Leaderboard

Popular Content

Showing content with the highest reputation on 09/24/20 in all areas

-

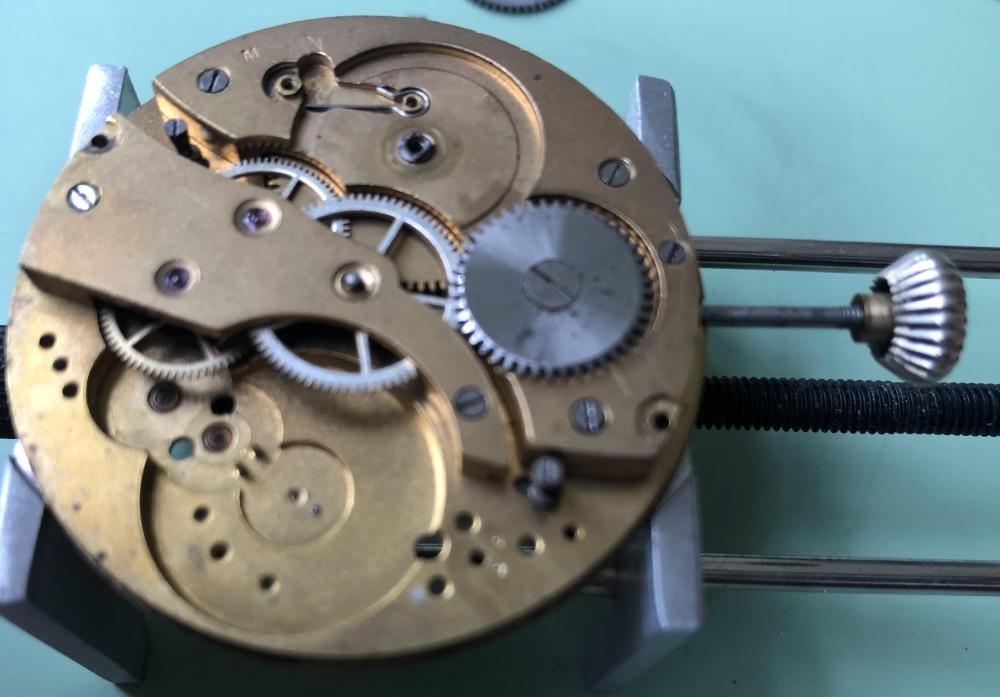

I'm always impressed just looking at these, and lucky enough to own a chronometer grade one, now finally had the chance to work on a repair, and all the positive opinions got confirmed. The owner lamented water ingress and the watch stopping all the time. Seeing no major damage on a first inspection I undertook the work with good hopes. Starting with the dial side the overall feeling of quality and maniacal height saving design becomes evident. The dial fits so precisely that a dial washer was not present or needed. This being a time only version I can't do any praising to the calendar works. As soon I lifted the hour wheel the watch started running strong in all positions with good amplitude, then I pulled the cannon pinion which was quite tight. Note to myself, MUST get a cannon pinion remover. The black oxidation on the contact section was the root cause of the fault, but after 50 years it was time for a complete service, and I have the distinct impression that mine was the first one. One incredible fact is that Omega still updates their technical documents about this long discontinued caliber, I can only think of the aeronautic industry doing something similar for certain "never old" airplanes and engines. The way I did it may be called not fully professional, as I didn't do surface treatment, and used only 9010, HP-1300, and 9415 without an automatic oiler. However I'm happy with the results, and I hope that the owner will be too. That being said I plan to upgrade on the above points in the immediate future. One tool detail that I really recommend is to use soft metal tweezers whenever possible, I have got cheap brass Indian ones which I then dressed to eliminate any sharp edge. These are OK to handle most of the screws and all the bridges and plates. Keyless and motion works are rational, and easy to work with. Some dirt and micro-spots corrosion, but nothing worrying. The stem was the rustiest part, and the crumbles are all what was left of the crown gasket. It is defintely possible with some patience to open these and fit an o-ring, which luckily I had from an assortment box. Even the stem came out very decent after the due care. Just give a tap or two to the washer to make it seat nicely again. I've even refitted the steel ring which matches well the O-ring profile. Two screws hold the automatic bridge, and one can see that also the gib screw was removed. That allows the rotor to be removed even with the mov't in the case. For regular service to the auto works it's enough to remove the larger bridge. One of its screws is thinner due to more limited space. Note the use of a single reversing wheel, yet the winding in bi-directional and the overall manufacture is just amazing. I used HP-1300 on the pivots but probably that another synthetic type might have been better. Note the space above the balance, which hosts the automatic work. At the time of its introduction this was the thinnest automatic movement with sweeps seconds and calendar, at just 4.5mm. And the Reed regulator is nothing less than amazingly beautiful. The balance is then removed and inspected. Note the multiple tiny "drill kisses" on the rim for poising. To save height, the train is different from the common design. Seconds pinion is driven by a pinion sitting above the the barrel bridge, and has a tension spring which controls its end-shake. Releasing power is not easy as the space around the click is very limited, remember to use only something soft like a toothpick to do that. Only then we can remove the pallet bridge, another beautiful execution with two locating posts and screws. Then remove crown and ratchet wheels. We start to see the sophisticated design and the one-way automatic winding clutch. The machining of a cord on the crown wheel round holds precisely the hub of the crown wheel, with an off-center screw. Wow. The auto winding wheel has special profile inner teeth which allows one-way power transmission from the ratchet wheel to the barrel arbor. The small pinion catches only one way to said wheel, otherwise it turns freely. That makes so that turning the crown in the opposite direction has no effect whatsoever, and also that a single reversing wheel is needed in the automatic work, because movement