Leaderboard

Popular Content

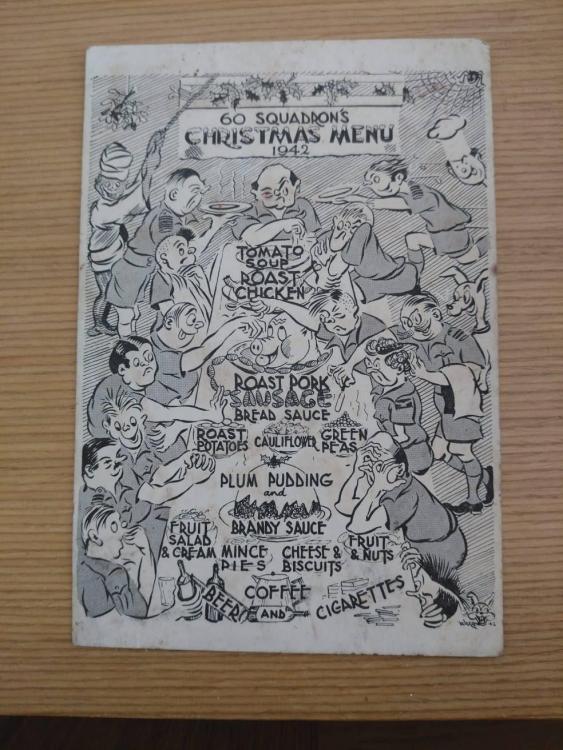

Showing content with the highest reputation on 04/26/20 in Posts

-

This picture does the dial much more justice........ I also have this one, a couple of years older (1975) but not quite as nice.....3 points

-

3 points

-

2 points

-

2 points

-

Lots of good stuff there @VWatchie you been really busy. And to confuse Deggsie even more I found a compilation I made not to long ago with some pictures which maby can bring some enlightment in your hunt for more amplitude. In my books most of the times one gain the most Amplitude when one concentrate in cleaning and lubricating the balance and escapement area since it is after all here the action takes place. Regulating the watch correctly also will give you a boost. A fresh mainspring will just add some more icing on the cake. So here is a small compendium I made just for you . Watch Theory Escape-Regulator.pdf2 points

-

So, an update to my repair. This watch has taught me a great deal about watch repair. In some respects, working on earlier movements has given me more of an understanding of the mechanics of a manual wind watch. The movements based on simplicity, without getting too complicated, and what a joy it was to do. In the end it was taken apart 3 or 4 times to overcome hurdles, aligning the bridge above the gear train to get them sitting perfectly in the jewels was quite an experience, thinking i've cracked it then then it would stop, only to find the hour and min hand colliding, then getting the click spring to catch perfectly through a plastic bag as i have a habit of making watch parts fly around my room. My biggest mistake was removing the front cap, slipping and colliding with the second hand which sheared off the top of the 4th wheel pin in which the second hand sits upon. A massive thank you to Rodabod who kindly sent me a matching Cal 59 movement the day after posting on this forum, which allowed me to replace the 4th wheel, then rebuild with the second hand now sitting correctly on the pin. And it works! I have it on my wrist and feel immensely proud. I am doing a shop for my dad this week and he doesn't know i've fixed it yet, i can't wait to see his face. Thank you to everyone who has given advice and helped me out on this post, I've learned a great deal from this and the watch bug has fully hit me. Once again, Rodabod, thank you. Keep safe all, Adrian2 points

-

2 points

-

It doesn't come out very often but I'm wearing my Burke today. I bought this in Plymouth back in 1985/6 when they first came out. All original and still keeps almost perfect time, loses about 2 seconds a month. I just wish I still had the box, but that probably got dumped by my parents when they moved house and I was away in the navy.2 points

-

Kind of... I was trying to un-clash the "logic and the physics"2 points

-

It is possible to replace the entire track, using self adhesive copper tape. This is a delicate operation, and I generally don't rely solely on the copper tape's adhesive, but instead use epoxy or at a pinch cyanoacrylate. Once you have the new track laid down, with care, you can bridge solder to whatever remains of the old track, but a better bet is to solder a fine strand of wire across the joint to join the old and the new. If the PCB material has been eaten away, then you will need to fill in the hole, and this is also best done with epoxy. This video is a reasonably good example of how this process is completed. Working on watch modules of course adds an extra layer of complexity, but it is doable.1 point

