Search the Community

Showing results for tags 'repair'.

-

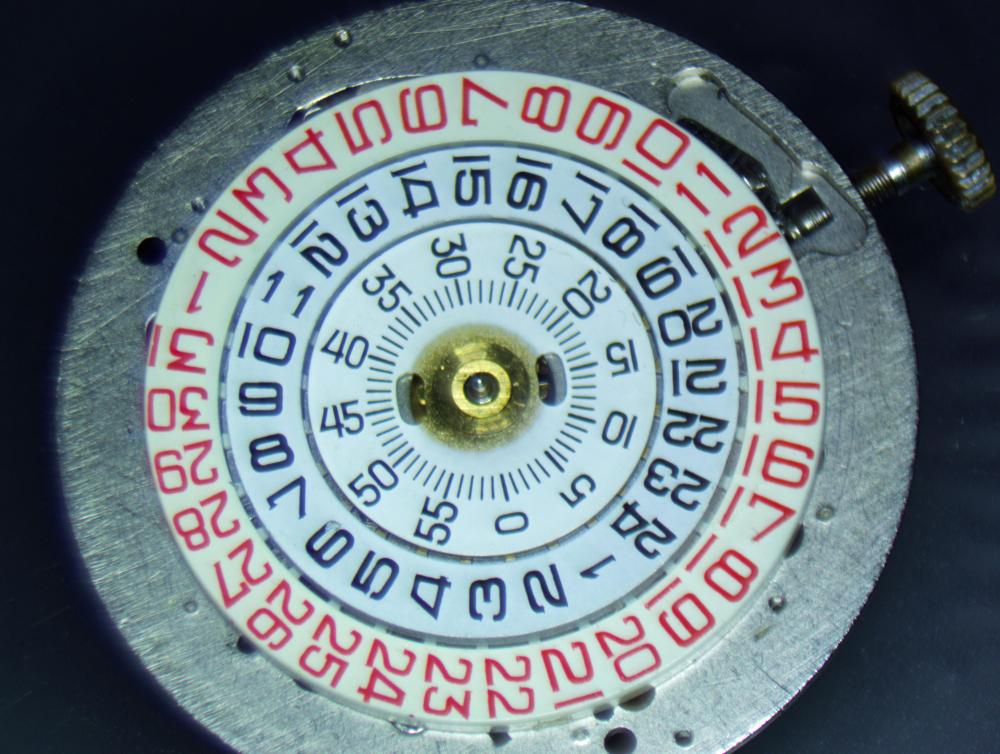

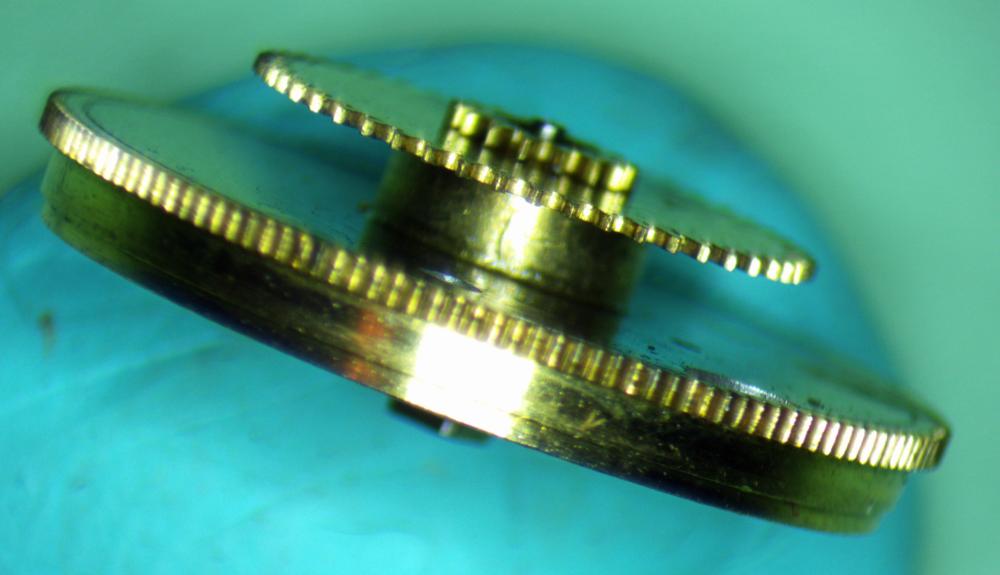

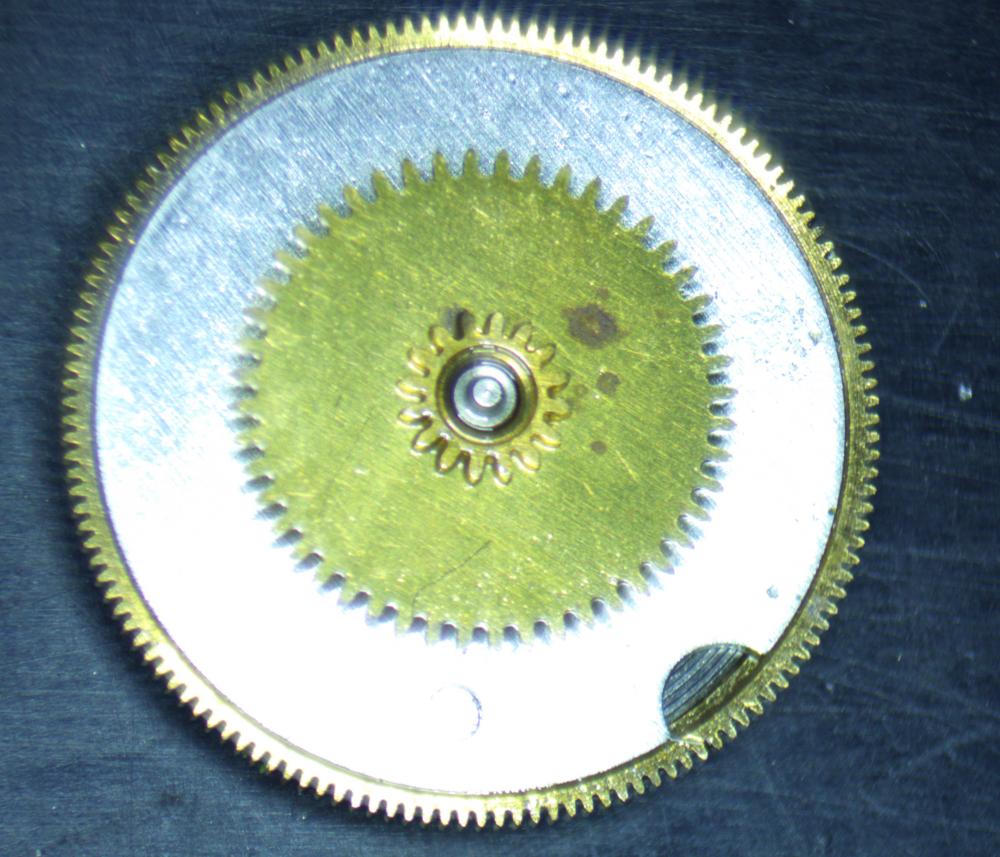

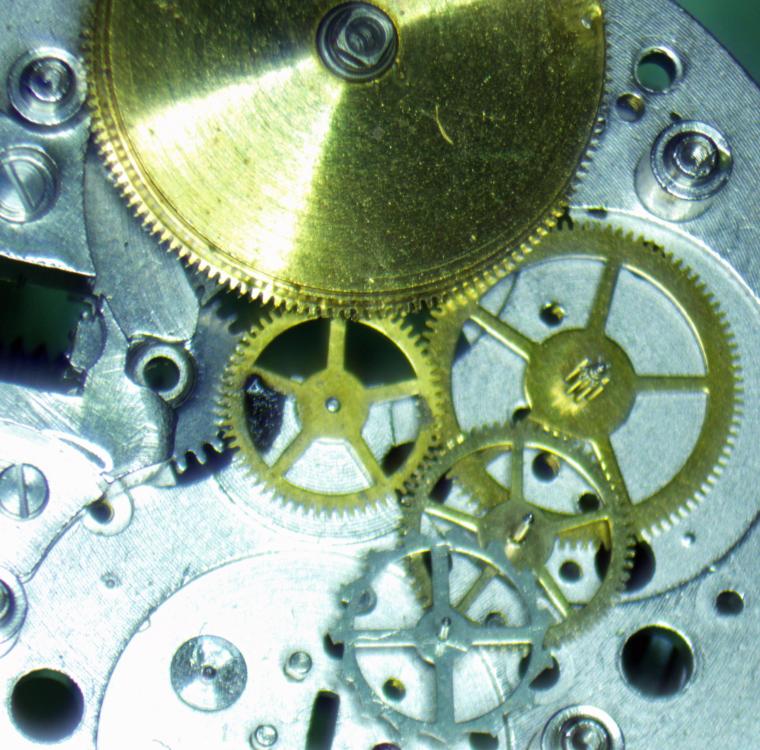

Hello again watchbangers! Here I am again with my newest project I had on my table with the appropriate walkthrough for anyone in the future! If you do not want to read everything, here is a link to the full Youtube Video: https://youtu.be/Fw2DmVTBdxQ Now it was only a matter of time until something really patina-ed would find itself to me and this was it! My very first pretty nicely patina-ed dial! I have had plenty of patina-ed watches before, with all kinds of horrible patina ( or damage), so I really grew fond of this “nice „ one while working it it! Ironically its a Dugena Tropica ( hehe) which is in rather good condition! From the outside the large issues were the extremely gunked up areas around the crystal as well as the battle scarred crown which would need a replacement! And the watch was ticking! Funnily enough, the case back revealed the habit of a previous owner wearing this watch on a nato strap for quite a while I think ( With the marbled pattern on the metal) ! Now opening the watch revealed many previous marking on the inside meaning that this watch was probably cared for well and a very pretty perlage finish ! The inside revealed a fairly simple movement with a pretty blued balance spring and nicely polished screw for the ratchet wheels ( even if they don’t look like that on the picture). There was a fair amount of dirt stuck to the case holder ring and in the thread of the case back, so I will clean that out with an ultrasonic before putting the serviced movement back into it! I released the movement from the case by unscrewing and taking out the movement clamps ( they where a real pain to work with) and plopped it out onto a cushion to take a look at the state of the dial. The dial had a nice hue to it with a few blobs of deeper colours scattered around the center. For some reason, there was a higher scale of “degradation” on the right side. Maybe there was more moisture there? Or more sunlight? If anyone maybe has a clue why this happened please comment! Otherwise its cool to realize that the hands used to be a bit too low on the dial as you can see the circular scrape