Leaderboard

Popular Content

Showing content with the highest reputation on 08/12/20 in all areas

-

Henry Fried's Watch Repairer's Manual has a section on graver types and specifically on turning a balance staff. Those DeanUK vids are good, that should get you going. I like that he turns at quite a low RPM, one of the biggest mistakes I see is folks want to turn at top speed, and while "correct" in some situations is usually conterproductive when hand turning. Some schools have the students using hand powered lathes for the bulk of their hand turning training. I generally use two speeds when turning, around 2k rpm, my fast speed, and around 800. While my machine is physically capable of going well over 10k the way it's set up it maxes around 4k and it's rare that I find any need to go that high at all. The main reason you go slow is you have to make a chip, not scrape metal off. At high speeds you either have to have very fast and confident reflexes or you end up scraping. Same goes for micro drilling. The books will tell you to spin at 50k for a tiny hole, the reality is about 1/20 is about all you can really react to when hand feeding.4 points

-

In addition to the technical communications from eta they used to have available the manufacturing information sheets. These are interesting technical documents with more of the technical specifications. I rather like him because the timing specifications are given. If you scroll down far enough there is some movement size information casually on not seeing the screw size but it might be there. Then this is for the 2824-2 version versus the version you asked for which I don't have a manufacturing information sheet for. ETA-2824-2-Manufacturing-Info-Fr-Gr-En.pdf3 points

-

2 points

-

maybe some light reading would help this first link is a nice book talking about the watchmakers lathe. sometimes it helps to start at the beginning to understand why we have the watchmaker's lathe we do today and the minor or not so minor complications of all the variations. The watchmakers' lathe, its use and abuse; a story of the lathe in its various forms, past and present, its construction and proper uses https://archive.org/details/watchmakerslathe00good Then the next link gravers are talked about their hidden in a variety of chapters so you have to go looking. Like chapter 3 does show gravers and sharpening them. Joseph School of Watch Making https://mybulova.com/vintage-bulova-catalogs Then a video. It does bring up a minor problem though is showing you to sharpen engravers for a lathe but if you read the first book you will know that the typical watchmaker's lathe does not have a slight rest. That's because watchmakers typically hold gravers in their hand resting on the rest. But modern watchmakers will typically use across slide the hold the cutting tools. Which brings up the problem of your question because a lot of it has to do with what you're going to be cutting what type of lathe you're using. Classic Watchmaking: Grinding and Setting Up A Lathe Cutter https://youtu.be/2R0l6I1yrrk2 points

-

It would probably be impossible to learn everything from this forum. There are many good watchmaking books available from Amazon and Ebay. Do get some of them to build up a sound foundation first. Jumping headlong into everything is not the best way of doing things. First learn the science behind metal working and machining. Learn the reasons why things are done the way they are. When you understand the science, then you can start to appreciate the intricacies of horology. Then you can start bending the rules and coming up with your own techniques of doing things. When you do get a lathe, don't go and try cutting a balance staff as your 1st project. Start with simpler things. Start with softer materials like brass and soft steel, then work your way up to blued steels and stainless steels. Be prepared to throw away many failures. Or keep them in a showcase to see how far you have come along in your journey.2 points

-

This is one of my latest projects I really should stop buying, the living room is getting over crowded with three Gillett and Johnston grandmother clocks one completed and the other two part way done but movements cleaned and running, a Grimshaw Baxter and Elliott grandmother clock to do, a Electric Regulator clock that came out of a old Clock Makers shop in Brixham which I wasn't planning on buying but went to pick up a milling machine and the seller just happened to mention he had a old clock to sell. And then there are the runners or mostly non runners because I am forbidden from having them all running at once because apparently it interferes with Coronation street and Eastenders two triple fusee's, three double fusees, two single fusee, four spring driven Westminsters, two vienna regulator's two Ting Tangs, various carriage clocks, and Swiss 8 day clocks and a Atmos clock and many more it's like a stock take at a zoo just when you think you counted them all another pops up. So one more won't harm I guess, I collected this today after putting a very cheeky offer on it yesterday on ebay which to my surprise was accepted. Best described as very High Gothic Victorian Its signed on the dial Bennett 65 and 64 Cheapside London I think it would date from 1865 to about 1880 because before 1865 the company only occupied number 65 Cheapside. It's a triple fusee striking on 8 bells and the hours on a gong, the movement is large and the plates are 8 by 10 inches and is so heavy the seatboard has metal struts underneath to support the weight the case is oak and is 18 inches across and 26 inches high There is plenty of evidence to show that the case was gilded in part with gold and some parts enhanced with painted details there is also a latin moto painted on to the gilding above the dial I think it says "many hours and days declared" but am unsure because I used a online latin translator. Much of the case detailing is loose and needs reattaching but the sellers kept all the loose bits in a carrier bag so its all there apart from one of the side frets the other is complete so I may take an impression from that and make a replacement from resin, the elderly couple I bought it off had inherited it from the Husbands father who he said would stop the clock every night and restart it in the morning because there is no silent switch on the clock and the chimes are so loud it woke him up . I'll have to give this clock a little thought I'm unsure whether to have the gilding renewed or to just wax the case I'm not very bothered by the crack down the front I may see once the movements out if there is any play in the wood to bring them closer together, I think the clock is all original but if anyone thinks not please comment.1 point

