Leaderboard

Popular Content

Showing content with the highest reputation on 07/06/20 in Posts

-

4 Hours later... Not perfect but the best I can do with my current wizardry level. I spent a further hour trying to get the stud pin back in and gave up at 1am.4 points

-

3 points

-

@AndyHull and I have been chatting, and we think it's time to formalize the 404 Club. 404 is the HTTP standard response code returned when a file (page) is requested and not found. You've probably seen the "404 Not Found" page a few times in your internetting adventures. Turns out though, watches can be found for such a tiny sum! Some surprisingly nice ones even! Every currency doesn't have the same buying power though. Fortunately, the Dollar to Pound conversion at the moment works out to about $5.00, and the 500 response code means there's an internal server error... Not quite poetic, but at least it's on theme. Similarly, Euro to Pound works out to €4.50. 450 is specific to Microsoft and means "Blocked by Windows Parental Controls" ... So you guys behave! So the way this works is you buy a watch for your currency/error code plus reasonable shipping (I've been saying $10 max unless I really like the watch, in which case I'll stretch to $15; the point is to avoid those $1 buy $200 shipping scams), fix it up for as little as possible, then add it to your personal collection, sell it off to pay for the next one, gift it to a friend, hang it around your neck as a tribute to Flavor Flav, or whatever else strikes your fancy! Somewhere in there though, post a picture of it here!2 points

-

Think this should just about qualify?.. this job lot of 6 'dead' Accurist movements + 1 case was £12.85 including postage (so less than £4.04 with $10 postage for the whole 6), 4 of them were ETA 2390s, 3 of which I have killed now... but one I have got running well enough that I built it back into the case that was also in the lot and it has been running with reasonable accuracy (within +30s/day dial up, better than that if worn) for a couple of weeks now. I used the most patina'd of the dials as I kind of like it and jazzed it up with a bright orange second hand. Since it is my first 'saved' watch since starting this hobby I intend to keep it! I haven't done anything yet with the 2 other movements, but since I don't have another case it will be tough to rescue them fully!2 points

-

When cleaning the movement, I put just the balance back on the mainplate, then get a line of sight down the centre of the escape wheel/pallet jewels and between the banking pins to the impulse jewel. If not central, rotate the balance and make a mark opposite the stud. You can do it with the movement assembled, but I find it easier with a bare movement and no pallet. I can usually get to about 1 m/s just by sight. Which is good enough without an adjuster - I think people worry too much about a bit of beat error. As @clockboy says above, things can easily go horribly wrong.2 points

-

As a former teacher and professional of 20+ years, bravo, that's fantastic, especially given how messed up it was and your first go! It won't be a chronometer but I bet it runs.2 points

-

Hi In addition to all the sterling advise you may find the attached document useful in future. TZIllustratedGlossary (2).pdf2 points

-

As per title, just wondered if there were any collectors near Great Yarmouth. Spotted a nice GPO clock which is collection-only which may interest someone.1 point

-

These are the antiques. Top left is my 1883 Elgin model #1 in its Keystone case. Top right is my little 1897 Waltham model #1891 "Seaside", also in a Keystone case. Center is the (circa 1942) Public Watch Co. "Louis XIV" alarm pocket watch. Lower left is my 1888 Hampden in its Dueber case. And lower right is my 1919 Longines 18.50 calibre. The pictures don't show as well as I'd like, but I'm checking them with my phone, so that may be part of it. All run, and I wear each one off and on.1 point

-

I'm a great believer in learning from our mistakes but when this happened to me my heart sank. It's from an ETA 2452 so about £20 for a replacement. It's not going to break the bank but I'll have a go at fixing this first. I've searched the forums for fixing techniques so have some good ideas on how to proceed. "The difference between a master and a student is that the master has failed more times than the student has tried".1 point

-

1 point

-

My first 404 Club member to arrive: Purchase price: $3.93 out of the Czech Republic. I haven't put it on the timegrapher yet, and the amplitude is obviously low, but it runs! Fully jeweled Swiss movement! I have 7 watches in transit that collectively came in under the 500 limit. All NOS, silver plated (I assume), and with fully jeweled French movements. I also won auctions for two watches out of Germany well under the limit, but Coronavirus craziness surprised the seller and I with shipping that was NOT OK, so they were cancelled. Bummer.1 point

-

It wont help much in your case seeing as how it's slipping so early.1 point

-

Has anyone suggested adjusting the bridle for increased friction. That’s what I would try.1 point