marks of the hour hand which probably took away some of the patina! When I checked the hand height however, it seemed like someone fixed that issue already in the past! The indices as well as the hands looked sharp and I might just polish some grime of them with some pith wood later. Taking of the dial and the hands reveals a petty complicated dial side at first but after a closer look is basically an older version of the typical eta calendar system nowadays. So I start by taking of the hour wheel with the friction spring, the cover plate for the setting wheel and the wheel itself. As the cover plate was also keeping the date ring in place, I can now remove that aswell while also not forgetting the date lever and its spring. Thirdy I took off the date wheel which pushes the date ring one day further. Now I know that it works on a similar “spring” concept as I also removed a spring lodged underneath it but I somehow cant wrap my mind around the exact method yet. Then I removed the newly revealed cap jewel ( love those) for the escapement wheel. Then I took out the setting cover plate and then yoke, the clutches and the yoke spring. The setting lever was screwed in from the back side so I will just unscrew that later. Don’t forget that! With that done, we can switch to the back side of the movement and take off the balance wheel first to make sure that we don’t accidentally damage it when further working on the watch. That also revealed the caliber number which turned out to be the ETA 2408 movement. Then we take of the ratchet and winding wheel with the click and the click spring , which where lying in the milled groove beneath, which I found pretty neat, the click also had a cool curved shape which I like, you can see that in the video. Off goes the train wheel bridge revealing the simple gear train. Then I took out the gear train as far as I could, so the seconds-hand wheel, the third wheel and the escapement wheel. I took of the pallet fork and its bridge in the same step.. Then I turned my attention to the last two “wheels” and revealed them by taking of the barrel bridge. I removed the barrel and the minute driving wheel ( which basically hooks through the entire plate to the front side and drives the minute wheel.) With that the movement was basically disassembled and I had a quick peek at the shock systems. This