Leaderboard

Popular Content

Showing content with the highest reputation on 06/14/19 in all areas

-

That's right- except for Rolex where it's mandatory (they won't work right without it).2 points

-

End stones limit friction to a rounded point bearing on a flat surface, as opposed to a shoulder bearing against the perimeter of a pivot hole.2 points

-

What JDM says. I seem to repeat this a lot, but: you are more likely to have issues at the faster end of the gear train (including the balance/escapement) as there is considerably less torque at this end. It's a common assumption of beginner that mainsprings should be a likely cause of stopping a watch. Unless they are broken or slipping, this is unlikely to be the case.2 points

-

A dirty MS doesn't make a watch stop. Escapement fault (in first place), and other faults do. You can also get important clue looking at it on the timegrapher.2 points

-

Are the hands catching on each other or the crystal ? is it stopping in the same place2 points

-

A lifetime of interest but now that I have the time I find that my eyes, hands, coordination etc have gone. I have spent a good few hours reading through the threads and I am in awe of some of the things you guys achieve! I'm quite happy just spectating and who knows I may be able to help someone along the way. Thanks for accepting me.1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. Now you are a member on this forum. Many on here would like to see your pictures.1 point

-

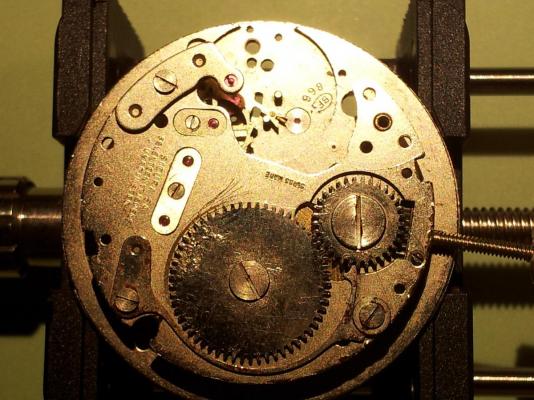

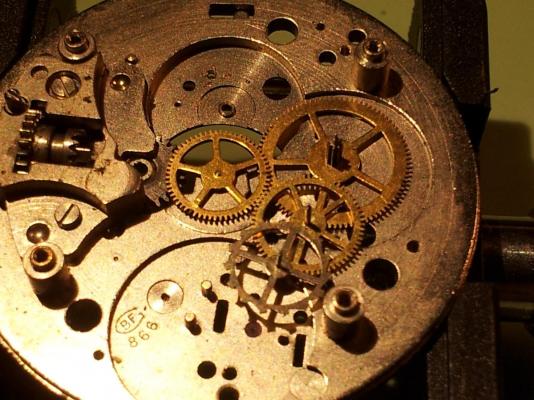

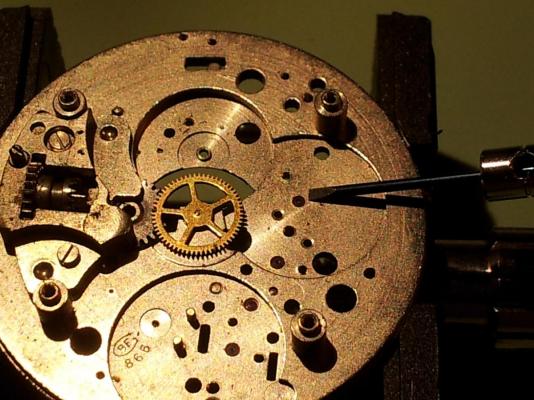

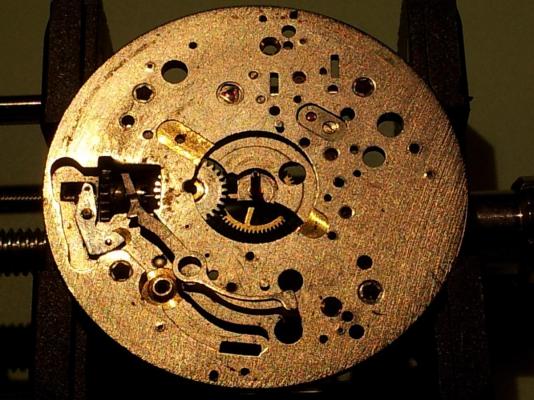

I have been working on this little Baumgartner 866 pin-lever engine for a few days and finally put back all of the drive components back late last night. It is ticking away very nicely. Tonight I will replace the minute, hour and calendar wheels--Yes, they are all wheels! I have posted the disassembly and will post the other pictures later. I want to thank Mark for his excellent video showing the AS1900 overhaul because that is what I used for guidance. During several places I simply had to follow my own way obviously because this movement is very different than that one, but it worked! I cleaned it with Naptha and afterward got my little oilers and put it back together. The hardest part was getting those wheels seated properly in their pivots and also the pallet lever. One thing I couldn't figure out was how to remove the Novodiac shack system.....I'll have to return to it later. I also replaced several parts from a new BFG 866 I bought for $20.00. I could not believe when the little thing sprang to lif after assembly...it was still running nicely this morning when I left the house. Joe1 point

-

1 point

-

Fixadrop helps oil stay where you put it, stops it running flowing, but is very expensive.1 point

-

