Leaderboard

Popular Content

Showing content with the highest reputation on 04/01/21 in all areas

-

New polishing motor with three pads, progressively finer. use Stainless steel polish lightly on the first pad and fine blue on the last pad. seems to work well. maintain heat through pressure to melt the metal into itself....an art that gets better with practice.2 points

-

Considering its a mobile stud carrier( beat adjustor) , I just get rid of the new stud and glue( epoxy 5) the hairspring onto the old stud slot. The new stud is likely to be laser welded to hairspring at production line, in which case the safest option is just cutting the hairspring as close to the stud as you can. Once you got rid of the new stud, thread the hairspring through regulator slot as usual, instal the balance and cock on bare mainplate, next you slide the hairspring into the old stud slot and apply glue( little glue just enough to fill the slot), leave it all in cock down (imporant) position till glue cures. Good luck2 points

-

In the past watchmakers had to spend a lot of time adjusting precision watches, sometimes weeks. With a timing machine things are much faster. In chronometer certification, COSC, Besancon etc., they are cased and dialed with white test dials, and photographed with a camera that takes the image at a very precise time, triggered by a precision (nowadays atomic) clock. The images are taken for the various positions and various states of wind, temperature, etc, over a period of days. As to poising and further adjustments, in a modern watch the balance is poised very precisely by an automated machine, the hairspring is attached to an engineered collet that is also "poised", and there is typically very little adjustment needed once assembled. With a perfectly poised balance, and a well adjusted hairspring system (true at collet, regulator pins well adjusted, flat, etc), there may be a little bit of residual error in the vertical positions that can be adjusted by dynamic poise. But as we are taught in school dynamic poise is done on a watch that is in perfect running order. All that said sometimes I will correct quite large poise errors with dynamic poising, for example I did a LeCoultre 145 pocket watch a couple of weeks ago; this watch is 1.38mm thick, and I didn't like the idea of pulling the hairspring and sticking the balance on a poising tool. It had over 100s delta in the verticals, by stroke of luck one added timing washer brought it to 15s, which is fantastic for such a piece. Other than the vertical delta it was in terrific shape so it was an easy decision to dynamic poise.2 points

-

For this watch, you wouldn't remove the jewel settings secured by screws. They can be removed, but they weren't intended to be routinely removed. Think of them like friction-fit plate jewels in an modern ETA 2824, only held with screws. As you noted, the balance jewels would be removed. I believe the crown wheel screw on those old Walthams is reverse threaded. You don't need to remove the watch crown from the watch stem. When you unscrew the 2 dial screws, the movement can be removed from the dial side. (You might need to pull the crown to the setting position.) In nearly all cases, the crown and stem stay in the case. I'm not positive but just in case... (1) the balance staff is probably friction fit, not riveted, and (2) the mainspring barrel might be a "safety barrel" (much like a motor barrel, with an arbor, a lower barrel cup with a hook, and a cap with a riveted hub). If the barrel looks unlike what you usually see in modern watches, it's probably that.2 points

-

I'll be starting on the Waltham pocket watch this weekend. You've already advised me that I can't wind the mainspring via the ratchet wheel and helped me with oiling. This is my first pocket watch and I'm more used to the more modern movements. I would appreciate if you could let me know what to watch out for, what to be careful with etc. Stuff that differs from wrist watches. Couple of questions: Do I need to unscrew the jewels from the bridges? I will have to remove the jewel from the balance to clean it properly but I'm not certain about the other jewels. I presume that It will be straight forward putting them back? Is the crown wheel screw reverse threaded? Detaching the crown, is there a chance I may strip the tread on the stem? Pictures of the jewels and the movement are below.1 point

-

1 point

-

Thanks Jon. I appreciate everyone’s help and will post what I find tonight. Great pictures too!1 point

-

1 point

-

Thanks Jon. Good luck with it. I thought my watch and I just had a screw loose in common.?1 point

-

1 point

-

I've got a 7750 with exactly that problem... the stop lever has got jammed against the balance. You can just see it when you look at the balance from the side1 point

-

Did you mean to say " there is a crown position that stops the oscilator( hack feature) ". No crown position should stop the Rotor. I agree it sure sounds like the problem is in the keyless, perhaps stuck in hack position.1 point

-

A guess, but the dashed symbol could mean same as the solid symbol, but on the reverse side.1 point

-

If it's the one I'm thinking of it's likely a snap back. As this is a 7751 base (with column wheel), my first guess would be a screw came loose and is blocking the movement. The 7750 calibers are known for working the movement screws loose if they aren't tightened to 80ft/lbs.1 point

-

Dose it run any when you shake the watch or advance the hands? if so , I put the crown in set position, shake to get the oscilator running and advance the hand when running, see if that makes its run as long as you keep pressure on advancing the hands. Try giving it a full manual wind, listening close you might here a sound of sudden power discarge from the barrel. Dose it make a difference weather in chrono mode or not? Regs1 point