watch interestingly had a screwed down Inca-Bloc on the main plate side, I wonder how that would work when adjusting end shakes? I took both jewel packages out for the cleaning Now after cleaning all the movement components in a 1:2 ( Cleaning / Rinse) cycle with Elma WF Pro and Elma Suprol in my trusty Glashütte cleaning machine I reassembled the watch by following the steps backwards and lubricating on the way! Here is list of which lubritation I used where: Moebius 9010: Escapement wheel, seconds hand wheel, jewel caps. Moebius HP 1300: Mainspring Arbor, Barrel pivots, minute wheel (both), minute driving wheel, Pivots for transmission and setting wheel and contact surface of the date lever. Moebius 9415: Pallet fork jewels Molykote DX: All strong friction points in the gear less works and on surfaces which showed high stages of wear. After the reassembling the watch and lubricating everything I slapped it onto the timegrapher. Of course I demagnetized it before. The dial up side had an alright rate and beat error however I am unhappy with the amplitude. As I didn’t have a spare mainspring, a new balance spring or the ability to manipulate the palettes, I just hoped that the amplitude would rise a bit after the watch had run in a bit and would maybe even gain a bit more through the tension of the case clamps. I also replaced the crystal with a one and cleaned up the grimed up case with some physical force and an ultra sonic bath. The final product was this beauty: This project was a fairly simple one! However pressing in a tension ring crystal was a first! It defintly felt weird pressing down on an acrylic crystal haha. Otherwise it is a bit frustrated not being able to physically influence the ampltiude other than by replacing parts. I will definetly be looking into getting a heating plate and some tools soon so that I man manipulate the escapement! Gotta get those degrees up! What I also found really cool is that I could see a previous version of the modern Eta date wheel! It was like a little time machine going back 40 years! Anyways.. I am rambeling on now so I will cut it short! I hope that this post helps anyone in the future and I am sorry for any misinformation! I am not a professional of any sorts and am just doing my best! If you guys have any thoughts, comments and complaints, please comment!

