Leaderboard

Popular Content

Showing content with the highest reputation on 07/30/20 in all areas

-

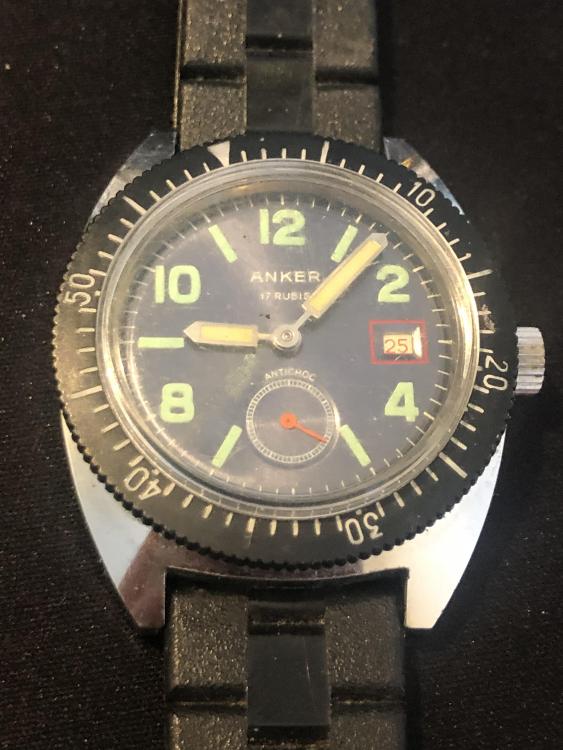

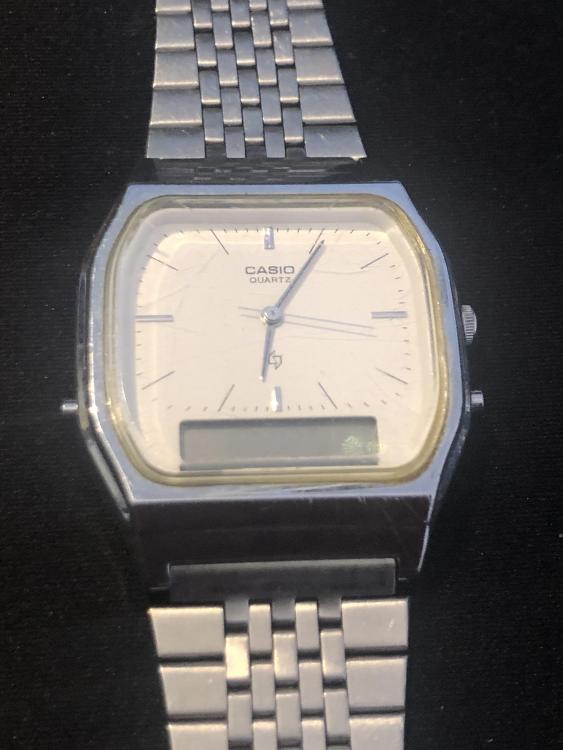

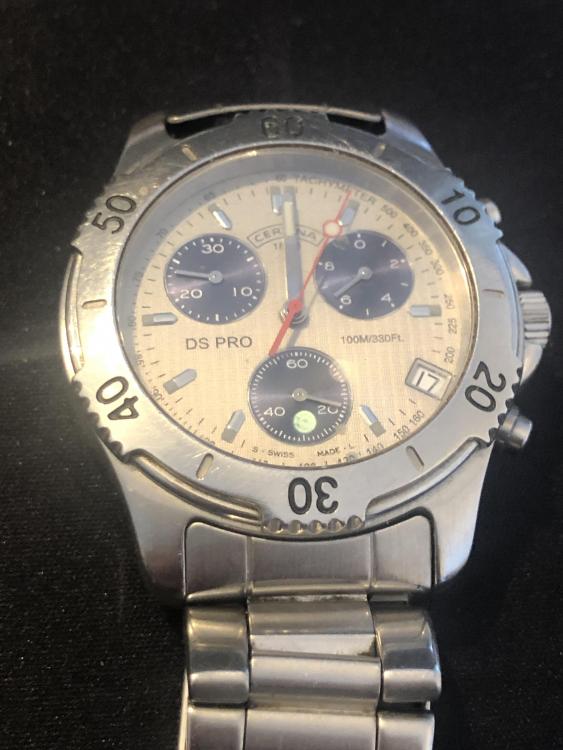

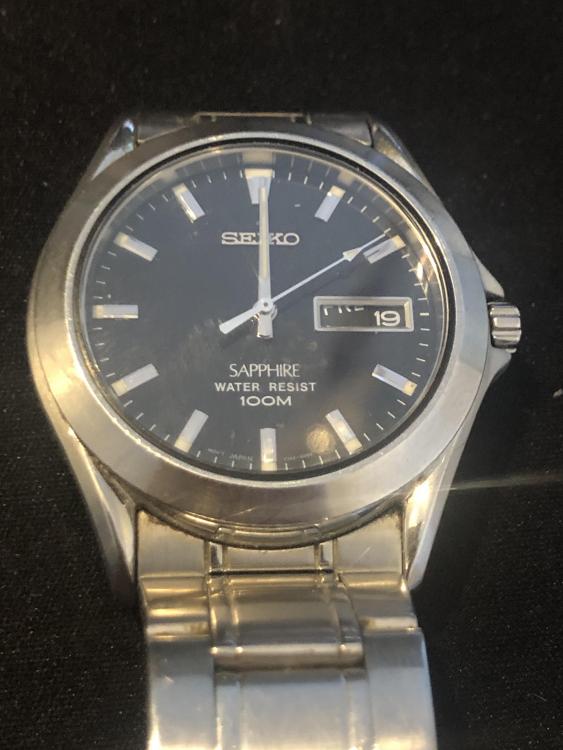

This is my personal watches. I got the as birthdays presents over the years. The blue Seiko I got from a work project as thanks you. They were daily use and abuse. Except the Anker. Im not in to quartz. But I will change batteries, service, and and buff them up. Not in picture. But daytime I use a Applewatch. Hopefully it will soon change to a pure mechanical watch. That I have restored my self. The Anker is a very beloved watch. As a kid, I got it new from my father in 1978. A year later he passed away suddenly. It is totally original, plastic bracelet and all. I pretty much never wore it, because it was too big at the time. He was a sports diver, and of coarse. He got me a divers watch. I remember trying to punch a new hole, to get it to fit it to my wrist. But was still to big. And when I grew up. It wasn't cool anymore. So it is pretty much scratch free. It has a problem that I need to look in to later, when Im much more experienced. I remember many years ago. I tried to wind it up. But something broke. And it now only moves the hands. Even in winding position. I will look in to this with great care! I have recently searched high and low about this particular model. But came up with nothing. I find models with the same bezel, and hands. But no one with a separate second "bullseye?" if anyone have info where to find Anker info. I would be much appreciated! In the near future, I hope to find a cpl of pocket watches. Also find my self starring at Landeron movements. Cheers!3 points

-

3 points

-

A few bits of advice from my experiences with the same issue: Sometimes you can gauge how much the new spring is too strong if you can get it to run in a position where the amplitude drops (eg. crown down). Or perhaps it runs ok on a lower level of wind, eg. up until 3/4 wound. Although the torque follows the thickness by a cube rule, I’d say you are more likely to be successful by dropping to 0.10 if it very easily starts to bank. You are already getting what is in effect probably more than 360 degrees of amplitude..... I would not alter the temper of the spring to deliberately cause it to set as this is not the same as having a set spring which remains at the correct temper.2 points

-

Hi I have a new 40mmHamilton King Khaki quartz coming tomorrow (Or rather, Later today!) I borrowed this pic from their website! It's actually on a mid brown leather strap rather than this dark one! (At least I think it is, The other pics have gone now!!) Can't wait for the knock on the door!! John2 points

