Search the Community

Showing results for tags 'pocketwatch'.

-

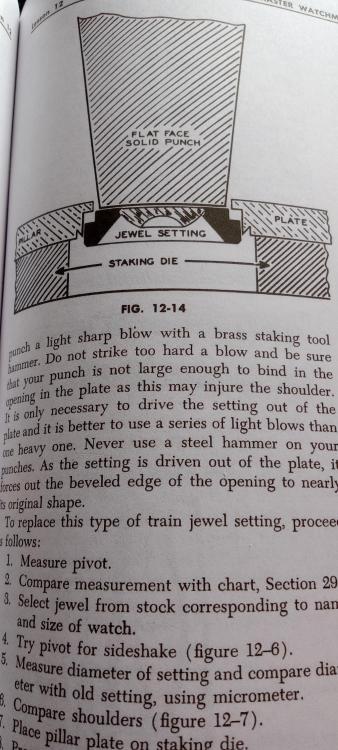

hi all I have a Hamilton gr 974 size 16s that needs a new center wheel jewel in the pillar plate. This is my first encounter of this type and so far what I've read is this type of jewel setting is one of the most difficult, if not the most difficult to repair due to its hybrid friction setting. it seems it's a two part setting to include the jewel, set into an either steel or bronze hub, then the beveled edge in peened over to hold the jewel, and then another beveled edge on the opposite side is peened over to affix the entire setting into the pillar plate. Anyone have any experience or advice before I attempt this one? below are the sorry excuses for pictures showing the plates side by side. the one on the left contains the donor jewel, and the one on the right is the missing center jewel. the third and second to the last is the donor jewel and the last is Section 300 out of the book, The Chicago School of Watchmaking that shows a cross sectional view of the procedure. Again, advice needed! i have to do some running but will check back later. apologies on the late wish: to our friends across the pond-my sincerest sympathies on the passing of Her Majesty, Queen Elizabeth. A great, remarkable and very special lady indeed.

- 6 replies

-

- 1

-

-

- hamilton

- pocketwatch

-

(and 3 more)

Tagged with:

-

Hi all doing my very first full repair on a balance staff/wheel assy. which includes removing the broken staff to replace it, roller table to re-shellack the impulse pin, clean, poise, truing, etc etc. After i removed the bad staff I noticed in the balance arm bore looks kinda ragged. my questions are: do I take a jeweling reamer or broach to remove those or proceed with staking the new staff in and prepare for riveting? 2nd question: looks like the old pivot measures .12mm and the new one is .13mm will i need to remove that extra .1mm? i'm thinking I do but all I have is a Levin pivot polisher, a few ruby and steel burnishers. I have no lathe. pic #1 shows the burrs.

- 4 replies

-

- pocketwatch

- balance staff repair

-

(and 1 more)

Tagged with:

-

I don't know that this belongs here - I'm not certain that I'm going to document my progress step-by-step but since I've just begun and it's not done yet, I'll put it here and somebody can move it if that's what's needed. I received my first practice movement yesterday and wasn't able to leave it alone - after all, there's been all of these tools arriving over the last couple of weeks. I didn't expect the movement to have a dial and hands. I thought the dial was nice but it's not clear that I'll be able to clean it up.

-

Hi, I've posted about my challenges sorting out broken jewels on three separate movements in another thread (see below). At this point however I've decided that the job requires skills, materials and tools that I do not posses (with skills being the most critical void). That said, I'd like to find some help and am willing to pay to have the work done. I've reached out to JD Richards on two separate channels (his gmail account and this forum's messenger service), since I believe he does this kind of service, however he has not responded--so not sure if he is otherwise engaged or simply not interested. If anyone else on the board is a serious hobbyists with the proper qualifications and is willing to take this kind of job on for a fee (or knows of others who they can refer me to), please message me directly or feel free to contact me directly using my personal contact info below. These movements are not valuable or historically significant IMHO-they were purchased for less than $50 each on eBay as learning platforms for me as I attempt to teach myself basic watch repair through on-line courses, reading and practical experience. In that sense, these movements have been 'successful'. However having reached the limit of my skill with these particular movements, I would like to see them in working order so I can case them up and hand them off to friends/family as originally planned . Thanks in adavnace--Levine98 (804) 998-3519 *****@*****.tld