-

Mostly its aesthetics, but the bluing provides corrosion protection. A lot of really old watches have blued hands that have gone black with time, and it'll be fun to restore them. Long term: I'm working on some custom watch projects, and would love to be able to sell hands that I've blued, or custom watches with certain blued components.1 point

-

Hi Dan, What good would blueing do? just aestetic significane? or colour lasts longer, wont whipe off? hardens the metal? have some catalougues, bereguet for one, that show and seem to take great pride in craftsmanship that goes into such heat treatment, but don't understand the significance of it. Red your first post and understand you need to make you a set, but you seem to have taken further interest in the subject.1 point

-

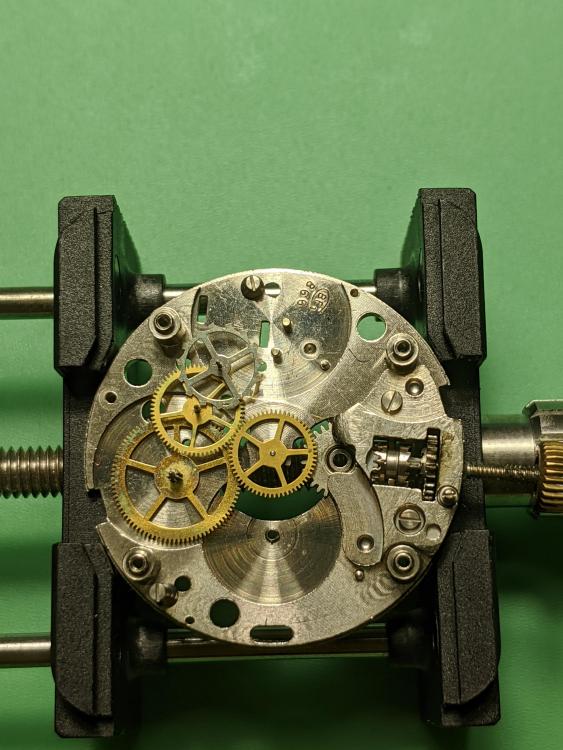

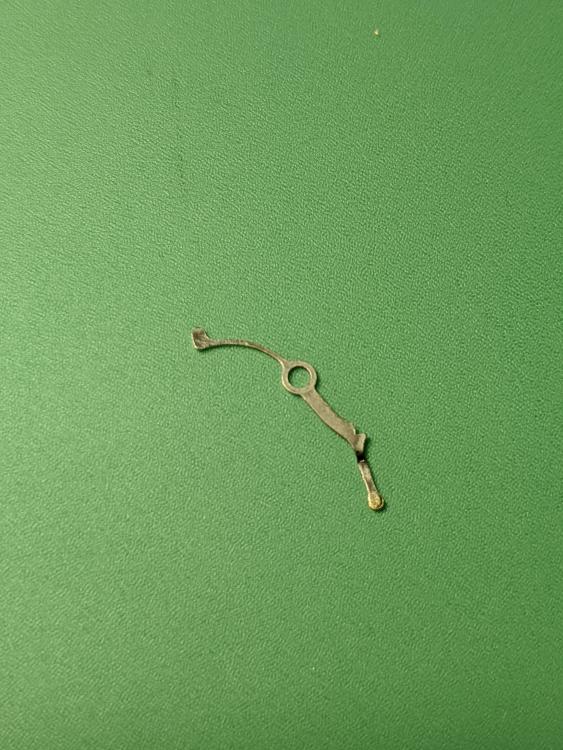

Love and hate these electric q quartz watches. When they run they usually run well if they don't my success rate at servicing is 50%. I hate the day and date indexing springs which are really fiddly and then you have a dial with tabs to fit over them its painful! Fitting the coil balance, near a magnet also has its moments of frustration.1 point