-

Ok, So the screwdrivers, tweezers ect arrived today. Could not wait to start! Have got a Fortis as first project, that seems to come from a lot of sparepart watches. It has the FHF 96ST movement. Looks brand new, and was sold as a non runner. It is missing the stem. And the dial looked loose. Pried up the case lid. And the movment fell out. So, I tried to wind the barrel a little with a screwdriver. No surplice there, It didn't run. After a little closer look. I saw the balance jewel is missing. Also looked like the pivot might be broken. Bit exited, I started with removing the hands. Had little trouble there. The houerhand was pried to dial face. But after a little more fiddling than expected. I got it off. For my life. I couldn't find the screws to the dial. Turns out it was glued on to the movement.. Even more intresting! But got that off too, with little "fiddling" Tried to get it running again. But noticed that the balance looked out of alignment. Time to bring out the new "chunky" Bergeon screwdrivers! (love them already) With a "some" intresting trying out different work positions, shifting between 4x and 10x loupe. Half scared to mess up the balance, possibly even more. Still exited. But with some fueling with the tweezers. Tha balance came out in one piece with the hair spring. Im not sure why its called hairspring. It sure is thinner than a hair.. After som try and tribulations with the loupe. I managed to notice that the lower pivot on the balance staff is ok. Had hard time to see if the upper pivot was existing. The hairspring is in the way. Im not sure how you guys do it? Im sure scared to mess up the hairspring! But eventually, I got a glimpse of it. Looked at the fork and timing wheel. It seemd to want to "tick". So I decided to remount the balance again. Well..That took some time. Again very fiddly! First time, I got the impulse jewel out of alignment. Took me a while to figure out. And even more time to reassemble with it in alignment. But got it there on the second try. Im not telling you about how long it took.. With everything back. I I tried to "kick" the balance. Veeerrry carefully. It wanted to go! With the missing to jewel in mind. I decided to give it "some" oil. Since it never has been up and running. It is probably very gummed up. So disassembly, cleaning and oiling have to be done anyway. So I thought it is the perfect first oiling effort, as I can clean upp my mess, anyway. Oiling. Jeez.. Those jewels is tiny!! Let say.. Comparing on what Ive seen on turitorials ect. My jewels isn't missing any lube.. But it started ticking!!! It definitely isn't strong ticking. But an houer later, writing this. It is still ticking! Mezmerasing! I call this evening a success! Some notes to self: 1. Im getting a bit shakier over the years. Loupes magnifies that too.. LOL! 2. Improve working position. Sitting on the floor isn't an option. So raising the office table some how, is needed. 3. I did like to use the loupe better without the head band. It was quicker to change between magnification. (have only 4x and 10x) 4. Amongst many other things. A microscope is now on the wishlist for the future wallet enlightener list. 4. When doing close up work. Don´t poke the nose with the screwdrivers.(unintentional, or not). The new Bergeon screwdrivers will be offended!! 5. Somehow, I need to find a correct jewel, spring ect. Find out if a jewel press is needed?. Hm. have to get a stem and crown too. 6. The only thing I got top quality tool to start with. Was the Bergeon screwdrivers. As the first set "stuff" needed. Didn't come cheap any way. But Im happy I got quality screwdrivers. So Im pondering if the wife get upset if I have them on the night table! Hm! 7. Today was a great day! lets make tomorrow even better! 8. Tomorrow is disassembly day. Remember to take maaany pictures!! 9. Get some sleep! /Johan1 point

-

Though I would share this here mostly for someone new like me who just started in this hobby. I think it be fair to say most of us started with this movement and is the one Mark uses in his watch repair course although it's says ETA the Chinese clone is the same. I used this myself and save me from having to take pictures all the time also show where to lub and what kind. This might have been posted before, not sure. Make sure you have flash player enable . https://www.eta.ch/swisslab/6497/6947.html1 point

-

1 point

-

The movement is a cal.53530. search 'Orient 53530' in ebay and with a bit of luck you will find a working watch 'cosmetically challenged' with movement that you can swap out...1 point

-

Inmates? Is that what you call people in an asylum? Is there not a more politically correct term ? Like residents?1 point

