Leaderboard

Popular Content

Showing content with the highest reputation on 08/07/20 in all areas

-

You would need to modify the barrel. Manual barrels have a hook or notch in the barrel wall to engage with a tang on the end of the m/s. Auto barrels don't so what ever mod you did to the m/s you still wouldn't get that fully wound feedback. Quite a lot of Auto movements have a manual winding equivalent. You might be better off swapping the barrels out.3 points

-

That an SII PC10 quartz module with markings erased to conceal this secret information. Stem 354.0302 points

-

If you check Omega 751 on Ranfft he lists the various family/generations which should give you a starting point. It would be worth checking all of the dimensions involved first to make sure that you can just swap.2 points

-

Just take the selfwinder out and you are done. If barrel discharges power at low wind, that is an issue onto itself, breaking grease and some tricks would improve the power reserve. Inspired I just might cut my car in half to come up with two motorcycles. Just kidding Kaan. Keep safe.2 points

-

2 points

-

Just to avoid making too many new topics with the same subject I will post these PDF:s in this old thread. Since flashplayer is obselete due to security lacks and not every one wants to activate it I have made some PDF:s with two of the most popular movements. This version uses a normal PDF format which you can print out and make notes in while servicing the movement, you can brows them offline while lapping sun. ETA 7750 Chronograph. ETA 7750 Service Notes.pdf ETA 6497 SwissLab_6497 Service Notes.pdf2 points

-

when you replace the staff did you measure the old staff versus the new staff? then what was the actual staff number you used? Also are you aware of that Elgin staff numbers are not unique parts? In other words typically with each of their balance staffs the pivots sizes could very. So for instance for the grade 303 your staff numbers 2802 which came in four different pivots sizes. unfortunately unlike Swiss watches where one staff is probably the right staff American pocket watch staff replacement has issues. It's why it's very important to measure all of the dimensions of the old versus new staff to avoid unpleasant surprises. That's because there are variations in sizing not just with the pivots size. Then a lot of times with modern replacement staff's rather than having four different pivots sizes they will just have a large size and allow the watchmaker to reduce the pivots to fit their watch.2 points

-

Be very careful when offered any "alternative" method of payment for any online transaction. One other thing to be aware of, any domain that contains a subdomain. For example. "amazon.it.259348523592638952348752892.023789465298359283685922632.com" The domain here is not Amazon, or indeed anything to do with Amazon. Domains read from right to left, and should match the primary company domain. In the case of Amazon, generally things should end in amazon.com (ebay is slightly different, and can be ebay.com or ebay.{country_suffix} for example ebay.co.uk or ebay.ca etc.) Anything between the suffix and the company name is a red flag, so amazon.wibble.com is likely to be fraudulent. Also be aware that *ALL* genuine e-comerce sites use an https: prefix rather than http: If in doubt, some suggest the use of a link checker - for example https://www.urlvoid.com/ however, these are not reliable. Finally, for any online transaction, or in response to any email, never, ever give out pin numbers or bank account details in response to any request. Banks will never ask for these, and nobody else should ever need them.2 points

-

This is one of my latest projects I really should stop buying, the living room is getting over crowded with three Gillett and Johnston grandmother clocks one completed and the other two part way done but movements cleaned and running, a Grimshaw Baxter and Elliott grandmother clock to do, a Electric Regulator clock that came out of a old Clock Makers shop in Brixham which I wasn't planning on buying but went to pick up a milling machine and the seller just happened to mention he had a old clock to sell. And then there are the runners or mostly non runners because I am forbidden from having them all running at once because apparently it interferes with Coronation street and Eastenders two triple fusee's, three double fusees, two single fusee, four spring driven Westminsters, two vienna regulator's two Ting Tangs, various carriage clocks, and Swiss 8 day clocks and a Atmos clock and many more it's like a stock take at a zoo just when you think you counted them all another pops up. So one more won't harm I guess, I collected this today after putting a very cheeky offer on it yesterday on ebay which to my surprise was accepted. Best described as very High Gothic Victorian Its signed on the dial Bennett 65 and 64 Cheapside London I think it would date from 1865 to about 1880 because before 1865 the company only occupied number 65 Cheapside. It's a triple fusee striking on 8 bells and the hours on a gong, the movement is large and the plates are 8 by 10 inches and is so heavy the seatboard has metal struts underneath to support the weight the case is oak and is 18 inches across and 26 inches high There is plenty of evidence to show that the case was gilded in part with gold and some parts enhanced with painted details there is also a latin moto painted on to the gilding above the dial I think it says "many hours and days declared" but am unsure because I used a online latin translator. Much of the case detailing is loose and needs reattaching but the sellers kept all the loose bits in a carrier bag so its all there apart from one of the side frets the other is complete so I may take an impression from that and make a replacement from resin, the elderly couple I bought it off had inherited it from the Husbands father who he said would stop the clock every night and restart it in the morning because there is no silent switch on the clock and the chimes are so loud it woke him up . I'll have to give this clock a little thought I'm unsure whether to have the gilding renewed or to just wax the case I'm not very bothered by the crack down the front I may see once the movements out if there is any play in the wood to bring them closer together, I think the clock is all original but if anyone thinks not please comment.1 point

