Leaderboard

Popular Content

Showing content with the highest reputation on 01/28/20 in all areas

-

I have been asked to look this beauty. It is heavy and is real quality and the name on the dial is (I think) is William Goffe. On initial inspection it looks like the cord /gut has broken from one of the barrels. Also to open the front is via a key which is missing, I will investigate in a few weeks as I am away on a short break. I must say I can't wait to delve.3 points

-

So were in agreement it's probably not the balance wheel or the jewels but? So when you get your other movements before disassembling them check out the end shake see if they feel the same as the current watch. The balance jewel assemblies in this are different than others and it's possible that the working just fine but when you're verifying by grabbing it it may appear to be too much. The problem for remote diagnostics is we rely on your observation your skill set and as you still learning like we all are but your farther down in the learning curve there may be things that you're not seeing or grasping. Which makes remote diagnostics much more difficult. So when the Watch is running and your rotating it around in your hand does the balance wheel jump out of the jewels Which would occur if there was an excessive quantity of end shake? Then looking at the pictures of the timing machine as there is a definite difference between dial-up and dial down that would indicate there's a problem but not necessarily the pivots/you will assembly. Does your hairspring look absolutely flat this is one that's really hard to see sometimes it's just touching the balance arms were really really close and when you turn it upside down maybe it is touching. Then the balance protection system was trying to find somebody with another picture of your movement this link is interesting in that apparently the system is they are's? Except I've seen it somewhere before but it's unfortunately there's lots of variations of protection systems. https://17jewels.info/movements/e/eterna/eterna-1408u/ Then you have a picture of the dial side of the balance jewel assembly we could see? Other things of interest everyone should have the physical and/or PDF copy of this book it has interesting stuff. So for instance someone a snip out some things of interest. https://mccawcompany.com/featured-products/bestfit-encyclopedia-books-111-111a-digital-download-pdf-version.html One of things bothering me is the movement number has the letter U and I might have possibly discovered why? So it looks like that may refer to the particular balance protection system. So I have two pages out of the bestfit book and Snipped to section out of the parts List. It looks like the best way to buy these would be the complete assembly if they were still available which the probably not. Or find another movement on eBay exactly what you've done and swapped from their once you verify whatever the problem is or is not.2 points

-

Dirt is the most likely cause of a sluggish movement. Did you give the whole mechanism a long thorough soaking in lighter fluid? You shouldn't need to disassemble it, just give it a good slunge. The process has been described a few times here on WRT. This technique applies *only* to Timex pin levers. Other watches wont be quite so forgiving about this kind of treatment. One other thing to watch out for. When oiling the pivots, use oil sparingly. A tiny drop applied with the very tip of a sewing needle (or better still a proper watch oiler) is all that is needed. If you over oil, particularly if you over oil the balance, escape wheel or fork, then this will be counter productive. You do need *some* oil, since the metal on metal pivots in bushings mechanism will have far higher friction without oiling. If you don't have access to watch oil, you could use a light oil like sewing machine oil, but a proper quality watch oil is way better. You might get some better performance by oiling the v-conic balance pivots. Don't get any oil on the hairspring, or damage it in the process. Of you do get oil on the hairspring, it will probably start sticking to itself. This will probably have the opposite effect to the one you might expect, as it will typically cause the movement to run way too fast, rather than too slow. If you get oil on the hairspring, wash it off again with another trip for the whole mechanism through the lighter fluid bath. The pins on the fork, and the faces of the teeth on the escape wheel may also benefit from the merest whiff of oil too. Can you post pictures of the balances as they currently sit?2 points

-

Before you reclean, the diesel fuel test will show if pallets are badly scratched. D fuel will reduce drag to minimum, I didn't mean it will replace the oil. I doubt if balance is causing the poor amplitute. Good you got extra movements to try dif balance etc .2 points

-

1 point

-

I've had so many questions lately. I have never had to post one since there so much has been covered for noobs! This is just a thank you to all the veterans who offer their advice freely. Your time is appreciated.1 point