-

As the title of this post hints at, I had been wanting to find a watch that was a challenge. I looked around and found something that I honestly thought was in better shape. It's a 1971 Seiko Lord-Matic with a 5206 automatic. It was clearly stated to be a non runner, but that's such a grey area I took it a grain of salt. There was a bit of a stain around the date window, but all in all it looked pretty clean. It arrived yesterday in the largest box I've ever received a watch in, 10 inches square, very impressive packaging skills and thoughtfulness. At first glance it looked pretty good though the bracelet was tiny, as many of the links had been removed. As soon as I got it home I opened the case and instantly regretted my purchase and my desire! I was absolutely aghast with what lay before me! Very clearly there has been a very large case of water intrusion many years ago. This had been festering in here for quite some time. The rotor was stuck solid. Thankful the hub was not and it unscrewed very easily. The bearing of the rotor is perfect and, once cleaned, should operate just fine. Under the rotor was not a pretty sight. If children are near, please, have them look away! Shockingly, as bad as this looks, that is the worst of it. Only 2 things were damaged from sitting in water, the mainspring arbor... And one gear train bridge screw... The entire gear train, the day/date mechanism and the keyless works were pristine. There balance is also fine. So, hopefully, after sourcing a replacement mainspring barrel assembly and another bridge screw and some overdue attention, I'll have this on my wrist. One final note, I learned the hard way after eagerly scrubbing the stain on the dial that the varnish used on the dial is not impervious to rubbing alcohol. Now I have to address that, hopefully it's not ruined by my enthusiasm. Will post updates. And if anyone has a spare mainspring barrel complete and at least one bridge screw for a Seiko 5206 please let me know.1 point

-

Thank you. It was challenging and intimidating at first, but thankfully it all came together.1 point

-

This is a really inspirational post! Thank you for sharing your photos and progress reports. I'm not yet brave enough to take on a project like this, but it's really cool to see what is possible.1 point

-

1 point

-

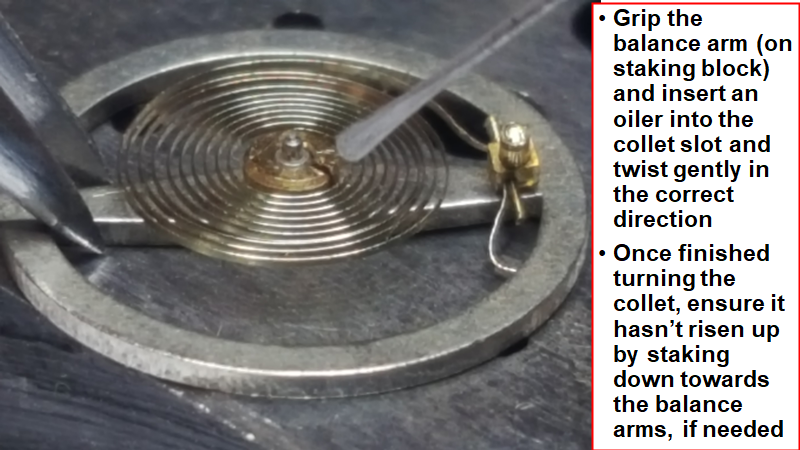

Fraczish, if you are afraid of damaging something, leave it as is! A beat error of 2.5 ms does no harm at all, it annoys owners of Chinese TMs only. If you want to correct this "error", you can at least determine the direction of the needed move: Release the mainspring fully. The now loose fork will stand a bit more near to one banking pin. In the same direction the collet must be rotated a tiny bit. Then test again with balance wheel mounted. To get comparable values, the balance must swing with same amplitude on each test. Procedure can get time consuming like this writing! Frank1 point

-

iHi There are specific tools for doing this job by Bergeon but at £45 a go not cheap. TMuir put up a post with a tool he made and I also have made them myself using the metal insert from a winscreen wiper blade and a lot of work with the Dremel and an oil stone. The red,black,and green ones I bought over 30 years ago.1 point

-

Congratulations on a sucessful service and walk through well done1 point

-

1 point

-

1 point

-

Hi This video on the kink might be interesting for you1 point

-

This, what seems a simple job can go horribly wrong. On close inspection see if there is any reference point in relation to the collet split. Before any adjustment make sure the screwdriver shaft is clean with no grease deposits. If you have a ref point move the collet a tiny amount towards that ref point. re-install the balance and see if the direction is correct. Then move in tiny increments until you are satisfied. Getting this style to a zero beat error is difficult, personally providing I get it within 0.9 or below I leave well alone.1 point

-

Everyone to their own method. For me I release the mainspring per ASAP just as a precaution.1 point

