Leaderboard

Popular Content

Showing content with the highest reputation on 12/06/19 in all areas

-

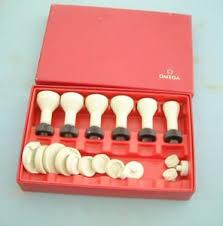

Crystal remover for certain cases . If it's says tool 107 on the Omega case you should use tool 107 . Only work on the specific omega crystal as it have a groove in the crystal . Very good tools if you work a lot on Omega watches with front loading movements.2 points

-

Right. Then 10 or 11m but the balance cock looks like a 15. https://www.time2tell.com/category-database/landeron/2 points

-

Hello, I'm not sure who are you talking to. This is a watch repair discussion forum only, and does not offer or perform any sale of good or services.2 points

-

Hi we need to see the dial face and back to asses the limit of the damage, can you post a photo please.2 points

-

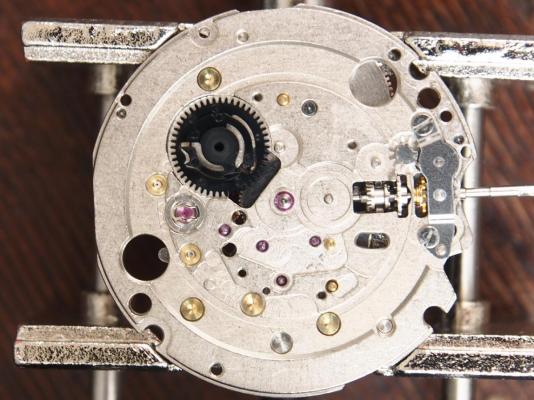

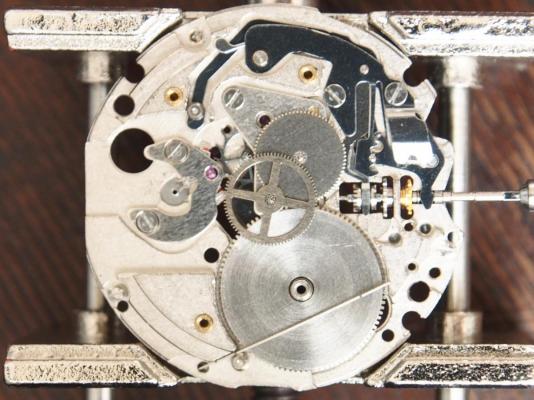

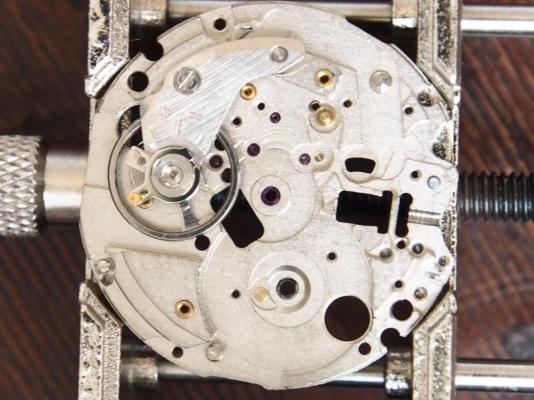

This is my first service walk-through, for which I've chosen this well know Seiko movement. It has a lot of similarities and common parts with the 7S and 4R families. The most notable differences are a separate bridge for the auto winding, and a better mainspring giving 50 hours power reserve. Also, the tiny anti-shock for the train wheels (of debatable usefulness) are not present. Some version have a cotes de Geneve finishing, the one pictured does not. Just like the others it is quite easy to work on. Find attached the technical guide for the SII version, which is named NE15B, In this walk-trough my intent is to give practical advice on certain aspects, which comes from my personale experience and reasoning, Reassembly and lubrication will be covered in the 2nd part. Let's start with the disassembly for which the absolutely indispensable tools are: Movement holder Hand remover tool 1.4mm and 2.0mm flat head drivers Seiko cross-head driver Fine or medium tip tweezers First, I recommend to remove rotor weight with the movement stil in the case, as it it of impediment for all the work to be done later. The movement is kept in case with 2 screws and 2 tabs (not pictured). Remove these, case ring and stem (usual pressing point with crown full in), the movement can now drop from the case - unlike the 7S and 4R where the plastic ring keep it place with some friction. You can now place movement on holder, reinsert stem as it's needed to hold related wheels in place until the very end. Remove hands with your favorite tool, then keeping movement in hand or placing it on the holder with a plastic protection, quarter-run dial the feet retainers at 3 and 10. Gently push the dial out, I recommend to place it in a plastic bag for additional protection. The movement ring goes with other parts not to be washed. Tip: label the tray sectors as in last picture to make it easier to sort and find small parts. Of course some parts will get mixed for cleaning, more on that later. First, remove the balance cock to protect balance wheel and hairspring from any possible incident during subsequent work. When removing the balance push gently the wheel from below to set it free from the fork, and avoid as much as possible suspending the balance by the hairspring. Store it wheel up with pivot set in hole. Turn movement over again to remove all dial side parts, starting with date maintaining plate screws. These can be four flat head screws, or three screws 'A' and one screw 'B' which requires the Seiko or equivalent small cross-head driver. Lift the date maintaining plate and the underneath parts will be exposed You can now remove: Date dial Date corrector wheel (white plastic) Date corrector wheel E (metal) Date jumper Intermediate date wheel (white plastic) Date driving wheel (black plastic) Hour wheel Minute wheel Cannon pinion Now, remove two date corrector wheel guard screws, wheel guard and corrector wheel C. Note: depending on versions the date corrector wheel B can be either a separate part, or attached to the guard. Turn over the movement and referring to 1st picture removing the two automatic bridge screws and bridge, and 2nd reduction wheel. Now we can let down any tension left in the mainspring. Just keep the tip of pegwood on the barrel to prevent it from spinning to fast, with push away the click away from from the ratchet wheel. Now we can