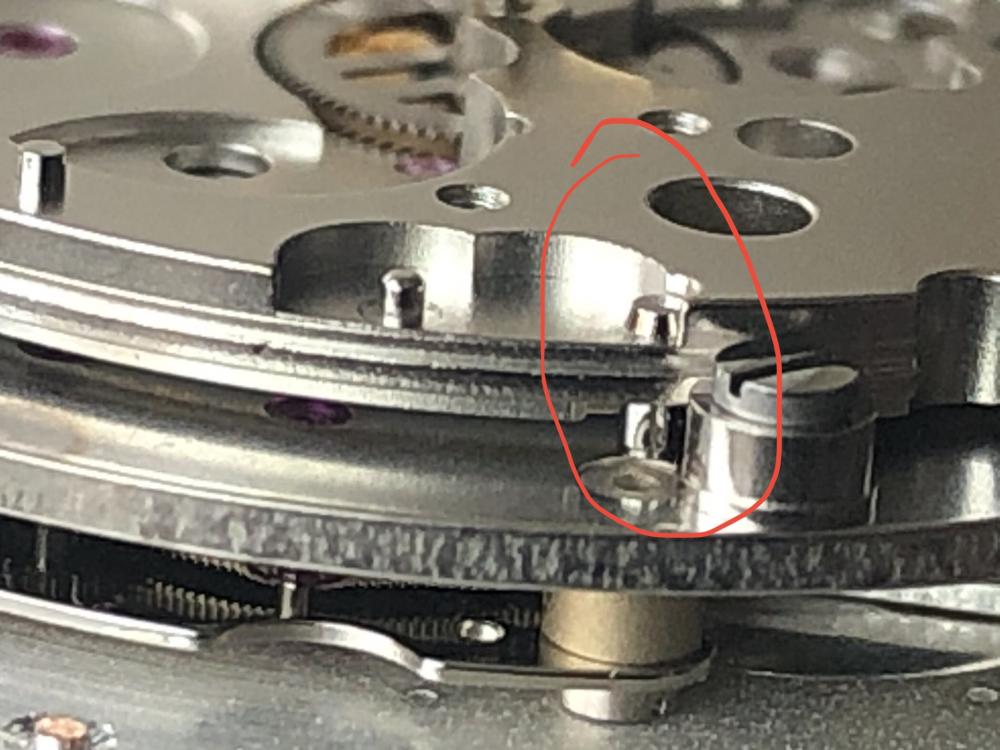

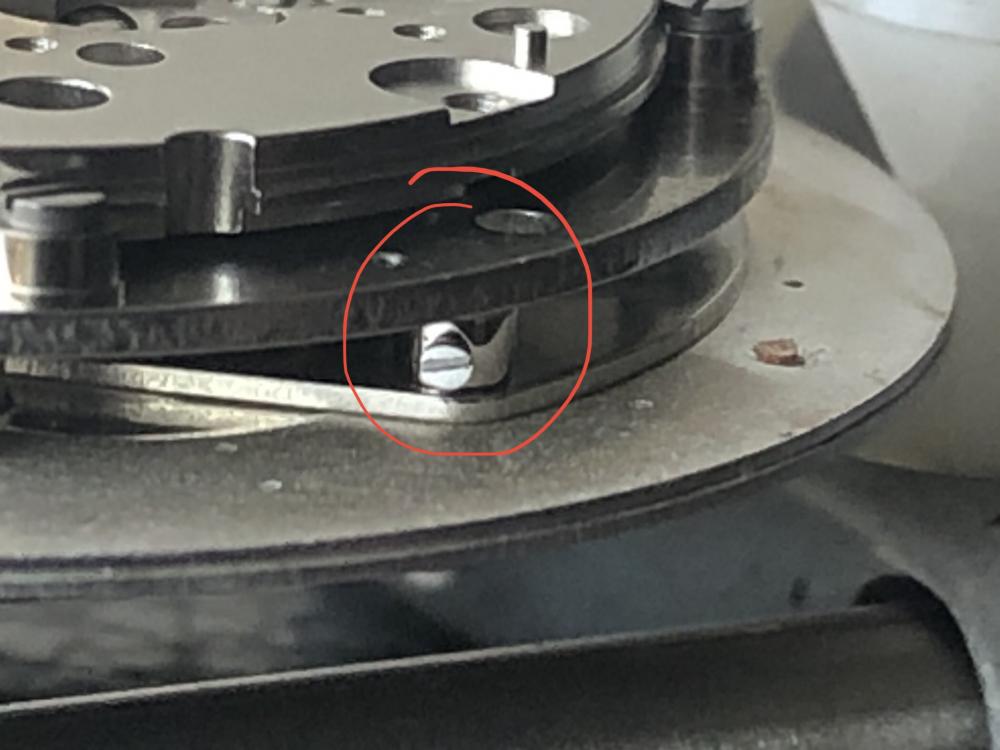

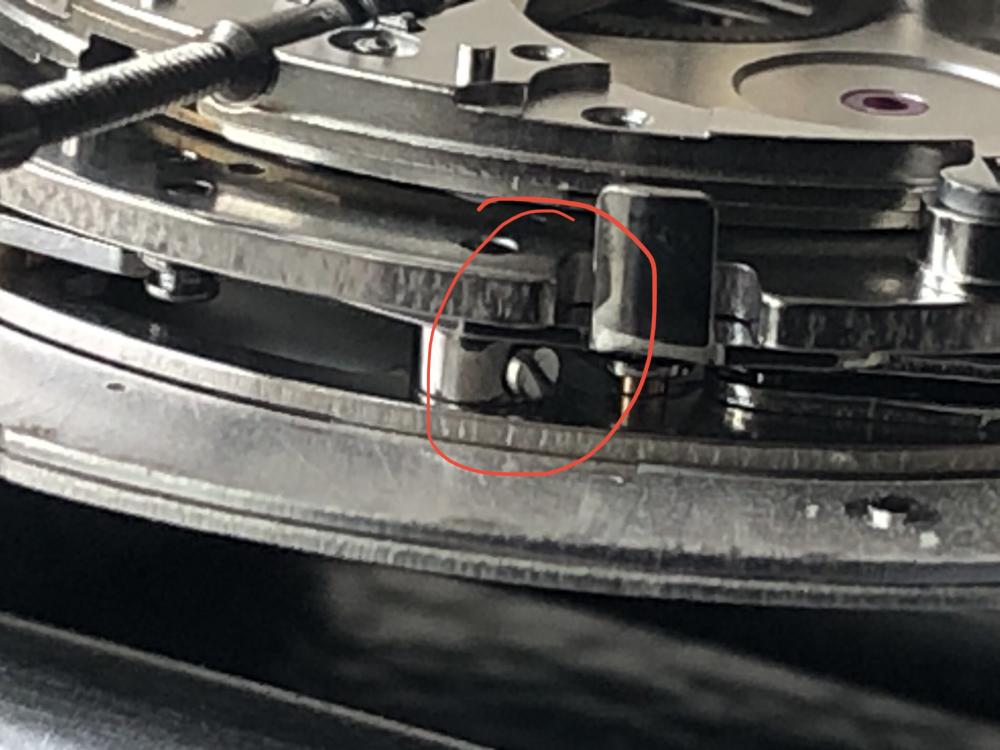

Nicejoe nicely explained the purpose of that lock, Here is how it works: Step 1 - apply some force using a flat screwdriver or something similar to slide the lock to release the dial foot Step 2 - using a pegwood, tweezers, or whatever you prefer to push down the dial foot. This should be done after both locks have been unlocked. You may want to use a flat screwdriver to insert it between the dial and movement plate to separate them gently.2 points