is transmitted only in one direction from the wheel on the arbor to the auto works. I for one find difficult to understand what I wrote above and the principle of operation of that mechanism. We can now remove the train bridge which only holds third, fourth and escape wheel. Al-tough, that does not make it particularly easy to fit back. Finally the seconds pivot spring, pivot, barrel bridge can be removed, followed by the barrel and center wheel. Speaking of the barrel, once opened it I found it quite dry, with the lid slightly corroded and heavily grooved. As an experiment I hand polished this surface with a wide micro-fiber stick, and car polish compound. Grooves were gone, but it remained scratched. I switched then to grade 20 or 30 of Chinese diamond paste until it got better. And better with finer paste, to an acceptable smoothness Now, I must say that I did not replace the mainspring, and not even removed it from the barrel as I don't have a winder, and wanted to avoid any distortion to it. In the end the watch performed well with plenty albeit not stellar amplitude. The stripped main plate in its equally magnificent A and B sides. Cleaning and reassembly was uneventful even if some screw are small enough to require full attention. I had some doubts about the seconds pivot being supported by jewel on the auto works when refitting hands, but in fact that worked OK. After lubricants settled the timegrapher response was completely positive, One last note, you know you're holding a genuine vintage Omega dial when it has a fine clove watermarking, a recess for the balance anti-shock device, and the feet are shaped for the screws to hold without damage. After a long time spent hand polishing the acrylic crystal and other details the complete "Omega Geneve" watch came out stunning, sorry I didn't take a picture Hope you have enjoyed this article.3 points

-

2 points

-

2 points

-

2 points

-

Well, I have destroyed around four of them so far. I was told by a friend who uses them for automotive work that you must use a basket to preserve the machine, so I reckon this probably shortens the life of them if you don’t use one. The only time I won’t use a basket is when my inner container of soap and parts floats inside the main bath of water. This stops the pressure of your container from interfering with the case resonating.1 point

-

Steve, if the mainspring slippage has a particular feel or sound when it happens then you can count the number of turns before slippage to give a rough indicator of how well that action is performing. I’m not that familiar with Seikos as I tend to avoid them, but I’d expect around 7-8 full turns from unwound before it starts to slip. That may sound a bit vague, but it may help as it’s a quick test to make. 320 degrees sounds surprisingly strong for a Seiko. I’d maybe try giving it a few winds while it is on the timegrapher and see how it responds.1 point

-

That balance has a different number of screws, a different number of hairspring coils and a significantly different stud location. It could have the hairspring accidentally fitted 180 degrees around, or it could be from a different caliber. It’s unlikely to be the former if it is NOS as it would be roughly adjusted for beat-error in the factory.1 point

-

Thanks for the responses. I took all apart, installed just the third wheel and train bridge - it looks and feels like it's as it should be. Thanks for the details Nucejoe, this is all a bit of a learning curve. I'll take it apart again and try that sequence watchweasol, see what it looks like. I've got my best technician checking it for me now as you can see in the photo, will see what she says1 point

-

I've been restoring a pocket watch that I found as a barn find. The dial bears the Berna brand and the movement has an M written on it and the number 179. Other indications of identity are lacking. While reassembling I ran into the problem of how the spring should be placed that presses on the pin that locks the mainspring barrel. (or, correctly, the wheel above the barrel, that is connected with the barrel through the square end of the arbor). I think the previous restorer did not correctly place back the parts here. Can I ask you if you can identify this movement and/or indicate how this should be correctly put in place? Let me know if I can make additional pictures. Thanks!1 point

