Leaderboard

Popular Content

Showing content with the highest reputation on 07/08/20 in all areas

-

Broken drills in arbors is a real problem. When repivoting, which generally requires a much shallower depth/diameter ratio (general rule is at least 3 but better 4 or 5 diameters depth), I almost always use a spade drill. These I make up as needed freehand out of tungsten carbide, and make them with noticeable back taper. The advantage is twofold; being hand ground they will almost certainly drill slightly oversize, and being "waisted" they don't stick in the hole in the event of breakage. I just did a LeCoultre escape wheel with one last week- pivot was 0.08mm, was able to do a hole of 0.14mm and have decent wall thickness. Then plug and turn down and burnish- I always figure the ultimate test of the new pivot is if it stands up to the Jacot tool. With handmade drills they are better held in a pinvice and guided by hand as they are rarely perfectly centered on their shank. As long as the center is caught correctly before drilling it's no problem.2 points

-

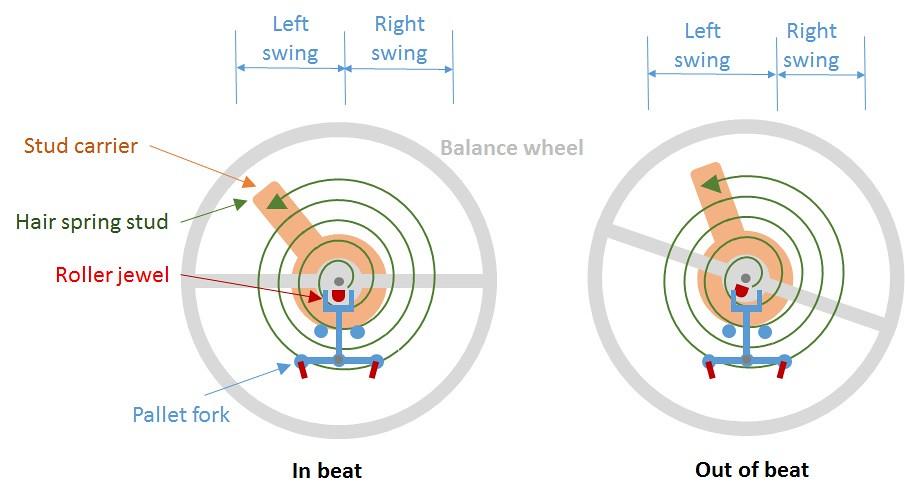

Hello, short question, but a bit difficult answer. This error has little to no influence on performance as it is compensated by right and left swing of the balance wheel. There is little info on the topic. Values claimed in the net are just opinions without substantiation. The manual of a timing machine gave the answer: limit for the esc. error is 15 degrees. Here the unpowered escapement still rests in lift position. Unfortunately most TMs do not display the real esc. error (degrees) but just milliseconds that are not directly related to the real esc. error - ms value changes with amplitude and with bph despite a constant esc. error! One exception is PCTM that displays degrees, too. If you convert deg to ms, 15 degrees equates 9.6 ms @ 200 deg amplitude, @ 18000. Adjustment to 1/10 of that limit = 1.0 ms will be excellent. Frank2 points

-

First thing to do is to unpin that hairspring off of stud.( most important). (Your search show should a similair advice I gave, OP didn't listen, spent ages like thisand ended up buying a new HS. ) To unpin I insert the stud back in the stud carrier even instal the cock, then unpin. Next remove the HS and put it on a white sheet of paper. No tac is needed. Run an oiler through the coil, start form collet outwards, to untangle any circle stuck under another, each time all the way to the end of HS, then you will see a much less tangled coil that is not hopeless at all. Good luck.2 points

-

Hi again I have had ago at restoring the dial using spray paint and a ink jet printed numerals etc. I think I will have another go at it now that I have a better idea of what I’m doing but I think it looks ok for a first attempt. Also the completely knackered movement I repaired seems to be going well so overall I’m happy with my efforts for a £20 punt. Let me know what you think. Many thanks for all the help received.2 points

-

1 point

-

1 point

-

A friend posted me this beautiful Services watch to work on. Opened the back to have a quick look and saw that there was a lot of oil so quickly took the dial off...1 point

