Leaderboard

Popular Content

Showing content with the highest reputation on 05/08/20 in all areas

-

2 points

-

The camera is an ordinary Carl Zeiss AxioCam 412. But if one wants something were you can choose and swap cameras too I recommend something like the Nikon SMZ800N, It's the one to the right. To that one I sometimes connect the Sony a7 iii 42Mp camera. One can swap out the fasteners to a multitude of brands.2 points

-

2 points

-

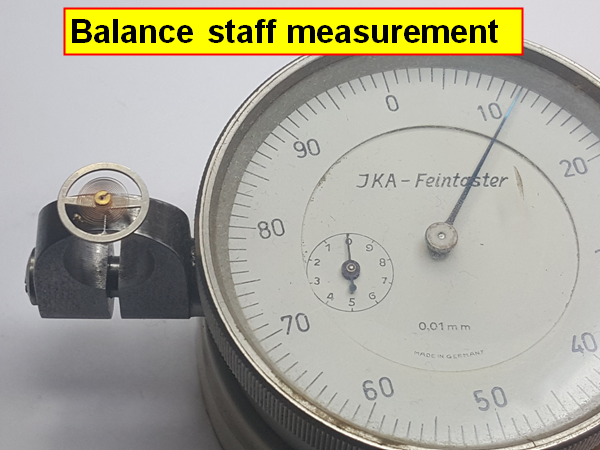

when you modified them with the fine stone did you do this by hand? Or did you have access to a watchmakers lave? then staffing a watch is usually not a beginner's task. That's because you need to understand a whole bunch of stuff basically have a really good understanding of how the balance wheel works in the watch so if it's not quite right it makes it a lot easier to grasp what's going on. Then depending upon the watch the replacement staff will have issues. For instance American pocket watches lots of variations for the same staff number. Or pivots they came in a whole variety of sizes. Or replacement staffs that are made larger on the grounds of the watchmaker will shrink things to fit. This would include things like the length of the pivots being too long. So you have to bill understand how to shorten the pivots properly. so unfortunately it means changing a balance staff is not a plug-and-play operation and is going to work perfect in every single incidents there will be times that does happen and other times you're going to have to fit the staff. This is where a watchmaker's lathe comes in very handy.2 points

-

Hello from Scotland. I recently re-awakened an interest from my youth in watches and clocks. Strangely the catalyst was searching for a replacement hand for a Starrett dial indicator that I picked up for pennies on ebay and which I though might be useful for leveling the bed on my 3d printer. It was missing the dial hand, which looked very like a watch second hand, so that led to a search for a suitable donor watch. Needless to say I then got distracted by the vast array of old time pieces to be had for pennies, and grabbed a couple of basket cases. The first one was a Sicura Voyageur. It only says Voyageur on the dial, but it has all the hallmarks of a Sicura, with the seahorse emblem on the caseback, and the remains of hands that look like the Sicura "Marine Star" It was in a sorry state, but after a quick clean, polish and minor overhaul it's Rondo-matic heart is now ticking away nicely. I'm awaiting a suitable second hand for that, currently on the slow boat from China, and it has parted company with its bezel, which I may fabricate a replacement for if I get the time. The problem there is that I can't find another "Voyager" to compare with, and Sicuras had a variety of different bezels. I found WRT by watching some of Mark's many excellent Watch Repair Channel videos, many thanks for those Mark. I have a couple of other basket case watches ordered from ebay. I set myself an artificial ceiling of £4.04 per watch (although I have already blown that a couple of times), as I figured that there was a lot of fun to be had from resurrecting an item destined for landfill and costing less than a trip to the coffee shop. My day job involves computers, and I dabble in electronics as a hobby, which means I'm fairly patient, and used to dealing with very small fiddly components, and already have a bunch of small tweezers, screwdrivers, clamps, magnifiers and so on.1 point