-

Hello to everyone! My first post ever here! I would like to kick off by saying I’m glad I’m here and I have been watching YouTube videos made by WatchRepair! My name is Stan and I’m trying to get in watch repairs and would love to build my own shop to do this as my life business! And I started by going in to Rolex so I bought an post car crash totally destroyed Rolex submariner 2022 126610LN case was bend and cracked, crystal was smashed glass on inside date wheel and dial which was beyond repair missing hands and broken strap with missing clasp! Total mess AD Rolex at Stratford and in Sheperds and Bush Westfield advised wheel just buy new watch! As also it did have water damage! Sounds crazy threatening haha but hey my life is to sweet so I wanted trouble on my head! Could not keep out of it! Won the bids and watch was shipped from Netherlands crazy part paid 780£ with customs another 90£ approx to be released to me from DHL! Now fast forward bought loads of parts and genuine parts along with aftermarket to keep within reasonable costs! Most genuine parts are new except few that are original from the watch some light rusting was on automatic movement but managed to clear most just few bright orange spots but hey better than it was! Now balance wheel the hair spring and bridge and palet fork and escape wheel brand new extremely expensive around 1900£ for those parts as had no choice! Now all assembled on aftermarket service main plate with Rolex standards quality! Some movement minute wheels and gears are generic aftermarket, all automatic movement and all bridges are genuine original, same for barel and spring all original, date and date disk genuine! Has some of the most beautiful sound of changing date what a pice! now the issue after assembly and oiling the jewels with Moebius hp9104 and hp9010 and also with grece 8301 on some friction parts and on inside wall of barrel spring all was put together and I use spring winder tools I also have magnifying glasses and magnifying headset got loads of toys to make it work just don’t have the ultrasound cleaner and microscope sadly, all money went to this life project! so issue is that somehow my minute wheels would stock won’t move freely when fully assembled and same time for paper fork and escape wheel, and my balance wheel would only rotate half way it’s like there is something not allowing it to move! I have re visit watch movement 2 times and also checked under magnification all pins and pivots all in place and in great chape as I learned if something won’t move to not force as this can cause tension and brake something and that would be an crazy money lose! So I’m very patient and cautious! At this point need some help and guidance step by step! As still new in this and I did practice on a clone movement to make sure I know were is all and in process broken escape wheel on clone but again that is 78£ comparing to my now 4890£ 3235 movement! see some photos below and YouTube video

-

Hi! My name is Sebastian and I know not a lot or anything about watches. But this old xeric is watch my father gave me. The skinny hand on top fell off and isn’t working anymore. I’ve tried taking it to xeric company and several jewelers in town. However, no avail no one is able to fix it. And idk where to go or who to ask to get it fixed. I would love to get it fixed since this is my first watch and it means a lot to me