-

I have been repairing mostly clocks and some watches for several years. I have a several clocks and watches of my own that I need to repair and it seems like I never get time to do them. I am always (so it seems) working on items belonging to other people. With that in mind, I am thinking of retiring. With the shutdown, it has been easier to work on several of my own things. I have also become involved in woodworking and have built a couple of clock cases using old movements. I get a lot of satisfaction in this, but my woodworking skills are limited. I have been a member of NAWCC since 1972.1 point

-

If the watch is in for just cleaning. I always let the spring down first, then remove the complete balance, put it to one side and cover it. Doing that you won't cause any accidental damage. You know you can remove all parts without things going wrong. If the movement has something wrong with the balance it is best to let the power right down and the give it a few turns so you can see what is happening with the escapement. That is what I was taught and it is just my preferred way I used to work.1 point

-

I don't think there is any hard and fast rule. I take off the balance with full power in the mainspring sometimes. Like when you put the watch on the timegrapher and something doesn't look right. My only rule is never take the pallet fork out when there is power. But.... Is there anyone out there that hasn't done that accidentally? On older pocket watches with cylinder escapements, there is no pallet fork. In these type of movements, taking off the balance before power down will result in the gear train running at full speed. Don't ask me how I know that. On automatic watches that the winding stem does not engage the ratchet wheel, the way to power down the mainspring is to use a large screwdriver to engage the the barrel screw then release the click spring. Then slowly allow the screwdriver to release power from the mainspring. I wish there was a proper tool to do this, like a special screwdriver with a friction controlled release button. Does anyone know of a tool like that?1 point

-

Yes definitely as we can speculate what it's going to do but it would work out much better for all of us if we find out what it really does so go for it1 point

-

1 point

-

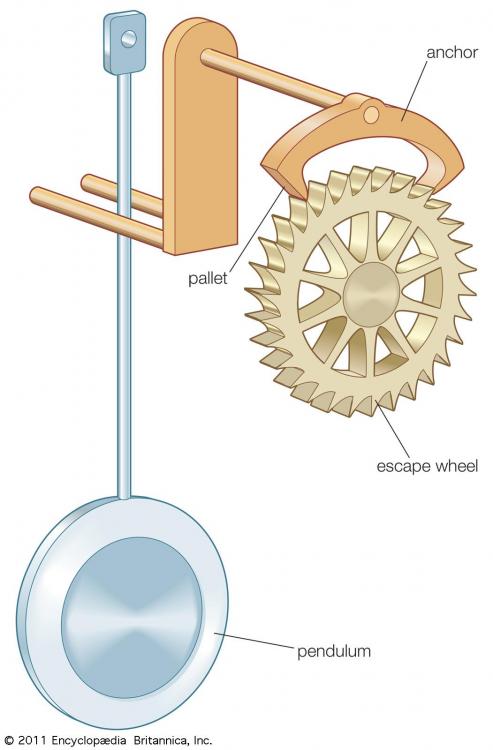

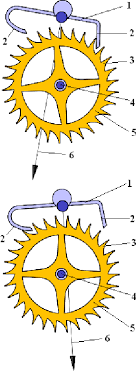

The bit that has come adrift is the escapement anchor, some of these fit onto a shaft and are retained with a spring wire with a flat end . The Anchor operates on the escapement wheel locking and unlocking the wheel. Look for the shaft on the plate where the anchor is located. Easy way will be to find the spring retainer and rotate it, it will lead you to the shaft. attached images of the anchor escapement1 point

-

If you have a 3d printer then it's possible to make a movement holder to position the movement correctly inside the case. I've done this for a custom watch I made. I also printed a dial is it was a skeletonised movement. It takes some time and effort to get right, here's my prototypes...1 point

-

THIS IS MUST BE DONE IN ALL WATCHES. IF ANY BODY HAVING THE FACILITY OF PALLET JEWEL MODIFICATION AND DO IT AND TELL ME THE RESULT. FUNCTIONAL MODIFICATION 2020.pdf1 point

-

A: because laws of physics do exist inside of a watch escapement. Vigorous movement will add force to the balance wheel, causing it to store more energy and run faster. The amount of energy stored will depend on the duration of the activity...and that will determine how long it takes for the additional force to be expensed and return back to normal rate. B: nothing you can do its the laws of physics at work.1 point