-

2 points

-

Well... That was interesting. Tore it down. Cleaned it up. Interesting movement. First off, the ratchet wheel screw slot was cut at an angle and all the way through on one side. First time I've seen that. The main plate is sort of two pieces, I think for a little intermediate gear, but probably mostly to save cost. In order to clean the balance attached to the main plate, you have to clean the main plate, the 3/4 plate, and the intermediate block separately, then put it all back together and run it through again with the balance installed. That's where the first insurmountable issue arose. Water ingress was an issue in the past, and the very long screw that only threads into the very thin main plate was rusted tight and broke. It was so long though, that I didn't even realize it was broken until I went to put it partially back together to clean the balance. I could probably dissolve out the screw, but then I'd need to be able to make a new one or source a donor movement. The pinion is at an angle to the plane of the escape wheel. Fixable, but I'd need to buy a truing tool or a donor movement. This watch has zero significance other than being less than $5. I got it as a victim on the altar of learning. Looks like I wasn't the first. I tagged it with what's wrong with it, bagged it, and put it in the "art drawer". If I ever come across another of these movements, I'll have a donor movement.2 points

-

2 points

-

One is ETA Caliber 280.002, i believe. Did they come with a bottle of Heinz White Vinegar? You will need it for cleaning as some batteries leaked.2 points

-

2 points

-

1 point

-

This is the motor of the National Watch Cleaning Machine, it seems that the motor cable directly goes to the coils??? I was expecting a soldering point. Never seen such a thing before regardless how old the motor was. I only have about 1 cm left I could possibly use for soldering a new cable and the remaining insulation is hmm seems a bit weary, i must use some heat shrink.1 point

-

Hi There is some sound reasoning and sense In what JohnR725 has said and would be well advised to read and remember, I have been doing clocks/watches for 50+ years and don't know half of it and probably never will . Learning is an ongoing process through life. Just have confidence in your own ability. If you need help ask. no one knows it all' but forums like this cover most bases there is always some one who will have an answer, Shared knowledge, professionals Amateurs, beginners, we all benifit Long may it continue.1 point

-

Beautifull clocks, as clockboy said got to be spot on.. Kieniger Obergefel ( Kundo).1 point

-

Thanks for your kind words :-). Yea, at the end it was "like new", but Man-O-Man, winding that beast feels so different from any other watch. I did everything - from mainspring to the balance cap jewels - cleaned / oiled properly, but due to poor poor winding gear ratio - it is a pain to wind that watch. No wonder one that intermediate crown wheel could not take it anymore :-(. I found small piece deep inside the movement between the mainplate and bridge. What did not help that Cousins sent me the wrong part due to cataloguing error on their website. Then i had to re-order Buren part (identical). Took some time to sort things out. Btw, the coupling wheel (automatic winding component) requires braking grease just like mainspring barrel wall. All extra friction while winding is actually created mostly by this, swastika-like looking, coupling wheel... ?1 point

-

Hi As an add on to the Griener posted by JohnR725 you may find this handy to have. Witschi Training Course.pdf1 point

-

Funny, my only micro-rotor (I think same base movement as yours but with added date and extra jewels) came to me via a similar route, only with an extra "red herring" part to test my patience. Mine also took me a very long time to sort out because I'm a skinflint and didn't want to fork out for new parts if I could source a donor at an appropriate price ?. These are great fun to work on though, yours came up rather nice...1 point

-

1 point

-

Unless you have done some work on the balance (staff replacement, etc), you probably don't need to poise the balance wheel. I have not yet seen a single balance wheel Vostok, Poljot that would required poising or truing. And if you did replace the Staff, poising shall be done with the roller fitted.1 point

-

1 point

-

1 point

-

Also one point is that if you talk about Landeron 48 and other chronos from landeron, they have different versions. Besides shock resistance, they come in 3 different variations in no shock resistance. One of them “annulaire”, has thinned part where you fit roller and next 2 varies in diameter of part where hair spring collet sits. Patience and accuracy of measurement of disassembled balance is critical, specially in case like Landeron. Good luck!1 point

-

It is the trap of this hobby. One becomes many be fore you know it.1 point

-

1 point

-

And here are a couple of pictures to illustrate @Nucejoe's very precise description: https://1drv.ms/u/s!AnVrKJ9agkNWjYpEcJt4OKF9U7e0QQ?e=6XG8vY https://1drv.ms/u/s!AnVrKJ9agkNWjYpCMWlDVrcAFnMH-A?e=1bwt6F1 point