-

More like 5 jewels I would think.I dont like taking apart quartz movements myself. Too many plastic parts to break. If it isn't dead dead .you could try the spray and pray method. Plastic safe electric contact cleaner. Remove the dial and hands.and GENTLY let the cleaner run through the movement washing out the gunk. Let it dry THOROUGHLY and oil. There's a good chance it will work.1 point

-

1 point

-

1 point

-

I'm sorry I can't help you! Needed a going barrel for an Orient and desperately searched for one everywhere. Eventually wrote directly to Orient and beg them to help me. Their response? Never heard from them! Eventually found a compatible scrap calibre on eBay but it was long and painful process. Finding parts and replacements is sometimes so difficult it almost kills the fun and the hobby. It should be made illegal to make spare parts unavailable to the public, like it is with spare parts for cars. Anyway, good luck!1 point

-

the Allen key idea looks nice on paper the same as WD-40 would probably be a good lubrication for watches after all its cheap. Although neither one is really the way to do things. It does appear to be set up to function like an American pocket watch. In that when it's out of the case it is in setting that means the watch isn't going to really run well unless it's in a case. Later pocket watches did have methods to allow the repair people to put the watch back in winding but yours does not appear to have that. So even if you use the Allen key you're going to have to hold it in your hand continuously pressing it in to keep it in winding. in the early days of American pocket watches and I do not know if was unique to this country the watches were manufactured by one company another company manufactured the cases. If you look at the link below it appears to be that you have a 16 size American pocket watch. So all you need is a 16 size pocket watch case. Then I probably shouldn't even bring this up but the part that keeps the stem in place is found inside the case it's known as a sleeve. It's adjustable because conceivably the different watches require the stem to be in a slightly different position. It also unfortunately wears out after 100 years or can wear out. Unfortunately you won't know that until you buy your case. https://cwrnh.com/watch-movement-size-conversion-chart/1 point

-

1 point

-

I have one about like that coming in but has the 7019 movement. Knowing how Seiko numbering is from what I can tell mine was made in Oct of 79.1 point

-

1 point

-

1 point

-

Ah so it is 12 to 12, so the ratio won't change. If the 10l do mesh correctly it could work.1 point

-

With a 370W motor, it should be a geared headstock type? However parting 44mm is hard work even for lathes much bigger than your. Definitely an hard proposition. Check what the carriage does. Even when fully locked it may still move a little. When it does, all bets are off, chatter comes, the cutting point wanders, machinist swears and the suppliers get a chance to sell. Below, good machinist receives 316 work just to be parted off1 point

-

I do take them apart, but they're tricky. I have a special tool made by Star decades ago but alas 19/20 it doesn't fit. I slide nickel tweezers between the upper and lower pinion, and push on the pivot with the tail end of another nickel tweezer. A Platax tool would work too (about the only good it's for in my opinion). If you clean it assembled, put some good thick oil like HP1300 at the seam, hold the upper pinion with nickel or brass tweezers and turn the wheel so it works in. Do it a couple of times, then remove any remaining oil with pithwood. If it's not lubricated it will fail and then you have a bigger job on your hands.1 point

-

Together with the good advice by master nickelsiver, I repeat the fundamental question, what lathe are you using? What you're attempting to do requires a pretty sizable lathe, a very minimum of 1Kw motor perhaps. And from your writing I gather you're using HSS, but for hard metals you really need indexable tools.1 point

