Leaderboard

Popular Content

Showing content with the highest reputation on 10/01/20 in all areas

-

I hold my loupe up against my phone and then adjust distance to gain focus. No added stuff to buy.2 points

-

Stud holder is fixed in eta900 and hairsprings came in flat and bereguet overcoil versions, either way if your BE is stemming from wrong H/S and impulse pin mal- adjustment then adjusting would be a pain. Just because it is a NOS doesn't mean its the right one, the new mainspring can be too strong, usually MS coil should cover a third of barrel bottom surface area, if strong the mainspring is thick therefor covers more than third of the area. A NOS balance complete can easily have got magnetized or dirty/sticking. I test the tg, just test a healthy watch on it. You can also bench test the watch, put the hands on, despite no dial and cover the watch, check its time kerping over a day. So, I make sure balance complete is the right one, demaged and clean. To check for sticking which mostly is a case of intermitent, video it while running and check at slow motion is best, but to sit there and count the beats on video shorten your own life. Good luck2 points

-

Then just a reminder notice your beat error of 6.9 ms and the graphical display looks pretty decent? Because of the size of the graphical display it will only display up to about 4 ms in that it has a rollover error Which gives impression that you beat looks really nice but the numeric rate is probably correct And the display was much bigger those lines would be really far apart. Out of curiosity how did you lubricate the escapement? Then I was looking at the parts list for this watch to see if there is any variation in or indication of different beats and there didn't seem to be any variations that way. There were variations for height of parts on the dial and from the link below the As usual with an older movement looks like variations but no indication of variations for timekeeping. Why did you get a balance complete for the watch? Then a little about the history of its condition before you started servicing it? Didn't run for instance? http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_9002 points

-

Try setting your timing machine to 18000 bph manually, then see what you get on the screen. If you have slo-mo on your phone, use that to check amplitude and frequency.2 points

-

2 points

-

The green mats are drafting table top. An art supply store should have them. And they’re green. I have an IKEA desk top, lifted on blocks, which sits on an old kitchen table in the basement. Overhead I have an LED shop light from Home Depot. I bought two, thinking I’d need more light but one is quite bright. Im 6’2” tall so hunch over to work but it’s not uncomfortable. The top work surface is huge (I have a tuner and cassette deck piled up on top along with all my tools and parts). I could make it another 2-4” higher but it’s working and cost was very low.2 points

-

I think that the course is excellent in that it sets a high benchmark on how work should be done properly and also goes into a decent amount of depth in the theory. I did mine largely at home, but did do some of it at an accredited school. I think two years is a reasonable amount of time to cover it if you also have a full-time job. I think it's fair to say that it is fairly challenging. Many people who I started out with dropped out - especailly those who were not interested in learning the theory. A. For practical work, it was useful to be shown in person how to do things. Even something simple like someone saying that your vice is at the wrong height for filing flat. B. For the theory, not really. C. Yes. The exams force you to read get clued-up on the material. D. No problem. You'll just need a small lathe, decent vice, quality files, scriber, centre-punch, Sharpie pen, piercing saw and a full set of drill bits. E. I believe so. You could purchase older revisions of the material to learn and just sit the exams, but it's not easy to get a hold of. F. I can't really comment as I have not done Mark's course. Remember that the BHI course also includes clockmaking material which does cross over to watchmaking when it comes to making/adapting parts and making tools. It covers topics like metallurgy in good depth which a lot of people seem to be lacking in.2 points

-

1 point

-

Hi all, I am on the cusp of making a significant investment in the BHI DLC, Technician Grade. I live in Toronto, and while there is still a watchmaking school in Canada, dropping everything I'm doing and moving to Trois-Rivieres, Quebec, is not really possible at the moment. I am interested from people who have taken the correspondence course. I want to hear all details, but I'm particularly interested in: a) Was the tutor option worthwhile, if you bought it? b) How much did you miss in-person instruction? c) Did you do the exams? If so, has doing so benefited you? d) How did you cope with workshop / space issues for the practical exercises? e) Overall, is the course good value for money? f) Did you learn much that you did not learn from Mark's course? How much material is going to be redundant? Again, I would reiterate that I'm simply not in a position to move to a town with a watchmaking school at the moment. So while I appreciate that in-person instruction is undoubtedly best, the question is, given that it's not feasible immediately, am I making a worthwhile investment by taking the DLC? Thanks, looking forward to hearing from you. John P.S. If you also live in Toronto and the surrounding area and are interested in forming a BHI "class," message me!1 point