I plunge whatever I want to treat, except for the pallet fork, since it's been demonstrated that it's detrimental to epilame the fork slot and pivots.1 point

-

I use a little bottle like the pic, 30ml, got it at the drugstore. I fill it about 1/3 of the way. Escape wheel get plunged in with tweezers, cap jewels the same, for the pallets I dip closed #5 tweezers in which suck up a little, and deposit a bit on the stones. My colleague uses a 10ml plastic lab bottle with a really fine spout, and squirts some on a fine artist's paintbrush (like really tiny) and applies where he wants. I know they say to soak for a while but that's tricky to do keeping contact with just the pallet stones, and the quick dip really works fine.1 point

-

What would be a good method for applying Fixodrop without using a special epilame bottle? Servicing my first ETA cal. 2824-2 I’m going to follow ETA’s tech sheet the best I can. Probably not necessary but that’s what I’ve made up my mind to do. This means I will have to treat certain parts with Fixodrop (8981, Fixodrop ES/BS-10). No big deal, right? Wrong! Big deal! The Fixodrop 100 ml is £107 (incl. tax) and the epilame bottle is £162 (incl. tax). In total with shipping (to Sweden) that comes to £278 (€312/$352). These prices are from CousinsUK.com and those prices are competitive, trust me! So, for my money, I get a solution and a glass bottle, although a bit special. There are some less expensive epilame bottles, but the prices for these bottles are still "criminal". Am I going to place an order? NO! The Fixodrop can be bought on eBay for approximately three times as much as offered by CousinsUK.com, but it can be bought in smaller quantities. So, that’s what I’ve done. I’ve ordered 10 ml (still very painful, $54 with shipping ) So, what would be a good method for applying the Fixodrop to the parts without using a special epilame bottle? As I understand it, Fixodrop is very volatile so I guess that can pose a challenge!?1 point

-

Hi all, I'm using WOS 1.3 and I like it very much. I had some problems (freezing oscilloscope view) on a particular laptop (Lenovo with Realtek soundboard) so I moved it to an Asus Laptop; no more problems. I noticed that my old Timetrax ticking sensor was picking up a lot of noise from the surrounding ambient, surely related to 50 Hz mains and other sources, like LED lights. I looked at the cable connections: There were only one "hot" wire and a shield, connected to both the piezo ground side and the plug ground side. That creates what Audiophiles call a "ground loop", acting as an antenna to pick up the noise. So I replaced the cable with a good quality shielded Microphone Cable, with two wires inside and a good shield. The shield was connected ONLY to the plug ground side, and left "floating" at the sensor side; that's the important trick. Now the noise is reduced to near zero; I checked with an oscilloscope, and by hearing it at the output of the Timetrax amplifier. Hope that this will help some of you, Paolo from Italy1 point