-

Thanks for the replies! I've tried applying the tips and it nearly works; I think the spring is just a little bit too short to keep the click thing in its right position. In the meantime, I've finished it as-is, see the result here: Things left to do: polish (or replace) the glass, check the spring for the click element, get case screw (one missing), and likely get a new hairspring (when 'wound', the balance doesn't rotate as much as it should..).1 point

-

I know Rolex gets all the glory, but I’ve known for a long time that Omega has been eating their lunch for decades. Rolex is a tractor to Omega’s formula one car (though they are easy to work on) Early Swatch Group offerings were far below this movement’s standard, but the Omega DNA slowly crept into ETA and they are doing amazing things now. I always love that warm rose gold glow when you open an older Omega.1 point

-

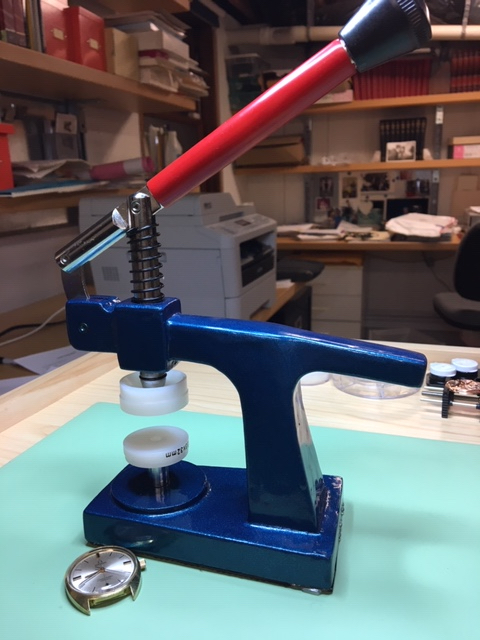

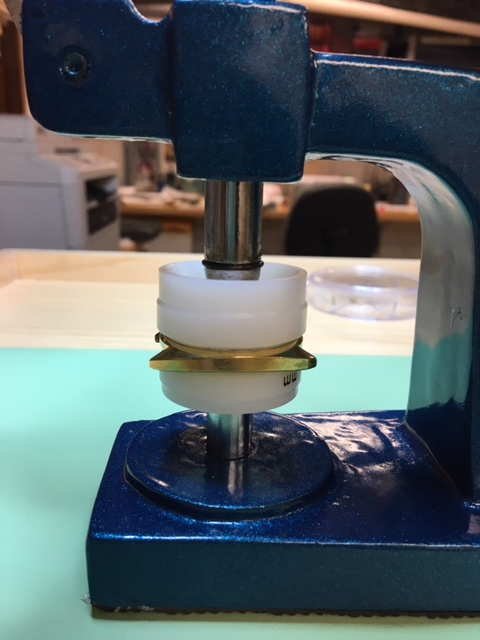

Having good tools makes life a little easier. Nice to know it worked out for you.1 point

-

1 point

-

Hi all, I'm glad to report that the press from Esslinger did the trick. I had several tapered dies to choose from and the 34mm die fit nicely easing the crystal right into place. Having pressure only on the perimeter of the crystal avoided any trauma. Though my experience with this press is literally less than 24 hours old, I'd say it looks pretty robust. The dies fit nicely and they sit parallel to one another when on the press. For $60 it was well worth it.1 point

-

Lots of places. If you tell us more about yourself (clue: introduce yourself) and describe your watch, someone Here will be able to help. If you are really a Wizzard, I also wish it could be Christmas every day.1 point

-

Thank you - I’m pretty sure I may use everyone’s advice at some point, but I will certainly look at oldhippyy a lot he seems to give consistent excellent advice about a wide range of topics.1 point

-

I always try - I’m sure you’d be amazed at some of the blank or confused faces I saw while trying to find certain ingredients/products!1 point

-

Of course there are independent watch repairers, however be aware that if for example the value of your Vintage Seiko is 100 (USD EUR, GBP,?you didn't event mentioned where are you located), a typical repair / service bill can easily be 200.1 point

-

Hi. im new to the forum so trying to work my way around the system so I apologise if this is wrong ... I am replying to oldhippy... I try and replicate traditional methods when restoring a case for example. I only use Hyde glue and will use Shellac & Beeswax etc. I hope that answers your questions?1 point