-

1 point

-

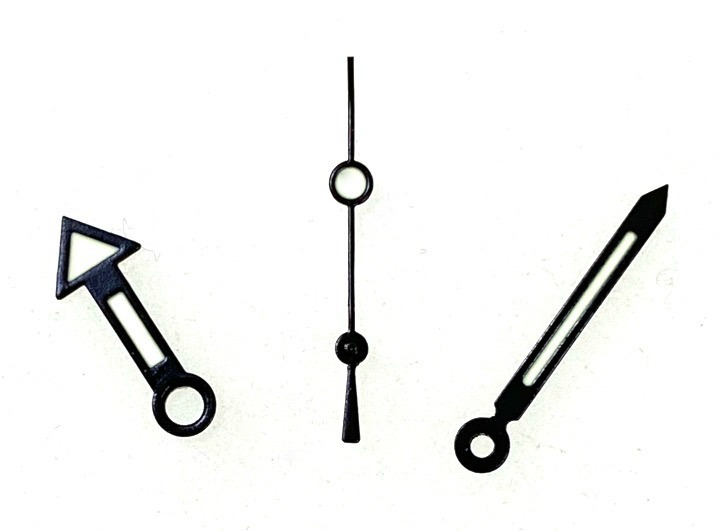

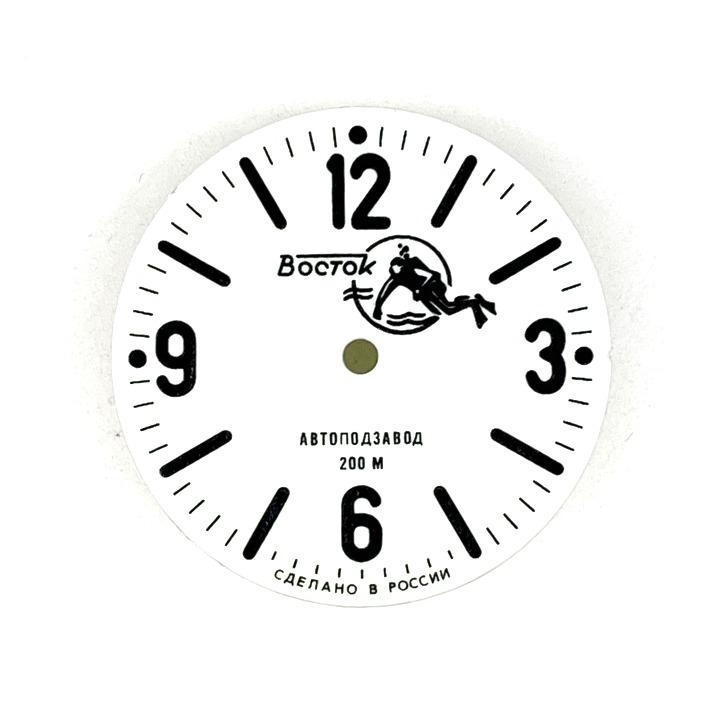

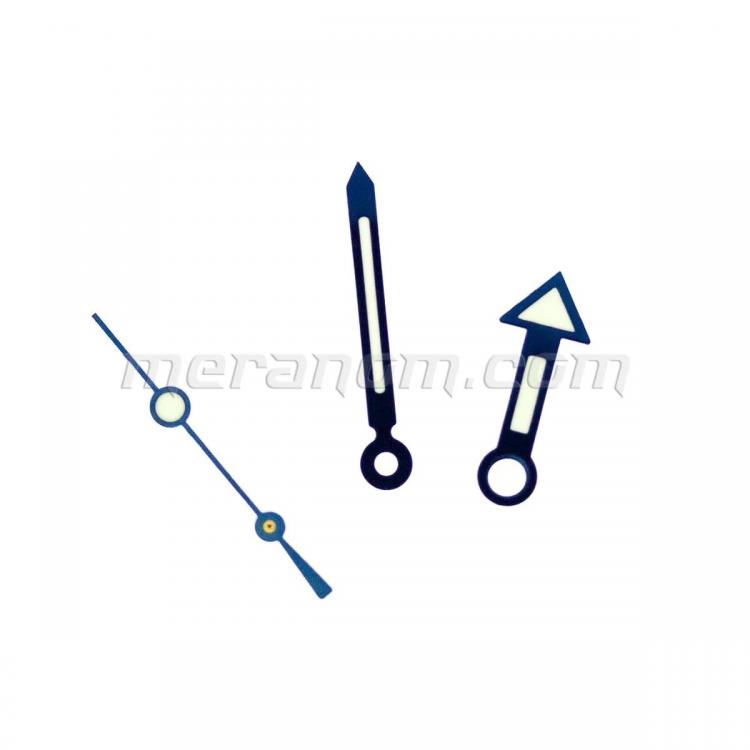

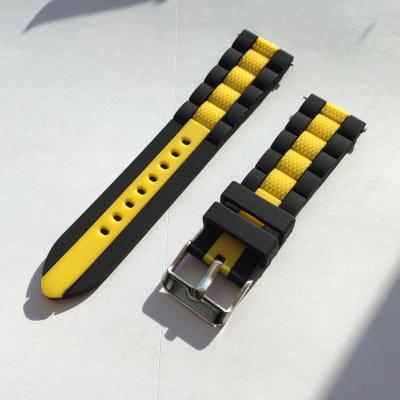

So, I've enjoyed assembling and modding ETA 6497/6498 and Seiko watches. I realized last night that I wanted to buy a true "beater" watch -- something that I'd like wearing, but that I'd trust to be waterproof and rugged enough to wear everywhere. My wife commented yesterday that I frequently don't wear a watch despite having a nice collection, and I realized that it was because I'm really worried about damaging my really nice watches. Even my most rugged watch, a Seiko SKX779 black monster, has a lot of sentimental value and I don't want to beat it up any more than I already have in the ten years I've owned it. As I've never owned or worn one of the Vostok watches, I decided to buy one. The specific model I was most interested in wearing, a Vostok Amphibia SE with a fully lumed dial, was sold out. No worries there, as I realized I could build myself something equivalent or better -- taking advantage of all the cool variations of case sizes and shapes that are available. Here's what I have coming in the mail: A "tonneau" case Vostok Amphibia 090662 (~$64) A compatible fully-lumed dial (~$22) A "heat blued" set of Vostok Amphibia hands (~$6) An all black set of Vostok Amphibia hands (~$5) A 22mm mesh bracelet (~$8) A 22mm black silicone strap (~$8) A US-made upgraded stainless steel bezel that can accept Seiko SKX007 bezel inserts (~$37) My plan is to swap out the dial and hands first. I think that the all-black hands will probably look