-

What lathe are you using? 316 (and 316L, most common for case parts) is usually ok as far as stainless goes, but is going to be more difficult than a typical steel for sure. When I part a piece that size in my lathe (Schaublin 102), I do everything possible to maximize rigidity. Cross slide is positioned so the tool is over a dovetail, not hanging out. Tool retracted into holder as far as possible. I use two parting tools, one quite stubby, maybe 15mm stickout, and another longer to take over from there. I'll even snug up the gibs for a little more rigidity. Use a good cutting oil, preferably one for stainless or difficult metals. 330rpm would be too fast for me. I kick mine into backgear and inch up the speed until I get chatter, then back off. With a parting tool in 316 you may or may not get a real chip, depending on the foundry that made it and even the batch. If you do get a chip it often doesn't want to break and you have nice long moving razors around the workpiece- resist all temptation to grab it and pull it out of the way! Use pliers. And interrupt the cut to break it. If you're getting chatter you either need to increase the feed or reduce the speed. On a Monarch 10EE or Schaublin 150 or Weiler yeah go ahead and increase the feed. On a smaller machine you can only reduce speed. 316 will work harden in 1 revolution. Your tool has to be SHARP. Stop and touch it up as often as you have to. Sometimes once chatter has started it won't go away no matter how you mess with speed and feed, in really crap chatter situations I might take a few strokes with a hacksaw in the groove to knock off the chatter ridges on the part. This can remove a work hardened skin too. Are you using carbide or HSS?1 point

-

I'm not an engineer, but I think you can do it like that! At least it seems to correspond to practical experience.1 point

-

Never take that apart. You will never get it together and have it at the correct tension. Clean it in your watch cleaner (if you have one) oil it. If by chance it doesn't carry the hands around it is because it has worn and become loose. Re place is the best. Only an experienced repairer would attempt to tighten this. It has to be the same tension all around, if not the hands will not carry.1 point

-

As for differences in strength between steel and modern alloys, there are a few things to consider. Elgin was the first to offer a modern alloy as a mainspring, Elgiloy, which is still used extensively in industry. Others followed, and nowadays we have most new springs coming from Generale Ressorts. They offer springs in two grades, stainless, or Nivaflex. There are a few properties that one would look for in a spring, first being "springiness" or strength, which boils down to Young's Modulus. Another would be durability, and another ease of manufacture. To see the differences of the common mainspring materials we have: Carbon steel- Young's modulus of 206, fairly durable Stainless steel- Young's modulus of around 190, quite durable Elgiloy- Young's modulus of 211, very durable Nivaflex- Young's modulus 221, very durable While Elgiloy is still used in industrial applications I don't think anyone is making watch mainsprings from it anymore. One of its particular qualities is that its point of plastic deformation is very good compared to other similar alloys. So you can have a spring that can be pushed further without deforming or breaking- no doubt one reason it was such a good mainspring. I don't think anyone makes carbon steel watch springs anymore, nor have for some time. Nivaflex is the #1 choice of manufacturers for new pieces. As seen above, it is significantly stronger than carbon steel, and even more so than stainless. I have noticed that replacing a carbon steel spring with a stainless spring of the same thickness is indeed a step back in power. Likewise, replacing a carbon steel or stainless spring with Nivaflex offers a boost in power. I order directly from GR, and always request Nivaflex specifically. In some cases if they only have stainless in stock I will look elsewhere for old stock. Bottom line is Nivaflex is stronger than carbon steel, stainless is weaker (as springs). Stainless springs will not have the reverse curve at the hook end like Nivaflex does, it will open up like a regular steel spring.1 point

-

buying Russian watches off of eBay can be interesting. Actually by any watch off of eBay can be interesting. Depending upon the seller condition of the watch can vary considerably. Last time I bought a Russian watch off eBay promised you working at a super bargain price it was rusty and if it was working it wasn't working very well. But seeing as how I got it so little money it wasn't worth sending it back. So you cannot always believe what the seller tells you. as you do to watch repair this really isn't the watch the start on as an automatic as you pointed out which adds to the complex of the things. I would find something else to start with until you can successfully take a watch apart and put it back together without destroying it. Start with a Chinese clone of the Swiss pocket watch movements is a good way to start. Also good if you have a timing machine because it's good for evaluation of problems like watch you have. In the meantime even take the back often do a really good visual evaluation. look at the stem do see any signs a rust? A lot of times the gaskets will disintegrate water will get in any signs a rust anywhere. But at the pivots do they look like they still have oil. Usually can see the oil on the balance pivots it looks dry minutes indication that it hasn't been serviced in a very long time which is my wild guess. Timing machine would be nice for evaluation while it's running.1 point

