Leaderboard

Popular Content

Showing content with the highest reputation on 06/08/19 in all areas

-

0.5ms beat error is a perfectly acceptable value and will not influence accuracy. If you don't believe that, regulate to the best positions average, wear the watch few days and let us know. Unless you are interested in learning how the hairspring collett is adjusted, which is a pretty delicate task, I would not recommend you try that on a balance cock with movable stud arm.4 points

-

Engineer today New OEM crystal gasket and crystal Still to do - refinish bezel, refinish bracelet, find or make bezel filler ring2 points

-

All is good with your watch. I'm so embarrassed, I posted with the brain disconnected, that is just the progress gap in your picture.2 points

-

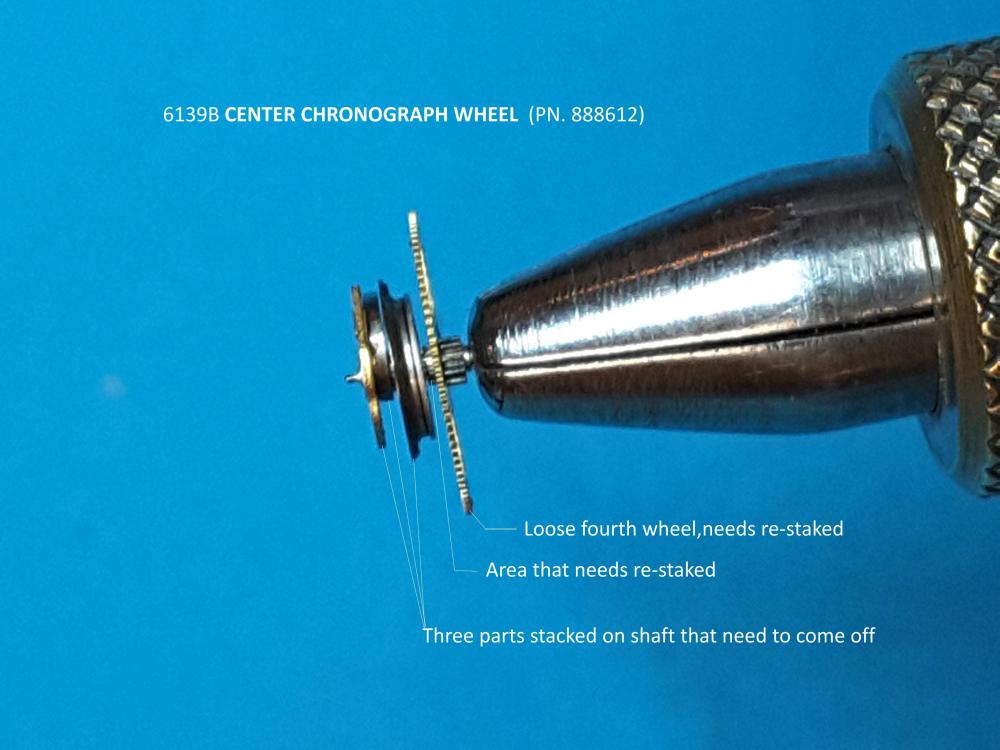

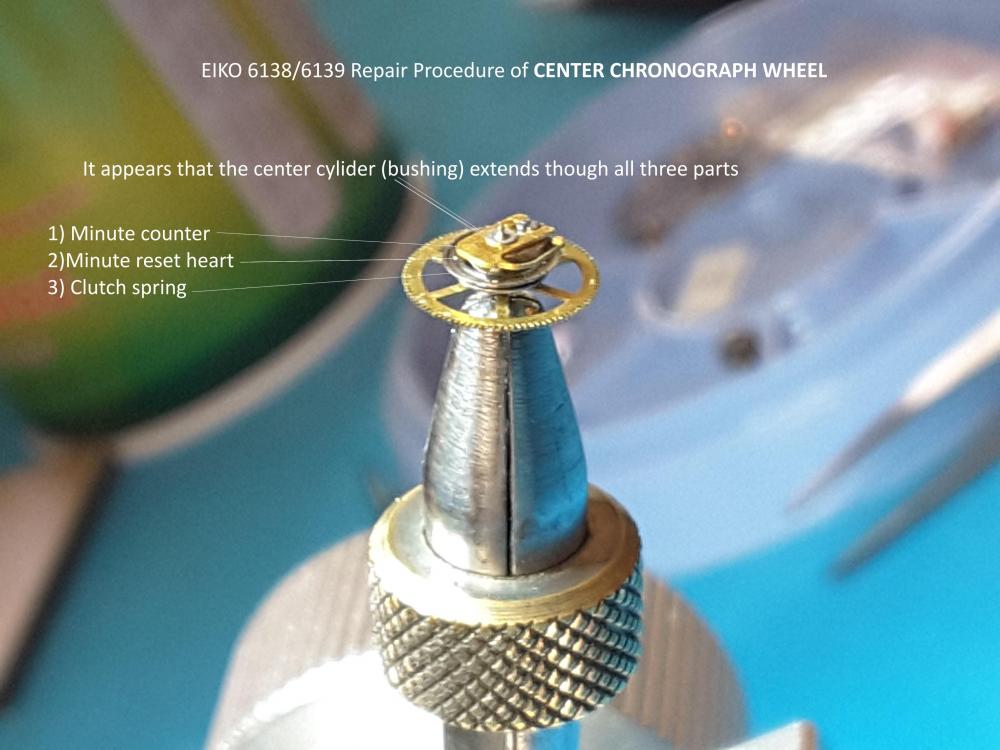

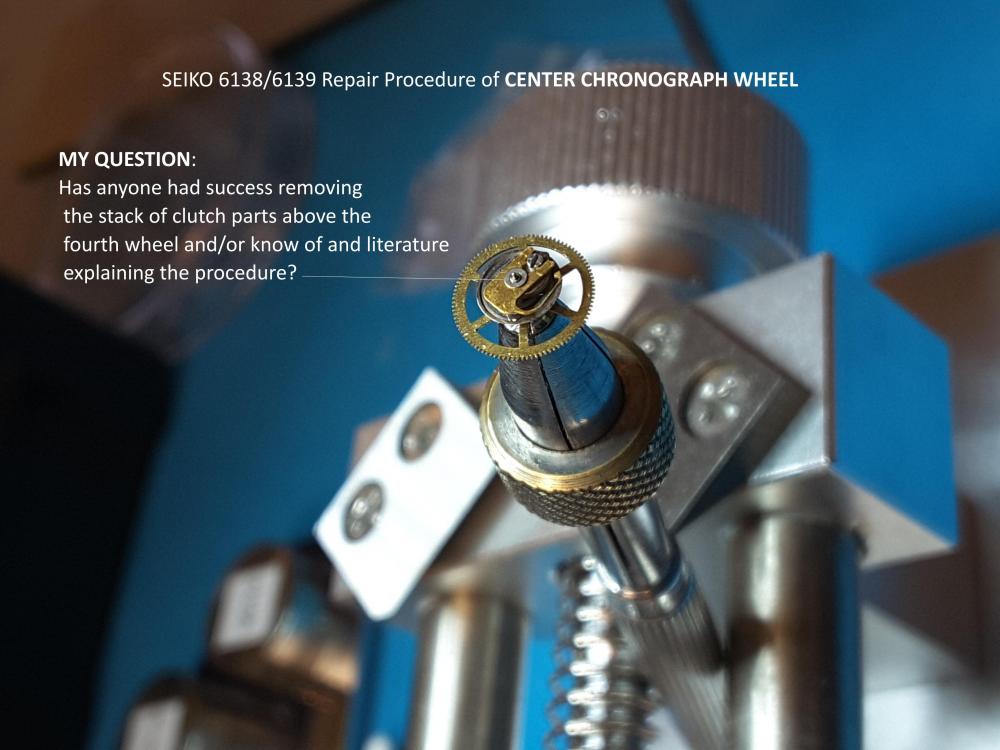

SEIKO 6138/6139 Repair Procedure of CENTER CHRONOGRAPH WHEEL PREAMBLE: My Quest for a Repair Procedure of Seiko 6139B CENTER CHRONOGRAPH WHEEL (PN. 888612) I have on several occasions searched for information on how to repair the infamous Seiko (6138, 6139) CENTER CHRONOGRAPH WHEEL, to no avail. Threads about the subject matter are generally sprinkled with authoritative sounding comments that they cannot be repaired. My question is why? Why can the number of parts stacked on the extended pivot shaft, stacked above the fourth wheel not be lifted off of the shaft, giving access to the fourth wheel staking location? In my case I have 2 chronos where the staking on top of the fourth wheel, holding it in place, has loosened making the wheel loose)? Logic leads me to believe, if I remove the 2-3 clutch parts (above the fourth wheel) off the top of the shaft, exposing the top of the fourth wheel, I could re-stake it and