best, but I'm super curious about the quality of the "heat blued" steel hands. I've been learning how to heat blue steel myself, and I'm dying to know what a $6 set of heat blued hands from Vostok are like. I'm a tiny bit suspicious of them; given the premium charged by other manufacturers for real heat blued steel, $6 is a huge bargain. For the all black hands, I'm very tempted to pull out the lume and see how they look as "skeleton" hands. I haven't settled on whether I'll keep the stock chromed-brass bezel, or whether I'll like the SS bezel with a Seiko insert instead. I'm not looking at a super fancy sapphire or ceramic bezel insert, but want something that matches the overall aesthetic of the watch (with its industrial-finish steel and thick acrylic crystal). In retrospect, I probably shouldn't have bought the US-made upgraded stainless steel bezel until I become 100% convinced that the chrome-plated brass Vostok bezels aren't what I want. Since they're readily available used for just a few bucks each, it would have been smarter for me to have just tried a couple of those options first. Adding the SS bezel (and buying a Seiko bezel insert) will push this watch out of cool-but-cheap-enough-to-beat-up sweet spot I'm looking for. Also, if I had just purchased the watch, dial, heat-blued hands, and mesh bracelet, I would have come right in at a total cost of $100. As purchased last night, I spent $150. With one of the fancier Seiko bezel inserts, this climbs to $200. ? The base watch: The fully-lumed dial glowing and under normal light: The heat-blued steel hands and the black hands I'm thinking about skeletonizing:1 point