-

1 point

-

WWI trench watch! I think it's probably an Elgin movement too; an open-face pocket watch movement cased in a wrist watch "trench" case. That is a very cool find!1 point

-

1 point

-

Please have a look a the video below by our Host Mark Lovick that covers the entire procedure. Be sure to use a bit of thread lock as he also mentions towards the end.1 point

-

Cut with nipper or any plier thats got wire cutter blade. You then fit the stem in a pinvice and dress it on sandpaper spread on a flat surface.1 point

-

First time for me placing my hands on a true watchmaker's lathe to repivot a central wheel (small seconds), under the guidance of my mentor master Lino. Work isn't complete and practically it never will be, because ase the pinion was picked from a box of spares that he accurately set aside. Lots of of technique details were passed to me, probably these are explained in most books, but the experience of learning first hand is priceless!1 point

-

1 point

-

Had one these back in the day. Found this at a fair price going to take some work.1 point

-

Here's what shows up with that SN https://pocketwatchdatabase.com/search/result/elgin/19420131 point

-

It's looks to be an Elgin of some kind. But the number in their database does not match what you have. The scroll work on the balance cock is common on the watches from the 19 teens.1 point

-

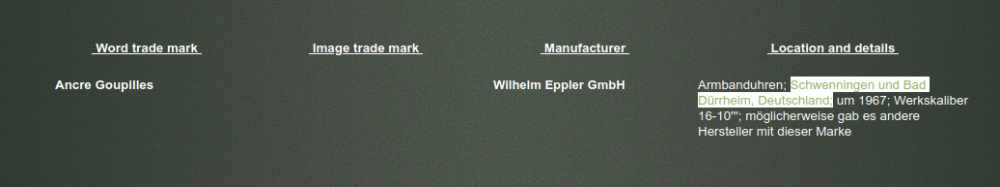

Another little known brand heading its way to the healing bench. This time it originated in, Schwenningen und Bad Dürrheim, Deutschland. This little Wilhelm Eppler movement looks in need of a good clean, and some minor rust removal, but for under four quid, what have we come to expect? More info about the manufacturer here -> https://translate.googleusercontent.com/translate_c?depth=1&pto=aue&rurl=translate.google.com&sl=de&sp=nmt4&tl=en&u=https://watch-wiki.org/index.php%3Ftitle%3DUhrenfabrik_Wilhelm_Eppler_GmbH&usg=ALkJrhjcJLUQvedGuteCCOne-lOaD94cxg1 point

-

Hi I believe its whats called a Trench watch around WWll era. probably need the bestfit books ti Identify it.1 point