-

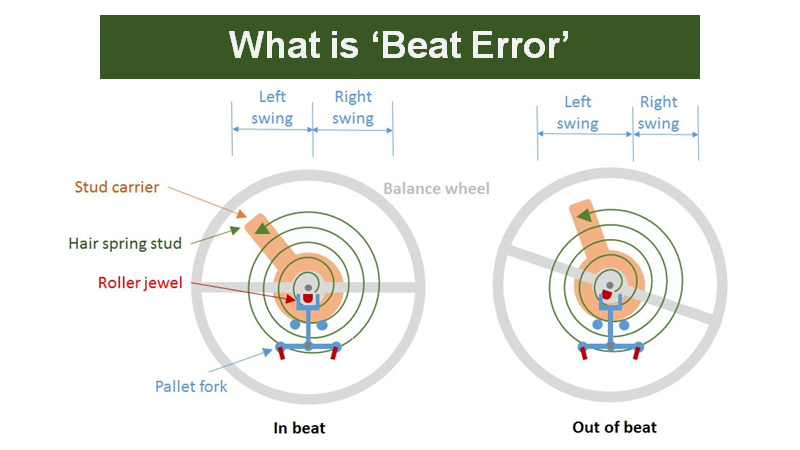

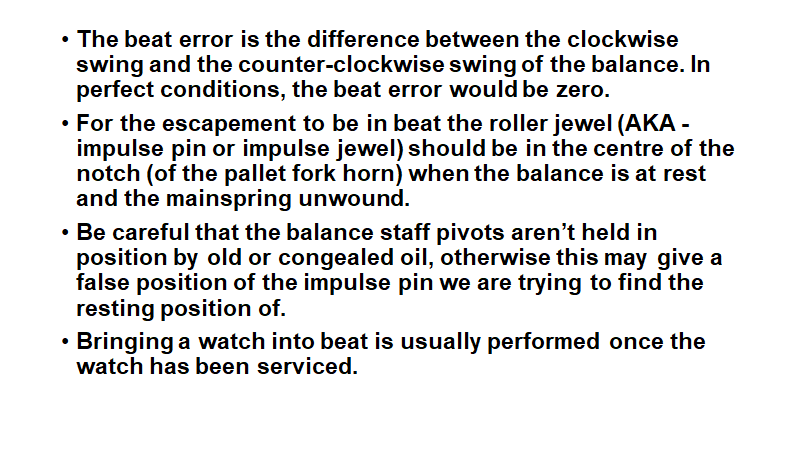

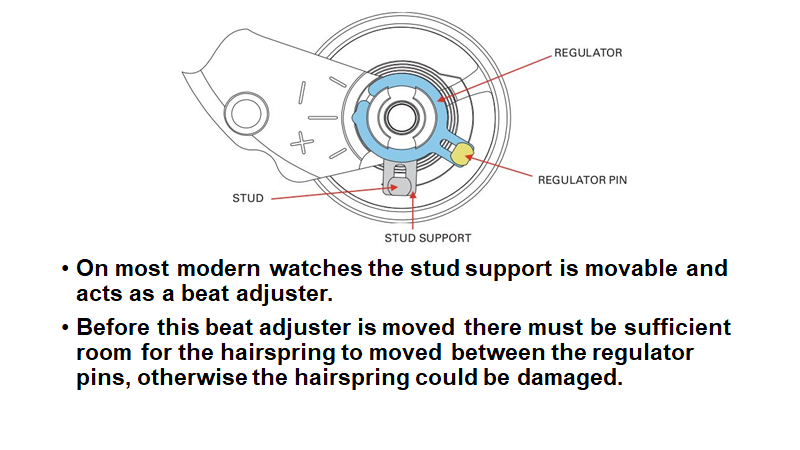

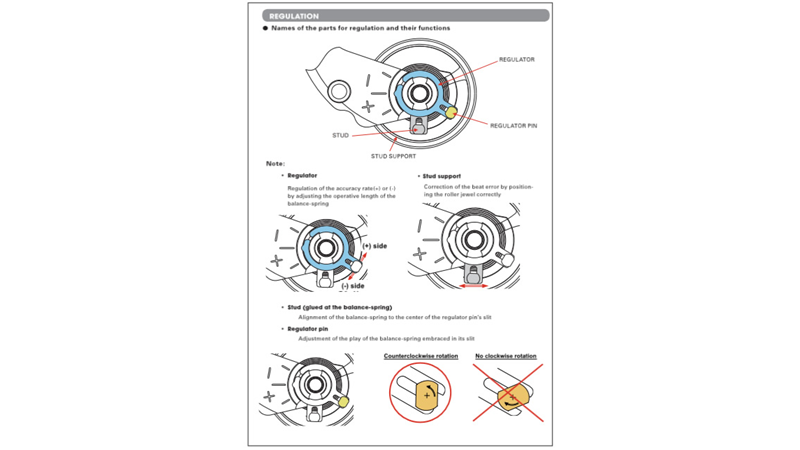

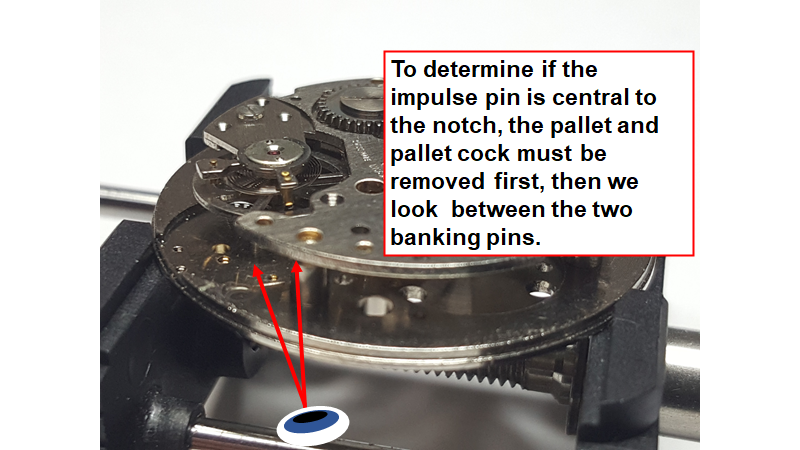

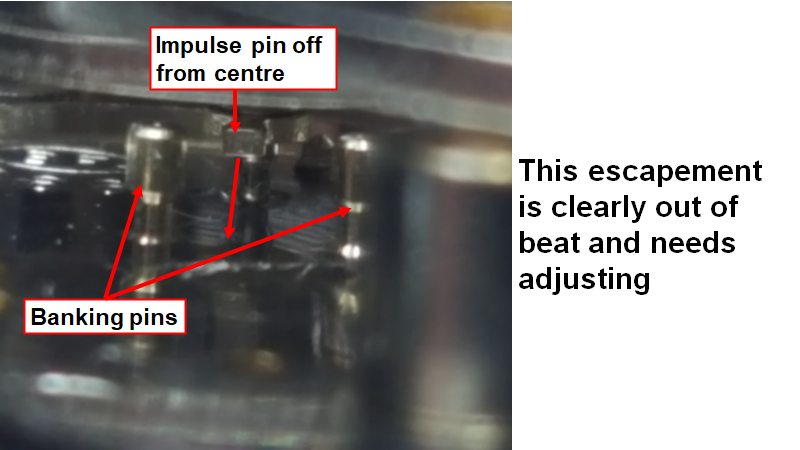

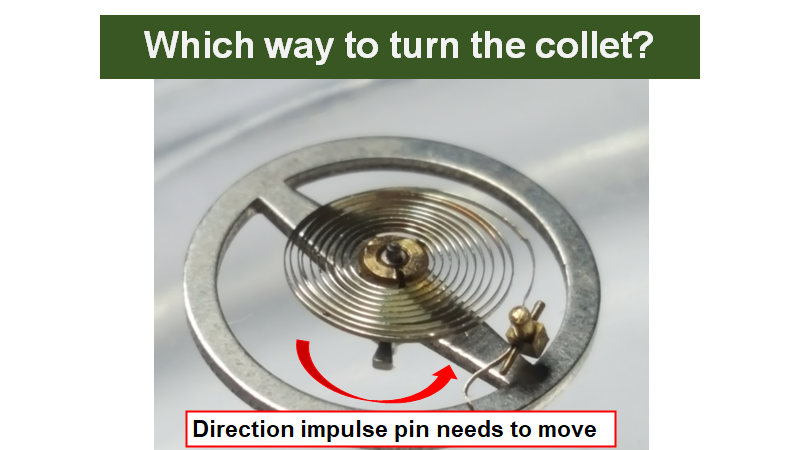

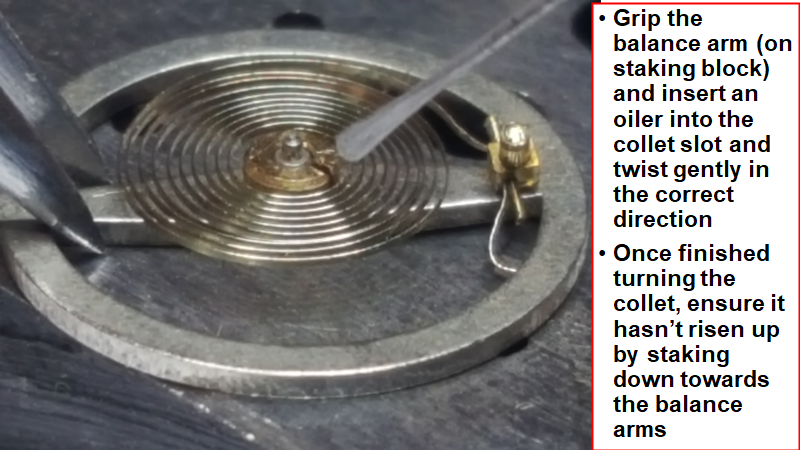

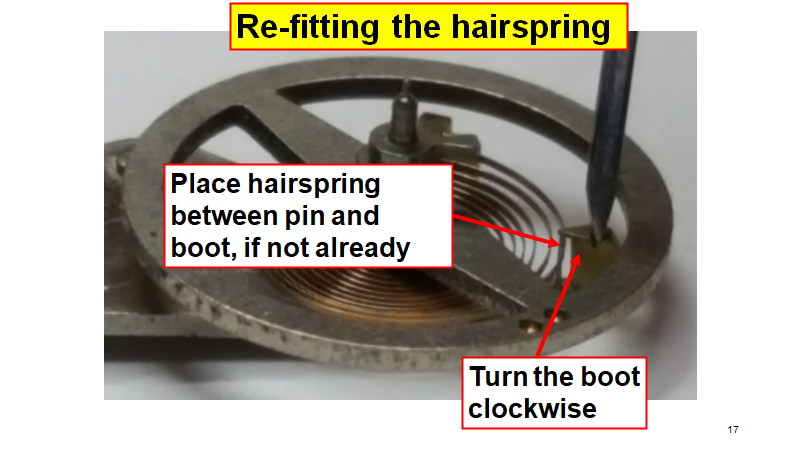

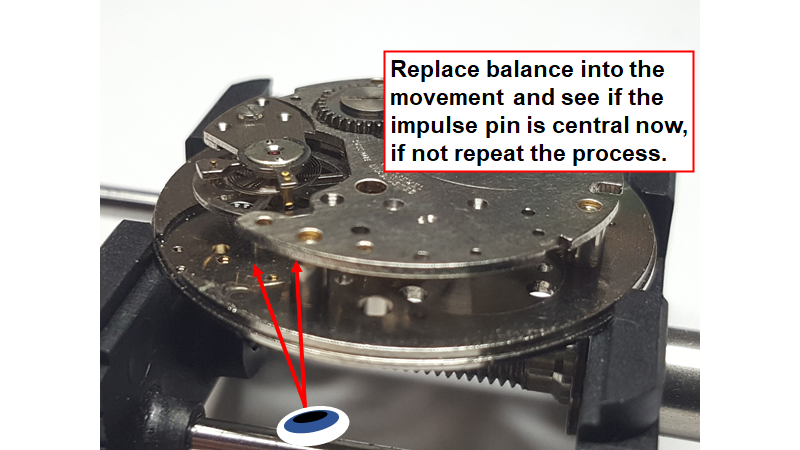

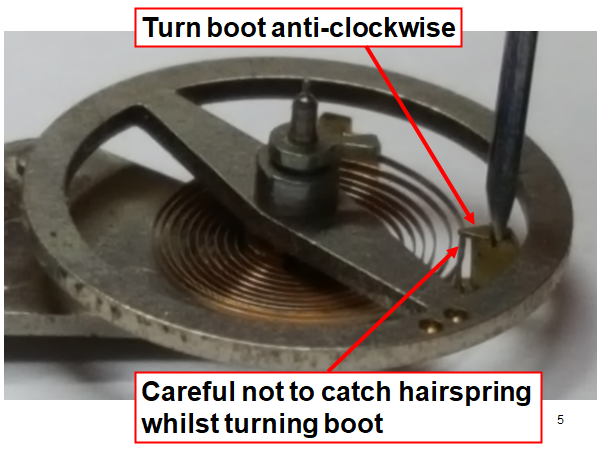

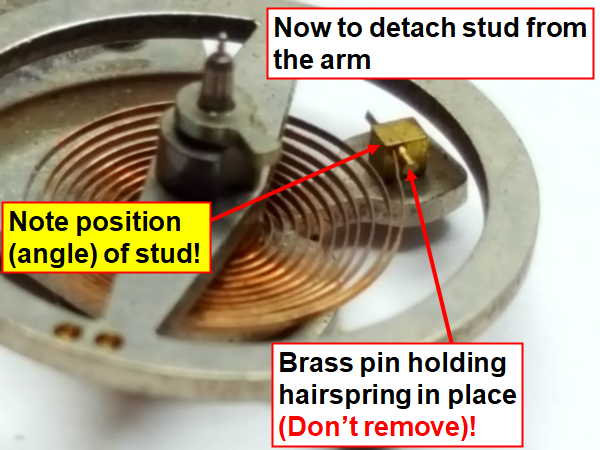

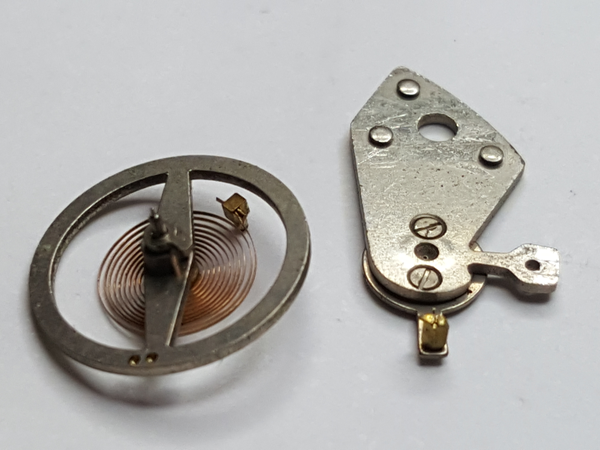

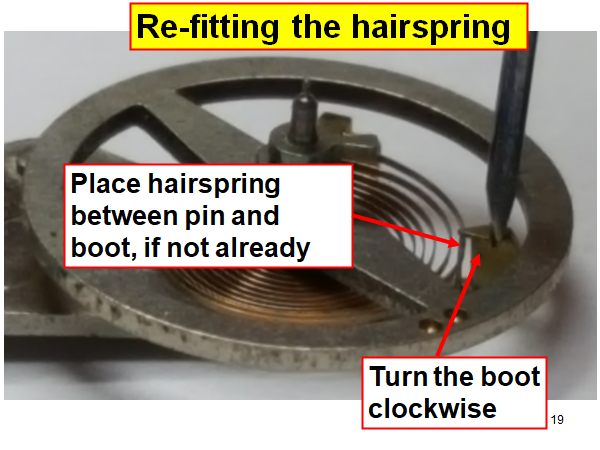

Hi, This is the third instalment on the Baumgartner BFG 866. I wanted to show how to bring the watch into beat On a previous walk-through of the BFG 866, I have described in detail how to remove the balance and hairspring to be able to oil the cap jewels As you look between the banking pins, the impulse pin is off to the left side slightly, putting the watch out of beat. The collet is turned in the opposite direction to the direction the impulse pin needs to move. So if in this case the impulse pin needs to move anti-clockwise to get it perfectly between the two banking pins, then the collet needs to be twisted in a clockwise direction You can attempt to turn the collet whilst fixed to the balance cock, but there is a much greater risk of damaging components, especially the hairspring. This is the way I teach my students, as it gives them the skills and confidence to remove the hairspring and balance from the balance cock and while removed they can oil the cap jewels as I've shown in this other walk-through on the BFG 866. I've got two more walk-through's on the BFG 866 that I'll post on the subject of adjusting the friction fitted minute wheel that is on the barrel and removing/re-fitting the centre seconds wheel and oiling the movement...1 point