-

Hello This is my very first watch service, and I need some help identifying the mainspring, and perhap also the movement. What I know so far is: BWC pocketwatch 41mm FEF movement, no serial number or any other code I can see in it. The mainspring is: 1.22mm height, 0.25mm thickness, ~51cm long. The barrel has an internal dimeter of 16.21mm. I've opened all the FEF documents I could find in the cousinsuk website, but I was unable to get my one. Can you please help me finding the replacement for the mainspring since the bridle is broken? I found this one that seems very similar, but I dunno if it would be ok or not considering that the measurements are donw with a caliper Thanks in advance for all the help. Alessio

- 8 replies

-

- fef

- pocketwatch

-

(and 2 more)

Tagged with:

-

Ok, I need the WRT detectives out there and their help. I've searched and as far as I can tell this symbol or trademark belongs to the Chicago Watch Co. 1895-1903 and made by Elgin. The movement came in an old but intact tin stamped "Elgin Watch Co. I looked up the serial # on PWD.com under 'Chicago' and that's what came up. But, there are a few pics of others and mine looks nothing like any of them nor has this trademark. Anyone recognize this trademark? It's a size 18s with no case. Aaaand I just noticed I didn't provide the serial number. I'll post it here in a bit. Thanks Mike

-

I went to an estate sale at the corner and befriended the seller. I asked about watches and he told me he had some at home and since I seemed nice, he’d bring them to me. He had some nice pieces and after disassembling this pocket watch, I’m under the assumption it’s a no name. The dial material is copper and I assume porcelain because it’s hand painted. The only word on the movement is “Garantee” and it’s my first cylinder escapement. If anyone has clues to the movement manufacturer or dates, please comment

- 18 replies

-

- pocketwatch

- identify

-

(and 1 more)

Tagged with:

-

vintage American pocket watch screw sizes

MechanicMike posted a topic in Watch Repairs Help & Advice

greetings all-been a few months since I've visited hope all is well with everyone. question: do any charts exist telling of American screw thread sizes for vintage pocket watches? I seem to be having a tough time finding anything other than the fact that back then prior to the 1955 "thread summit" I'll call it, where the European and American powers-that-be agreed on a universal standard thread pitch across the board(UNM miniature), that European was metric and American was their standard inch pitches, with the exception of Elgin and Waltham, who made their own specific(adding to my frustrating confusion) threads. I have threaded holes I need to repair and/or chase, and I'd just like to have it handy if I need it. maybe I haven't looked deep enough? Bueller, anyone?- 11 replies

-

- pocketwatch

- screws

-

(and 2 more)

Tagged with:

-

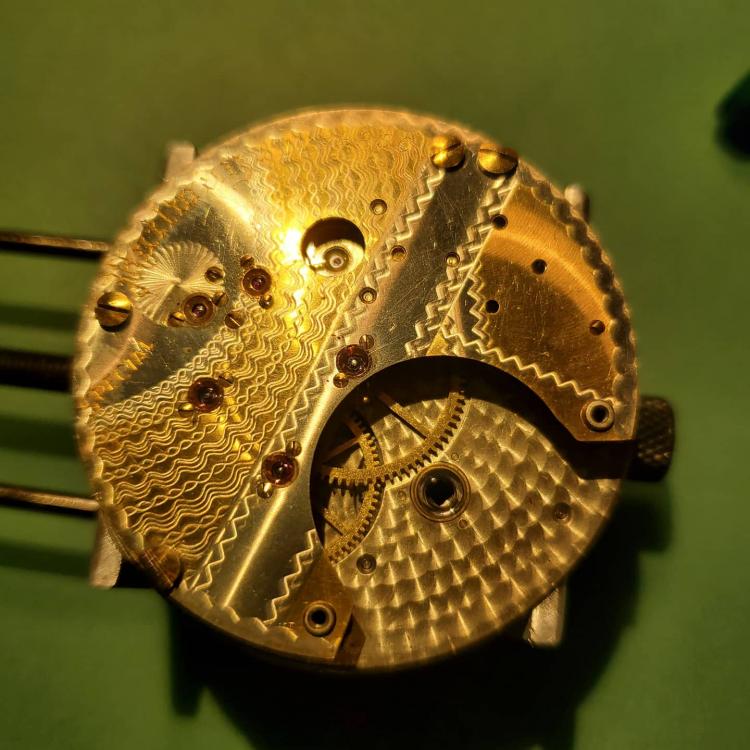

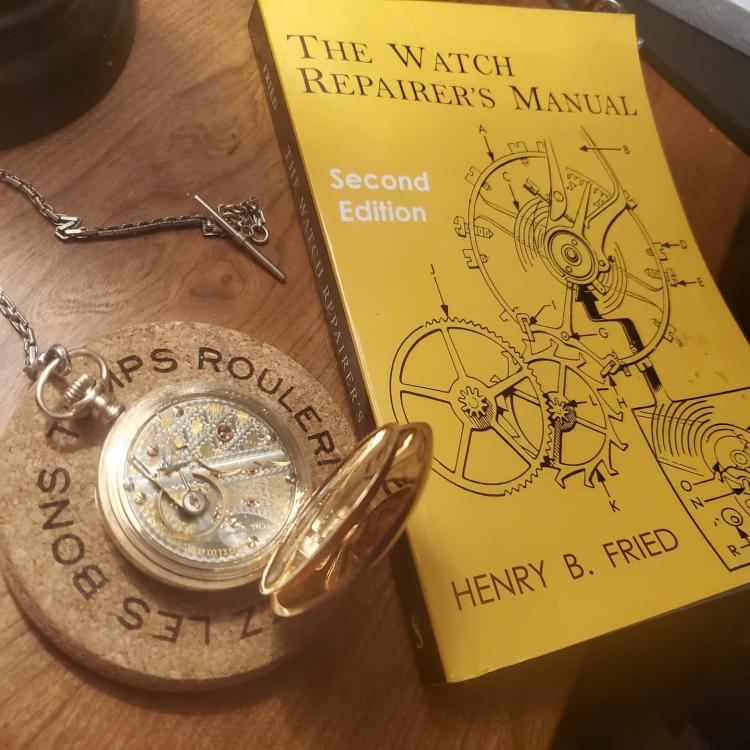

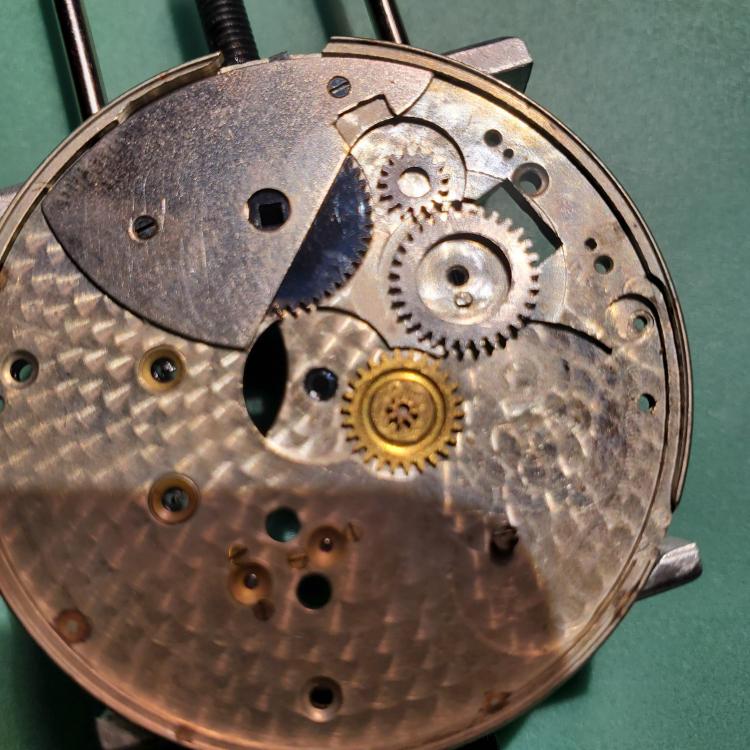

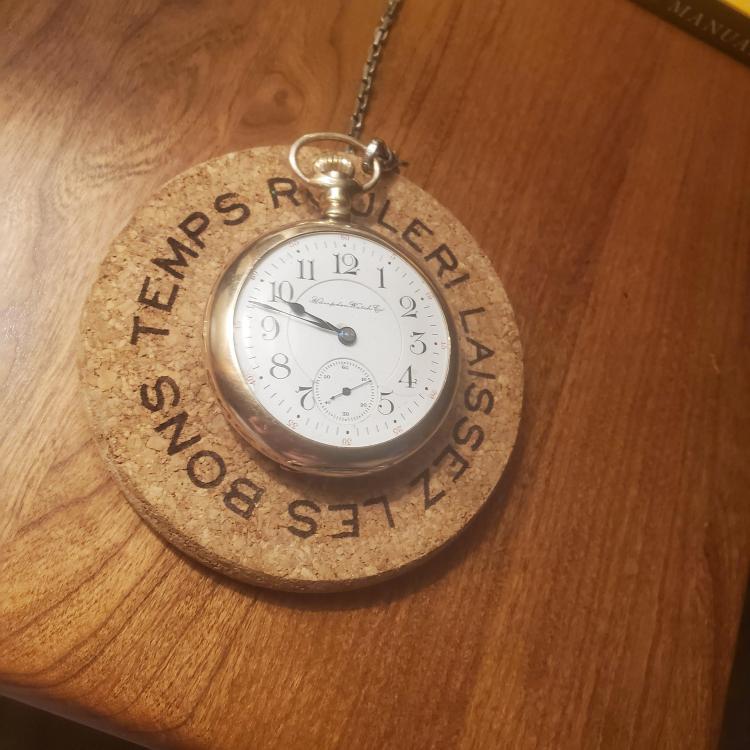

I just wanted to share this amazing watch. The damaskeening is special, and it has only lost 10ish seconds over the past 8 days while in my pocket.