-

Yes if I didn't give you enough to read, I checked one other source I have so I will attach that and snip out something. If the watch companies didn't print timing specifications sometimes it can be found in the books that came with timing machines. After all you have a timing machine what sort of timing should you expect the watches you're trying to time? 1452880703_GreinerMicromatWatchtimingmachine.pdf1 point

-

Finding technical information about watches is always a challenge as most watches don't have a service sheet. Then if they have anything at all It would probably be a parts list this is because watch companies have this silly notion that people who repair watches know what they're doing and they don't actually need a detailed service sheet. Then even if you had anything resembling a service sheet seldom does it have any specifications on performance expectations. The French a very long time ago used to publish books of information on their watch movements. The one I'm currently looking at has a nice section on the French watch industry talks about types of watches how they run but I don't see anything on timekeeping other than a little on the chronometer timekeeping. Then even the movement sheets basically are the caliber size the beats per hour and a rather nice drawing of the movement with some minor technical descriptions but no ratings specifications and strangely enough zero parts list. To give you an idea of what I'm looking at I googled the title and Amazon came up first interesting price considering mine was free a very long time ago which makes you wonder if maybe there is a PDF out there somewhere? https://www.amazon.com/French-Watch-Movements-Technical-Characteristics/dp/B00AQKAW34 Another thing before we get the timing specifications is you should look at performance? My definition of this is the amplitude which also translates to the running time of the watch. For instance you start off with the watch it needs to be serviced wind it up put it on the machine you might perhaps regulate it but with a set mainspring possibly extremely dirty lubrication issues is it going to run for 24 hours? This is one of those misleading things where watch is in pretty bad conditions set mainsprings etc. wound up tight on the timing machine can sometimes look pretty good. Then another thing that will come up with all of this what exactly do you mean by seconds per day? That seems pretty straightforward your question but watch on machine regulates read off seconds per day. Except that's not what the watch companies do? Usually they time in more than one position the better quality or better timekeeping of the watch more positions. Then they usually do averaging. Then I will attach a whole bunch a PDFs for your reading enjoyment first up Omega Working Instruction 81: Basic Checks & Settings of a Mechanical Watch. Before he gets what's interesting in here have you noticed how on all the newer Omega stuff they watermark who downloaded it on every single page in the corner? This one came from cousins material house. Makes you wonder why the watch companies are paranoid over who has their documentation. On page 3 are things that you should be aware of the next page is the timing specifications. You'll notice lots of numbers and this is done with the nifty machine that does this all by itself. In case you're wondering how all the numbers come into existence there is another PDF that comments on how to do all those calculations. Even though your watch specification may be for only one position is always nice to look at the watch in multiple positions. Then basically when you look at the bottom line all the concerned about is the X and the Delta. As I pointed out normally timing specifications aren't usually found in the service information. It's becoming a little more common now but originally it just wasn't there. Except usually were a lot of times it was there was just in another document that you may not have been aware of. So for ETA there the manufacturing information PDFs. I'm attaching Two of them because each of these watches has multiple of grades. Then the 6497 should be recognized by everyone on this group. Scroll through it to get a lot of technical information and finally get to timing. You'll notice that unfortunately if you look at enough of these it doesn't seem to be a universal if it's this grade it will keep this time it varies between the various watches. Or basically each watch has its own timing specifications unless it's chronometer grade and then that's controlled by whoever does that. You'll notice that they also in addition to giving you the specifications farther down they specify how all these specifications came into existence. So basically when you look at the rating is an average of the positions. It also noticed that they're more concerned of amplitude at the end of 24 hours. Then back to your original question is read all the information you'll discover that your original question has problems. Conceivably we could regulate a one jewel watch to keep really good time. But if you look at the manufacturing information you find out that the better grade watches a keep better time keeping have better materials that the made out of. So on the short term your one jewel watch can be regulated that have nice timekeeping but temperature changes long-term use etc. probably won't keep that timekeeping. 8643_WI_81 BASIC CHECKS AND SETTINGS OF A MECHANICAL WATCH_EN.pdf witschi X-D-DVH-Di-Im-N_EN.pdf ETA 6497-1 Manufacturing Information.pdf ETA 2892-A2 Manufacturing info.pdf1 point