-

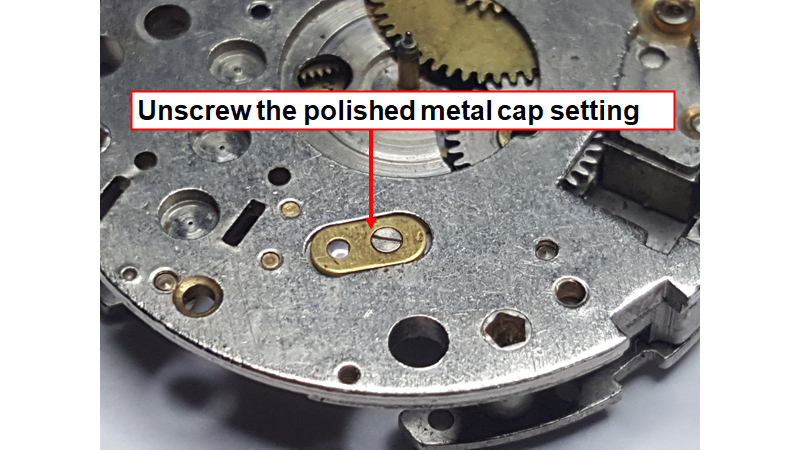

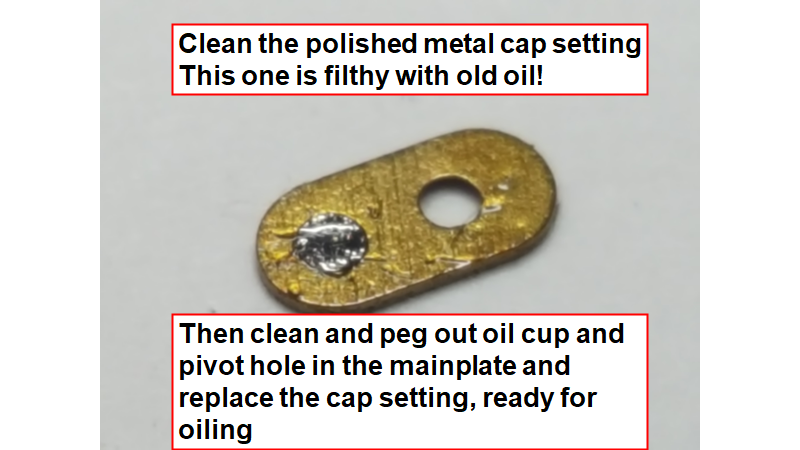

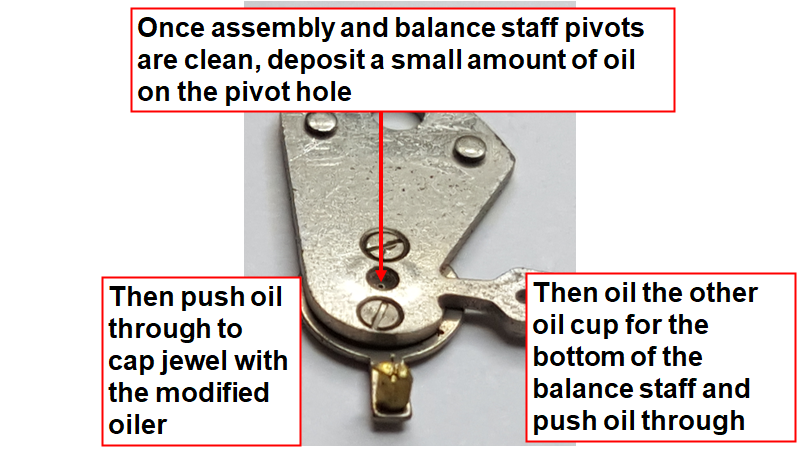

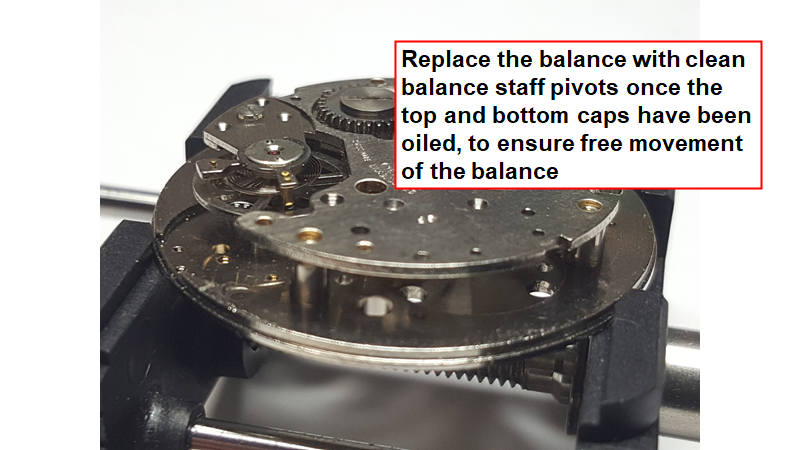

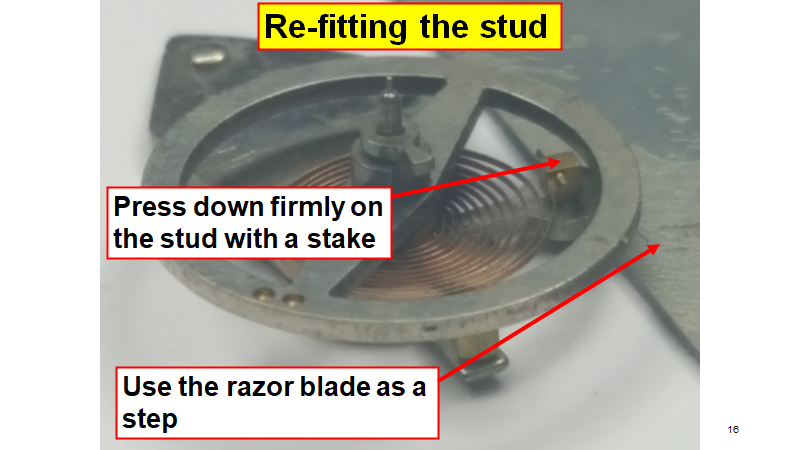

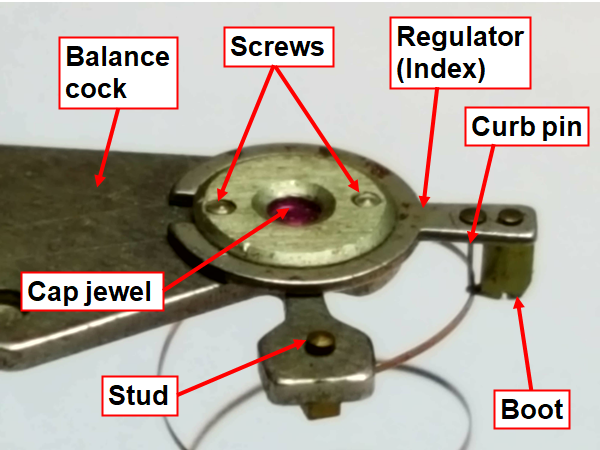

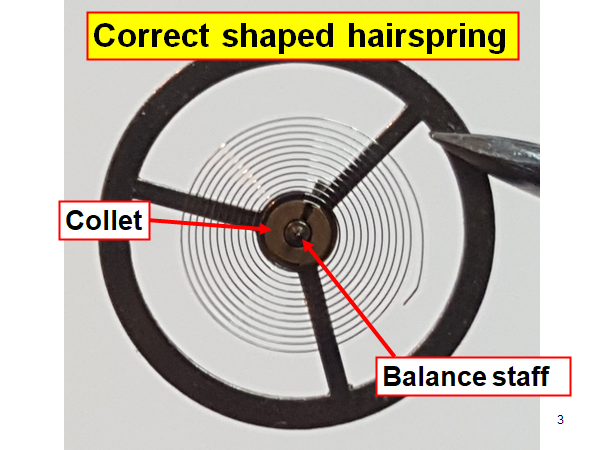

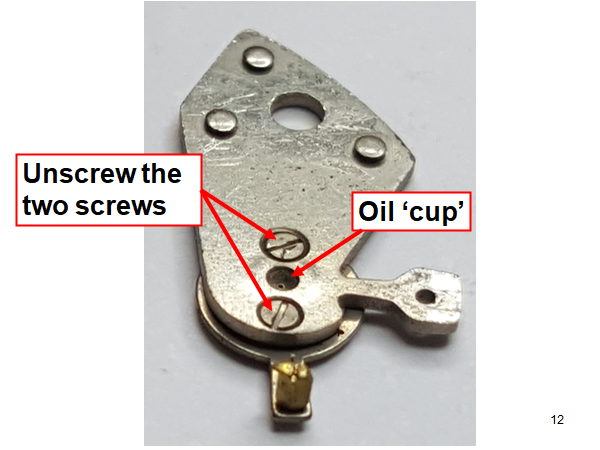

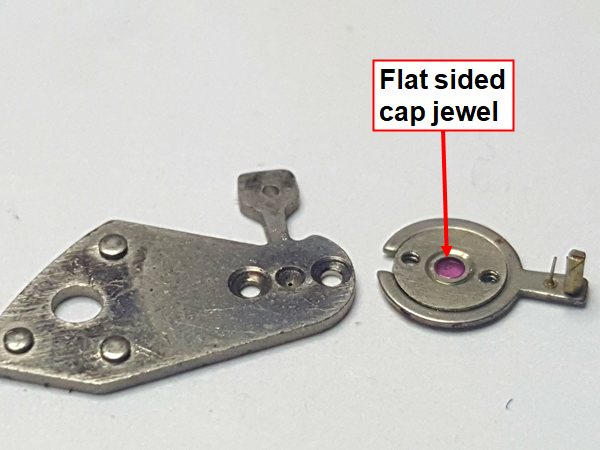

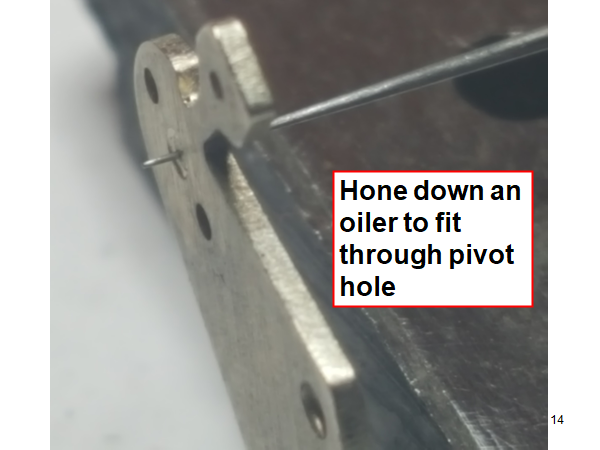

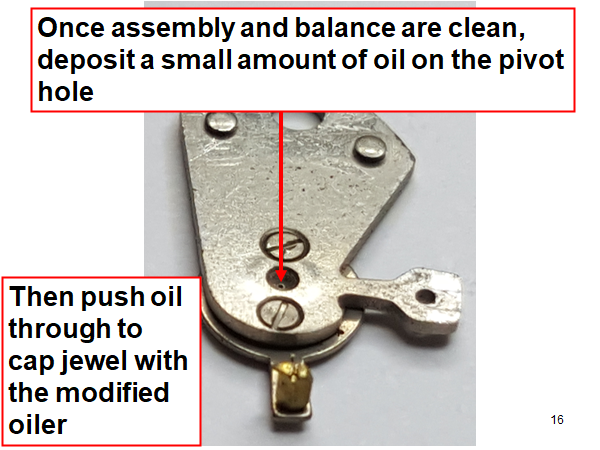

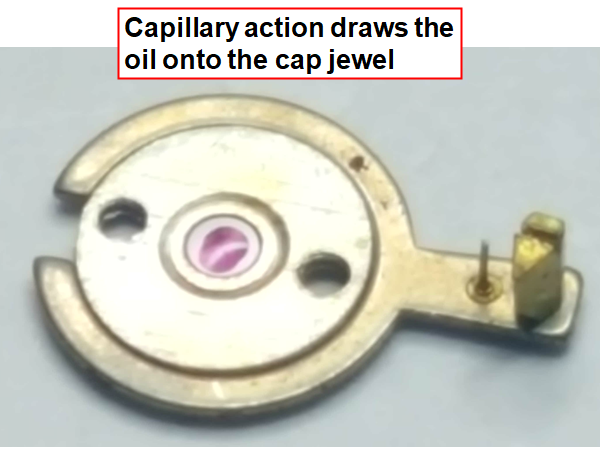

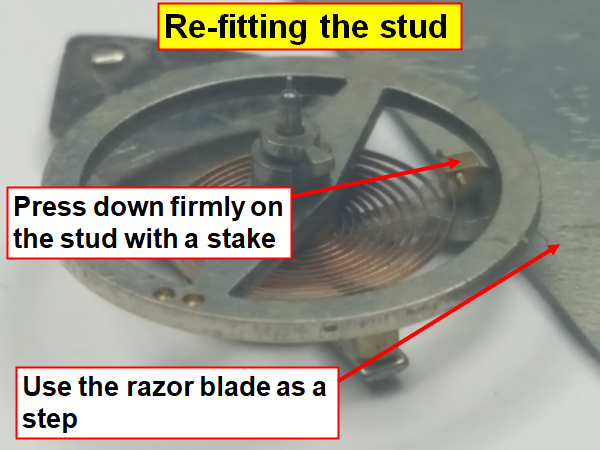

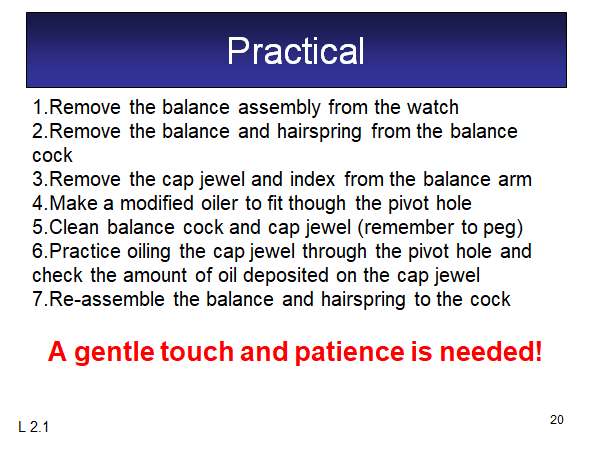

Hi All, I posted a while ago a walk through of the Baumgartner BFG 866 and wanted to add to it, especially as there is little out there to explain how to oil the cap jewels of a non shock proof watch. This is the balance cock of the BFG 866 and as you can see it has a cap jewel held in place with two screws, screwed from underneath. Some pull the hairspring out of the way to oil through the oil sink, but I find it safer to remove the hairspring, but also it is good practice to do so. If the balance and hairspring is removed the shape of the hairspring is seen a lot easier and any manipulation can be done. The hairspring may have to be taken off the balance if it isn't a simple tweak. Removing the balance from the cock is quite simple Measure the balance staff to find out how big it is, so when we make a tool to push the oil through to the cap jewel, we will know the correct size to make We need to unscrew the cap jewel to clean it Now we are going to hone an old oiler to fit through the hole in the oil sink that the balance staff pivot passes through Be careful not to damage the pivot hole Once the balance cock and setting has been cleaned thoroughly, we can then oil the cap jewel through the oil sink with Moebius 9010 If you are not sure you have oiled it enough, or your technique is correct, remove the cap jewel and have a look. Obviously before screwing back the cap jewel it will have to be cleaned properly again This is a safer way than oiling whilst the hairspring is attached to the balance cock. It may take a while longer, but it is a lot safer! It is also good practice in removing the balance and hairspring from the cock, but also checks the state of the hairspring, especially the uniformity of all the coils and how the hairspring is studded onto the collet The other cap jewel in the mainplate would be oiled in exactly the same fashion. Trying to oil the cap jewels and then fixing them onto the setting isn't a good way to oil them, as the oil will probably be smeared when re-fitting them. This is the way I teach my students to oil their non shockproof cap jewels I Hope this helps someone else in the future. More BFG 866 practicals to follow....1 point

-