-

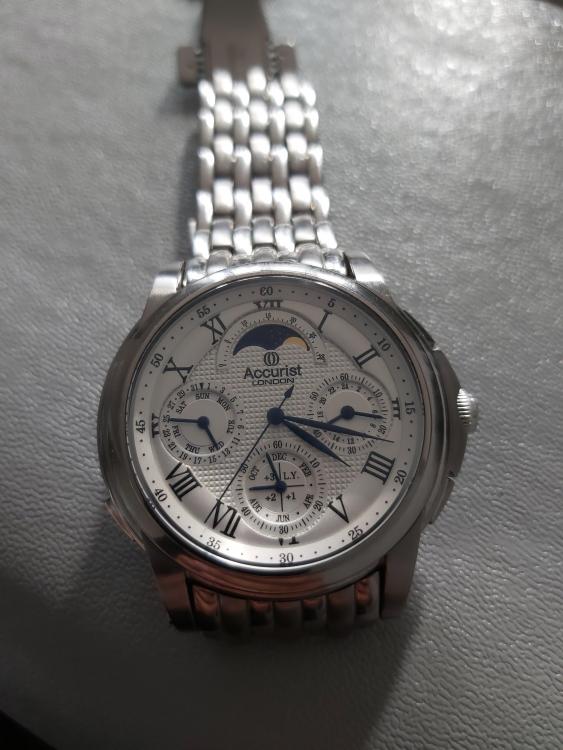

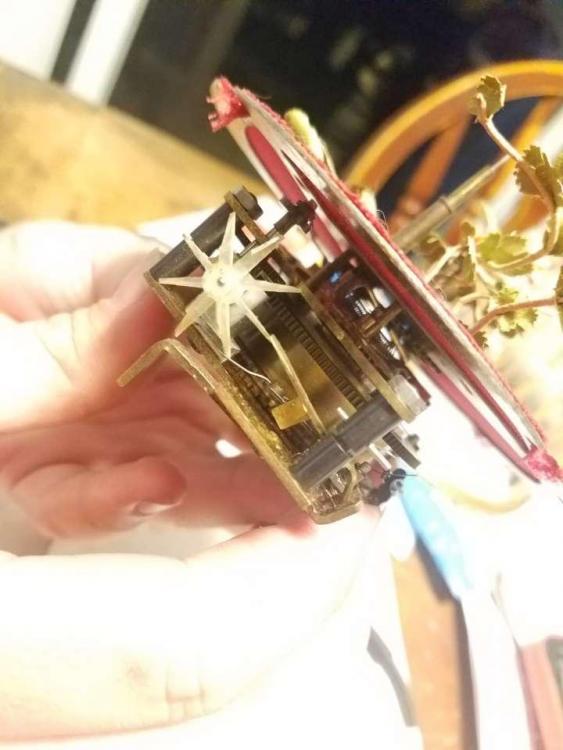

Hello Everyone, I recently bought myself a cheap repair kit and I successfully changed the battery on this watch that was dormant in a drawer for about 4 years! However, the problem is I haven't done something right as the day sub dial is ticking away same as the second hand sub dial!, I'm sure it isn't meant to do that. I'm obviously putting it back together incorrectly and also the two little white plastic cogs you can see in the pics, I can't remember where they go?! If someone please can talk me through the process it would be massively appreciated or any pointers, advice would be great. Thank you

-

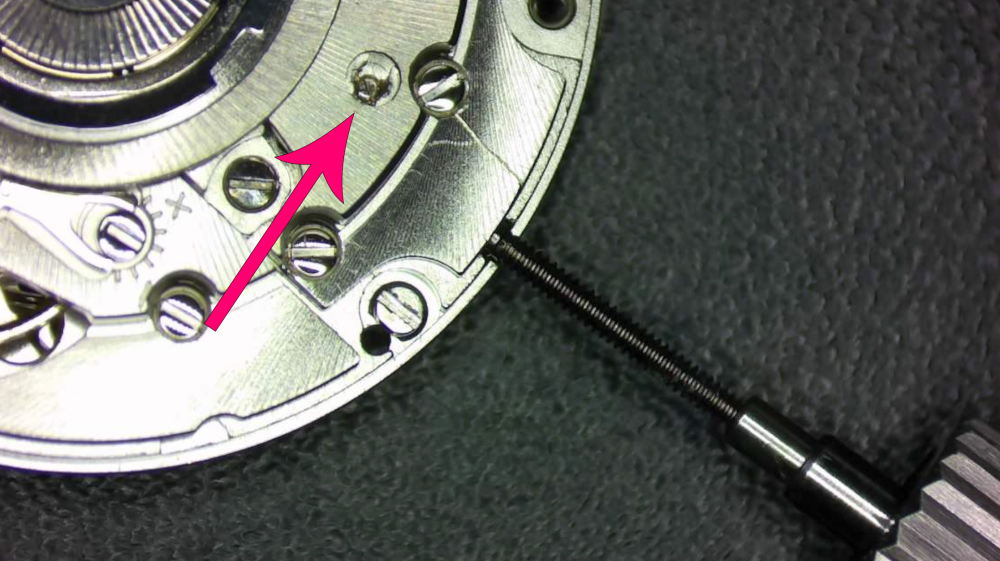

This movement is a little over my head for a newbie. I wanted a GMT watch so thought I would build one. I am baffled by the mechanism that retains the stem and how did I mess it up. The first challenge was removing the winding stem by pressing on the noted spot in the following image: This is a mystery to me when trying to find this in the technical document [https://drive.google.com/file/d/1juZKswxGGjhlCn_CD255w7OnV31vqrDF/view?usp=sharing] Was the stem position an issue when I pressed this release button? A button that seemed to have no movement when pressed. Is there something in the keyless works that got messed up by having the stem in the hand-setting position when pressing the button? How do I fix it?