-

Don't you get tiny hair on the needle as you touch it to paper towl? You can dump the excess oil if you just touch the needle to the cup. I use contact lenz container for cup, since they got a lid to close. Bergeon and another oil cups are retired. Acupuncture needles make good oilers.1 point

-

I believe my machine comes with a basket for that purpose, pictured here: https://imgur.com/7kdCVrj Thanks1 point

-

1 point

-

I guess that qualifies quite nicely for @jdm 's thread on "Strange things inside a watch", and indeed in every watch and clock, although you could argue that it is not only in the watch, but indeed is the very essence of the watch.1 point

-

Good idea ! Putting a bit of Rodico on the hole showed that the gap was much too big. I pushed the hole jewel up a fraction of a smidgen using the gauge on the top of the jewelling tool. And now the oil forms a nice circle. Just the other one to do now. The chatons and caps are listed as the same part for top and bottom in the Kif catelogue. The caps fit perfectly so I don't know what happened to the hole jewels. Maybe when I was rubbing them with some pegwood, I pushed them down a bit.1 point

-

Its a pity the person didn't take it back and told them to put it into the same condition as when they took it to that incompetent person, they should have sued them. Because of the damage they have inflicted on that watch they have removed any value to it. The movement is called a 5 bar movement and are normally Swiss made. Good luck with what you are willing to do in helping your friend, not an easy task. I look forward to the video if you record one.1 point

-

Thank you for everyone's thoughts on this subject, very helpful indeed! I decided initially that I would tackle this and took the balance out. On closer inspection the index finger (is that what it's called?) Wasn't like any I'd played with or even seen before in that it didn't have a slot to rotate it in order to release the hairspring. At this point I decided that this was not the movement to be trying this on and I can live with it for now. I will probably revisit it when a little more confident. Definitely going to have a go at adjustment with the spring on, just on a few scrappers first. Thanks again chaps.1 point

-

Hello, well done in getting this far. Firstly, for Seiko there are more knowledgeable people than me. Regarding oil, there is a sticky in one of the forums here - I think it's the watch tool area.. Basically you'll probably want (or equivalents of) 9010, 9415, HP-1300.. there are also a couple of different slipping greases for automatic watch mainspring barrels which you can choose from but budget will probably be the biggest factor with those. I'm aware that Seiko has it's own specifications which include Moebius 9010. In terms of cleaning, I use little single serving jam jars in an ultrasonic machine - that allows me to use a volatile cleaner and clean parts by groups of mating parts or by muckiness. Rodico.. I use it all the time for holding things more than actual cleaning - it's really useful for holding things while inspecting.. that being said, it's good to practice picking up and moving things with tweezers. It's really important that tweezers are correctly dressed at the tips as it makes the difference between huge amounts of frustration or being able to pick up really small stuff without problem (with a bit of practice). I switch between the outside and inside of the tips to bring both surfaces to where they need to be in shape and position. I've found a hand-held diamond hone is about the right thickness (6-8mm thick suits me) to do the inside in a way which will allow both tips to meet nicely - switching between them so one tip is on the abrasive, and the other underneath on the smooth plastic.. as well as making sure the tip is relatively flat to the middle of the inside. Tweezers.. partly covered above.. there are a few types which are handy. I mostly like to use brass tweezers for most stuff, switching between a wide 2mm tip and some really fine tipped - suitable size for hairsprings, can't remember the number/ 5?. The brass tweezers rarely leave scratches but need to be touched up a bit from time to time - the finest brass tips can also bend easily.. I've got nice quality tweezers and some cheap brass ones shaped by myself.. for steel the anti-magnetic tweezers are usually worth considering over plain steel (which seem to be stronger but need to be demagnetized periodically). I don't have experience with the carbon fibre tweezers but realise they will have some uses.. I really like to aim for greater precision and have gradually gone smaller with my usual tweezers. Oilers.. the smallest basic Black or sometimes Red oiler is generally a safe "if only one" choice but a set aren't overly expensive and will allow you to get a feel for what you prefer. I keep meaning to get a nice basic set but the cheap ones are good enough. Oil Cups.. There are some really cheap and good options on places like ebay or the Cousins website. Oil cups are used at the bench so that oil bottles are not contaminated and so that they can be stored somewhere less likely to get knocked over etc. You don't really need anything fancy but in use they should be cleaned, partially filled with a little bit of oil in the bottom of each, and the top replaced when not in use so that dirt and dust is less likely to get mixed in. Oil should be replaced at reasonably regular intervals to reduce dirt building up in it.1 point