-

1 point

-

1 point

-

It's usually accepted to use HP1000 or HP1300 instead of S6. I use the later on the 2nd reduction wheel.1 point

-

@FALLINGTITAN Let it run for a couple of days. If it stops somewhere, make note of where it stops, and see if it's a recurring theme in the same area. If for some reason it just stop, it could be a certain position, or timing that causes something to foul the balance or one of the train wheels or something. I would wind it up manually to make sure it has enough power to run for a couple of days. I wouldn't worry too much about it. If it keeps getting stuck/stopping you can investigate further. Again, I'm far from an expert.1 point

-

Mass produced monster movements these. Extremely well made fusee, I hope you have a good mainspring winder when it comes to removing the springs from there barrels. Defiantly mid to late Victorian, everything looks right about it. Ebay is full of these types of movements in Victorian bracket clocks. It must be deafening in your home at 12. I always loved that time in my workshop all going off at 12, longcase clocks striking out of there cases was a hoot you couldn't hear yourself speak out in the main shop.1 point

-

Hi According to the watchsite the equivalents are Moebius 8141, Mob D5 Mob M9103, So appears to be some choice. Find attsched Mob oil and grease application chart. Moebius Oil and Grease Application Chart - Leosics.co.uk.html1 point

-

1 point

-

1 point

-

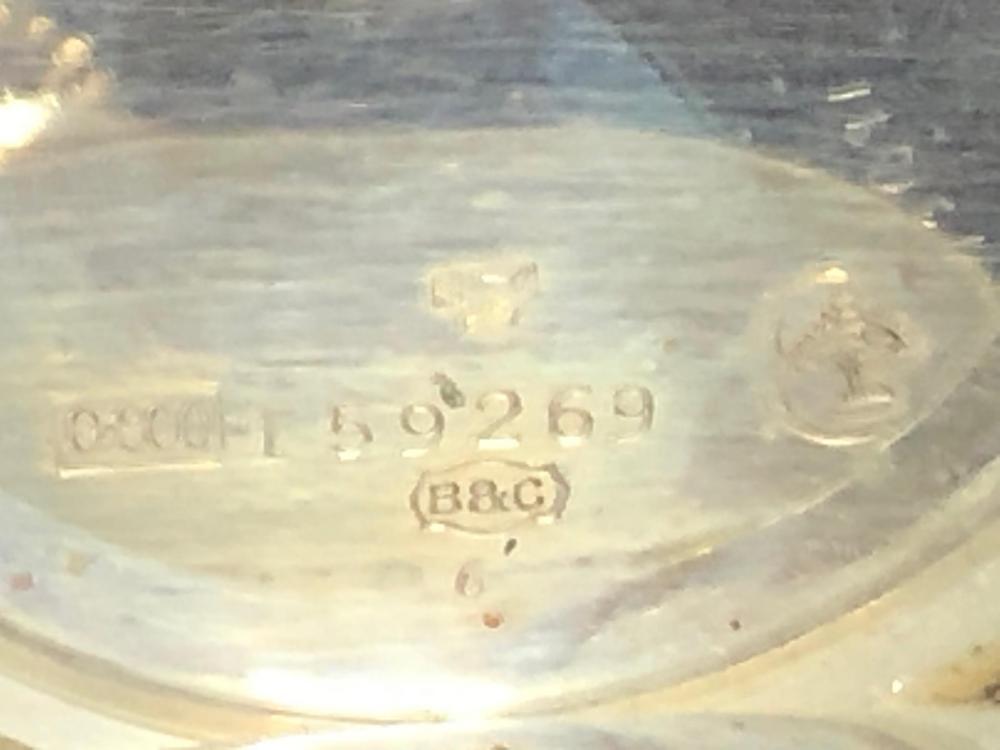

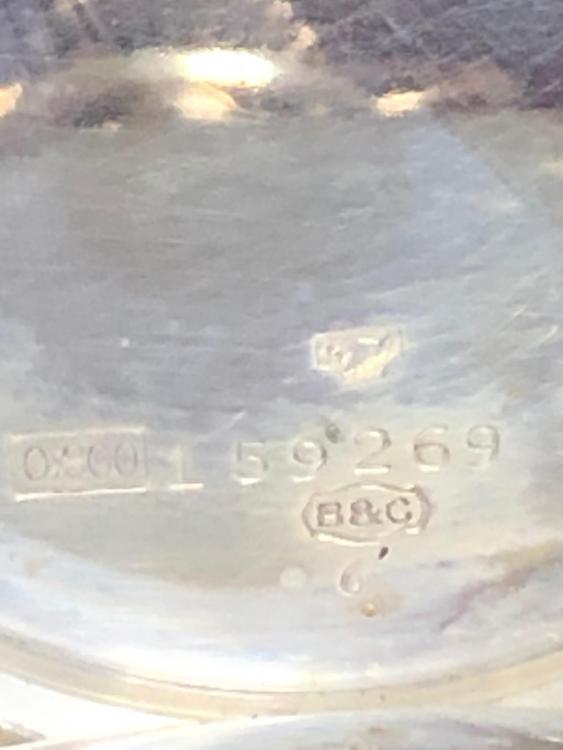

Shouldn’t have.. Bit couldn’t resist bidding.. I always wanted a pocket watch. You know classy looking. Bit “chunky” with loud and “chunky” ticking. Won this at a good price. I have no clue what it is. Seems like a no name. But is in nice condition. Have been serviced at least a cpl of times. There is some watchmakers markings. Include a few pictures. So Maby one of you specialists have some leads? It has now been laying ticking on my desk for 6hrs. Seems to keep time very well. Took a look at the balance with my loupe. Someone has been adjusting it. But the hairspring doesn’t look concentric. Well, it is Maby a project for the future. I’m happy just having it, ticking on the desk!1 point