-

I love jump hour watches, and I couldn't resist this black and white Oberon. Overpaid for it a few months ago as "needs repair," I'm finally tearing into it now. It looks like the previous owner did the old "soak it in oil to make it run" trick, but it was definitely not running. Came to me fully wound. The balance seemed free, but wouldn't oscillate, so I set about disassembly. Everything, including the dial, date, minute, and second rings are completely soaked in oil. The main plate is marked BF 866, which looks like Baumgartner's mark. Now I just have to figure out how to get the barrel open. Well, there's your problem. I don't know what that black crud is, but it was definitely gumming up the works.

-

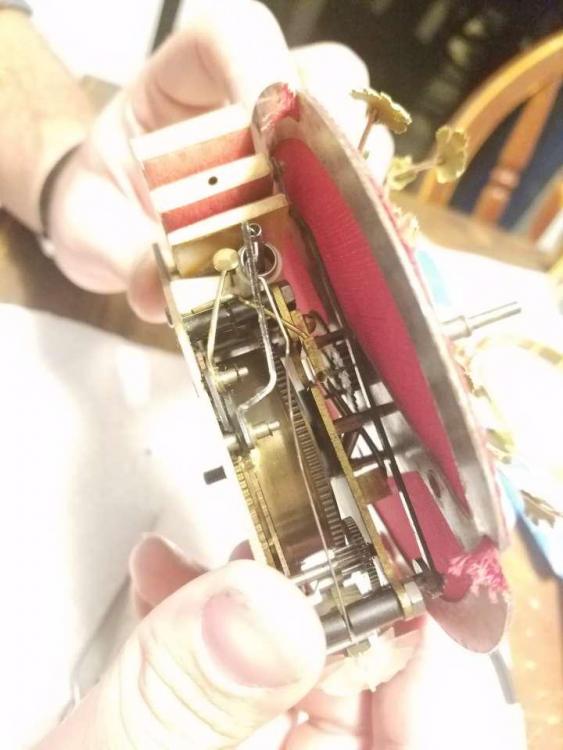

Hi, I have managed to get hold of a singing bird cage at a reasonable price after years of trying. It's not working...I would like some advice on what solutions to use to clean it as I think it just requires a good clean, nothings broken. Can anyone tell me what make of cleaner to use and what lubricant would be best, have attached photo's! Thanks

-

My latest repair/restorations — running super strong. I’ve done like 2 dozen of these repair/resto this year alone and generally put them back on eBay to try to recoup costs. I like these so much I might just keep them for myself.

-

Good (insert time here) everyone! I am relatively new to the world of clockwork repair and maintenence, but have done delicate metalwork, mechanism cleaning, and enjoy fixing things. Just recently, my sister brought home her boyfriends late great grandmothers singing bird in cage automata. For those of you who dont completely know or understand what it is, its basically a spring driven mechanism using bellows and a variable organ pipe to make bird sounds and move a little birdie around and "sing" (Example of singing bird mechanism working). His aunt wants it to be operational again, and after opening it up (not yet taking much apart) I have come to the conclusion that it could just use a good cleaning and oiling. But, my question is, what kind of oil should I use and how should I apply it? I don't have any fancy oils except for a bottle of valve oil for my trumpet at my current disposal, but I would like to buy some decent clockwork oil for this project and a sankyo music box repair I have waiting. Note: come to find out while writing this, it was made by eschle reuge I'm Germany, probably around the 50's or 40's.

-

Hi all, Can you help me identify this movement? I think I know what it is (cheap chinese) but just wanted to pitch for confirmation... (so won't say what I think it is) I have measured it as: (I think...) Diameter 26.0mm Height 4.9mm Height with hand pinion 7.3mm I am a complete newbie at even taken a case back off despite being a bit of a collector. This movement is broken and crunches when I wind it. So I want to replace it. The watch itself was a gift (and undoubtedly a fake/replica) but I want to get it working again by replacing the movement. Ideally, I want to keep the current hands (hr, min, sec) and crown/stem. It just has a date complication at 3 o'clock. Just a like for like swap seems the simplest thing to do? But open to any suggestions. I'm not bothered if it's a cheap chinese movement, I just want to get it working so I can wear it now and again. Any advice or help would be most appreciated. Many Thanks, Dan.