-

Because it's faster usually use a timing machine. If you look at the various watch companies they usually have recommendations for timing specifications. In other words you rotate the microphone to a position allow it to stabilize like Omega typically 30 seconds then they have a measuring time. If you have a really fancy witschi machine It will do all that for you use programs at times push the button and you get the numbers. You could do it by looking at the hands comparing at the something else but because problematic because in other words like if you had one hour per position and you did six position timekeeping it would take six hours. This means the effect of amplitude between a fully wound up watch and six hours later we change the timekeeping. So would probably suggest that you would wind the watch up let it run 15 minutes compare it to time source and timer for one hour in each position and repeat that for it would take you forever timing machine would be better. Or I suppose if you're really obsessed wind it up and put it in a position and let it run for 24 hours. For each of the positions. I was one set a lecture where the person explain their frustration with precision watches. It was not the problem with the watch it was a problem with the owner of the watch or this case several owners. They would compare their watch time standards like now ancient history VCR clock. A variety of other clocks not known to be very precise at all. So you'd have frustrated customers using improper time standards and wondering why their watch didn't keep time. As far as a time reference goes in a variety of countries around the world there are or at least were shortwave radio broadcasts. There is also lower frequency broadcasts were your clock will synchronize to those. But it looks like a lot of them are now replaced by GPS timekeeping. You can actually in a special GPS receiver for timekeeping purposes and even a regular GPS is not be so much better than your watch especially if you timer watch over a period of time. Then understand how the timing machines if you have a really fancy one come up with all the numbers I've attached a PDF otherwise you can do the math by hand. I once gave a lecture on timing machines. One of the things I was looking for was how did they do it before timing machines so I found an interesting book. The person explained everything they did and it took a couple months. That's because each adjustment would take several days to verify whatever the adjustment was to take effect. True there were some breaks where they took weekends off but it took some time. One of the things especially in the early days they would deliberately introduce errors in to fix other errors in the watch. Otherwise if you aren't so obsessed you could set the watch to a time standard like most towns would have a railroad train station they should have a decent clock. Set the watch to your clock time come back in a week see what it's doing or come back every day. Adjusting without a timing machine is going to take you some time. Even with the timing machine uses still verify that the watch actually does whatever the timing machine says it's doing. witschi X-D-DVH-Di-Im-N_EN.pdf1 point

-

Do you have any end shake when cock screw is tightened? Ideal end shake its .02mm. Acts like you have a coned pivot facing a flat jewel. Is there an end stone to the jewel on the mainplate? Bent pivot or unlevelly seated jewel.1 point

-

Look up "Tommy Jobson" on youtube does some excellent videos not aimed at the beginner, but if you have time to kill they are a good watch also some good links to other clock videos on his you tube page.1 point

-

Here is the title to the original thread in which I purposely showed a SMALL ZIPLOC BAG. " Tips on removal , cleaning and reinstalation of fiddly cab jewels " The bag Idea occured to me over thirty years ago and has never failed. The story has undergone many changes eversince, cutest version was someone made a plastic tent to carry out the task under, run short on oxygen under the tent a got dizzy. ? Regs1 point

-

Polishing the crystal is one thing you can do which doesn't harm the value and improves the looks more than a little. A thorough clean and oiling of the movement is essential if it is to be used again. This watch has an interesting history, and I would not want to erase that completely.1 point

-

I really appreciate everyone’s comments. To synthesize and summarize some of the lessons learned (maybe it will help out another newbie): 1) Minimize the amount of time a hairspring sits in lighter fluid inside an ultrasonic machine because the combination can remove shellac that is holding the impulse jewel in place. 30 minutes in my case was too long. 2) When removing stubborn debris from a hairspring: a. Perhaps the best method is to use chemical wash and rinse solutions (such as L&R) in an ultrasonic bath. Cost and volume being the major drawbacks. i. Careful not to have temperature too high and leave in too long or damage can occur. Someone recommended 4 minutes maximum time. b. Other chemicals such as One dip/B dip are meant to remove oils from the spring and not really to remove stubborn debris. Naphtha/lighter fluid has small amounts of oil in it. 99.9% Isopropanol can also be used to remove oil. c. Be careful about using (or maybe don’t use at all) a brush on a hairspring to remove debris due to risk of damage. 3) Liquid shellac (and perhaps nail polish) is a suitable alternative to shellac flakes. 4) It’s a good idea to remove the hairspring and clean it separately from the balance to reduce the risk of removing shellac around the impulse jewel. 5) Finally, and most importantly, beware of Loose Soviets. ? *PS does anyone know of a source for a commercial wash and rinse (like L&R) that comes in sizes smaller than one gallon? **PSS I have other issues now to tackle on this restoration, but I’ll post in a new thread. Thanks again.1 point