-

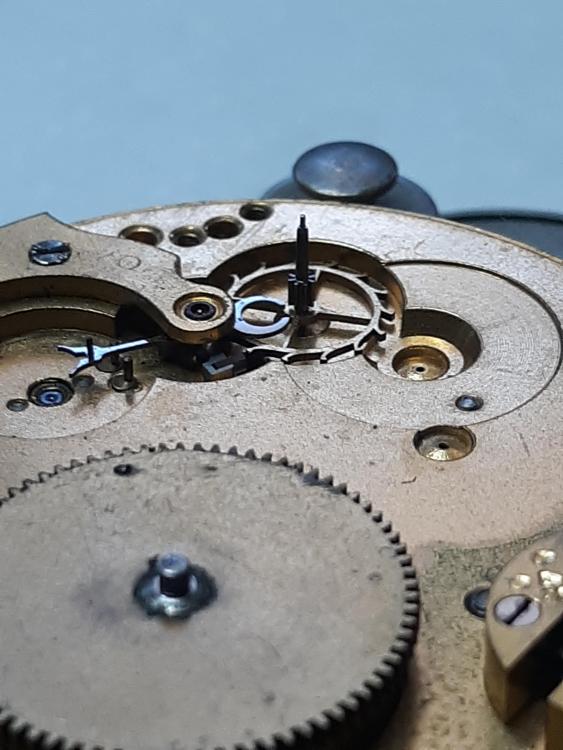

Hi all-is there a name for the crescent shape of this fork and its purpose? Vague memory of seeing one like this but can't find where I had seen it. Thank ya MM

- 13 replies

-

- pallet fork

- vintage

-

(and 2 more)

Tagged with:

-

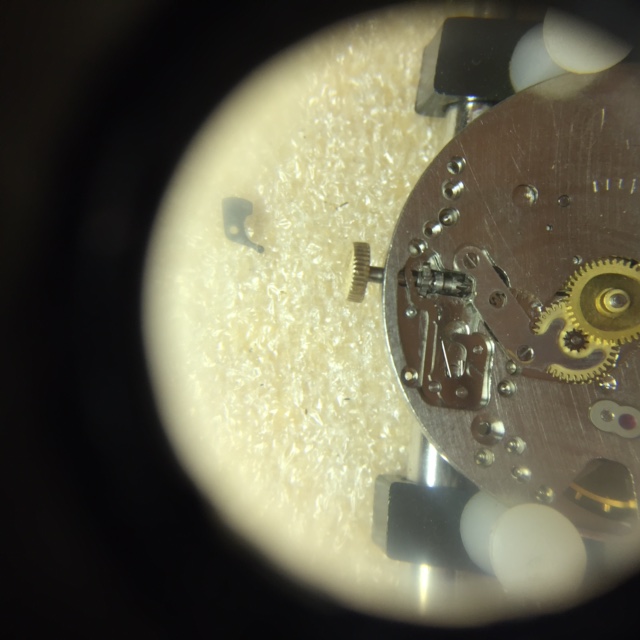

Hello everyone I recently bought a lot of pocket watches on Ebay. Between them I found an Alpina pocket watch with movement UH 1116. I saw on internet that usually is referred as Alpina 1116. I got the following situation, while removing the wheels bridges, one of the ruby remained on the wheel. Please take a look on the following pictures. I also took some pictures with a microscope in order to explain better the situation. Could you please suggest me what I should do? Is what I got complete? Looking to another ruby it seems there is something missing (holding piece?) Is the movement common? Do You believe I can find the bridge somewhere? BTW I have also found a broken spring Many thanks in advance for your suggestions Regards Buf

-

Just got my hands on a Waltham 6 size Model: 1890 Grade: W The other one's I saw like this in the pocket watch DATABASE (4) all have sub second hands. Mine does not. Is this possible?

-

Hello A friend of my father gave me this old pocketwatch to see if I could repare it. As you see in the picture, the balance wheel is extremely bent. I tried to bend it back, but i cant make it good enough. Does anyone know where I can find a balancewheel for this Revue 30 movement? I have tried to search around online, however, I cant find any. Is there a generic balance that would fit in here? Best regards Nicholas

- 2 replies

-

- pocketwatch

- revue 30

-

(and 2 more)

Tagged with:

-

I have an old Waltham pocket watch movement which is missing the impulse pin (roller jewel). I have a limited number of actual jewels and since this is just a practice movement I thought I'd try to make one out of brass. I've seen this several times in old pieces--usually a very sloppy job. So I got some brass stock of the same diameter as the "D" in the roller table, filed it and burnished it to a high gloss. Then I took a small, very fine diamond file and filed it half flat to form the "D" I then polished the face using progressively finer sandpaper on a steel block. This works fine--so far! Problem is separation of the piece from the stock. Again I used a small cutting file to do this but it doesn't leave the end very pretty. So what I've done so far is to fit the good end into the roller table. I then plan to shellac it in place and see if I can very carefully adjust the length and clean up the end. Has anyone done this before? Any suggestions as to how best to do it?

- 5 replies

-

- roller jewel

- impulse jewel

-

(and 2 more)

Tagged with:

-

Hi, This is my first watch repair project beyond battery replacement and bracelet adjustment. After buying 2 non running Ingersol Triumph pin pallet lever pocket watches I now realise that they are not the best to start with, however now that I have them in bits I'm going to continue. One watch was really a basket case, the other ran for a few seconds then stopped, I have stripped both, cleaned the good bits and reassembled one watch (several times) I have got it to wind and to run but when I try to adjust the hands the crown is jammed solid. To recap, the crown will wind the watch but not change the hands. This watch doesn't have a conventional cannon pinion, it has a rather flat pinion (see photo). Please excuse my terminology, everything seems to be a pinion. So this little pinion (gear wheel) fits on the shaft (pinion?) of the centre wheel, I suspect that it is too tight, as I understand with a conventional cannon pinion there should be some friction to drive the hand but also enough slippage to allow adjustment of the time. I'm not sure with this watch what sort of fit the pinion should be, and I would like to ask for advise before I remove any material and make it too loose. Best regards, Alan