-

As you're new to watch repair I will start off with the basics. The basics are people new to watch repair look for problems were they don't exist in other words it's usually the simple things it's usually the basic things but those are not the things you're ever going to see. Then changing components doesn't always have the desired effect of improving things. Unfortunately if you mutilate the balance wheel you have to change that. But changing components has consequences unless the watches super new were manufacturing skills are almost perfect and you can swap with usually zero problems. Soon always empty careful in changing components as you can introduce new problems. Then the mainspring yes the white springs can be stronger than the blue Springs but it usually isn't a consequence. It's a much bigger problem in American pocket watches where once you might have five different sizes and now you just have one and it's probably too strong but even there it usually isn't a problem most of the time.. I snipped out a section of the mainspring catalog to the sizes listed agree with the size the mainspring you put in? Where exactly did you purchase your new old stock balance wheel? Then unfortunately I don't have a cross reference to the number you have plus if it's a different size it's not the balance wheel for your watch. As the diameter is wrong I don't suppose the roller parts are wrong in size also? Like the safety roller the roller table the roller jewel are they physically different? Also it be really nice if you could get a close-up picture of the balance wheel in the watch for us preferably one looking straight down and one looking sideways. Along the lines of basic problems balance wheels fall under that category it is really easy to do things undesirable here and it is exceedingly hard to see those things by just about everyone on this group.. It's one place where you have to really really pay attention because there's a lot of faults that are very bad under very hard to see. If your balance wheels physically smaller is the hairspring physically smaller? Visually when you look at your balance wheel in the watch does they hairspring appear to be centered, is they hairspring going to the regulator pins is it flat is it touching anything it's not supposed to. If they hairspring is physically smaller you going to have issues with it being where it's supposed to be for the regulator pins you're going to have issues. One of the things nice to do with incoming watches is to attempt to determine why it's not running. As opposed to assuming that cleaning will fix all problems because many times there were pre-existing conditions as to why the watch wasn't running and cleaning doesn't necessarily fix those problems. Then a new updated picture of the timing machine where it's showing you nothing that's because the timing machine is trying to reach out and communicate with you unfortunately it does not have artificial intelligence to do that correctly. The same as your original pictures you need to visually verify that whatever the machine is telling you the watch appears to be doing the same thing.. So if the amplitude looks like it's super superhigh visually it should look like at superhigh. Occasionally it's more common problem with Chinese machines but it will happen to all timing machines if the amplitude is super low for instance it won't numerically look to be super high. This is where missing features from the Chinese machine would be helpful if we had such as the oscilloscope where you can look at the waveform and see where the timing machine is attempting to pick up the signal. Because oftentimes you'll find is looking at the wrong part of the waveform so if your timing machine says you're doing 300° that balance wheel better look like it's doing 300° otherwise you have a problem.. So the basics would be let the power off get us some photographs.. Visually verify the watches in beat. Look carefully at the hairspring if necessary look at another watch or look at several watches as I said it is really really hard to tell if they hairspring is flat and where it's supposed to Be. Then one little warning about stock? Typically and watch repair especially if you buy from eBay if the package has been opened there is no guarantee that at actually is new old stock despite what the seller might think.. It's a common practice of watch repair people to put the old part back into the package so any opened packages should always be suspected that they're not correct.. Unfortunately this also does not apply to watch repair there's been other things I purchased off of eBay that were listed as new old stock and they were definitely not because the seller wasn't paying attention in my case I wasn't paying attention to the photos either I took them at their word.1 point

-

I don’t understand how we can conclude that the new mainspring is too strong. Your timegrapher is unable to capture a trace which quite possibly means that the vibrations are either very far out of range in frequency, or the impulses of the escapement are too weak to distinguish. Either way, the trace is close to useless. What you may be seeing for the brief period of time when it does appear to capture is the effect of aliasing. An example of aliasing is when a video of a helicopter rotor looks as if it is turning very slowly as a result of the capture sample rate which may be 25 or 30 frames per second. If you are unable to monitor the rate of time via the hands then is it easy enough to listen to the watch beating with your ear? You could compare to a known-good 18,000 movement and see if it sounds way off1 point

-

Well, you are welcome to post questions here, or post photos of work you have completed. My practical tutors were absolutely brutal with me and told me when they thought my work was crap. That’s an old-fashioned way of teaching but I personally find it works.1 point

-

Hi Mark the only ones found are the AS 577 as 530 I have attached both in the hope they nay be of some use to you AS 577.301 and eta 277.001.pdf AS 530.101.pdf1 point

-

I would not suggest to proceed with converting am M31 to M107. I should have an NOS M107. Where are you located?1 point

-

Hey I wouldn't want to rush into things and blow a shed load of cash on just one watch. ? Admittedly I appear to be going slowly bankrupt in two quid increments... ? but I'm having fun doing so.1 point