-

1 point

-

Hi, thank you sir! This forum really is a resource I managed to adapt a spring I found in another movement I had for spares, stripped the movement, cleaned and oiled. Seems it works nicely now, however looks like I’m unable to adjust the beat error lower than this. I guess I can live with that, as the movement is a cheap chinese 17 jewels!1 point

-

Hi Theo, your movement is a Damas 9 (height 5.2 mm). Mainspring 1.9 x 16 x 0.20 The jewel has more than a 'slight' chip and should be changed. Also the pivot shows considerable wear! Frank1 point

-

The finished version. I rounded the corners on the major indices and added sub-second marks. Grab yourselves an old Russian 1800 bph movement or one of those old beat up Chinese standard scrap watches in your junk box fire up the inkjet printer pop in some ebay special Chinese decal paper and have some fun with it. You could also grab a Quartz clock mechanism and make your own erzatz USSR ships clock. Attribution-ShareAlike CC BY-SA USSR30.100Centre1.79RoundCream.svg1 point

-

https://speedtimerkollektion.com/ is a good source of parts for Seiko you will just have to keep looking, both the watches you need backs for are very collectable now and demand high prices so I doubt any one would sell any case parts for them cheap.1 point

-

It is a man's man solution to repair....should have used duct tape a la Red Green Sent from my GT-N5110 using Tapatalk1 point

-

To assist with a search the size in Ligne and a pic of the keyless side really helps to narrow down the hunt. Also be aware there were a lot of pocket watch manufactures that made pocket watches just to be sold on as un-branded so finding the calibre is really difficult. Ie I recently repaired an un-branded Pocket watch that needed a new balance staff and just by luck I found the watch on the net but it was made by Omega. I purchased the Omega balance and it fitted perfectly so job done.1 point

-

You are getting amplitutes in 200degree and runs region in all positions, that shows pivots got some life left in them and that pivot shoulders do not come in contact with the jewels. Your location is listed as little elmTexas, I have been there. Regards. Joe1 point

-

Chrono tension spring was decreased, checked, and also removed with no improvement. Adjusted eccentric on coupling clutch to go from 30% tooth depth to 70% with no improvement. No damaged teeth noted and bearings are clean. Clutch wheel also spins with air puff. Thinking of just getting another Landeron 248, servicing it and swapping chrono parts out one by one just to find fault. I appreciate all the help immensely and any new thoughts are greatly appreciated.1 point

-

1 point

-

Have been giving this one a test drive today after a complete rebuild over the weekend and it's rapidly becoming a favourite. At just 32mm across the all stainless steel case (not including the original signed crown) it's small by today's standards but it feels perfect. The movement is Citizen's 21 jewel "Homer" which according to Sweephand's fantastic Citizen site is part of the 02 movement family with it's origins going back to 1960. The only stampings on the main plate are 00, J, and either M or W, none of which are obvious caliber identifiers. There are no numbers on the case back either that could help with ID or dating, but my gut feeling, given its size and also the Citizen script on the dial, is that this is an early one from the front end of the '60's. If anyone can shed any better light on this then please do. Either way, it's super comfortable and running very nicely indeed.1 point

-

1 point

-

A Texan needs ten acres to park his truck and surely has bought his Massy Ferguson before buying truck. So I get me some diesel fuel ( garage) and try a bit of it on pallets to reduce drag there, you just may be surprised of the amplitude picking up. I don,t think you need a jewel, hiwever, we need a datasheet to find the part number. Julesborel material house knows or has them. Regards1 point

-

The ones on the arms are know as 'Mean Time Arm screws' and the ones in the middle are 'Meantime Rim Screws'. I've never had to do this but when you think about it you must adjust all 4 equally or the balance will go out of poise. Henry Fried's book says half a turn can give or take out to a minute a day.1 point

-

1 point

-

Good info. OP: do your wife watch have an hard red gasket, of a softer, black, NBR (syntehtic rubber) one?1 point

-

Actually tissot does like to use those red gaskets to hold the caseback in much the same way as most crystals are held in place: not with a lip, but with only friction. You might want to consider replacing that gasket.1 point

-

The gasket is not supposed to hold the case back in place. If you look at the rim protuding from the case back there should be a point with a slight deformation that you can be bend a little more. And if there isn't you will have to create one with point nose pliers.1 point