-

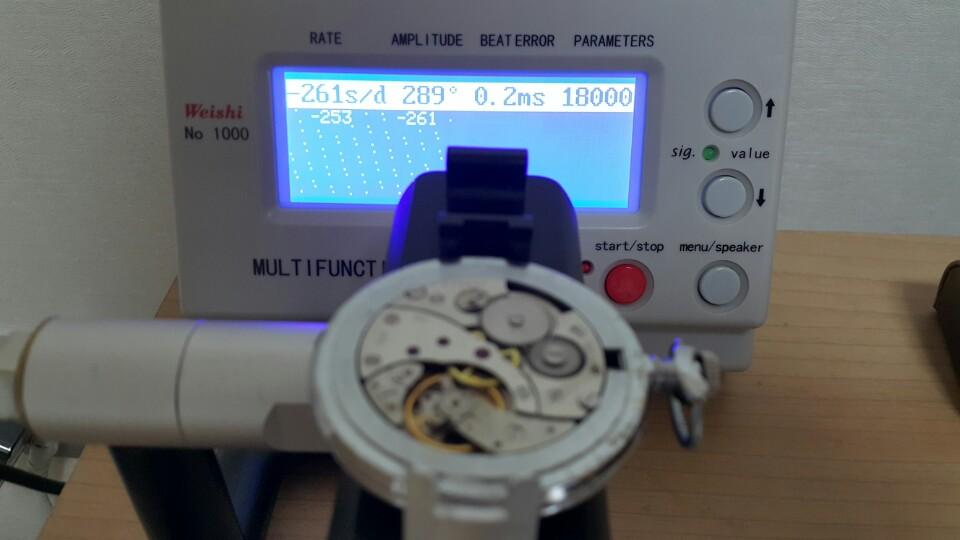

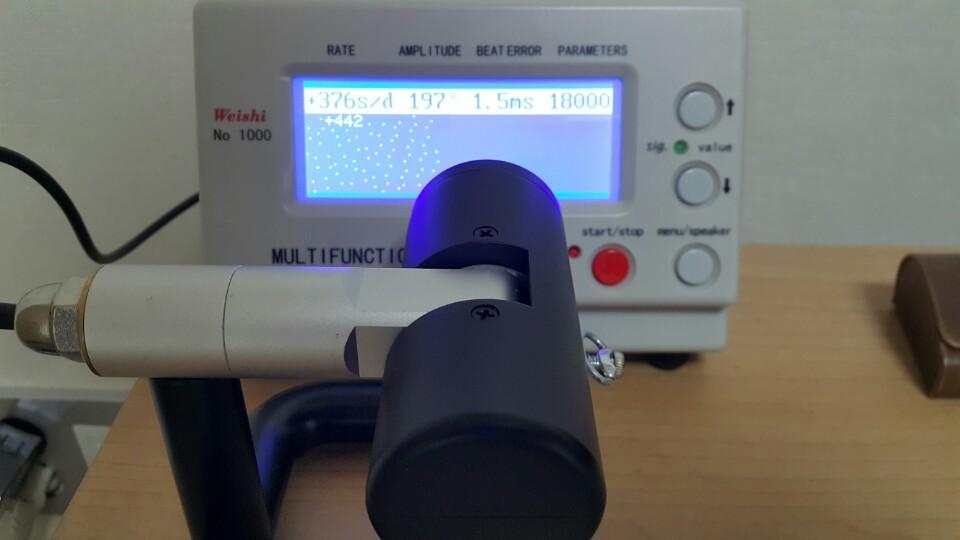

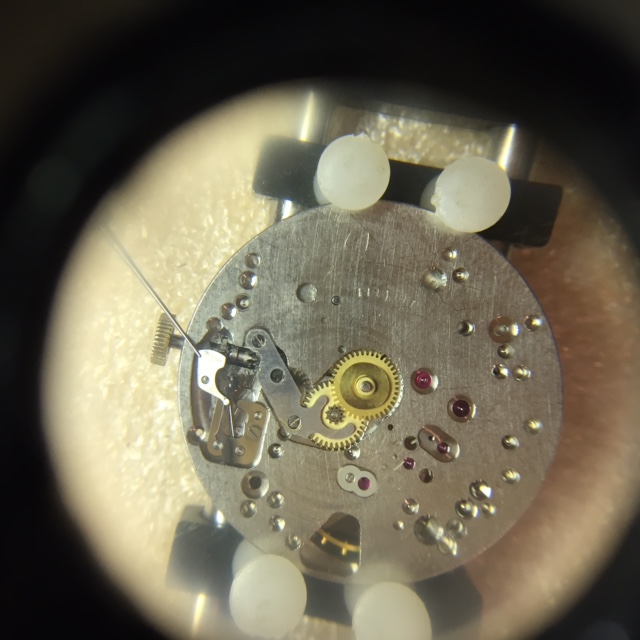

Hi I have a movement which I think has some serious problem. I serviced it a week ago but the timegraph shows great gap between results with dial up position and dial down position. Also the balance seems a little shaky from horizontal view when watch is running. What can be done to make this watch run in appropriate way?