-

1 point

-

Yes...a small piece of the interior woodwork. Only offered on this reference I believe...2006. GB1 point

-

1 point

-

The most of your reasoning is correct, regardless on how the power is lost, there will be some parameters which are the same, like the mass of the balance and the lenght of the haispring, to make a philosofical approach without a lot of mumbo jumbo the moment of inertia which is supposed to generate the mechanical energy in the hairspring isn't high enough after a while. When the balance is changing direction the loss of torque due to a low amplitude will result in a slower acceleration of the balance wheel, remember Newtons second law of movement F= m*a where the F part can be translated into the torque described by hooks law. So (a) which is the acceleration equals a= F/m , with lower torque you get a slower acceleration, a slower acceleration results in loss of time. Guess that was what you initially were woundering about? Just a thought ...1 point

-

You can make a torque o meter of your own, solder a ratchet screw to a bar( hand) and some weights to hang on the bar. Surely there are proprietory tools made for manufacutrers, based on the same principle. Your watch is best tool itself, wind and make a record of how long it runs, to have a better graph repeat at half wind and fourth so on to get a graph of primery coils strength and thereon , in addition to power reserve you theoretically want a smooth curve for the torque throughout the length of mainspring. You agree why just replacing with a new one is the easiest and cheapest.1 point

-

1 point

-

1 point

-

1 point

-

Okay, I tried mimicin couple of times, I think I want a glass of cola to get my own voice back.1 point

-

1 point

-

1 point

-

1 point

-

Yes, I'm a dentist and I have tried. The problem is, in dentistry, we are trying to get our materials tooth coloured and translucent. Dental materials will not mask out darker material beneath it. Recently I experimented with UV cured nail polish. But again, the colour saturation and opacity is not enough. I can get whites almost the same colour as porcelain dials by adding titanium oxide powder and blending it till the opacities match. UV varnish is quite viscous and cures with a substantial film thickness. For porcelain repair, it might work. But for touching up printed designs, maybe not so good. Another problem is matching the surface gloss. One more thing, UV varnish doesn't adhere to metal that well. Probably when this lockdown is over and when I get back to my clinic, I will experiment with priming the metal with a dental bonding agent first.1 point

-

So, the jewel is capped, like a balance staff? May I ask what calibre? I have serviced two movements having capped escape wheel pivots; an ETA 1080 and an ORIENT 46E40 (Diafix jewels). I'd say about a third of the watches I have serviced have increased their amplitude. The rest have either maintained their amplitude or lost amplitude. In one case (and one case only) losing amplitude was a positive thing (a HAMILTON Khaki housing an ETA 2824-2) as it was re-banking in one position. After servicing the amplitude was surprisingly even in all positions. Dial up/down 330 degrees and in all other positions about 280 degrees. BTW, that is the best result I ever achieved after a service, but I was basically just lucky as the topic is complex not to mention often difficult to do anything about. I've made the following notes which I try to check when I have amplitude problems: o Too much pallet stone locking. The amount of lock is generally considered to be one sixth of the width of the impulse face. o Over-oiling in general, for example, the pallet stones, the seconds hand pivot. o Jewel settings not sitting flat under the anti-shock spring creating friction on the balance staff pivots. o Too little end-shake (remember the Seagull having a hump under the balance cock to compensate for this). o Pivots and jewel holes not cleaned and polished well enough! o Cracked jewels (friction). o Too weak mainspring. o Hairspring problems (magnetism, dirt, debris, asymmetrical) o The hairspring index pin being bent. o The hairspring not moving evenly between the boot and the index pin. o Train of wheels not running smoothly (friction problems). The Moebius 9415 Pallet stone oil seems to be what everyone is using but I've had some very good (better!?) results with "Dr. Tillwich Type 1-3". Anyway, WRT is full of threads on this topic so I'm not trying to start another debate about it here. Just thought I'd mention it.1 point