-

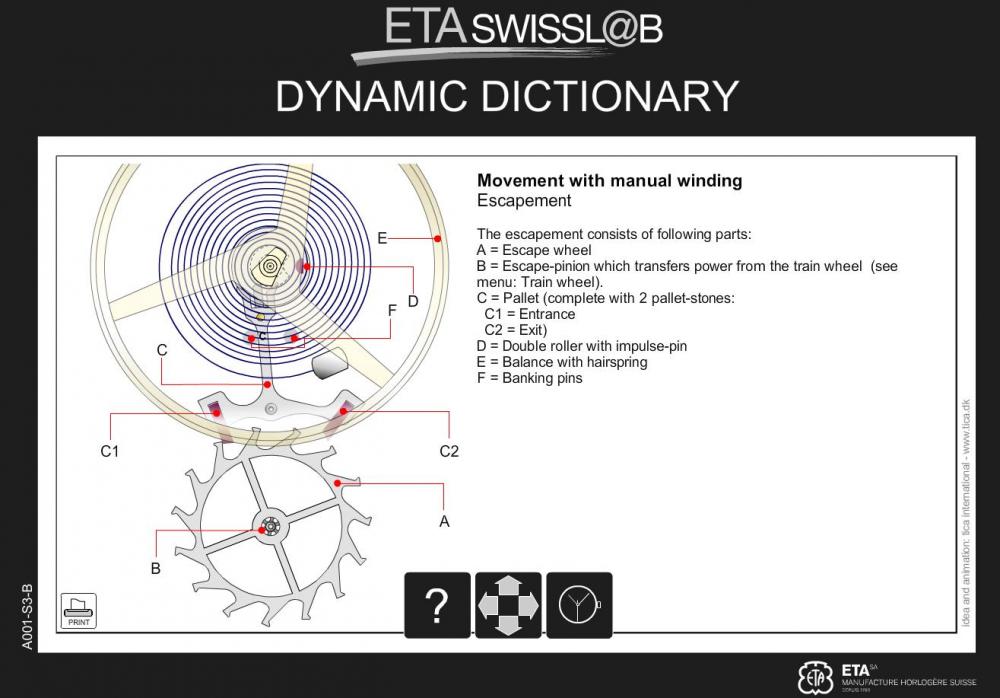

Just thought I should post some links here from ETA Costumer support. They are quite informative and gives you something to do on a rainy summer day. The first one is to their Dictionary, here you can find all their definitions and even how things works, like the escapement and so on. https://www.eta.ch/dictionary/dictionary.html The other ones are movement specific ETA 2892A2 https://www.eta.ch/swisslab/2892a2/2892a2.html ETA 7750 https://www.eta.ch/swisslab/7750/7750.html ETA 6497 https://www.eta.ch/swisslab/6497/6947.html ETA 251.471 https://www.eta.ch/swisslab/251471/251471.html When you go there the first time you probably need to get flash.. look up in the left corner. After loading it is just to start exploring the information.1 point

-

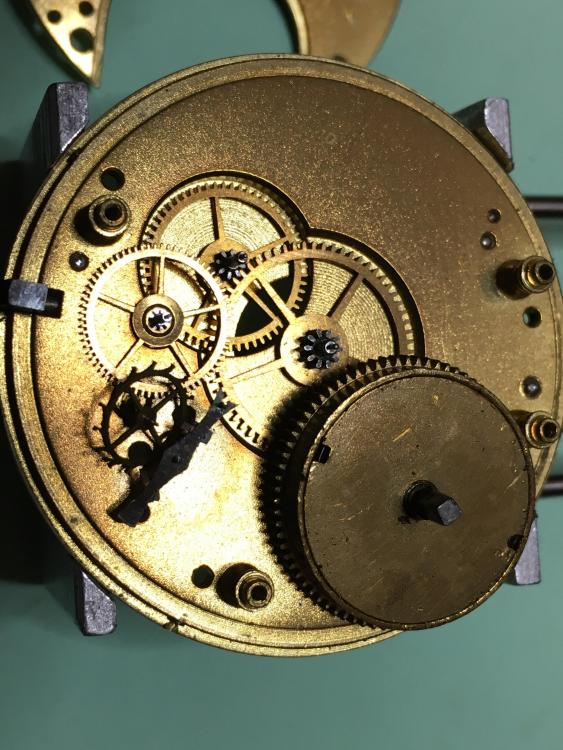

Here’s some shots of the movement, it’s all back together at the moment and running strong, only lost 3 mins in 12 hours so I’m happy with that, even with that canon pinion, which I shall find a replacement for. I had another post a while back asking for information on the “ climax trip action” a few that answered said it was to do with the case but I’m not sure. If you look at the top plate there is a wheel mounted on a yoke by two screws, one screw is fixed the other allows the yoke to move by a few mm via an elongated screw hole. you will notice a silver spring bar screwed to the plate which in turn locates under the wheel in a groove, of which there are two, not dissimilar to a setting lever. Now all I can see is that the wheel provides an interface for the barrel and then to pass the power to the train, I have no idea why it should be allowed to move or why, I can only assume that this piece of the movement is the “climax trip action” as I have never seen it on another movement. IMG_7837.MOV1 point

-

There's was nothing in there that was going to make anyone's fortune, however at $3.47 each everyone of them would qualify for @AndyHull's 404 club. Personally I would have had no interest in the 4 character watches, which leaves 11 watches of varying quality from the better end of budget to lower mid-range, none of which look like they have been abused. That would still make it less than $4.75 each for 11 project or donor spares watches, which is far from expensive.1 point