-

That locks dial foot in place, hinges open on the pin its mounted on and lets dial foot free to be pushed out the mainplate.1 point

-

The 404 club membership committee (me) debated long and hard, well in to the night and have decided to allow clocks under the extensive 404 club rules and regulations, so here is the first new member under the new rules. A relatively early Metamec synchronous mains, brush finished brass and mahogany mantle clock (serial number 60). I would guess its age as anything from the late fifties to the mid to late seventies, as this model had a long production run, even sporting a later quartz variant, which looks almost identical other than the Kienzle quartz mechanism and a "Quartz" designation on the dial. The mains synchronous motor and gearbox mechanism got a good clean and lubrication and the case, woodwork, plexiglass and brass all got treated to a bath and some polish. I had to re-finish the brushed brass as it was so heavily darkened and the lacquer so badly stained that it looked terrible. I should have taken some pictures of the works of this thing as it is a little more interesting than your average quartz mechanism. Maybe I'll take some pictures of the interior when I get around to lacquering the brass. it is virtually silent and has a nice smooth sweeping second hand, on account of the 50hz "tick" from the mains. It should be fairly accurate apparently, but that all depends on how well my local mains frequency is maintained. As you can see I added a modern two core moulded plug mains cord in place of the slightly dodgy looking existing wires (which were black and red, suggesting the thing was originally wired before the early 1970s). I should really use a 1A fuse, but I only had a 3A. I'll pick some up next time I'm ordering stuff.1 point

-

I’ve always been fascinated by accuracy and based on the video lecture linked to in my previous post, and without really being aware of it, precision as well. So, my thought is that any healthy movement can be reasonably well regulated to be accurate to its owner, even in the case of a movement with a specification of -20 to +60 sec/day like my much-loved Vostok movements. As a matter of fact, I have a Vostok caliber 2409 which on average gains about 3 seconds per month, provided I wind it and wear it consistently not subjecting it to any extreme motions of my wrist. However, in the various horizontal and vertical positions it varies between -25 and +17 seconds per day which is sort of better than the specs but still far from chronometer grade. During a short interval of time, say a day. It can be off by several seconds but over the span of a month it averages out to about 0.1 seconds per day. It’s really a bit of a miracle that I’ve been able to move the regulator arm to a position where it so precisely matches the way I wear it and wind it. The way I understand it, the specifications of a movement doesn’t really specify the accuracy of the watch and not really its precision either but basically just its extreme rates depending on the position of the movement. If we wind a movement consistently and keep it in the same position, most healthy movements will be very precise, although a chronometer grade movement even more so. The way I think of it, to achieve precision, the flow of energy from the mainspring to the escapement must be constant as possible and the escapement adjusted to perform equally in all positions. This is of course extremely complex with several interacting parameters and it’s a topic far beyond my present level of knowledge. Anyway, one especially important factor to achieve precision is the poise of the balance wheel. For example, with my mentioned Vostok movement I’ve observed that in pendant up position the rate is +24 seconds per day whereas in pendant down position the rate is -25 seconds per day. This could be the result of many factors, but to make a long story short, in this case I am fairly convinced that it’s a clear sign that the balance is out of poise. I have ordered a poising tool (still waiting for it) and will attempt to improve this imbalance through static poising. If I succeed my watch will (at least momentarily or I'm afraid likely permanently) become less accurate but hopefully more precise and the watch geek in me more satisfied and happy ?1 point

-

Yes a 400 day clock. Simple in construction but everything has to be spot on for it to run over a period of time.1 point

-

https://www.ebay.ca/itm/ANTIQUE-CLOCK-MOVEMENT/353322498900?hash=item5243a97b54:g:HQIAAOSwrDxf24pM (missing pendulum). https://www.ebay.ca/itm/ANTIQUE-C-1900-BLACK-SLATE-CASE-SINGLE-TRAIN-MANTEL-CLOCK-FOR-RESTORATION/293872292998?hash=item446c275486:g:JusAAOSwKGxfyOD7 (also missing pendulum) https://www.ebay.ca/itm/Antique-Brass-Clock-Movement-Repairs/264981328031?hash=item3db21e309f:g:QWoAAOSwYGNf3Kdl https://www.ebay.ca/itm/Interesting-8-day-Regulator-style-table-clock-with-centre-second-Bracket-Clock/303812254910?hash=item46bc9f1cbe:g:25oAAOSwUupf2TC9 (would be cool if you wanted to do a platform escapement clock, but isn't good if you want to study recoil escapements).1 point