-

Mumbay specials refer to Indian supplied watches on ebay Which are usually a franken watch many of them are cobbled together from several watches to make one so the one you get is usually a hybrid of many parts, as long as you dont pay mer than a few bucks they are ok to play with or a source of parts.1 point

-

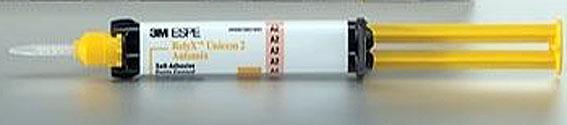

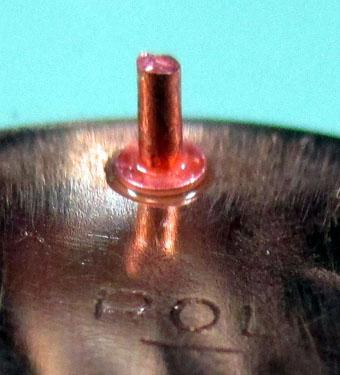

There has been some discussion in the past regarding the possibility of glueing dial feet. No really good glue was reported. However, my dentist suggested the use of 3M dental cement. She uses it for pemanent gluing of crowns etc. The strongest for metal cementing is 3M ESPE RELYX UNICEM 2. It is expensive but available on eBay with some limitations according to country. Here is an example of a test on a scrap dial. 6 mintes working time and after setting at room temperature for one hour I was able to lift, with the dial foot held by pliers, a 500g weight placed on the dial. Good enough as an alternative emergency repair when soldering could harm the dial finish.1 point

-

I started with small vintage women's watches.Then when you can work on them, a big man's watch is a very easy compared to a women's.1 point

-

The NH35 is date only and the NH36 is day/date. The only thing is that you have to use the original crown, fitted to the new stem, because of the extra complications the 7s26/36 stem isn't compatible with the NH35/36 movement. I 'upgraded' my SKX007 diver, replacing the 7s26 movement with an NH36 movement but because the crown cannot be separated from the stem on the SKX divers, I fitted an after market 'Jumbo' crown to it..........1 point

-

You can definitely skip sizes, but you want to use different sizes too; if you start too small you can lose your cone on the part.1 point

-

NH36, direct replacement, with the added bonus of hacking and hand winding on top of the auto.....1 point

-

The only time I have come across a gain in time as a watch runs down is in a Waltham 8 day car clock I recently serviced, which in effect is a big pocket watch with twin mainsprings. It kept good time for the first 6 days, then past that it started to gain time, because of the lowering amplitude, therefore a higher rate that the pallet fork was moving and turning the escape wheel. Between 6 days to 8 days it gained 5 minutes.1 point

-

The upgrade is to a an NH36, that hacks and manual wind. You can get it easily on sellers like Cousins UK, Ebay, or a bit more cheaply on Aliexpress.1 point

-

Hi welcome to the forum, An introduction would be appreciated, Whats wrong with the movement as is ? and a replacement movment complete 7s36m is available from cousins uk at £52.50, and I would guess they will be available else where, Jules Borel, Esslingers in the USA.1 point

-

I got a much simpler answer: index gap. Depending on the width of this gap, the lower the amplitude, the more time the hairspring spends floating between the gap, which = slower rate.1 point

-

That was back in... 2007 maybe? and more than 1000 miles away. If I'm honest, he was probably being a bit of a snob and wanted me to go away with my cheap crap and enthusiasm. As I recall, his justification was that it took him buying two other watches to find enough parts to make a single good one. I don't recall what was wrong with it aside from having been recased in a case that's obviously too big for it, but I imagine he didn't like his net on the job. These days, it's much harder to talk me out of my pursuits. I absolutely appreciate his showing me around the shop and educating me as he did, but once the tone turned I'd have probably written him off entirely had it happened today. Yeah. I should probably have spell checked it. I only know a handful of Russian words, and could only guess at the spellings of any of them. I bought it because I thought it was cool. Apparently I have an attraction toward military things. I don't like the military-fighting-guns-machismo of them, but the raw business like utilitarianism and simplicity appeals to the engineer in me. I have several military watches, there's a decommissioned military truck in my barn, my bandsaw was likely originally built for the WWII effort (it was sold a month after V-Day, and that's far too soon to have been much anything else), I could probably come up with a dozen other things if I looked around the house/shop/barn.1 point