-

Well I'm glad that I don't have to oil 100 jewels. I don't think that I could afford the oil.1 point

-

Farnkly speaking, I am lazier to even do this. Uncut pins come aprox 2 cm long, which I use while still adjusting, once I called it in-beat, I cut the pin in situ and push the rest home inside the stud hole. No loosing the pin.1 point

-

To insert the pin back , I put the stud back in its holder tighten screw, put balance&cock back on the mainplate, run the hairspring through the studs hole, put a bit of grease or thick oil on falt side of a screwdriver( not Rodico), pick up the pin with it( pin stick to the grease) and get the pin to sit perpendicular to screwdriver, ready to aim for stud hole and push the pin home. Some grease gets on the pin, rinse it off in lighter fluid. I easily sharpen the tip of the pin if neccessary.1 point

-

You can get natural light LED bulbs and tubes which are very economical and practical to arrenge a working, studying or living area. It's just a mid range white temperature, nothing special about.1 point

-

I think that you may find it's 83 that are non-functional. It's an AS movement, probably a 1700 as these were a favourite for over-jewelling for marketing purposes. It has no more staffs, arbors and pallets than a 17 jewel AS1700. As you go over 17 jewels the justification (on the grounds of time keeping) for extra jewels becomes increasingly more difficult, and past about 21 almost impossible in a standard h:m:s type movement. That's not to say that additional jewels beyond 21 are completely pointless. Jewelled bearings throughout the auto-wind mechanism have a value in so much as they tend to have lower frictional losses compared to metal on metal bearings and so increase winding efficiency and prolong component life, but their contribution to more consistent time keeping can be a difficult point to argue. Once you have jewelled and end capped every single axial bearing in the watch though you are going to struggle to justify a single extra rock on the grounds of functionality, which means that even with the most complex auto-wind system you're going to top out somewhere between 35 and 40 functional jewels and that's probably being generous, beyond that is almost always nothing more than marketing hype. There's an interesting article on the subject here.1 point

-

1 point

-

So, I have some interesting and encouraging news. Instead of analyzing what could possibly be wrong with my automatic ETA 2772 watch, I studied how exactly I move my arms when working out. It turns out that after each interval training session I would jerk my elbow quite violently while walking and recovering my breath. I'm pretty sure this induces a very unnatural stress on the balance wheel, and my elbow, so decided to go slightly easier without really sacrificing any natural motion of the arms. The result? My watch won't rush and works perfectly normal. I believe I read in an automatic watch manual some years ago that the watch should not be subjected to sudden impacts like when playing golf or tennis. The manual didn't state what "damage" it would do, but I think I know now. So, I believe @saswatch88 was right on the money in this post.1 point