-

Are you sure the right regulator arm in fitted on the cock? Doesn't look bent down. Perhaps the wheel was restaffed with a shorter staff. I am affraid previous watch destroyer chose the easy solution.1 point

-

Wow, interesting. I can imagine the procedure. Thank You very much for the help. Will try that and luck I need as well.1 point

-

You might consider laying a section of the HS on flat surface of glass and gently slide a needle over it, this will lets you press on the springas you like, works like a treat taking the kinks out as well as streighens somewhat, try AND continue in 3 to 4 mm sections, observe and evaluate the outcome, before you move on to the next section. The reason for going in small sections is to observe and keep the spring vertical to coil, as you streighten, vertical so circles come out parallel when you wind the coil. Avoid pressing too hard on the spring as you may worsen a fatigue in crystaline structure of the spring. Good luck.1 point

-

If bikes of all kinds are your thing, and you find yourself in Glasgow then I highly recommend the Riverside Museum (actually even if bikes are not your thing). Click the links for a little more of a flavour of the place. https://www.tripadvisor.co.uk/Attraction_Review-g186534-d214166-Reviews-The_Riverside_Museum_of_Transport_and_Travel-Glasgow_Scotland.html#photos;aggregationId=101&albumid=101&filter=7&ff=390872885 You can easily spend a day in the place. The Riverside is second (in my opinion) only to the National Museum of Scotland in Edinburgh as must see museums round here. The NMS also has some interesting cycling exhibits. https://www.nms.ac.uk/explore-our-collections/stories/science-and-technology/bicycles-at-national-museums-scotland/1 point

-

Had to take my Q Quartz apart to check. It stopped on my wrist 3 times today. Found quite a few magnetic particles stuck to various parts inside the movement. Being a quartz watch, I thought I've seen the last of my good friend - the contact spring. But lo and behold.... it's still here! Battling several technical problems at home and at work this week. It'll be some time before I can get down to putting it back together.1 point

-

1 point

-

Hairsprings were/are produced with traditionally preset values of CGS. In house manufactured hairspring were generally utelized on as many calibers as possible, unless a technical neccessity called for production of different CGS, since both calibers at hand are to beat the same and of the same family, I'd be very surprised if CGS varies between members of same family/ generation, unless design frequency is improved( increased).Your balance complete will produce the beat with considerable accuracy, the wheel will loose its poise therefor percision if you unscrew a weight, which according to nickelsilver manifests in hunderds of a second. While spring production was inherently inexact, each weight is in effect a micro-poiser, as we can clearly see on the wheel, two weights are not screwed down all the way to the last pitch of their thread allowing furthure adjustment of the poise, specially useful when the wheel gets restaffed or otherwise interfered with, In addition to weight washers you can remove material off of each weight with a fine file if not on lathe. You might even forget the weights for the benefit of the poise and simply cut the hairspring shorter to speed up the rate. Vice versa dose not hold true if the ballance complete ran fast. Weight- HS length are in fact two parameters left at disposal of repairman to use in combination in building a decent balance complete. Its down to repairman's skill and nowadays to availabilty of parts as well. Regards Joe1 point

-

One of the things you have to be careful about is if you look at the link below you're right there all in the same family. But look carefully at the descriptions just because of the same family doesn't mean that everything interchanges. If you look at the description of 268 versus your watch and even the picture notice that the balance wheel description is a little? Let's quote "268: ring- instead screw balance" Your balance wheel appears to have screws the picture of the 268 appears to not have screws. But as you pointed out to the same family it shouldn't matter should it? I will let somebody else who likes to toss out CGS numbers explain in detail what it means. Here's the problem with CGS numbers it's not exactly an exact science we have a problem. Then in your case You will probably find that your CGS number is different anyway that's an even bigger problem. But even if it was the exact same CGS number we still have a problem. Up until recent times the manufacture of balance wheels even though they look all the same isn't super precise. This means that every single hairspring Has to be matched to the balance wheel by a fun procedure call vibrating. This is why hairsprings are not listed as a separate component it's a balance complete. American pocket watches with over coil hairsprings the companies found it easier to pre-manufacture the hairsprings to get the characteristics they desired. Then to get the balance wheels to match they change the timing screws. So in the catalog hairsprings are available or were available along with the associated with timing screws. As you've discovered your hairspring isn't the right hairspring for your balance wheel. As you like your hairspring better than the old one you're going to have to modify the balance wheel to fit your nifty new hairspring. As others have suggested remove a pair of opposite screws to keep the poise. Then see what effect that has your more than likely going to have to remove several pairs of screws. Then the funds going to be where you're probably going to be unlucky and you really good and up needing half screws which you don't have. This gives you a couple options either timing washers to increase the weight they will allow more precise control or you're going to have to modify a pair of screws to reduce the weight. Then we'll see what other undesirable consequences may or may not occur. That's because hairsprings are more than just used for timekeeping but as your balance will be light in weight you probably won't suffer. It be much worse of the balance wheel ended up being really heavy for a hairspring that was wrong possibly. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_2681 point