-

Not that I know of, no non- invasives way. I agree all things being equal...... but at production line, balance wheel are vibrated with hairsprings which may differ in length or CGS to produce a desired beat. I am not sure if oiling fork pivot would reduce force of impulse enough to get an acceptable amplitude. What should the amplitude be? Do you have a datasheet?1 point

-

1 point

-

Check the picture of the example on fanfft for some clues as to how the balance should look. Is the regulator arm miles out from the example. Check for fouling hairspring, sticky hairspring, end shake etc. Finally, if you suspect the balance may be the wrong one for the watch, and you have the original balance, If you have some very accurate scales, then compare the weights of the two balances (removed from the cocks, as these may skew the results). If they differ significantly in weight, but are of similar construction and diameter, then it is may be the wrong balance. This is not necessarily going to be an accurate test, as it takes not account of the strength of the hairspring or the geometry of the balance. You really would need to check the balance more accurately to determine how it oscillates to be sure.1 point

-

I am under a self-imposed ban on new personal acquisitions - no imcoming timepieces unless they are a repair commission or for sale. I thought it best. I already have five antique pocket watches, four newer mechanical ones, six wrist watches, and throughout the house are numerous clocks, three of which chime. Somehow, God only knows, at home I have learned to tell time in my peripheral vision, because clock faces almost litter the landscape. I am acutely aware that if I am ever late for anything, it better be something like a flat tire, because nobody who knows me would believe anything else.1 point

-

I have a collection of watches of all types but only ever wear one or two, the day watch is a Lorus quartz lumibrite day/date. No an expensive one, but it stands up to the daily hammering without complaint.1 point

-

1 point

-

Hey John, I completed the technician's grade a few years back and worked my way through year 2 and 3. I've done final exams last year and only have the record of repairs left (not needed for year 1). I'm taking much longer with that since I have periods of being busy, and periods where I seem to lose all interest in watchmaking, until it flares up again. Self discipline has never been my strong suit -- even though I was pretty good at getting myself through the rest of the DLC. I'm in Singapore btw, where my hobby is seen as crazy/outlandish. a) I used a tutor, and would recommend it. It was the only way to getting any kind of feedback on practical parts and theory for me, since I know nobody IRL who's into technical horology. b) Very much, but no choice. c) Yep. Benefited only as a personal accomplishment. d) I'm lucky enough to have a spare room for a workshop, with equipment for horology, metalworking and electronics. All tools were painstakingly gathered over more than a decade. e) Hard to say, it depends on what you want or expect, and on your personal situation. Prices have increased sharply since I started things. This is not a cheap hobby to begin with, if I look at my tooling ? Take classes at Upton Hall for example. They sometimes have a class that I'd love to join, even though it costs like 400+ pounds for 3 days, etc. All moot anyway, since I can't just drop by.. f) I haven't done Mark's course, but I love watching his videos. The two courses are very different, with the DLC being more thorough and academic, and Mark being more hands-on. The DLC teaches basic metalworking skills in order to start making parts, but none of the tutor-related communication involves feedback on actual watch work that you may be doing. The first feedback you'll get is when you service a quartz watch for the exam, which is kind of crazy. Many people complain that the DLC includes quartz watches and clocks. I found that high-end quartz watches are actually not bad to work on, and I like clocks anyway. I've picked up several tips and tricks over the years from watching Mark's videos. If Mark's course was available 10 years ago, I probably would have started with that, if it wasn't too expensive (no idea about pricing). One thing I value is that if I would ever start taking in repairs for customers, being recognized by the BHI would be a good thing. Back in the days I was looking into doing a WOSTEP course, but I was not in a position to just drop everything and be off for two years, just like yourself. I also had and have zero interest in working for some big watch manufacturer doing part swaps on the same model all day. Cheers, Rob1 point

-

Hi, I attend a horology school which runs various classes every day, and they decided that they would run a weekly class to cover the BHI material which was covered by two tutors over two years. I don't think it would be easily possible to ask a similar institution to do something similar, if you could find such a thing. I just used an 8mm watchmakers lathe. If I were you, given your geographic location, I'd try to get an American WW-pattern lathe. They are usually built like tanks. An ER collet set from China which fits a standard 8mm drawbar expands what sizes of material you can mount if you are short on conventional collets. I reckon you could probably get a decent lathe for maybe around $300 US if you look around.1 point

-

And this is listed as an Autavia... https://www.classicdriver.com/sites/default/files/styles/two_third_slider/public/watches_images/21801-07efe993f0e6e4256151008b401a329c_4.jpeg?15949883111 point