-

1 point

-

I know this is a reply to a very old post of mine but just for the record, I think I've finally diagnosed the ETA 2832 day wheel advance issue. @jdm gave the best clue back on 30 July 2019 with the day/date jumper wheel. Having had the watch back again from my stepfather for a different issue, I compared photos I took back in October 2018 when I first disassembled the watch with a new photo. I have included an arrowed photo that clearly shows that a finger is missing from the day/date driving wheel (part 2555.1). As it happens I can still obtain a replacement part that's not been restricted by the mighty Swatch. Feeling optimistic!1 point

-

Most people dislike slow watches, and for good reasons. Always better to regulate slightly fast. You can try different positions for resting at night to find the one that better compensate.1 point

-

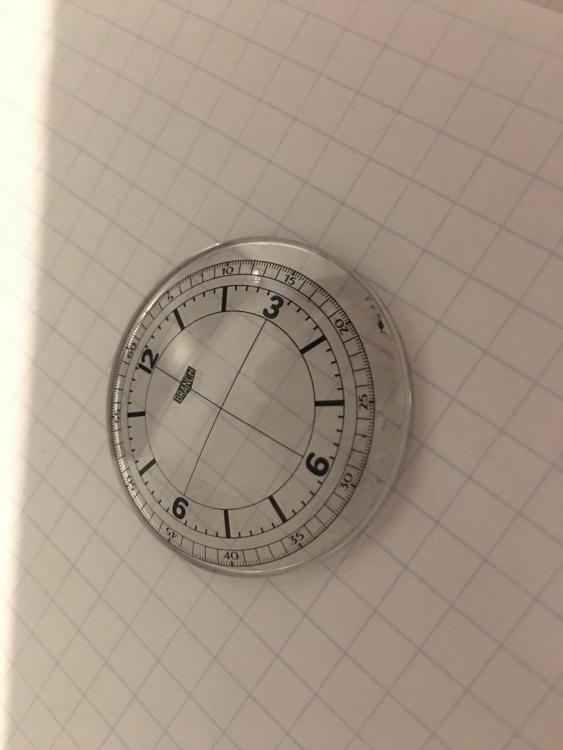

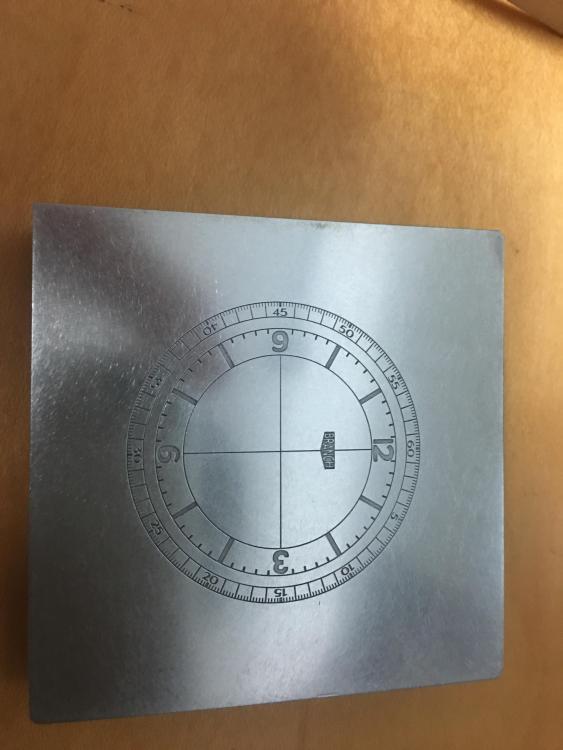

Hey guys, I have been working on a project to make my own watch dials over the past few months. I thought I would share my progress with you thus far. It has been an awfully expensive endeavour, and I have yet to reach a final dial but the work is well underway. I have purchased a pad printing machine, speciality inks and pads as well as a custom engraved cliche of my design. Now I’m putting it all together, I have been practing printing on plastic watch crystals, until I have my silver dials complete to print on. Let me know if you have any questions. Cheers1 point