-

In Seiko guides they'll use these to indicate how much oil. Wedge with one ball is normal, wedge without ball is minimal, and with two balls is generous. Hollow, solid, or angular will indicate different lubricants.1 point

-

I have over 400 videos on watch cleaning and other topics. They should help as I talk my way through each one.1 point

-

Gary, I just reassembled one of these in an AS 2063, and have done several others. I have two similar methods. I first place the bottom plate on either a small anvil or on some flattened Rodico, then put the large wheel thru so it goes into a hole in the anvil or buried into the Rodico. I add the other components so everything is level and all the teeth are engaged in the gears or click. The Rodico helps keep everything together and not able to shift around. I then place the springs into position carefully ensuring again that all the components are level so the spring tension force is horizontal and just holding the components in place. Having everything stuck to the Rodico also helps when adding the top plate so things don't move out of alignment, but if you do it on an anvil instead a tiny piece of Rodico can help keep it from slipping too. I do all the lubrication, including the spring tips, after it's assembled. Hope this helps.1 point

-

Also observe how the set-lever moves when you pull the crown, it should move smartly with no 'sticking'. On some watches (not sure if it applies to this movement) one of the bridge screws (from the other side) is shorter in the area where the set-lever goes. If the wrong screw is used it will interfere with the movement of the set-lever or stem release. Good luck Anil1 point

-

The anniversary clocks? With the rotary pendulums and glass globes and near 400-day movements? Those are cheap right now? I have no clue at all why they're going for cheap, but I know a "heads-up" when I see one. Güte Nacht, I am off to surf the internet.1 point

-

Personally I think because the watch is in very poor condition it would only be sold as spares. The biggest issue will be the refurbish of the dial. I had a Longines dial refurbished, cost £150. The bezel is in good order and the missing Pearl button can be purchased, although it will be an aftermarket one. The hands need a relume and as the movement is running it just needs a service. IMO it would take a while to refurbish but it can be brought back to a very nice watch.1 point

-

I would try to get some opinions from vintage tudor experts, who don't have commercial interest. The whole rolex and tudor (which is some kind of sister brand to rolex) vintage world exploded some years ago into complete price madness. So this watch (if genuine of course) could be worth several thousand bucks for a collector, especially because it has a "SWISS" marked early dial and a PCG (pointed crown guard)-case. Here is a link to give you an idea about original parts prices: https://tswisst.de/tudor-ersatzteile/rolex-zeigersatz-fuer-tudor-7928-3/ I would take some good pictures (daylight, smartphone-camera and 6 inches distance do the job) and ask your questions on www.rolexforums.com (as mentioned tudor is a sister brand so they deal with tudor too). A very good picture of the dial is essential, so it would be best to take the movement out of the case and take a pic then. BUT: The dial is marked "SWISS", much lume fell of the hands and the lume on the dial is black dirty. This shouts: Be careful, could be radium! So I personally would not open the watch. Maybe you can polish the plexiglass a bit to get a got pic of the dial? Anyway good luck with that piece. Nowadays about 98% of the rolex/tudor-talk is about money, I hate that. But I love such stories of watches with a personal history.1 point

-

You have a very nice watch there. I have a fondness for a big silver Longines (my profile pic has mine in it). I am glad you got it working. They are marvelous timepieces.1 point

-

Yes often overlooked by newbies. If the watch has never been serviced the mainspring is probably okay or at least okay enough to get the watch to run. But on older watches where they been serviced all sorts of interesting substances end up in the barrel that at one time supposedly were a lubricant and now are not. It's amazing how much energy can be lost to sticky glue like substances.1 point