then re-install the parts in sequence, thus repairing my problem. MY QUESTION: Has anyone had success removing the stack of clutch parts above the fourth wheel and/or know of and literature explaining the procedure? NOTE (6138B): interesting that the Center Chronograph Wheel PN.888611 is listed, as one part, (a complete) and in the diagram it is shown as one-part, but in the part list there are a number of additional parts listed. I’m assuming this is the stack of parts sitting above the fourth wheel that make up the (complete). So with all of this said, how do we lift these parts off the shaft without damaging them and the chrono ASSY so that the fourth wheel can be re-staked? Thanks in advance, Will2 points

-

I agree! It could be that he is not the person he claims to be. His voice and attitude sound very young. I associate the voice and choice of words (like "There's a shit ton more.") with someone in his twenties. Another indicator of a young person is all the quotes of wise sayings. I used to be into wise sayings when I was young and still forming myself. The story about being forced to work with watches from the age of 12, and hate it, sounds somewhat strained. Also, he claims to have been trained by all luxury brand companies. "I've been trained by Rolex, Omega, Breitling, Jaeger-LeCoultre, and much more." "I've gone on to learn watchmaking formally, attend many brand trainings, and earned certifications under my belt." If I were him I would proudly have displayed at least some of my certificates. My guess is that this could be a very intelligent, gifted and "street smart" guy who found a way to make money by slipping a bit on the truth. Marketing seems to be a major interest in him. Well, I'm not afraid to show my certificates. I've earned them (with a margin) and I'm proud of them!2 points