remove in order: Ratchet wheel screw and wheel Three train bridge screws Train bridge And will be presented with the train system From which we will remove Click and barrel Fourth and third wheels Escape wheel Pallet bridge screws, bridge and pallet fork. Note: I recommend to not disassemble the barrel on the 6R15 movement, because a special material (SPRON 510) mainspring is used link, for which one would not find an exact replacement, and the barrel is sealed and lubricated for life. If there is any issue with the mainspring, replace the barrel complete. Now, undo the single screw for central wheel bridge to remove bridge, and wheel itself. Next the keyless system, which is kept in place with two screws. There is not much tension in it but is always better to keep the setting lever in place with a stick and then lift the parts, which are: Yoke spring Yoke Setting lever Balance stop lever My tip for last remaining parts (clutch, winding pinion and date corrector wheel A) is to just pull out the stem and pick them up from the mat to place directly in mesh basket. You can now place back the balance back in the movement to protect it during cleaning, and in preparation for the next step, which is removing anti-shock upper and lower balance jewels (Diafix) . My recommended technique is the following: place the tip of the tweezers on the inside of the spring, and rotate the entire holder and movement. Once the spring is out of the frame, close tweezers and store spring in tray, pick up the jewel with Rodico, and place it directly in the metal mesh basket. There is one last task which is removing the 1st reduction wheel and pawl, as well the lower plate from barrel from the automatic train. Just pay attention to not lose the C-clip while pushing it out as shown in the technical guide. My recommendation about cleaning is that with a movement which is spotless like the one in these pictures, I do not wash all the parts, but only those that have jewels, or are to be lubricated. That means you can leave screws, some plates, plastic wheel in the tray, saving time and minimizing chances of losing them during handling. A small mesh closed basket and a larger plastic one are enough. For cleaning I use an household ultrasonic machine, and isopropylic alcohol only, then blow briefly with an hairdryer. Again the reason is that we only need to clean any old oil. Note: although alcohol is detrimental to shellac, I've found that even 10 minutes in there do no harm to the pallet fork jewels, but leave all parts perfectly clean without no residue whatsoever. This concludes the 1st part of this walk-through. NE15-TG.pdf1 point

-

1 point

-

What is a "Ligne"? https://en.wikipedia.org/wiki/Ligne To convert https://www.convertunits.com/from/ligne+[France]/to/mm1 point

-

Hi well done jdm a very comprehensive walk through. Anone working on the same movement would do well to read this before starting. excellent. As regards the non cleaning of clean parts screws an plastic wheels I can see where you are coming from and respect that opinion, I also see Old Hippy's point of view, being trained old school and very correct its hard to change. But as you say it works for you with no problems so therefore you do it your way. I have done it both ways and had no problems with either. Thanks again for a good and instructive walk through.1 point

-

Its a early Landeron possibly a Calibre 13, only way to identify for sure would be a pic of the keyless works, Eberhard in my experience from a number of years ago are a very good company to deal with if you require parts they will supply if they have them in stock, they also seem to have good factory records so if you contact them with the serial number they may be able to help.1 point

-

Very much appreciated, this walk-through. It's amazing how much quicker I can work if I don't have to photograph everything! I have removed the balance cap-jewels and settings for cleaning. I'm confident I can put these back OK. There are two other cap jewels held by Diafix springs on the barrel and train-wheel bridge, for the escape wheel and third wheel. These are smaller, and look like a challenge. Before I do something I'll regret, what are your opinions? a). Leave well alone, no need to tempt fate or b) Absolute must, if you are doing a proper job1 point