-

@rodabod thanks for a really detailed response. Two follow-ups. You said you did part of the course at an accredited school. Does that mean you just contacted a school and asked them to teach you some practical skills, like using a lathe? A second question, about the lathe. Were you able to get by with just a standard small lathe, or did you also have to get a watchmaker’s lathe? I’ve seen pretty cheap microlathes new, but even used 8mm watchmaker’s lattes are topping $1000 Canadian, and I know nothing about the condition of, e.g. bearings.1 point

-

Great project! Id very much like to have one of these old alarm watches. This, the omega or another. Great job getting it going. If you check the pinion size you can probably find a generic gold hand the right size, or slightly off, to be broached, or closed in a pin vice, to fit perfectly.1 point

-

1 point

-

I can’t see that clearly in the picture but the springbars should absolutely be replaced. The “adapters” should be carefully checked to be sure you don’t dump the watch unexpectedly. Im not able to measure the oyster mid link right now, but if it fit, it would open up a lot of aftermarket bracelets since it is widely copied.1 point

-

I don’t know about that movement but the ETA 2784 had two beat rates and the wrong balance wheel makes for an interesting afternoon...1 point

-

Is the balance vibrating too fast? Sticky hairspring? Hairspring bent or fouling something?1 point

-

1 point

-

Well, crystals, crowns and gaskets are the parts you will need the most of. Most retailers sell a gasket assortment, with the ability to replenish the ones you actually use. I think that's a good idea if you are servicing a wider range of watches. Crowns gets tricks fast. For example: Omega screw-down crowns are quite specific with their tube and crown combinations. And their numbering system is cryptic, so you must have the case manuals to get the correct part numbers to order... The non-screw down crowns are a bit easier- just measure the tube, make sure the crown ID clears it, and pick the height and diameter that fits the watch style. But you will always need gaskets/o-rings for them and Molykote 111* to lubricate the gaskets. *Not Molykote DX. 111 is pure silicone lube (quite thick) recommended by Parker for lubricating o-rings. I have one tube which is about 3.5 lifetimes supply...1 point

-

Hi Depends on the composition of the rubber some are softer and absorb shock and the hard ones stuff bounces on, The cutting mats are really quite good and relatively cheap, If the grid markings are a pest they can be rubbed off using Isopropyl alchohol, I did that with mine and now have a plain green mat.1 point

-

All these, and few more like gaskets, batteries, standards crystals, decorative stones, etc, are very good to have, especially if you take take watches for repair, as can happen when you give your nice business card to jewellers in your area. You will be spending initially, but then able to complete many jobs quickly. On the other side if you are an hobbyist and don't mind waiting for each order then you save buying parts individually, and won't have stuff taking space for no good reason.1 point

-

If in good shape some used parts work just as good as new, I go for new parts if the watch is pricy high grade and the part is senative, for instance new escape wheel and pallets even if the old one might still work, but a dial washer hardly matters as long as the right size and got the bend. I suggest getting parts as you need them and suspect these assortments to be out of parts no longer in demand. Regards joe1 point

-

Dial washers, case screws and stems are generally quite unique to a particular movement. Unless you work on the same (or, at least same family) movement all the time, these things are a case-by-case purchase. I work on Eta 27xx and 28xx movements and they use different stems, but the case clamp screw size is the same. Clamps almost always have to be trimmed to fit the particular case. I also work on Rolex movements, and the stems are unique to each family (15xx is different from 3xxx) but the casing screws are the same thread- but there are two "styles" one with a flat flange and one with a tapered flange. You drop the movement into the case, noting the cut outs for the screw flanges, and rotate them into proper position. Then the casing screws are backed out, to lock the movement into the case. I like to insert the stem, and observe it is well centered in the crown tube before I snug up the casing screws.1 point

-

Cousins also sell bits for jewelry etc. Some people make jewelry from old watch parts, so maybe more useful for them.1 point