-

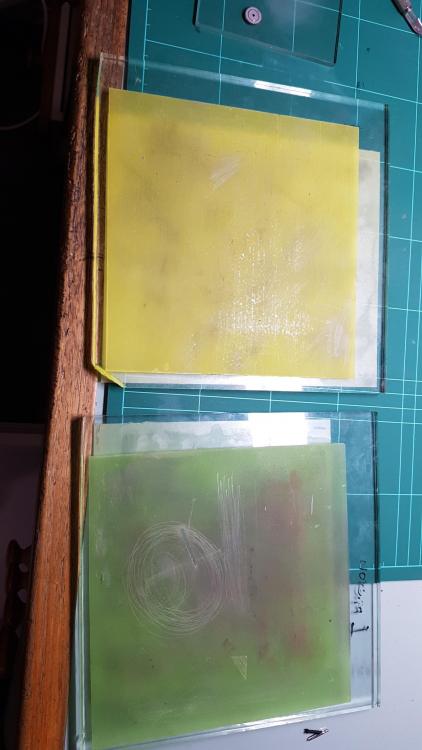

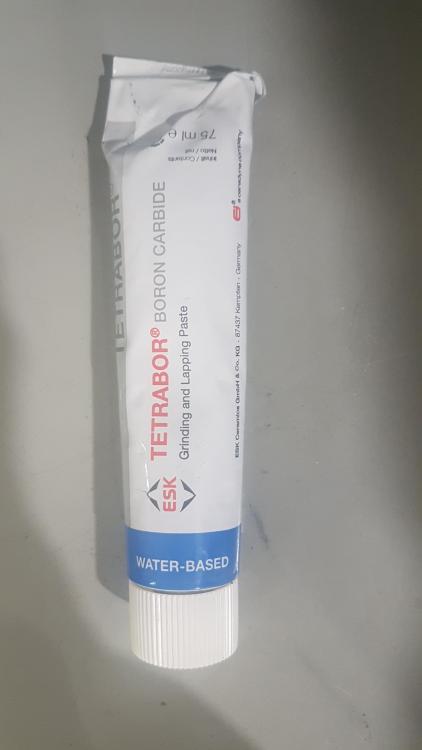

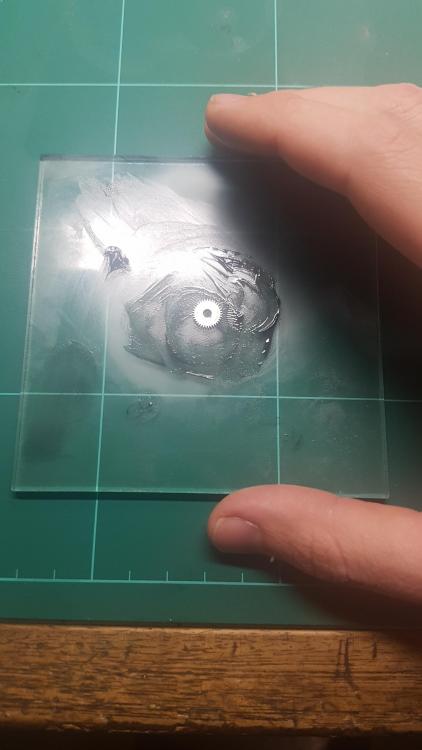

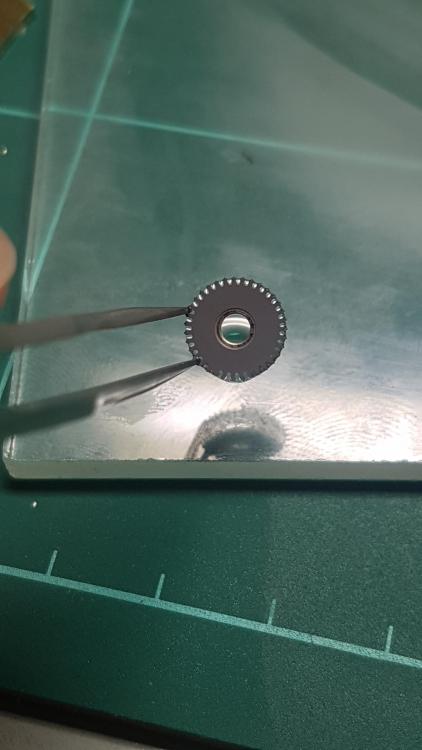

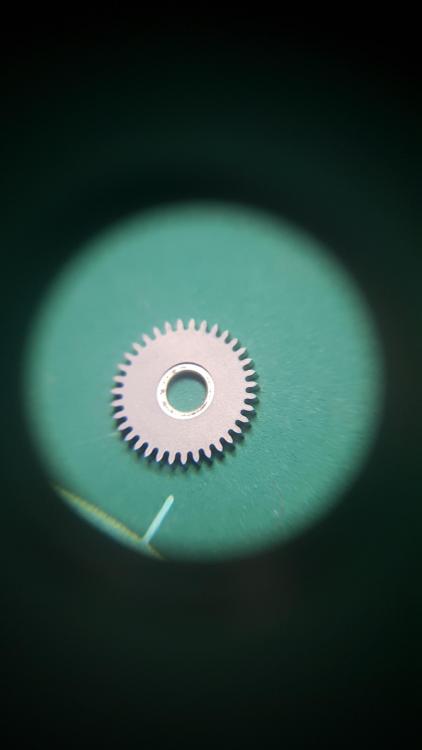

Hello All, This is my first post so I thought I would show a little finishing technique I learnt a while back. It basically turns the ratchet or crown wheel into a matte/ frosted finish. It was popular back in the day with some high end companies and still looks good in my opinion. I'll run through how it's done and try answer your questions as best as possible. What you need: 1. glass plate 2. Micron paper in various grits. 20 and 12 will do. 3. Tetrabor 800 grit/ mesh 4. Ultrasonic or cleaning machine 5. rodico First thing first, you have to flatten your ratchet wheel. To do this I use some lapping paper on glass. I start on a 20 micron and rub the ratchet wheel with my finger in a figure 8 pattern or circular or however I feel. (we arent trying to achieve black polishing flatness) If you are worried you can set up a jig to hold the ratchet wheel. but I often find using your finger will suffice. Once happy, move onto a 12 or 9 micron and do the same. At this point it is imperative to clean the wheel so that you remove all the grit from the paper that may be stuck between the teeth. So chuck it in an ultrasonic or your cleaning machine. Next place some tetrabor onto your plate, no need to add oil or water. place wheel onto plate and start rubbing it in. Generally it doesn't take to long no longer than a min or so. Doesn't hurt to check the piece to see how the finish is developing. if you want to check you can dab it with rodico, very carefully to remove the tetrabor. Do NOT wipe with a tissue or anything, this finish scratches so easy its crazy!! you can always chuck it through the ultrasonic (carefully) to see how the pattern is going. Its the checking and chasing that one last scratch which takes up the most time. The slightest bit of dust or dirt on the glass plate will scratch the wheel. You can always blue the wheel after, it comes out with an interesting tone when blued with this finish. This technique is fairly hard and does take some time to get good at, because it's just so easy to scratch and because of this scratches stand out against the matte surface. I'll try answer questions as best as possible. I try and post interesting stuff on Instagram regularly at least 3 to 4 times a week. obr_horology is my account on insta. its just time consuming to post (slow at typing) I plan on doing a youtube video in the coming weeks to better explain it. I learnt this from Henrick Korpela. Check him out if you haven't heard of him. He also writes in the AWCI and gives away a lot of info. Thanks O1 point