-

You can get by with an imperfect hairspring's END CURVE. 1- Remove all to have a bare mainplate. 2- install balance and cock back on the mainplate, this will increase your access to hairspring and you can keep checking it from both sides. Hairspring is to be centered concentric, level. In this case only end curve is jammed. Bring the end curve back to a circular shape, let us see pix as you progress. You are thinking new is a gurantee that the hairspring will bs centered once installed, it may be only by chance.1 point

-

I re cleaned and re greased the mainspring (moebius 8200). I wanted to replace the mainspring but didn't have one handy and it didn't look tired so i used it. The watch is back working fine now. If this happens again, i will have to look into the balance also. The timegrapher is giving me good numbers and lines. Thanks all.1 point

-

1 point

-

Open "boot" on index pins. Loosen stud screw. Remove balance. Remove two screws on underside of balance cock to remove cap jewel. Oil drop should cover around 50% of the cap jewel. Refer to BHI document.1 point

-

You don't want to see colored remains in a (skeleton) watch. The advantage of a colored medium is that you see what you have done.1 point

-

If one takes the time to read the entire Moebius catalogue there are many more subtle variations, that are not actually available to retail. As an hobbyist I think one should concentrate on more important issues, like applying correctly, etc.1 point

-

I have problems with 7 series mainspring also . I only oil the barrel walls with 8217 very little.1 point

-

You mentioned it was serviced.. Did you service it yourself? If you're going to dive in, suggest you start by removing the balance.. inspect pivots and hairspring. Next put some power into the mainspring and see if the pallet fork locks/unlocks properly. It should 'snap' from one side to the other. If that is fine then remove power from the mainspring and remove the pallet fork. Wind the barrel a bit and the train should wind down. Try to move the wheels, if it spins a few more times then your have to inspect the pivots and pivot jewels closely. On older watches I usually find barrel holes worn. Good luck. Anilv1 point

-

Dose it repeat stoping at same hands position( time)? You probably removed hands altogether. Eliminate hands one at a time. When it stops, remove seconds hand only. if the fault has remained. remove the minute hand as well, if the fault remains, remove the hour hand. Dirty or faulty center tube, bent seconds hand, worn out center hole, dial plate center hole drift, so on.1 point

-

Take it back to the person or establishment that serviced the watch. Agree with anilv's analysis + there are many other possible reasons too. The only way to detect the fault is for a close inspection of the movement.1 point

-

Potential problems. 1. Out of beat, could happen if the watch was dropped. 2. Mainspring not good. 3. Dirty. 4. Bent/damaged pivots or pivot jewels... I would take it back to the person who serviced it if the service was done recently. Good luck1 point

-

I dont have much more pertaining to watches and clocks, just this last leather band. I was to make a raised centre band but I got caught up in the scrollsaw cuckoo clock. I made other leather things like bracelets, wallets, belts and even art but those are not pertinent to this forum. This is another el cheapo watch and the first I came across with this type of band. The pin for some reason didnt want to come out so I actually sewed this band together on the watch and it came out pretty good. I've seen bands that guys made for pocket watches and I was gonna make one for a Bulova I have but I managed to fix the band it came with it.1 point

-

A priest, a doctor, and an engineer went golfing. They were frustrated by the extremely slow pace of the group in front of them. When they complained, the manager said, "Those guys are firemen. A few years ago we had a fire and they saved our clubhouse. Unfortunately, those 4 were blinded in the fire. In gratitude, we granted them free golfing for life." The threesome immediately went quiet and thoughtful. Then the priest said, "I'll certainly say a prayer for them tonight." The doctor said, "A friend of mine is a top eye surgeon. Maybe he can do something to help." The engineer said, "Why don't they play at night?"1 point

-

Just some curiosity facts about the Landeron movements. https://www.watch-wiki.net/index.php?title=Landeron1 point

-

I did one the other day and is the same as regular crown one. 1. Measure how much of the stem the crown takes in. 2. Fit stem and mark it at the pendant tube edge. 3 Add length from .1. and cut there.1 point

-

1 point

-

1 point