-

Hello Everyone, I am going to share the details of my adventure with a trinocular stereo microscope and a digital camera attached to it. I bought a second hand AmScope SM-1T (1st purchase) and I had no experience with stereo microscopes before. What I am going to write might be evident for some, but probably will help someone out with limited experience with trinocular stereo microscopes, I might be even wrong with some of the things I am writing/thinking, please feel free to correct me as the last thing what I would like to do is to mislead somebody else. You might have a different type of stereo microscope and you might have a different type of digital camera so you might be in a different situation I have been. A stereo microscope is incredibly useful and is a completely new world for the watchmaker in my opinion. You can see things you were not able to see before, worn pivot holes, pivots, cracks in jewels, bent hairsprings, and dirt everywhere, etc. I wanted higher working distance though and I also wanted to take pictures and record videos about watch movements and one of my initial goal was also to be able to take a picture about the whole movement. To achieve this I bought a number of things one buy one waiting weeks between the different items as I was not sure what to buy exactly. The AmScope SM-1T I own: The only thing I was sure about was the illumination so I bought a led light ring (2nd purchase): "220V 60000LM Adjustable Microscope LED Ring Light Illuminator Lamp For STEREO Microscope Excellent Circle Light EU plug" The first one did not work for long, its circuit board died after a week or so. I got a replacement however I am still using the original led light ring without its original circuit feeded directly by my bench power supply with 12V. I did not know that time that there are adapter rings for ring lights so I drilled 3 little holes into the head of the microscope. Now this sounds silly and indeed it is, but it became handy later as I can use these three little holes to attach my ring light to the microscope head without loosing much of the working distance if I want to. I bought an adapter anyway (3rd purchase): "M48X0.75 48 mm Thread Aluminum Objective Adapter Ring Stereo Microscope to Attached LED or Fluorescence Ring Light" The adapter ring: The next thing what I bought was a 0.5x barlow lens (4th purchase) for the AmScope as I knew it would increase the working distance and the field of view and additionally would decrease the magnification. I went again for aliexpress and my number one priority was to get one as cheap as possible. Now this might be one of my biggest mistake here. I cannot compare the one I bought to any other 0.5x barlow lens, but I am not happy with this one: "0.5x WD160 Working Distance 160 mm Barlow Auxiliary Reduction Objective Lens with Mounting Thread 48 mm for Stereo Microscope" I cannot get a sharp image with this one so ended up not using it at all. You can attach your ring light directly to this one. This article talks about the barlow lens and suggests to buy a quality product from a trustworthy manufacturer: https://www.microscopemaster.com/barlow-lens.html 0.5x barlow lens for the AmScope: Blurry images when fully zoomed in: Fully zoomed out, too much light and not very sharp: Then I bought a digital camera (5th purchase) for the trinocular port namely: "2020 Full HD 1080P 60FPS 2K 3800W 38MP HDMI USB Industrial Electronic Digital Video Microscope Camera For Phone CPU PCB Repair" but it was not compatible with the adapter the AmScope came with as it was designed for AmScope own digital camera, i did not know that at this stage though so I bought (6th purchase) a "CMOS CCD USB HDMI Industrial Video Camera Adapter Electronic Eyepiece Microscope 23.2mm to C Mount For Biological Microscope" because i hoped that it would help me to attach the digital camera to the AmScope adapter and I would be able to focus it. It turned out that this was not the case. I could not get any useful image, not even close. The digital microscope camera: AmScope adapter for their own digital camera what I could not use: And the adapter which fits into the AmScope adapter above but it did not help: Meanwhile I bought (7th purchase) a "0.7X WD120 Trinocular Microscope Stereo Microscope Auxiliary Objective Lens Barlow Lens" barlow lens for the AmScope. The other issue with the 0.5x barlow lens for AmScope was that the working distance went to the sky and I could not comfortably sit in my chair as I could not reach the eyepieces easily. I was hoping that the 0.7x barlow lens would sort that out, but it did not turn out the way I hoped for, I am going to write about the working distances later. However I am satisfied with the 0.7x barlow lens, I can get sharp images. You have to use a ring light adapter with this one as you cannot directly attach your ring light to it. I am happy with this/ fully zoomed in: Still happy, fully zoomed out: Then I was advised to buy a 0.5x or 0.35x c mount adapter for the digital camera so I bought (8th purchase) "0.5X C mount Lens Adapter Focus Adjustable Camera Installation C mount Adapter" first, and yes it worked finally! The digital camera came with a ring and that ring must be used otherwise you cannot sync the focus between the digital camera and the microscope. 