- 10 replies

-

- molnija

- pocketwatch

-

(and 1 more)

Tagged with:

-

I am in need of some advice on how to get a mainspring working in a Waltham 0s hunting case. This is a complete restoration of a rusted watch - spent way too much time on it already. I have it cleaned up now and in process of finalizing assembly but the mainspring I have installed keeps slipping from the center hub/barrel arbor. Hook of arbor hub appears fine and the tail of the mainspring is hooked well in the side wall of the barrel. I have installed 2 new but old inventory mainsprings and wanted to know if this may be the problem and I just need a new fresh mspg? I have installed many mainsprings but this one is terrible. I am using a pocket mainspring winder to install. movt serial #9535224 You can see my original mainspring below. I will add a picture of the inside of the mainspring barrel when I get the chance. Thanks for any help, George

-

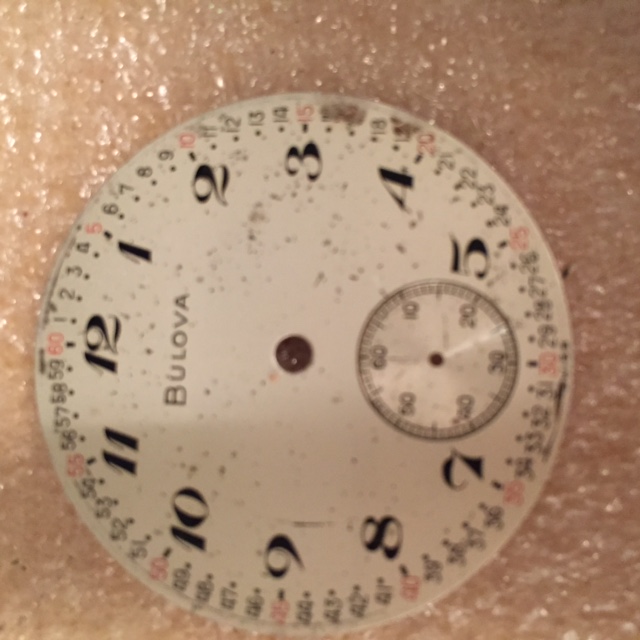

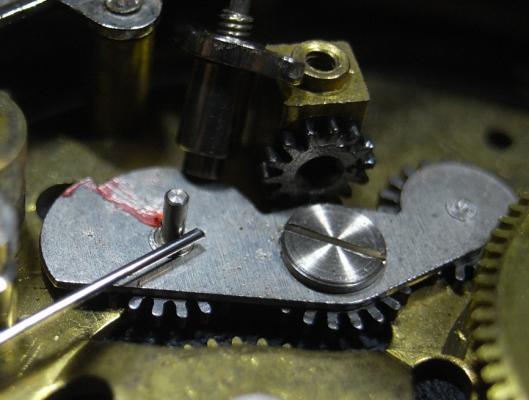

I have a problem with a Bulova pocket watch. The watch was running, but losing a few minutes every day. I opened the case to see if it was dirty or if there was an obvious reason for running slow. I did not see any problems, but I took the stem out. When I started to replace the stem a piece of the winding mechanism seemed to leap out of the movement and sail away. I think it was propelled by a spring. It took several hours, but I found the piece on the floor. Now for the problem. I cannot get the piece back in. I have rotated it into several orientations and tried to find a peg to fit into the hole in the runaway piece, but after several days, I cannot get it to fit back into the watch. In the pictures below you can see the piece oriented in a way that I think it should go. An oiler is positioned to point at the troublesome piece. In the other picture the piece is removed and you can see the springs that are supposed to hold the stem in place. That piece no longer fits into the groove on the stem and so I cannot secure the stem. The third picture is a picture of the dial of the watch. Does anyone have a suggestions? Thank you, Bill