-

Just finished this 1970 Seiko 2517-0211 for my sister's 50th birthday in 6 days time. I am so relieved that I got it finished in time. Main issues I had with it apart from it being so tiny were the barrel and auto bridges. The pivot holes for the reversing wheels were worn badly oval on both. A donor movement fixed that luckily. Hope she likes it. VID_20200923_151815818.mp4 VID_20200923_151815818.mp41 point

-

1 point

-

1 point

-

Another USSR Poljot/Sekonda joins the 404 club today. This time its a 2614.2H which is the date only version of the 2628.H from yesterday. These are relatively easy to work on, so long as you take your time with the keyless works and the day/date complications. They lack the date quickset of some of the other USSR movements, but this makes them a lot simpler and more robust. I'm slowly working my way through the Sokonda pile so there may be a couple more before too long.1 point

-

1 point

-

That's awesome. In non-power delivery gearing, often you can get by with some serious leeway as long as nothing binds. A friend of mine worked at Breguet around 2000, he had an 80s vintage watch come in with two brass pins in the minute wheel where teeth had stripped off. His boss said ,"if it works, leave it", which he did and promptly quit haha (Breguet has massively improved in that time btw).1 point

-

Wilkommen! Here will you find a group of friendly people willing to share a wealth of knowledge and experience with timepieces! You have peaked my interest with mention of the pocket watch. I prowl about at flea markets and estate sales to pick up non-running pocket watches, and I restore them to running condition, polish them up and, if I do not grow too fond of them, I will sell them later. This, and my part time repair service, helps a little with the bills. Please post pics of your own watches too. And feel free to ask questions; there are many helpful people here.1 point

-

The plot thickens. The upper escape wheel jewel hole is badly worn. Way too much side shake. So my theory is that the escape wheel is leaning in to the pallets messing up the geometry. So I might change the jewel before I move the stones.1 point

-

Made a quick video on a great “all night long” watch Lume. Super-LumiNova Watch Lume Sent from my iPhone using Tapatalk Pro1 point

-

My family has a long history in the watch and clock industry. My grandfather was a watchmaker, as was his brother. My great grandfather was a watchmaker and back in 1986 when he passed away at the age of 13 I was given his watchmaker lathe. My great great grandfather used to own a run a watch and jewellery shop on Oxford St in Sydney in the 1920s and although I have not found any positive evidence he was a watchmaker I would say it was highly likely he was. Three years ago I was given my grandfathers watchmakers toolbox which my steo uncle had stored in his shed for 15 years after my grandfather passed away, as a consiquence I have a number of old tools, some that I know where my great grandfathers, some my grandfathers and some that are old enough to of been old even if they had belonged to my great great grandfather. A couple of weeks ago I wanted to make a special graver for my watchmakers lathe and I was pretty sure I still had some old gravers in my grandfathers toolbox I hadn't yet refurbished so I went for a dig. I found one that had clearly started it's life as a needle file and as some point in the past the file had snapped off the square handle and this had then been made into a graver. I decided to clean this up and resharpen it as the graver I was making would only ever see little use as it was for creating chamfers on balance staffs. After sharpening it I noticed it had a brand name on it. 'Antonine Glardon A Vallorbes' I knew the brand Valorbe, but not Antonine Glardon, a bit of a Google search turned up the Valorbe company history page http://www.vallorbe.com/en-ch/company/history and it states ' in 1899, Vallorbe's three largest factories, Borloz & Noguet-Borloz, Antoine Glardon & Cie and Grobet SA merged to create Usines Métallurgiques de Vallorbe. ' So if I am reading this correctly this file must of been made before 1899. I also have a pivot burnisher labelled 'David Borloz Valorbe' so it would also date no later than 1899. A quick dig through my pivot files I use and other in my grandfather's toolbox turned up 8 or 9 files labelled 'Antonine Glardon A Vallorbes'. I am using the graver made from the handle of a file and the pivot file on the left in this photo below as it is finer and better than my new one I bought from Cousins, the otehr are just in the photo so you can see some other of these files. This would mean the oldest tools I am still using are atleast 120 years old. What's the oldest tool you still use?1 point

-

Got this sexy lady on my wrist today and find it shine and bright under the sun light. Not a fancy or any other luxury brand watches but this is the first and ever mechanical watche that I stripped down, service, oil and reassemble. Sent from my iPhone using Tapatalk1 point

-

Humor is a big part of it for me. Welcome and isn't cool make it run? Even if it's not all correct or whatever, it's a thrill. Congrats!1 point

-

0 points

.JPG.ebf152565316568e6b415c85730d1d88.jpeg.b1d1cfd6d768d8d9530c4c4c4ffa47d4.jpeg)