-

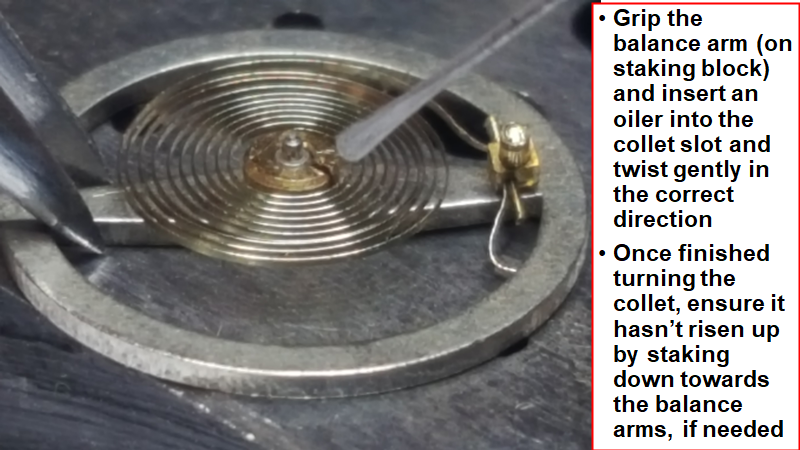

I usually place the balance on a staking block and adjust with an oiler if I don't have a purpose made tool which fits. I like to find the place the stud should be by bringing the balance wheel to the correct position when fitted and with the help of a microscope graticule, move the microscope to look down on the balance vertically, rotate the graticule to an angle to match the stud and pivot - so I can easily see where the line of the graticule sits on the balance rim. I can then use a screw or marker pen mark (sometimes there's already a scratch), then use it to help get the stud on that same line of the graticule, between the balance pivot and a pre-determined screw or mark on the balance rim. The microscope isn't necessary but makes it easier to be precise.. I used to do the same but with a screwdriver instead of the graticule/ microscope.1 point

-

When cleaning the movement, I put just the balance back on the mainplate, then get a line of sight down the centre of the escape wheel/pallet jewels and between the banking pins to the impulse jewel. If not central, rotate the balance and make a mark opposite the stud. You can do it with the movement assembled, but I find it easier with a bare movement and no pallet. I can usually get to about 1 m/s just by sight. Which is good enough without an adjuster - I think people worry too much about a bit of beat error. As @clockboy says above, things can easily go horribly wrong.1 point

-

4 Hours later... Not perfect but the best I can do with my current wizardry level. I spent a further hour trying to get the stud pin back in and gave up at 1am.1 point

-

Fraczish, if you are afraid of damaging something, leave it as is! A beat error of 2.5 ms does no harm at all, it annoys owners of Chinese TMs only. If you want to correct this "error", you can at least determine the direction of the needed move: Release the mainspring fully. The now loose fork will stand a bit more near to one banking pin. In the same direction the collet must be rotated a tiny bit. Then test again with balance wheel mounted. To get comparable values, the balance must swing with same amplitude on each test. Procedure can get time consuming like this writing! Frank1 point

-

iHi There are specific tools for doing this job by Bergeon but at £45 a go not cheap. TMuir put up a post with a tool he made and I also have made them myself using the metal insert from a winscreen wiper blade and a lot of work with the Dremel and an oil stone. The red,black,and green ones I bought over 30 years ago.1 point

-

1 point

-

Hi This video on the kink might be interesting for you1 point

-

Hi Once you get the balance out of the watch check on the underside of the rim there is often a mark at the point where the stud is as a reference. This adjustment can be done with the balance on a balance tack and working through the coils but needs great care. If its somthing you have not undertaken before remove the balance from the cock. but again check for the stud point if none put a mark on the rim yourself markerpen. You might find the attached useful.1 point

-

1 point

-

1 point

-

I remember my great aunt had one of these from the co-operative insurance well into the 1970's the insurance man would collect the money every quarter and log the amount in a payment book I also remember my grandma had a television that ran off 10 pence pieces to cover the cost of rental it would always go off half way through a program and every one would scramble around there pockets for 10p, the joys of life before direct debit.1 point

-

Now, redo it, but take lots of photos/video and repost as a how-to. I feel like dial refinishing is one of those semi-lost arts. They were cheap/unloved, and so were either parted or tossed, and anything with any value was done professionally. Dial refinishing needs to stage a serious comeback in the DIYverse.1 point

-

1 point

-

Smiths produced clocks & watches from 1851 eventually opening a factory in Cheltenham producing the high end watches equal to the Swiss such as the Deluxe, Astral & Imperial ranges. The factory closed in 1970. Also a factory in Ystradgnlais, Wales, originally & joint venture with Ingersoll (not the American one) producing lower end pin levers such as the Smiths Empire & Ingersoll Triumph range & eventually a jewelled lever used in the Streamline range (see here: http://www.watchrepairtalk.com/topic/3157-smiths-streamline/). The factory closed in 1980. In the final years before closure movements were sourced from the Swiss & the Far East. Smiths Group plc is now British multinational diversified engineering business with is headquarters in London, operating worldwide but unfortunately no longer produces watches. The Smiths watch name is now owned by Timefactors who produce homage watches in small quantities with Swiss & Japanese movements. Robert Loomes uses highly modified Cheltenham Smiths movements in his range, but you will need to save very hard to buy one.1 point