Hello, Here is my watchmaker's workbench that I made with my father today : Dimensions: 1m in length 50cm wide 33cm tall Here is some picture without my tools and my lamp : The cuttings arent clean and smooth because we went quick as I needed (and wanted )the workbench quick, but if do an another one in the future, I will do a cleaner version for sure ! Does anyone have any recommandations for the workmat ? (excepted Bergeon) Thank you ! A. Nogues, a french watchmaking student.1 point

-

1 point

-

Hi all This came up for sale cheap (£200) very very near to me (Around the corner!!), The only trouble was that the owner was in Australia and i'm in the UK!! He had left it with a friend of his five mins from me, When I initially queried the watch through facebook, The lad didn't get back to me for almost two weeks! I thought it must have sold but he explained it was with his friend, Fast forward andother week and I went and bought it yesterday whilst observing the distance thing!! It's been on three different straps already!!, A Darlena, A Di Modell and now this flieger style strap, The Di Modell was very comfy but it was brown! The Automatic Valjoux 7750 movement.. It comes with Sapphire front crystal and screw down pushers and crown.. It has marks but isn't bad for a 12 year old watch!! All in all i'm over the moon with it!, The lad said it had a service a few years ago, No receipt so assumed it hadn't but I have to say, The movement looks new so maybe it has!! HAGWE John1 point

-

If you are referring to the wrecked Sicura then yes, that is one of mine, and it is still a bit of a work in progress. I'm looking for suitable hands for it. It runs fine, but in my opinion, the hands need to be a little more interesting and 1970s. It recently acquired a new bezel, which I may modify too, as the name Voyageur suggests that a time zone bezel was more likely than a dive one originally. This is its current state.1 point

-

Hi tidy job and practical well done, as regards a mat the large cutting mats as used by hobbists with a yellow grid on the grid can be cleaned off using spirit and hey presto a green mat, They come in several sizes can be got on line or from Hobby craft shops.1 point

-

1 point

-

As Nucejoe says It will have a split stem once removed a sryinge is used to pump air in via the stem hole, this will blow out the crystal under pressure so make sure the watch is covered, attached is the Bergeon pump but a normal syringe (Ink Cartridge refill) and a piece of plastic to make the seal around the stem tube can suffice. BERGEON 5011 Watch Pressure Crystal Removing Pump.html1 point

-

1 point

-

now when you mentioned it, I too cheat with this one with the same task.. but Officially I work with the lupe..1 point

-