-

. I think keeping these old clocks is a duty, as with so many of them they carry memories and for that reason alone they need to be resurected. Thats a nice job sympatheticaly done.1 point

-

Looking at the existing spring that could be manipulated. However manipulating hairsprings is not as easy as it first appears. Practice, practice and more practice is a must. Choosing a replacement hairspring is also not an easy task. I have lots of hairsprings in my stock and it is amazing how, despite this when a replacement is required I do not have suitable donor. Hairsprings have to to be the correct strength, length and turned in the correct direction. Most hairspring centre studs have one side which is chamfered and this is the side that sits on the balance. The rule of thumb for strength is when attached to the complete balance assembly it should dangle 1/2" when held by its outer coil.1 point

-

There are assortments of these for a reasonable price. I have a feeling that the entire range of assortments is not made anymore so I'll be grabbing some for myself. https://www.cousinsuk.com/product/case-screws-wristwatch-movement-to-case-assorted1 point

-

I'm not sure to be honest. I think it might be like a varnish that can be dissolved in water but I'm not sure how well it will hold up when exposed to abrasive. I'll find out in the next few days. One of the advantages of tape it if you need to mask a strait line you get a strait line. Painting one on could be next to impossible.1 point

-

CGS Stands for Centimeter, Gram, Seconds, its a metric system of measurements and abstractly used in horolgy to refer to hairspring strength. The two springs you got, are of the same family generation, meaning have the same strength and only differ in length to resonate to different frequencies, much like a guitar spring. The resistance a hairspring puts up to the motion of balance wheel is fundamental to the beat the complete balance produces. As for this bent hairspring, thanks to largely undisturbed coil it is perfectly sortable in my book, you might streigthen the bends and kinks first and wind the outer circle of the coil a bit larger in diameter to increase the distance with the next inner circle, which eliminate the chance of the two outer coils to foul each other( one getting on top of the other). I hold the stud and run gently the spring in between your tweezers until all bends are streigthened, you can just clap your tweezers on any kink to take it out. Good luck.1 point

-

Maybe I over simplified my "I know nothing about any of it". I was only referring to the watchmakers lathe. I use to work in welding / fabricating. I did prototyping within the trucking industry. The engineers drew the pictures, I made the parts and assembled what ever it was from raw stock. Then it was kicked over to Jigs and Fixtures to sort out the rest for line production. Now I work from home operating a street rod /hot rod shop. I will frame off anything that will fit in the door (9'H 10'W). Though I won't shoot color, rebuild automatic transmissions or change oil for others. My dive right in attitude comes from my time in the service. I'm a paratrooper with combat time. Nothing can't be done with proper prep. I don't believe in the concept of failure. I believe you have found a way that will not get you the results you want and another must be tried. Scrap parts and pieces to me are valuable resources for another project. Anyway.... I like old pocket watches!1 point

-

Not even close. I did find these videos on YouTube that covered all I was looking for in my question.1 point

-

uuhh boy....you got a few days just to discuss: lathe fundamentals of operating a lathe including safety nomenclature of a lathe what kind of lathe and their uses lathe tooling-for wood or metalwork lathe specialties-WATCHMAKING and watch repair; MINIATURE lathes why sticking a loupe in your eye socket is not a natural feeling why doing miniature lathe work while wearing an eye loupe just ain't any fun obsolete lathes and tooling related to watchmaking and repair USED lathes, tooling Chinesium (ha) machinery EBAY buying a lathe, tooling buying a miniature lathe, tooling.... Can engine or benchtop lathes and associated tooling be used for watchmaking, Repair? ("yes, but....") making your own tooling, gravers for watchmaking and repair types of steel to make watchmaking and repair lathe tooling bench grinders, sharpening and honing stones, cutting oils ANGLES and RELIEF grinding and polishing in relation to lathe tooling get my drift? some of those I kinda made up, but as a long time apprenticed, journeyman machinist, I kinda didn't.(did that make any sense?) just going thru my head I made up the titles but I think you get the idea. it's ALOT to try and cover here, and alot for you to think about. impossible? heck no. just a lot. maybe narrow down the questions you might have to start? hell I wouldn't even know where to begin! did i steer you away from wanting to do watch repair lathe work? hope not!1 point