-

in case wear has shortened pivot so its shoulder rubs on jewel setting/ housing hole, one can instal end stones dome side facing the pivot to compensate for the wear, it also reduces endshake. You will notice the pivot rubbing on jewel setting if you were to put the end stone back flat side facing the pivot.1 point

-

1 point

-

I can’t answer your question but there’s an interesting difference between accuracy and precision very well explained in the following video:1 point

-

1 point

-

The Metamec synchronous mains clock arrived, so I stripped down the case and the brass work and cleaned it up. Its a hefty beast, and scrubbed up very nicely. I didn't appreciate from the auction pictures how it should look without all the grime and filth. The brass was black. Maybe it spent its life over a coal fire mantlepiece. I'll tackle the mechanism tomorrow, check it for electrical safety and fit a new cord and plug if I have the time, but here is a quick before and after shot. The plinth and the pillars need a quick kiss with some shellac button polish, and I'll strip and lacquer the brass properly when I have it running, but I must admit its actually a very attractive little clock, and they certainly didn't skimp on the brass, it weighs a ton.1 point

-

rotary avenger 17 jewel This is watch repair the word never doesn't always seem to apply. The reason why never doesn't really apply is that over the years some watch companies have produced really nice service manuals which spell out everything. Others do manuals only for unique stuff and in other cases you're lucky if you get a parts list. This is why it's always important when asking questions to give model numbers not generically say rotary avenger 17 jewel Because yes I searched online and didn't really get very far. Another thing important to remember digital technology can be your friend like digital cameras or phones that have digital cameras. There's a lot of things that you should be using your brain for like why doesn't the watch run rather than wasting your brain on how to fit parts that you could just taken a picture on.. Is a lot of times I've been very happy if I took a picture of something just because.1 point

-

Do you hold the block of wood and move it carefully with your hands. I do want to keep my guitar fingers.1 point

-

Any of the common French names pre-1900-ish should be decent. A common name is Japy Freres.1 point

-

1 point

-

Wear mostly occurs due to dried up oil, when the wheels rotate in dry holes dirt is also present and will cause sometimes wear on the pivots and its more common to the holes, brass is harder than steel. The more modern the clock it is more likely to be what looks like brass, certainly not the real hard stuff from way back. I have restored hundreds of long case clocks which are weight driven and wear occurs in both plates. I can tell you central heating is not good for any clock as it a form of dry heat and will soon cause damage so never stand or hang a clock near gas/ electric radiators.1 point

-

1 point

-

1 point

-

1 point

-

I've not stripped the pocket watch down completely but I think the bushing is probably all right, however there is an issue with the mainspring barrel. Either the barrel arbour is shot, or the spring is, as the thing doesn't take any tension. It feels locked solid. Initially I thought it was simply fully wound, and the reason for its inability to run for more than a few seconds was down to the hairspring. However I have just un-jinked the hairspring and taken another quick look at things, and I discovered that I couldn't let the mainspring down. I gently released the tension, and it moved about 1/8th of a turn then stopped, and it wouldn't wind. I then removed the winding gears, but it was still locked up, so it is time for a complete tear down. Since I will need to strip it down completely anyway, I'll take a look at the bushing and all of the jewels etc. then. I also need to go through my stash and see if I have a suitable stem, or can adapt one of the ones I have. I'm fairly certain I don't have a suitable crown. Not that I have the time to do any of this tonight though. Perhaps over the weekend. I also took a quick look at the other Rotary in the bundle. This is a tiny ladies two hander, and other than a few minor signs of age, it seems to be running fine following a very quick clean. I didn't do a full strip down, on this one either as I had a bunch of other household tasks to complete, and besides, I need to be "in the zone" with no other interruptions or distractions, to strip down and re-build anything this small.1 point