I still have my good old Carl Zeiss Stemi DV4 (and a couple of more), perfect for the use I do with it, inspection, otherwise I just use lupes when working with the movement. Right now it just have a 12Mp camera but it is next in line is a long wanted upgrade to 38Mp. I don't use the camera so much since it takes both of the occulars in use. Find it faster and easier to use it like a ordinary stereo microscope. Once I tested making an adapter for these but like the original camera better, except the price.1 point

-

I have a Tag Heuer Aquaracer that recently came back from being serviced and repaired. The original problem was that the screw down crown became very difficult to screw down and eventually became impossible to do so. I did some research and it seems likely that I may have tightened the crown too much and stripped the threading. Ok, my bad. I sent the watch in through an AD and I had to pay almost $400 to have it serviced and repaired. They returned the watch and I have had it for about two weeks now. It worked fine at first but about two days ago the crown has become very difficult to screw down, just like it was previously before it became impossible to screw it in. I am quite flustered as I have been very careful about not screwing it in too much this time around. I have owned cheap invicta watches in the past and had no problems whatsoever with the crowns, yet a $1500 tag heuer watch is causing me these problems. From what I understand, the problem is that the threading is on the inside of the stem and it is therefore easy to cross thread the watch when screwing the crown in. Is it possible to go to a repairman (not the AD) and have him replace the stem with a non tag one? If so, how much would it be likely to cost. I would like to get this problem out of the way for the foreseeable future so I do not have to pay 1/3rd of the watch's value to have it repaired after two weeks.1 point

-

1 point

-

Each not much larger than a sewing machine bobbin, four more Timex Petites each got a well earned bath. The brown dialled one also got a new crystal. These are actually quite attractive, if basic little watches. They are also ubiquitous, with hardly a job lot on ebay that doesn't include at least one of these. As a result I have quite a number, in a wide range of colours. They are also very easy to work on, and it seems almost indestructible. The brown one is from 1979, the lower white one from 1974, the red from 1976 as far as I recall, and I don't think I checked the upper white one, but it is clearly the most recent of the lot. All except that recent one are from Dundee, it was assembled in the Philippines.1 point

-

I just found this video on YouTube today. I wished I had watched this when I was starting out on microscopy work. It would have save me a lot of pain. I urge everyone using a microscope to watch it.1 point