-

Prior to this watch what was your experience with watch repair? In other words is this your first watch your taking apart? With new bees and problems like this you need to slow down and do the basics. When you disassemble and clean the watch did you take the mainspring out? Usually when people are reassembling the watch things become obvious before you reach the stage or in them but not always. Like for instance when you've assembled the gear train without the pallet fork in the wind the crown does the gear train spin effortlessly? When you put the pallet fork in your lubricating the escapement did the pallet fork snap nicely with energy? Oh and trying to swap the hairspring bad idea each hairspring is matched to the balance wheel That it is on. Okay as I'm reading through things again I see your order a new mainspring what does the old mainspring look like? Then even with a set mainspring the watch will run it won't run overnight if super set but the watch will run fully wound up. How easy was it to get into the watch? In other words they hairspring and didn't just bend up itself somebody did that. If they bent that what else did they do while they were playing with the watch? This is where conceivably you may have other issues issues that you normally don't have because somebody has played with it with zero idea of what they were trying to do. I'm with a repeat some things from above. Mainspring barrel out pallet fork out just the gear train. If you give the center wheel a gentle push does the trains spin effortlessly? It should require very little force on the center wheel to have the entire trains spin. This is where when you were assembling it you should check the end shake of each of the wheels to make sure there was a little bit and shake and you should verify that the train would spin effortlessly. But the mainspring barrel back in a wind on the crown the gear train should spin. There is a test for gear train freedom called back spin. his is where when your winding the watch the gear train is spinning you stop winding and the momentum of the gear train will go past the end of the mainspring basically and back wind the mainspring just a little bit. So if you looking at the escape wheel and you have to look carefully for this you'll see the escape wheel spinning you probably can't see the direction Elgin stop and actually spin backwards a little bit this is usually a clear indication most the time that you train is free then pallet fork in wind it up a little bit and I assume you lubricated the escapement? When you pushed gently on the pallet fork doesn't snap if it doesn't snap your watches and going to run. Once you verify that the pallet fork has energy going to it and everything's fine even with a set mainspring the watch should run providing the balance wheel is correct and it's exactly where it's supposed to be? Although it looks like in your first picture it may be correctly located? That is with no power the pallet fork should be between the banking pins your watch should be in beat. Then we need sharper pictures in the absence of that you have to look carefully at your balance wheel and hairspring. Often times when people start playing with the hairspring this they fail to grasp how important it is that it be flat and not touching the balance arms. If it's touching the arms the watch isn't going to run. This is why asked what your prior experience to watch repair is because you need to have experience with knowing what the watch is supposed to look like and how things are supposed to work so as you run into problems it makes it easier to grasp where the problem may or may not be.1 point

-

Face and hands can be replaced at any time but are only original once. Replace them and the value will drop. Nothing wrong with an old watch looking old.1 point

-

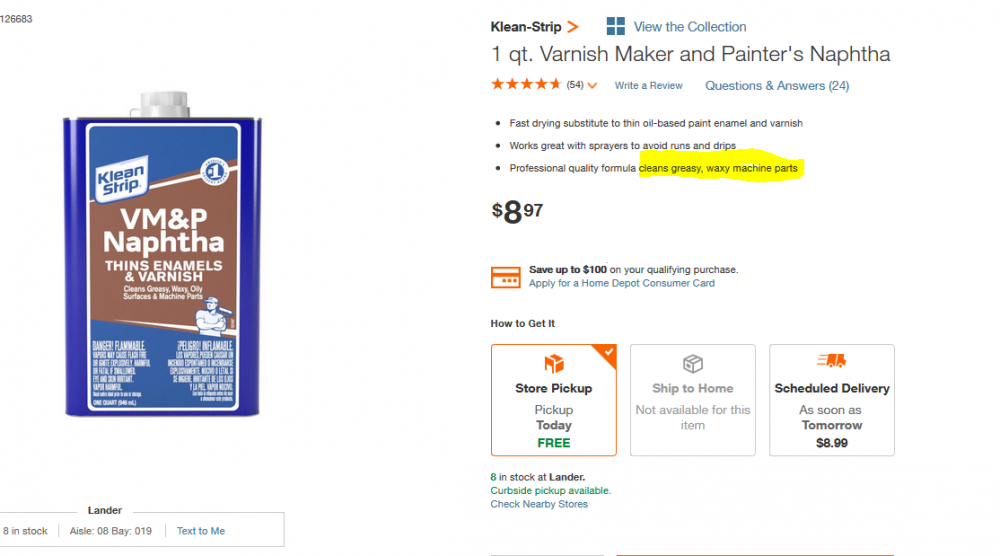

It seems to be the number one product used for cleaning watches at least on this discussion group. That's because they don't know anything better and it's what they use. It also depends upon where you're located? For instance in the USA you can order at least it's on the website watch cleaning fluids from Amazon the only catch is you have to buy a gallon of the cleaner in the gallon the rinse which will last you forever. Or other parts of the Orworld you order cleaning products from cousins. Or if you rest the problem and we really want to have your lighter fluid you Google what lighter fluid is new find out that it's Primary ingredient at least according to Wikipedia is Naphtha. Then if you just look at what your local hardware store has you might find something like this. But I would still try to go with a commercial watch cleaner if you could as it does more than degreasing it's actually designed to clean watches it's amazing what happens if you use a product that is meant to do whatever you're trying to do.1 point

-

That's a good point. I will check that later (wifes 70th birthday today. My 74th yesterday so a little fuzzy) ???1 point

-

I always refer P G tips as monkey tea, all due to those lovely adverts with the chimps. My favourite is the removeles and the piano. For those that don't know what I'm talking about look at this.1 point

-

I found this blog to be very helpful in understanding watch adjusting. https://adjustingvintagewatches.com/what-is-watch-adjusting/1 point