-

The AF Swiss ones are perfectly good. Far more important is the quality of the tips and keeping them well dressed.1 point

-

1 point

-

1 point

-

1 point

-

Well it's just like watches and car parts were classified once upon a time, and I'm surprised that Bergen still plays this game. Chrome plating is applied on a cheaper metal to prevent oxidation and make it look good. Stainless Steel is tough and looks good by itself. Eventually the industry advanced so much that SS become preponderant for most uses.1 point

-

No I think you're showing a poor attitude you'd have to keep up that enthusiasm and purchase one of these courses. That's because we would like the honest truth from somebody with experience as to what they think. A lot of times when newbies take courses like this there so dazzled and so impressed we don't get a real proper feel.1 point

-

If you look at all the marketing at least what we can see a heck of a lot of effort is put into this. But as the question was raised above it does make you wonder why we just get a first name? My first impression when I see something like this is to run away and assume it's a scam.1 point

-

+2 what JDM says. Always a chance of damaging the hairspring or collet.1 point

-

I will. Thanks for the suggestion. Sent from my SM-G950F using Tapatalk1 point

-

I would double check the size of the generic crystal. Generic parts are notorious for being marginally different. The other issue depending on the watches age, a genuine Rolex crystal has a holographed Rolex logo at 6 o'clock which can be seen with the aid of a LED torch. If this is missing the watch has been devalued.1 point

-

Messing with an old Elgin pocket watch. The impulse pin is dead center of the banks and I can only dream of .5 MS!1 point

-

1 point

-

You have to move/rotate the collet. Have a look at Marks advices.1 point

-

This is the time when you need to adjust the hairspring. It’s the next level up in complexity as you have to remove it, put the wheel on with the pin in the middle of the way and mark the spot on the wheel where the pin is located while the impulse jewel is right between the safety banks. Thought to describe without pics! Maybe others will have images or a shortcut? Good luck! Sent from my iPhone using Tapatalk1 point

-

1 point

-

Just my view, but I think the stem should come out after releasing the stem retaining screw. I think there is a movement spacer in there as well that is probably held fast by possibly corrosion and or the remnants of an o ring. Penetrating oil might do the trick, but also might cause dial staining. See if you can gently tease out the spacer after movement retaining screw removal or at least see if you can get any movement in it, this would provide a clue. I provide this advice without any knowledge of this watch or movement.....one thing for sure though, when it comes out you will know exactly what was holding it in place. I guess the trick is to find out before something gets damaged. Good luck1 point

-

Correct. This low-cost attachment enables you to machine thirty-six different unified thread pitches (Pitch range from 80 to 5 threads per inch) and twenty-eight different metric thread pitches (Pitch range from .25 to 2.0 mm). It also allows you to cut them as either left-hand or right-hand threads.1 point

-

Most people describes it like that. From what I've researched all specs are virtually identical, except for the chuck register of 15mm instead of 14. I like that is cheap, easy to get and it comes with base and screen, however from the net some (early ?) units came out with problems. Below the1 point

-

Get yourself a Unimat 3. It’s the only one I have and it does everything. Loads of accessories still available. The one I have has the milling attachment. Some good second hand ones on Ebay.1 point

-

Trying to post, just stick the pivot into a tooth pick longitudinally.1 point

-

The problem with these small movements is that each time you manipulate things, you get close to disaster. And it's a game of numbers. Cheers. .. well put sir! Sent from my iPhone using Tapatalk1 point

.thumb.jpg.a42f74a51c04ccee48e4af6912ff067a.jpg)