- 3 replies

-

- identify movement

- identify

-

(and 6 more)

Tagged with:

-

So I went to a place to get my battery replaced and the person ended up knocking one of the pointers out of its place, now I image to get this fixed I would have to remove the crown in order to access the front part, I however am not sure how to do this in this particular watch as there is no release as far as I can see, but yea in the first picture the sub dial has fallen into the area where the other sub dial is, and I am trying to get that back in place and the second picture I have removed the plastic bit and trying to figure out how to remove the crown but the things I have tried did not work, and I do not wish to damage the watch. Any help would be appreciated thank you!

-

I got a replica rolex 3235 movement, a complete clone as far as I can see with me. Used for a submariner homage project I embarked on. 2 Months in, when I took the hands out for a polish and cleaned the dial, after I had replaced the hands and recased, the minute hand and hour hand started to intermittently stop and lag behind. The second hand was perfectly running at a nice -5 seconds a day. I took it apart for an inspection, nothing looked broken in the gear train, and the timegrapher numbers were still excellent, but realised that the hands would shift extremely easily when pushed. I never took notice whether that was normal or not, but based on my suspicion and a little extra research I concluded that the canon pinion was loose on the center wheel arbor, So here is the issue, there are no known 'good' watchmakers in Singapore that will work on this replica movement, and its quite difficult to find parts, unless I swap it out with a genuine canon pinion. I've heard of a cheap way to tighten it using a shaved down blunt nail clipper, but would like to know. How 'tight' is tight, when I push the hands while the crown is in the hand-setting position, am I able to push it? will it require alot of force? or just not move at all without breaking it? Is the friction-fit canon pinion just supposed to be tight enough that when the setting gears are tucked away, the centre wheel can continue to power the watch? and while the second hand is hacked, there enough slip that the hand can be set by the crown? Are there any other options to repair it? Im still a student so a cheap option of repair would be nice. Thank you all for reading.

- 3 replies

-

- repair

- canon pinion

-

(and 1 more)

Tagged with:

-

Hello everyone! This is my first time posting here, so please bear with me if I’m not used to the structure or layout of how to properly use the forum. So, I have an issue with this movement which is labeled M 102, and had a curious arrow-triangle engraving on the barrel bridge. I bought this watch for cheap, and even once I screwed a new crown onto the stem (old crown was broken and lost before I got it), it wouldn’t take a wind. I opened it up, and observed the ratchet wheel spinning with no resistance when winding. So my first though of course was a broken mainspring. But in fact, the mainspring, mainspring hook, and the hook on the barrel arbor were all in superb condition (albeit dirty covered in old grease). So my next thought was to see what was happening more closely when winding. And it turns out, when winding, the entire barrel spins with the ratchet wheel! Okay, so broken escapement? But no, the train of wheels didn’t move at all while the arbor spun. FINALLY I looked at the next step in the train of wheels, the center wheel. With just the barrel and the center wheel fitted, the center wheel is turned properly. But with ANY resistance (such as the third wheel being put in), the center wheel itself stops, and the center wheel pinion spins freely, loose in the wheel. With the wheel removed, at one point I put it in a pin vise (with BARELY any pressure applied) to showcase just how loose the wheel actually is, and it is very barely on there, able to spin and wobble freely Attached are pictures of the center wheel removed from the movement. Also attached is a picture of the engraving on the barrel bridge to help ID the caliber if I haven’t already. So, my question is, does anyone have any reference material, or perhaps know which stake/method I should use to stake this pinion back tight into it’s wheel? Thank you so much!

-

Hi, I've posted about my challenges sorting out broken jewels on three separate movements in another thread (see below). At this point however I've decided that the job requires skills, materials and tools that I do not posses (with skills being the most critical void). That said, I'd like to find some help and am willing to pay to have the work done. I've reached out to JD Richards on two separate channels (his gmail account and this forum's messenger service), since I believe he does this kind of service, however he has not responded--so not sure if he is otherwise engaged or simply not interested. If anyone else on the board is a serious hobbyists with the proper qualifications and is willing to take this kind of job on for a fee (or knows of others who they can refer me to), please message me directly or feel free to contact me directly using my personal contact info below. These movements are not valuable or historically significant IMHO-they were purchased for less than $50 each on eBay as learning platforms for me as I attempt to teach myself basic watch repair through on-line courses, reading and practical experience. In that sense, these movements have been 'successful'. However having reached the limit of my skill with these particular movements, I would like to see them in working order so I can case them up and hand them off to friends/family as originally planned . Thanks in adavnace--Levine98 (804) 998-3519 *****@*****.tld

-

I decided to build my own ETA 2824 automatic watch recently. I spent time picking out all the parts I wanted, received them and put them all together with minimal trouble. After sizing the stem and fitting it to the crown I cannot get the stem to go back. After struggling for a minute or two I noticed that even when the stem was removed the movement continued to tick. I did make sure that the watch was in a time setting position before removing the stem. But now I’m one step from completing my watch build and have no idea what to do to fix it. This is the only watch experience I have yet had so I really hope it’s not a difficult fix. Any help would be greatly appreciated!