-

I'm on the same track as @jdm here in that we're talking about a Landeron .. although my thoughts were around the 52. Probably easier with a side by side: Now granted this isn't an exact match (the hammer and parts around that area) but we have to be on the right track as there's a distinctive match to other parts! Reading about another Eberhard chronograph (https://shop.analogshift.com/products/eberhard-chronograph-as02089) they modified a Valjoux 65 to create their Calibre 16000. Could this be a similar situation where they've taken a standard Landeron movement and made alterations for some feature differentiation?1 point

-

With a vernier caliper and convert to french lignes. Ranfft does not care about watch "brands", only mov't makers. To identify a mov't sometime you need a picture dial removed because the Swiss liked to change the bridges layout to obfuscate the true maker. Another way is from the setting lever and then the bestfit catalogues as mentioned by watchweasol in another recent thread.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

I actually have some bronze tweezers, for me they hold up a bit better than brass, but have similar non-scratch qualities. But I am a non-professional, and I have to protect my poor watches from my clumsiness :-) I think it's worth trying as many types as is feasible for you, it's interesting how different various tweezers can feel and behave as you use them. Tweezers inevitably fall pointy end down, bends the tips on brass every time, bronze sometimes, fancy steel usually survives. That's a good thing, as I don't relish the idea of trying to dress my Dumont #5's.1 point

-

Another test, less violent than spring running which in the ends does something the mov't isn't really designed for, remove click or ratchet wheel, blow air, train must spin easily and stop kind of slow.1 point

-

Thank you for your reply! I was able to get a proper part mainspring that fit properly and looks to me right on. I'm mainly troubleshooting the poor balance wheel function and fit and I wanted to start checking with the wheel train, which is where I'm a bit stock not able to determine if it's free enough to proceed downstream or if it's something I need to address before I move on. Julian1 point

-

I don't agree with that. The (attached) user manual details all the setting and parameters, and there is one page summarizing technical data. Maybe you're referring to the interpretation of the data, which is not there and I see god reasons for being so, but you can search the forum for the many discussions and downloads on the subject. Now regarding the support for coaxial reading there is a post by an inactive member claiming that it is supported in models with the latest firmware, he even linked an YT video but isn't accessible. Nothing from the Internet really proves that amplitude can be correctly displayed, anyway if I'm wrong my apologies. 8445_W47107.pdf1 point

-

1 point

-

I'm very happy with the way this one turned out. The case has very slight wear on the back, but other than that it is pretty much immaculate. The dial is as fresh as the day it left Dundee, and it is ticking away very nicely following a quick clean. Not bad considering it is 37 years old, and only cost just over two quid.1 point

-

Yours is the first version I've seen with a date complication. Shame about the hairspring, but a little TLC would probably sort that out, now that you have a couple of similar ones to compare with.1 point

-

1 point

-

Looks very similar to a couple of French made movements I wrote about a while back. Have a look for the Lijac and the Rodeo1 point

-

1 point

-

Hi what you suspect is usually correct with a free running train but not always, from your description It sounds more like the mainspring not delivering the power required and is a candidate for replacement. when cleaning did you check and clean the jewels and use the correct lube. I have attached the tech sheet for the cyma !!!! a bit scruffy 2047_CYMA 214,215,216,217,234,235,237 (1).pdf1 point

-

1 point

-

1 point

-

I put this one on earlier as I was going out in the rain Sent from my iPad using Tapatalk Pro1 point

-

Wait. I was looking to a set of 6 with a nice stand for 100 pounds. Horotec, roller bearing and SS blades. They are the absolute best according to a known someone that also A*F and Bergeon before, and having handled fora try I agree. That is not crazy expensive. Even better news, my Chinese ones that want to be a bit like the above are cheap and work perfectly. I think one can do very good with a total of 100 ponds/euro/dollars if using a PC based timegrapher. And remember it's the watchmaker that does the good work, not the tool.1 point

-

Welcome here. One can't go wrong with the blessing of the wife and a son producing the breakages.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Maybe you'll want something like that Especially likable .,. her almost indiscernibile Chinese accent.1 point

-

Well, I have finally found the "true source of the problem", and I feel equally elated and embarrassed The problem is that I replaced the setting lever screw after I replaced the barrel bridge, when in fact the setting lever screw must be replaced before the barrel bridge. Doing it in the wrong order "works" but it will make the oscillating weight slightly foul the head of the screw and it will make it impossible to remove the stem without the setting lever detaching from the setting lever screw. This mistake I won't be doing again!1 point

-

I have the 1900 & have had no issues what so ever. If there is a fault they come with to say the least little instructions1 point