-

1 point

-

I think I'm right in saying that if you could eliminate all energy loss from a balance wheel then for any given temperature its rate would remain constant regardless of its amplitude and it would oscillate with a perfect conversion between potential energy, which is at a maximum at the point where its direction reverses and for an instant the balance is stationary (kinetic energy zero) and the hair spring has maximum deformation from its rest state, and kinetic energy which is at a maximum (highest rotational velocity) at the instant the balance passes through the rest state point of the hair spring (zero potential energy). However, even before we introduce the rest of the escapement into the system there energy losses, mainly through friction, but also through hysteresis in the h/s, both processes which ultimately cause energy to escape from the system as heat. So you have to top the system up with energy via the escapement in order to keep it going, a process that introduces even more friction and therefore even more energy losses. The escapement transfers energy into the balance wheel via the interaction between the pallet fork and the impulse pin. This process only happens for the duration of the interaction between these two parts (i.e. the lift angle of the escapement) and during this part of the balance oscillation the balance wheel is accelerated by the input of energy as it rotates through the lift angle. The lift angle is a fixed parameter and does not change in relation to the changes in amplitude. However, during the engagement between the pallet fork and the impulse pin, frictional losses in the system are at their highest. This effectively means that the overall rate of the balance system is made up of two components. The period of acceleration as the wheel rotates through the lift angle (rl), and the period of swing through which there is no outside interference (r). r can be considered a constant determined by the physical parameters of the balance and h/s. However, rl will vary because as the m/s winds down and provides less torque, less energy will be delivered into the balance through the lift angle and therefore the balance will accelerate less. rl at full wind will be higher than rl at half wind. Also the influence of rl over the overall rate will increase as the amplitude reduces. When the amplitude is at say 310 degrees at full wind in an escapement with a lift angle of 52 degrees, it effectively operates as a free oscillator (without outside interference) for 83.23% of its swing, its rate will be r for 83.23% of its oscillation. During the remaining 16.77% of the oscillation, as it rotates through the lift angle its rate will be rl, so its overall rate will be (83.23%r+16.77rl). The escapement delivers enough energy into the system for the overall rate to remain constant. If the balance amplitude drops to 180 degrees at half wind (the lift angle doesn't change) then it effectively operates as a free oscillator for only 71.11% of its swing, so r only operates for 71.11% of the time which means that rl now influences 28.89% of the overall rate, so the overall rate is (71.11%r+28.89&rl). But rl is now slower than it was at full wind so it's impact on the overall rate is further amplified, and the overall rate will drop even further. If the balance amplitude drops as low as 52 degrees at a quarter wind though then the overall rate will be 100%rl, and rl will be further reduced by the fact that at a quarter wind the m/s delivers even less energy. So the watch slows even further. The ideal is to keep the torque from the m/s as constant as possible over as much of it's wind as possible so that the rate remains constant. However, once you get to the threshold below which the m/s torque starts to drop appreciably the rate will start to drop. If you've read this far then congratulations. If you've managed to follow it as well then I'm impressed This is just me thinking the system variables through though and coming up with a mechanism that seems to work. I know that it's not perfect as I know of scenarios in which very low amplitudes can result in an increased rate. In the true spirit of "The Scientific Method" please anyone, shoot my mechanism down.1 point

-

You're forgetting two very basic principles of physics here. Friction and Mass. No matter how polished your jewels and pivots are, or how slippery your lubricants are, there will always be a minute amount of friction. Specifically where the teeth of the gear train mesh with each other along with the barrel, mainspring and arbor. Add to that the inherent friction of the pinion and the hour and minute wheels and you have quite a bit of friction to overcome. All watches have a minimum amount of power required to drive the works at the correct amplitude. When the spring winds down, friction takes over. Finally is the mass of everything in the gear train but most of all the mass of the balance wheel. That alone is enough to bog the works down at very low power. An engineer who knows the mathematics involved should be able to calculate all of this information and give you the optimal power needed to properly drive an average watch movement at the correct amplitude. Nearly forgot, the balance spring itself also becomes a source of resistance at very low power. It can cause a tiny bit of feedback resistance that has to be overcome.1 point