-

Small success story... not long after my wife and I were married (25 years ago) we were walking through Fordingbridge UK and the small jeweller's shop was closing down. In the window they had a display of new old stock Oris watches including an SA7445 with an exhibition back... later on that year, my wife presented me with the 7445 for my birthday. I wore the watch every day for 10 years, had it regularly serviced. However, about 15 years ago I was giving a lecture (cell biology (yawn)) in Belgium and whilst waving my hands around enthusiastically I felt something go cataclismically "sproing" inside it. The auto-winder span round and it died. The watch has sat in a draw neglected since. I've made half hearted attempts to get it fixed but no watchmender has been interested. Recently have been reading around, watching various videos, acquiring tools and started renovating quartz watches. Last weekend I plucked up the courage, sharpened my screwdrivers, got out rhe tweezers, loupe and rodico and investigated the Oris... I found that the all the screws in the rotor and the automatic mechanism were loose and the click had become disengaged. After a couple of hours I reassembled the auto wind, re engaged the click ratchet but the watch still didn't work. Then I noticed that one of the screws that holds the auto wind mechanism in place was missing. As I'd never had the watch apart before the logical conclusion was that the screw was somewhere inside. So... I carefully disassembled everything again and started to delve deeper into the movement... sure enough... there was the screw, jammed in the gear train. Gentle prodding and coaxing loosened it and I was able to shake it loose. Hey-Presto... the watch immediately started ticking and woke up after 15 years of suspended animation. After reassembly and ensuring everything was screwed tight... I proudly showed my wife the fruits of my labours. Sadly... she can't remember giving me the watch in the first place... oh well....

-

Hi There. I recently bought an Elma Super Elite cleaning machine and need to replace the old metal holder with the new, blue plastic version. The problem is that the old are stuck to the metal rod. When I spin it, the holder turns freely, but when I try to pull it from the shaft it does not budge. I was therefore wondering if anyone had any suggestions as to what to do.

- 2 replies

-

- elma

- watchcleaner

- (and 4 more)

-

Here is my cat "Lew" helping me adjust a pocket watch and adding a hair to places one should never be.

- 132 replies

-

- 11

-

-

Hi friends, I have a 1970's Slava Soviet made watch my uncle gifted me when I was 9... I have kept it in mint condition all these years and for some reason I decided to have it serviced. I took it to a watch repair shop (had 5 stars) spoke with the employee and specifically asked to have the watch back in the same or better condition, when I got it back 6 weeks later I noticed they had scratched and damaged the bezel and changed the spring (even through I asked to call me incase any part needs to be replaced) Now I need to replace the bezel so thats its not chewed up, the factory does not make parts for it and I am distraught as it was in perfect shape and it took someone else to ruin the watch. I only blame myself but it hurts ? Please help me find the bezel and get it back to its former self as much as possible.

-

Hi. Aftet many hours trying to fit a seagull st36 to a hamilton kahki case I think I'm done. First recieved movement and put all parts together with a pleasef smile on my face. Then the second hand stopped.... Aftet advice i took parts apart fiddled with second hand and rebuilt parts. This time the stem just doesn't engage properly and slips in and out easily. Movement is fine it seems but stem just doesn't want to play. It did when first assembled. So i am figuring i just want it working and want to send it off to someine far more experienced than I....any sugestions?

- 4 replies

-

- hamilton khaki

- stem

-

(and 2 more)

Tagged with:

-

hi am not by any means any type of expert but thought this was the best place to start

-

hi everyone, today I was working on a watch (the movement was eb8810) and after I was happy with the result I put the movement under a. glass, come back to it 2-3 hours later, still ticking so I put it back in the watch case and after about 15 seconds it stoped ticking as I started to move it around I don't know where to go from here wether or not it needs re-oiling or a new part in the balance operation, this is not the first watch I have experienced this in and didn't end up doing anything with the other watch. thanks in advance, Ali p.s I am looking for an eb8800 movement in working condition so message me if you have one

- 2 replies

-

- watch repairs

- repairs

-

(and 3 more)

Tagged with:

-

Hello. A few weeks ago, my watch got broken. Please see this image: It's not possible to put it back in, because it wont allow you to change date (it can still be taken out as well).. This happend when I tried to change the time of the watch. Any clues? What can I do to fix it? Is it easy to fix?

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)