-

Kienzle Markant Pocketwatch Service One of my Mum's friends dropped off a pocket watch for me to service. It was her father's watch, and she used it all through her nursing career: so it held quite some sentimental value to her. She told my Mum that it did run; but only for a few minutes and then stopped, unless the crown was moved. It's a German made Kienzie Markant. I popped the back off and the movement and saw that it was VERY dry, but in good condition. First thing I notice was the stamping .... Zero (0) Jewels - Unadjusted. So this thing is no RR Standard Hamilton; but none the less a nice little project, and one that will make my Mum's friend happy :) The front was also removable via a case blade, and since the Main Plate was riveted to the case is required to be removed in order to service this movement. With the hands removed, the dial was next. It is secured by two screws on the face. Motion Work is a very basic setup. So I removed the Cannon Pinion and moved to the back of the movement. While inspecting this movement carefully, as this is my first attempt at a pocket watch, I noticed a few things that I'd never seen before... Firstly, the timing adjustment is done by a sort of jack screw arrangement. (Note: The two large screws for securing the Balance, and a smaller "Jacking Screw" to adjust the timing.) Secondly, the Fork arrangement was also something new to me. Posts instead of Pallets to engage the escapement. Here's another view the Fork removed. So I removed the tension from the Mainspring, and removed the Balance and Fork. I was a little nervous removing the Bridge, as it's a 3/4 Bridge and I couldn't see the layout of this movement, and since this is a very new style of movement to me I wanted to take reference photos. Well my nervousness was justified, and EVERYTHING lifted out with the Bridge!! ACk!! :startle: Again, something new to me was the layout of the Keyless Work. It's a rather clever rocking pinion system. Rock one way and the Mainspring is wound, rock the other and you engage the Motion Work. Thankfully the Click Screw was marked as a left-hand thread ... Note the extra stripes either side of the Driver Slot. Movement is fully stripped and ready for a bath :) Here's that nasty 3/4 Bridge that stopped me taking reference photos of the Gear Train Layout. Once all the parts were clean, it's time to get this thing back together .... Gulp! :lolu: My Heavenly Father has gifted me with skill and cunning when working with watches, and I thank and praise him for it!! To assemble the Gear Train, I placed them upside down on the 3/4 Bridge, and then lowered the Main Plate on top of them. This made the alignment of the train and pivots a breeze. I then flipped it back over, and with a few gentle wiggles and very slight pressure on the Bridge, everything was in place. I replaced the Second Wheel, and the Spring Keeper. Refitted the Motion Work and Cannon Pinion. Then the Fork and Balance. Adjusted, fitted the Dial and Hands, and Re-Cased. The Kienzie Markant is now running smoothly and continuously. It was great fun to work on, and I hope you enjoyed the walkthrough. PS. when held to the ear, the ticking sounds like an old grandfather clock :P Gotta love dem pocket watches!! Click here to view the article

-

I have just bought this on eBay (http://www.ebay.com/itm/Antique-1917-Elgin-Pocket-Watch-Beautiful-Octagon-12S-Case-Not-Running-/331529042187?pt=LH_DefaultDomain_0&hash=item4d30abb90b&nma=true&si=steVwbb4TuJ0zQh2WWiGY4LpEJ4%253D&orig_cvip=true&rt=nc&_trksid=p2047675.l2557) as a project for myself. I have never tried to disassemble a watch before, because the interest to watches is a new hobby. About this PW I bought, the mainspring is working because i managed to release it, and re-wind it. The hairspring is also working (i think), because I tried to move the balance-wheel and it is doing 3-4 movements until it stops. Also the crystal is bad I think, and needs to be replaced. So; is this a project that is manageable by a newbie? What equipment do I need? Is i.e. this good enough as a starter-kit? http://www.amazon.com/Premium-Watch-Repair-Reusable-Aluminum/dp/B00CZDBXU6/ref=sr_1_12?ie=UTF8&qid=1430563002&sr=8-12&keywords=watch+repair+kit When it comes to lubricating, I saw another posting about that, but when it comes to cleaning the mechanics - what is the recommendation? What else do I need to think early about, to have ready? Where do I find crystals for this watch? -Tore

-

I seem to have developed an affinity for pocket watches and I found this video by Fran Blanche, she has some really interesting electronics tear downs and articles, if you're into that sort of thing, and now I find she's into pocket watches. I think its the embellishment on the insides of the pocket watch that catch my eye. Nothing in depth, beginners level, which is probably why I like it. https://www.youtube.com/watch?v=qMQdXAZm044#t=556