-

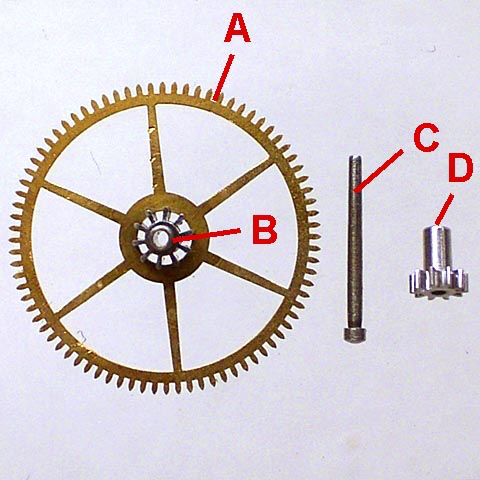

In order to press the arbor C into the cannon pinion D a staking set is ideal, using a punch or hammer is not the best practice since you will have to support the top of the cannon pinion and press from the head of the arbor, but your support should have a hole big enough for the conical end of the arbor to fit or basically you hammer will sandwich the arbor which will cause it to bend, but if the canon pinion is not seated correctly then you didn’t do anything to solve your problem. The arbor is already slightly bent in order to create a tight fit. Now You can go the other way around but then a punch will be needed with a hole big enough for the canon pinion to fit. If there is a jewel present it should NOT be used as a support. If you have any pegwood you can make yourself a stake. And a staking block out of a piece of wood. Micro drills come in handy here.1 point

-

1 point

-

1 point

-

Oil a few of the teeth of the escape wheel, by doing that oil will attach its self to the pallet pins, and it will prevent the oil from sitting at the bottom of the pallet pins.1 point

-

You are correct - that small screw closest to the stem is what you need to loosen in order to withdraw the stem. NOTE: you only want to loosen that screw about 1.5 turns. So, make sure it's not loose when you start, then unscrew 1.5 turns. You made need to push down on the screw just a little when pulling it out. oldhippy's advice on size is good. My guess is that should probably be a 0.8 mm (yellow - if you are using Bergeon screwdrivers). The base movement for that is a Peseux 335. So, you are looking for a case to fit that. But it's not an easy task to find a case for an old movement like that (at least it wouldn't be easy for me). I'd suggest eBay. Find a complete watch with that movement. Even if the movement isn't running - it's likely to have a number of usable spare parts for your project. -Paul1 point

-

The screwdriver blade should be a little bigger then the slot of the screw that is damaged, you don't want it to slip, but not to wide as you do not want to mark the the cut out sides of the plate.1 point

-

1 point

-

Good question. I had looked into the faster and more aggressive methods of acids or electrolysis, but went with a product called Evaporust. It's most important characteristic is it doesn't react with the base metal. It's a chelating agent formulated to specifically break the oxygen bond in rust. It's basic chemistry, but it is rather slow acting and kind of pricey. I gave the set a 24 hour soak before attempting to break it down to parts and then soaked another 24 hours. The stakes and stumps sat submerged in a jar for a good 48 hours. Then, everything got a nice warm clean in the ultrasonic -- broken into manageable lots. Finally rinsed in hot water and thoroughly dried. (see second set of images). I then set about polishing each piece with a soft wire brush or 320 grit wheel on a small Dremel tool. Finally wiped each with a lightly oiled rag before putting the tray. I rather enjoyed the whole process.1 point

-

Fitted replacement crystals to both of these today (arrived from 'Cousins' lunchtime), currently wearing the 7S36 'Superior' .........1 point