-

1 point

-

This appears to be a similar product : https://www.cousinsuk.com/product/liquid-protection?code=V49991 Or Boley sell this one https://www.boley.de/en/shop/3118.protection-lacquer/1838282485.protective-lacquer1 point

-

I suspect the issues here are due to mixing up parts from the 2nd series and 3rd series of balances from the 30T2 and 200-series family. 1st: bimetallic cut, blue steel hairspring 2nd: monometallic, screw rim, two arms 3rd: monometalic, smooth rim, four arms1 point

-

Not sure of the size of that movement. It looks very similar to the old 30 hour Smiths & Ingersoll pocket watches.1 point

-

Bicycles are another fixation of mine. I like to work on them almost as much as I do watches. I tend to make my tools and skills available to the neighborhood kids who nedd work done on their bikes. I also always wanted an early motorbike, like from the 'teens to early twenties. Being tremendously expensive though, I had to find another way. So I built one. This here is "Tempus" (because time flies). It has the frame of a 1948 JC Higgins balloon-tire cruiser, to which I bolted a 50 cc two-stroke engine. I fabricated the tank, the headlamp (which is actually electric) the clutch lever, and a number of other little parts. It has a leather saddle and a little leather-covered trunk. It's not very fast, maybe 30 mph tops, but for in-town it does very well. And it's almost theft proof, in that nobody has anything vaguely like it for miles around.1 point

-

Hi I have attached the tech sheet for the 2836 for you although they list the case screws they do not state the tap size. Perhaps this is one for "nicklesilver" ETA 2428 (1).pdf 29_ETA2801.2-ETA2836.2 (1).pdf1 point

-

Hairspring should be centered better, but that won't give you a rate like that. Are you sure the hairspring is in the regulating pins? That's like 600 minutes/day slow; you can try removing a pair of timing screws (screws from opposite sides of the rim) and see what that does.1 point

-

The next one from my ebay job lot, a 'Gisa Soleure', another Baumgartner 866 based watch, this time with centre seconds, the dial branding is a bit 'naughty'! I assume the 21 is meant to fool you... (note there is no mention of 21 what!, it certainly isn't jewels!) Many watches from the era seem to employ this ruse, and I've seen Ebay listings where these are stated as '21 Jewels' so it is still fooling/conning people today! This one was a little dirty and wouldn't wind, crown would just spin, on opening it up I found the setting lever spring/yoke (single part) was broken so it wouldn't stay in the winding position. With it open I held the sliding clutch and wound it a little, but there was then the telltale slipping noise after a few turns of a broken mainspring. Going through the rest of the batch, I found a Regalia also with a BFG 866, it has a badly damaged case,dial and crystal, so I raided it for its setting lever spring and going barrel. Another note on how clever this movement is in terms of cost down, the four screws securing the top plate, which serves as both train and barrel bridge, also secure the click spring, click spring hold down, balance cock and pallet cock. It does make reassembly a bit more challenging though! After a good clean, strip and reassembly/lubrication, it functions reasonably well (within a minute +/- all positions which will do so far as I am concerned). The crystal has some light marks, I have some polywatch on the way to attack it with. I didn't need to jazz up the seconds hand on this one as it had a funky one already! I quite like it, the dial is a little squint (only a fraction), but the position is fixed by crown and dial feet, and when I look at others online it looks like they all may have been like this! I could resolve it by removing the dial feet, might do at some point if it bothers me. Just fitted with a new strap today and I'm quite taken with it, but I'll probably re-sell this one at some point.1 point

-

The simpler explanation is that you're installing with the impulse pin outside of the horns. Depending on the mov't you can actually see if that is the case. When it happens like that, leave the cock screw lose, and lift the balance so slightly that it can fell within the horns. Assuming there is at least some power it will start beating right away. Just a passing note, it is said impulse jewel that makes the pallet move, not vice-versa.1 point

-

I've briefly had the movement out the case just to see what I'm dealing with and because some of the hammers where not striking, that's now been dealt with it sounds fantastic. The movement must weigh a good 8 to 10 kilos and it quite a tight squeeze getting it in and out.1 point

-

I'm glad it worked out! Couple of more parting observations. The tool should be on center, but if it's not, you want to be below rather than above. If above center, with the flex of the machine and slides it will go down, which effectively makes you cut depth double or close to it. This is where tools break, parts pull out of chucks, and in extreme cases with enough power the tool post rips out the top of the cross slide. If the tool is lower and flex decreases the cut. And, when parting a piece that doesn't have a center hole, especially larger work like this (all things considered), it's very common to finish off the last bit with a saw. With a bit of care you won't even mark the part.1 point