-

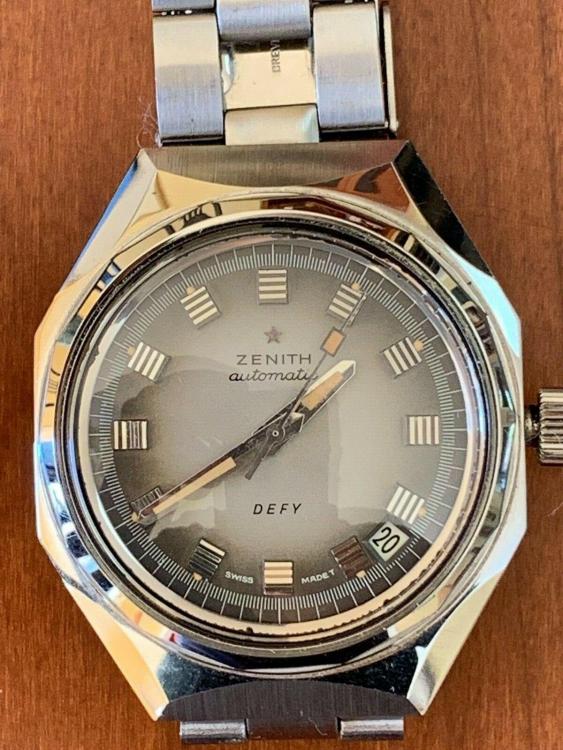

I have one more incoming watch that I'd like to share: A ~1972 Zenith Defy (A3642). I've been looking for a nice example of this watch for a few months, and have purchased and returned two examples because of undisclosed problems and generally not being as nice in person as they were pictured and described as being. This one, I hope, will be the keeper: It is completely original, not overpolished, and looks like it has been kept in a safe for years. It was purchased new in ~1972 by the father of the person who is selling it to me. Once I get it open, I'll be able to date it from its movement (which should be a 2552PC). It purportedly runs well, but the seller didn't offer any pictures of its movement. This is a watch that I'm definitely going to send out for an overhaul, either to the Zenith factory or to someone recommended to me. Normally I wouldn't send a watch back to the factory for repair, but I'm concerned that parts availability will be an issue with this model.1 point

-

As the title of this post hints at, I had been wanting to find a watch that was a challenge. I looked around and found something that I honestly thought was in better shape. It's a 1971 Seiko Lord-Matic with a 5206 automatic. It was clearly stated to be a non runner, but that's such a grey area I took it a grain of salt. There was a bit of a stain around the date window, but all in all it looked pretty clean. It arrived yesterday in the largest box I've ever received a watch in, 10 inches square, very impressive packaging skills and thoughtfulness. At first glance it looked pretty good though the bracelet was tiny, as many of the links had been removed. As soon as I got it home I opened the case and instantly regretted my purchase and my desire! I was absolutely aghast with what lay before me! Very clearly there has been a very large case of water intrusion many years ago. This had been festering in here for quite some time. The rotor was stuck solid. Thankful the hub was not and it unscrewed very easily. The bearing of the rotor is perfect and, once cleaned, should operate just fine. Under the rotor was not a pretty sight. If children are near, please, have them look away! Shockingly, as bad as this looks, that is the worst of it. Only 2 things were damaged from sitting in water, the mainspring arbor... And one gear train bridge screw... The entire gear train, the day/date mechanism and the keyless works were pristine. There balance is also fine. So, hopefully, after sourcing a replacement mainspring barrel assembly and another bridge screw and some overdue attention, I'll have this on my wrist. One final note, I learned the hard way after eagerly scrubbing the stain on the dial that the varnish used on the dial is not impervious to rubbing alcohol. Now I have to address that, hopefully it's not ruined by my enthusiasm. Will post updates. And if anyone has a spare mainspring barrel complete and at least one bridge screw for a Seiko 5206 please let me know.1 point

-

Hello there, thanks for your replies, I shall attach some pictures of the movement below, I'm sorry they are not very good, I just used my phone which has a camera of questionable quality. So I removed the back and began to tilt the watch to gauge if it was stopping at certain angles, it was not stopping at all during this little 'test', I then shook it with a good strong shake and yet again no stopping it was ticking away very happily. This is strange because whilst wearing it if I whisk my arm away from myself very quickly and violently it will stop, however it now only stops briefly not indefinitely like before, so it works well enough, then I shake my arm with a good deal of force such as that which may occur when I am working with it on, and it will stop momentarily. So now I know that it stops when I move my arm very quickly but only away from myself not towards. Also lightly tapping it on a table will yield a similar result, it will stop for a second or so then continue to tick. As for how it runs I hadn't worn it yet today because I was wearing another watch, and it continued to tick and keep time fine, it gains a little bit each day but not enough to upset me. Yesterday whilst it was on my wrist it stopped dead for about half an hour, thinking it may need a wind I began to wind it and heard no signs of the energy going straight to the train wheels, instead I wound it and heard the usual sounds you'd expect from winding a watch and yet it wouldn't tick, a light tap to the back of the watch and it began to work and continued ticking all night, into this morning and now in the early afternoon when I put it back on. Any thoughts? One thing I did notice is that the rotor doesn't move as freely as other automatics I have had and looked at, could it just be due a service and therefore lack the lubrication required to run non stop? I am a massive amateur so I'm not sure I can help, but you are all providing helpful insight that I am sure will be helpful Thanks for your time0 points