0.5x adapter for the digital camera: And the ring what must be used: As I was not happy with the 0.5x barlow lens for the AmScope but I still wanted to take pictures about the whole movement I thought i would buy (9th and final purchase) a 0.35x c mount adapter for the digital camera what would bring me a wider field of view so I bought a "0.35X C mount Lens Adapter Focus Adjustable Camera Installation C mount Adapter" too. And indeed it was the case, but it seems that the body of the microscope comes into the picture, what you can see in the upper right corner of the following picture so I ended up not using it. 0.35x: Check the upper right corner: When you use the microscope your field of view is a circle, but when you use your digital camera your field of view is a rectangle. So i give you and idea about the dimensions and the working distances now. Digital Camera with 0.5x adapter for all cases. Field of view with 0.5x barlow lens for the stereo microscope: Zoom full in 7.5 mm x 4 mm Zoom full out 5.3 cm x 2.9 cm Field of view with 0.7x barlow lens for the stereo microscope: Zoom full in 4.5 mm x 2.5 mm Zoom full out 2.9 cm x 1.6 cm Field of view without barlow lens for the stereo microscope: Zoom full in 4.5 mm x 2.5 mm Zoom full out 2.9 cm x 1.6 cm Stereo microscope field of view and working distance. No barlow lens. Zoom full in diameter: 4.5 mm Zoom full out diameter: 30 mm Working distance: 8 cm (from the workpiece and the bottom of the ring light which is attached to the 3 drilled holes) 0.7x barlow lens. Zoom full in diameter: 5.5 mm Zoom full out diameter: 40 mm Working distance: 11.6 cm (from the workpiece and the bottom of the ring light which is attached to the 3 drilled holes, ring light adapter is not attached to the barlow lens as it would further reduce the working distance.) 0.5x barlow lens. Zoom full in diameter: 10.5 mm Zoom full out diameter: 70 mm Working distance: 20.5 cm (from the workpiece and the bottom of the ring light which is attached to the 3 drilled holes) Conclusion: I ended up using the 0.7x barlow lens for the microscope, and the 0.5x adapter for the digital camera which is a must have. The ring came with the camera is also a must so you would be able to sync the digital camera with the microscope so they would be both in focus at the same time. I had to ditch the 0.35x mount adapter for the digital camera because the body of the microscope came into the picture and I had to ditch the 0.5x barlow lens for the stereo microscope as it did not give me sharp images. Even if I would have a good quality 0.5x barlow lens which would give me sharp images I still would need to sort out the seating position by purchasing an adjustable chair (mine is adjustable too but it did not go high enough to reach the eyepieces) however it would give you an amazing working distance of about 20 cm bearing in mind that it halves the original magnification. My original wish to be able to take a picture about the whole movement probably was not something reasonable. First of all a microscope as its name suggests is about to focus on tiny things not on things like a whole movement, my phone takes better quality pictures than this microscope if we talk about the whole movement. Additionally I could not take a good quality picture (apart from the blurriness) about the whole movement when the 0.5x barlow lens were on the stereo microscope (and they had to be on to be able to get the whole movement in the field of view), because there was too much light and regardless of the settings of the digital microscope i could not sort it out. An additional thought, as I mentioned earlier I hoped that the 0.7x barlow lens would sort out the "too high" working distance and instead of 20cm it would be around 15 cm, but it came to 11.6 cm which is doing the match is about right as the original working distance without any barlow lens is 8 cm, the 0.5x gives me 20.5 cm, but if it doubles the working distance it should really be about 16 cm. The 10.5 cm what I have with the 0.7x barlow lens is just about enough, it would be better if it would be a bit bigger. Probably a new chair and quality 0.5x barlow lens for the stereo microscope would be ideal for repairing, but none of the setup would be ideal for taking pictures about whole movements. AmScope video about the Barlow lens: https://youtu.be/ozPae_nnbH4 My setup: This video is captured by the digital camera itself, its size was just too big ~ 160M so I could not upload to wrt, however I wanted to show you its original quality so decided to upload it to my google drive, to my surprise when you click on the link the video quality is much worse than the original I uploaded, i dont know why is that happening, probably google tries to save the bits going trough the network: digital camera recording This is what I see from my chair: digital_camera_1.mp4 One more thing to add, the digital camera started to play up after a while, its main menu came up and it switched itself off. Contacted the seller and they gave me a new firmware. I flashed the camera and there is no issue since. This is my longest post so far, I am happy I am at it's end.1 point

-

I use a plastic rod usually. I see some really scratches balance cocks and it doesn’t look nice.1 point

-

1 point

-

Risk of mishap is greatly reduced if the regulator and stud arms can be moved smoothly, I often remove/ clean and make sure both function correctly before disassembly.1 point

-

1 point

-

1 point