-

1 point

-

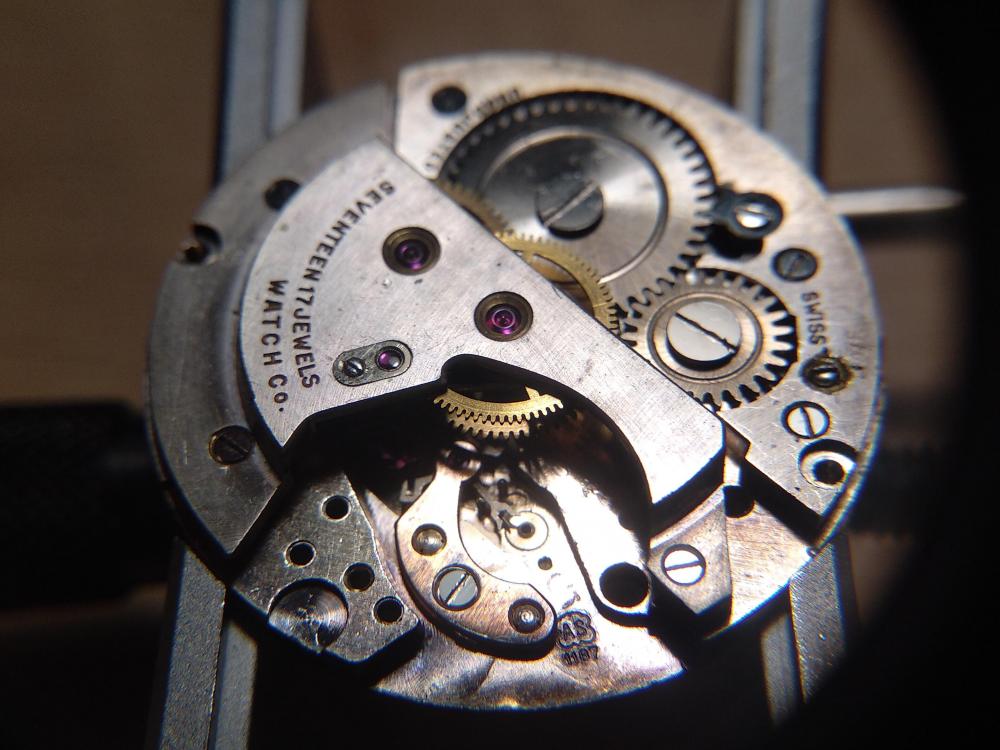

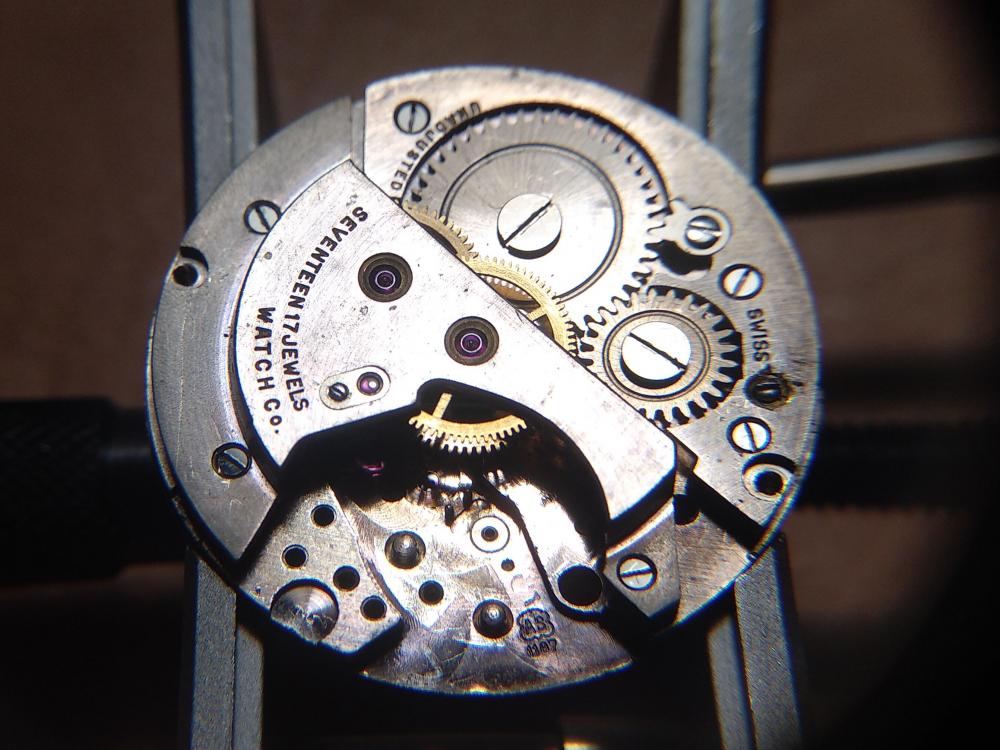

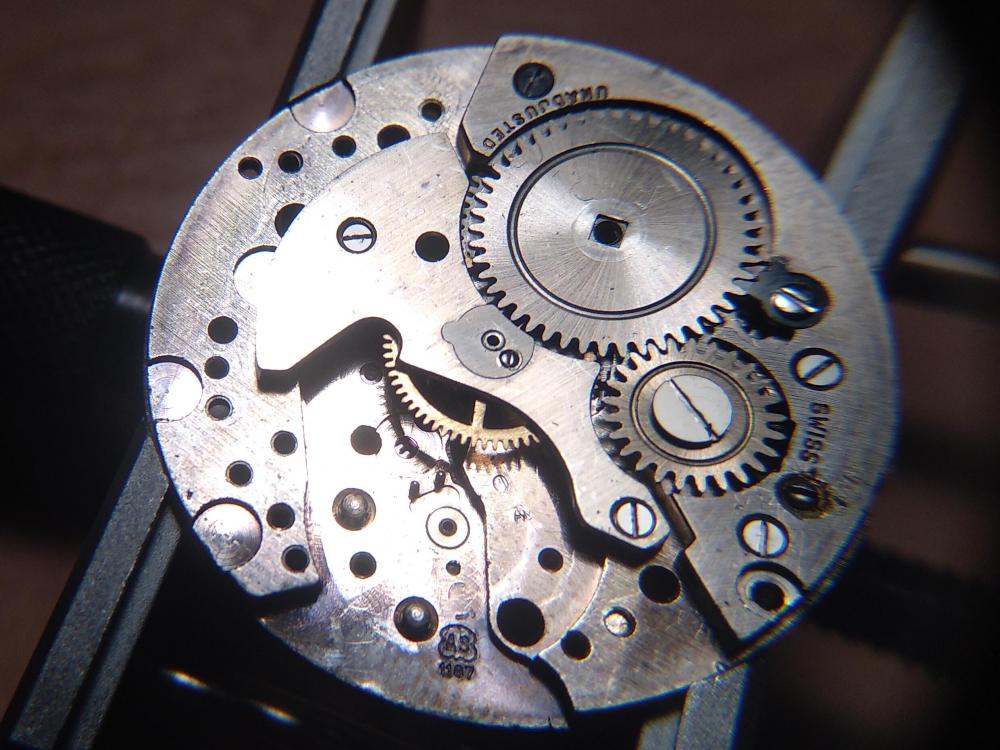

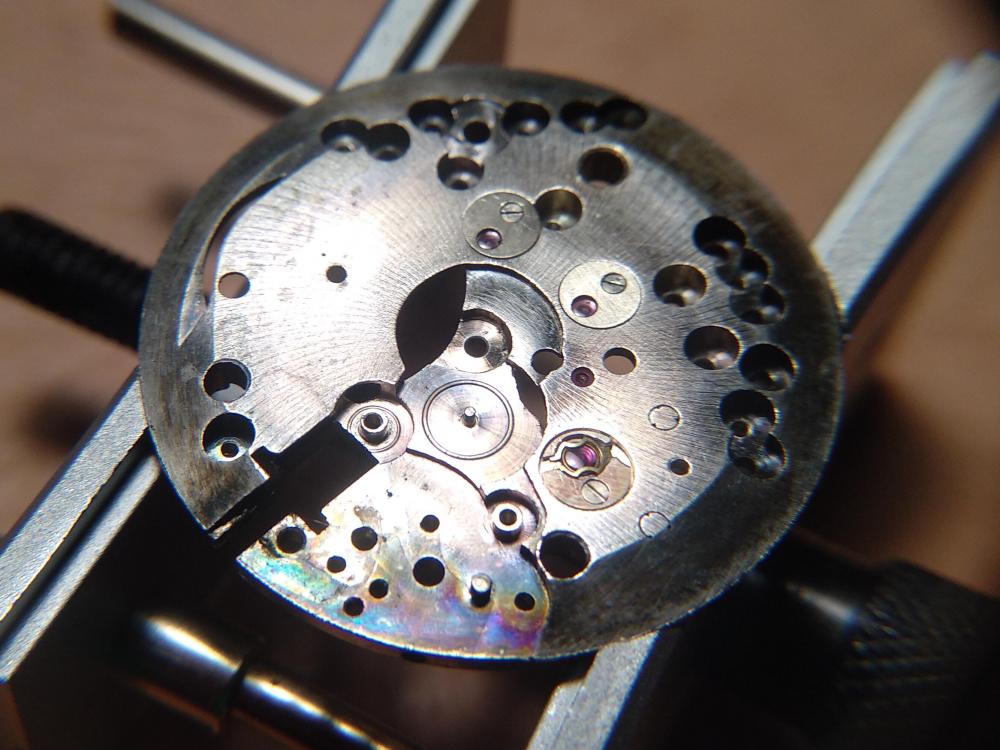

Hello, some updates regarding my project: After waiting a couple of days to receive my Bergeon 080 screwdriver, I managed to strip down the movement. Since my stem issue, I waited for the power to be completely depleted before attempting to take it apart. Unfortunately upon removing the pallet fork, I noticed that the movement still had some power and the pallet fork got caught into gear train. Exactly what I was not supposed to do. I believe I haven't damaged anything. Otherwise, the movement is now bare and ready to be cleaned. You'll notice that I left the mainspring in its barrel and the ratchet click hasn't been touched. I'm planning on cleaning everything with Zippo fluid. I do not have an ultrasonic cleaning machine at the moment. I'll keep you posted on any new progress.1 point

-

1 point

-

I would go with 9010 if that’s what you have, but the BHI recommends 941 or 9415 if you have that instead http://www.nawcc-index.net/Articles/BTI-The_Practical_Lubrication_of_Clocks_and_Watches.pdf1 point

-

Don't oil the pins. Some 9010 on three (evenly spaced out) of the escape wheel teeth faces should do the trick. Sent from my iPhone using Tapatalk1 point