-

I suggest you purchase a job lot of used watches from eBay. Trying to get them to work is often a challenge but whilst tinkering it improves your skills and knowledge and without any terminal damage to anything of real value.1 point

-

I will bring a vertex cal 59 into work and try to post it to you. Could you private message your address to me?1 point

-

1 point

-

So, you may find that the subseconds hand’s pipe contains the remnants of that pivot if it remained attached. What we need to do is identify the movement and find a spare. Shouldn’t be too difficult. Since this is an heirloom, if you can’t find a spare wheel then I will give you one of mine. But let’s try to find a spare first. Could you possibly post a “can you identify this movement please?” thread and see if anyone recognises the model? It will be one of the main Swiss manufacturers of the time like FE, FHF, AS, etc.1 point

-

I read your intro. My sister lives in Sac. Thanks for the welcome! My universe also thinks I'm an oddball. I like machines of all sorts, and have this odd notion that adding computers is cheating. By day, I work with computers and electronics. My best friend has a horological connection in that he built a new experimental resonator for the atomic clock at NIST that's 10,000x more accurate than the existing one. He thinks my tube amplifiers and pre-war woodworking tools are weird. I did get him into a car to wrench on though! I think you're onto something with the attraction to artisans and craftsman... A moment of personal revelation here (thanks for the inspiration!): the reason I have no real love for silicon probably has a lot to do the lack of artisanal craftsmanship. The engineers are mostly divorced from the final product. The devices are made by machines, and half-assedly slapped together by unskilled labor defined solely by price point... Certainly there are exceptions (and it's those exceptions that have me writing code today), but there's just no "soul" in a television set... There's a clear tie to the automotive world here too in terms of differentiating desirable classics from modern appliances, but I don't think this is the right crowd.1 point

-

Nowhere to go, nothing to do, get yourself a blank dial watch. .. or maybe one with GPS, so you can track your toilet rolls if someone steals them. .. or maybe something to help us go back in time and sort out the problem before it started.1 point

-

1 point

-

I had time to kill before an appointment today so I popped into a local thrift store and asked if they had any watches, The lady rummaged under the counter and brought out a box of random quartzs and, under a bunch of Genevas and "Frozen" watches, I saw this: Made in 1911, grade 336, 18s, 17 jewels... I said, "Yes, I think I'll have this one, please". It will run nicely sitting on its crystal but the balance wheel catches on the underside of the balance cock when turned on its back. There seems to be a substantial bend in the hairspring that may be the cause. I think I'll hold on to this one for a while.1 point

-

1 point

-

I clean all my balances in the ultrasonic and have had no problems, however I have learnt to be a bit more careful with the Pallets as the cleaning solution can get a bit warm if used for an extended time period ( I personally can use it quite a lot in a one session) and sometimes Pallet jewels can come loose due to the shellac/ adhesive softening because of the increase in temperature within the cleaning solution... Sent from my iPad using Tapatalk1 point

-

I have been collecting the tiny little Wilkin and Sons jam jars you get in some cafés, I can fit 3 in my ultrasonic cleaner and it means I can have a different fluid in each one if I wish. The brass fine mesh balls are useful sometimes as well for the really small bits. Like Bob and George I clean just about everything bar the dial and pointers. The only thing I would say is dont use any solvent cleaner type substance that could dissolve the shellac/glue holding the jewels in place. Since seeing Mark do it, I have started putting the balance back on the plate and it seems to be perfectly ok that way, it does not take long plus the plate gets a clean as well. Cheers, Vic1 point

-

Mark re-attaches the balance to the plate prior to cleaning in his videos, and the manually cleans the jewels after. Whipping around a liquid bath seems more violent and sitting stationary in an ultrasonic cleaner so I'd assume it's safe.1 point