-

as a reminder this is an American pocket watch swapping the jewels around doesn't always work because they're not always the same size. Then bent pivot shouldn't be an issue for a new balance staff hopefully. pocket watch database is a good source for watch parts. If it's an Elgin watch you know the grade number this is another place to look although it does have a minor issue. http://www.elginwatchparts.com/Script_Find_Grade.php the minor issue is there's a reference to the notes found at the bottom of the page. Like for instance those balance hole jewels that somebody claimed were identical don't appear to be identical depending upon your serial number. Then there's a reference the balance staffs but that refers you to another section that doesn't exist on this page. if you're going to work on American pocket watches there is a definite must-have reference book that almost no one has ever heard of which is Swartchild & Co Chart Book for American Balance Staffs. There is also a second book that has the jewels listed. I miss snip out the section on the balance staffs for you. https://www.ebay.com/itm/Swartchild-Co-Chart-Book-for-American-Balance-Staffs-reprint/162769575312?hash=item25e5d29d90:g:zhoAAOSw1HtfGEpv then I'm attaching another image another way to tell if your staff is sized correctly for the whole although you do need to do this test before you've attached the balance wheel it's a little hard with the balance wheel on.1 point

-

we need to establish a proper timing procedure and not jump to wild conclusions. For instance I agree with rodabod modern screwless balances almost impossible to have positional errors unless somebody got really creative. But if you're amplitude drops below 200° that is going to give you issues. The lower the amplitude the greater everything looks on the timing machine basically everything gets really magnified. Tiny positional errors will no longer be tiny the lower of amplitude. Even though modern watches unless there chronometer grade are not usually timed in six possessions for watch repair diagnostic purposes it's good if you would time your watch and six positions. On your timing machine change that averaging time to 20 seconds when it powers up it defaults to something much smaller. 20 seconds makes the numbers look more even. when changing positions allow a stabilization time like 30 seconds. Then time for maybe 40 seconds or so. Then give us the numbers so this is dial up dial down and as I like to call them crown positions four of those. I crown up down left right. Also if you wind the watch all the way up and let it run about 30 minutes to stabilize before you start timing. Then out of curiosity what lift angle are using for this watch?1 point

-

Looks like it's time for you to get a jewel hole gauge, a watchmaker's lathe, cutters, files, burnishers and start polishing down your pivots.1 point

-

That’s usually a screwless balance. Unlikely to have been put out of poise by material removal, but not impossible. Compare dial-up to dial-down rate to see if it’s likely that the rate is being affected by the hairspring sticking. Also, does how is the amplitude when the rate drops in the other positions? Is it relatively favourable?1 point

-

Congratulations on getting it to tick again! Don"t think of it as wrecking something. When things do become damaged or more damaged, think of it as a training aid to fix that part. I have a couple of training aids that I have created for my self. When I am ready to learn to straiten out hairsprings, I already have 2 to work on.1 point

-

Pivot shoulder might partially be entering the jewel hole and stick to it, I examine the jewel under magnification for sign of damage. No need to remove the jewel, just view it from under side of the cock. Jewel hole might be way larger in diameter than pivot, in which case you should feel excess side shake when cock is not fully tightened. Dirty upper jewels is likeliest and most common cause.1 point

-

Also have this beauty coming. Sent from my SM-N975U using Tapatalk1 point

-

That's incredible. I'm very pleasantly surprised by the difference. It shows what could be achieved by these movements.1 point

-

1 point

-

I have done Balance springs they take a lot of time and a lot of patience, the last one took days tweaking it and then leaving it untill my mind cleared then at it again not easy for the casual repair person.1 point

-

Congrats! Objectively it's still a lot of money for a crystal (you can get a great mechanical Russian watch for that money), but for a watch that means a lot to you, £38 can still feel like a bargain.1 point

-

Why? Well it's an unnecessary complication, 99%+ of the watches have regular crowns (not screwed), just the occasional 5-10 turns is enough to wind watches, I personally find the weight shift annoying too, and I just want to get the feedback when the watch is fully wound. When I have the option I buy handwinding varieties, but with vintage watches, most good ones are automatic :/ I'm sure there are others who feel this way too, while most don't care In theory, steps: 1) Remove the winding weight and optionally the winding assembly (easy) 2) Modify the mainspring to negate the bridle mechanism Any ideas how to most practically and safely approach the mainspring modification? The only thing I can think of is to weld the bridle/spring end to the mainspring barrel I want to do this with an Omega 550 series movement, I just wish NOS or used mainspring assemblies were available in abundance so I could just buy a new one and modify, or commission this project to an experienced and open minded watchmaker, but it seems they are all out of stock :/0 points

.thumb.jpg.37a99006119088dd18f20e2ccdfd4cce.jpg)

.thumb.jpg.246bc62db1ab9701d3c27b1b6dc28263.jpg)