-

Hello all. So i buy this really cool Gubelin pocket watch on ebay which is sold as not running. When I received the watch i immediately discovered it has a broken balance staff pivot. So what to do? I own a lathe. I own pivot wire. I own a complete set of sherline collets. Ive used gravers before. Done lots of machining too. But i moved my shop to a different town and lost my darn T-rest. So i call a watch machinist. He requires $200 to manufacture a new staff. Ugh. The sherline T-rest costs $220 plus tax and shipping. Ugh again I had the idea to contact Gübelin in Switzerland. I got a response email from a nice fellow who tells me my new watch is a Cyma manufacture from the late 1930's. Gübelin doesnt make their own items. They are jobbed out. I guess like Tiffanys. I look on Ebay and the was a Cyma 15 jewel missing its case with the exact movement plate design and configuration for $49. Hopefully I will be able to cannibalize the balance wheel or staff. We shall see.1 point

-

Hi all. Just an update on my Cyma made Gubelin pocketwatch. I said in a previous post the balance wheel would rotate only in face down or vertically. Face up it wouldnt run. The issue was quite simple. On the balance cock with this movement, the cap jewel is set onto a washer that has a beveled edge. The washer goes on top of the regulator and is fastened with two screws. The regulator has a countersunk/beveled edge as well. I had taken apart all of this for cleaning. When i reassembled this area i failed to line up both beveled edges such that they would mate. Thus the jewel was pushed up ever so much and the balance staff pivot wasnt running against it in dial side up position. 2 things: i love my microscope! I wish all problems were this easy to remedy!1 point

-

More from the penny lots. This time a Kienzle 57/03a black dial. Hopefully I have something suitable to replace the missing stem, otherwise I may need so spend more on a replacement than I spent on the watch. The seller stated that the balance was good, so I suspect it should be relatively easy to restore it to its former glory.1 point

-

As of yesterday, the watch is completed and running. I had to back track a bit during assembly, as I forgot to install the hacking "finger". Essentially everything had to come back apart as the hacking finger sits under the gear train. Today I was able to pick up a bracelet extender so it would fit without strangling my wrist. The extender is gold tone, but I can clean that off Monday at work. I attempted to "repair" the dial with an acrylic gloss varnish, but it was sadly a dismal failure! I spent 4 hours very delicately picking the failed acrylic of the dial. In the end, it acted like a super cleaner and made it look significantly better. At the right angle you can just see the discoloration around the date window from my initial cleaning attempt. This watch is significantly smaller than any Seiko I own which is a bit disappointing. Overall I'm very happy with the watch and thrilled I was able to bring it back to life. The only other thing I want for this watch is a new crystal if I can't polish out the deep scratches with diamond paste. Gold tone extender, gets the job done, lol. For those of you with a sharp eye and a keen memory, what is significant about the serial number? And yes, this is actually the serial number on my watch, lol.1 point

-

Gubelin sold here extensively, I just may have the staff you need, in which case I be happy to gift wrap and send you a few. My tablet wont always open pictures, please give the caliber No so I dig in my bag of tricks.1 point

-

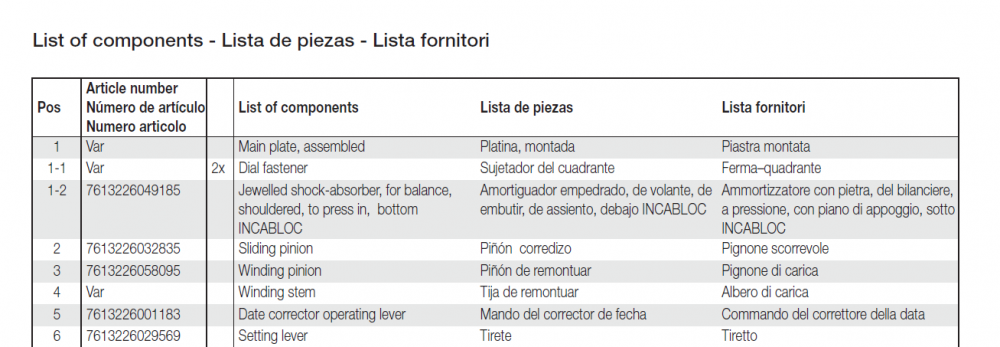

I agree with what you say but my Point is that when it comes to like different complications on movements they usually are made by the manufacturer and they Always make up a fancy definition of it in many languages. So to get it right when ordering it one Always have to get the correct name and partnumber. That you only can get from the technical sheets and In many languages. So making a list of the general Components is ok but one have to keep in mind propper or not they don't Always comply with the specific manufacturers definitions and when ordering parts it's those that counts.1 point

-

This post containing contribution of those who shared back in 2018, has pracially proved useless, since many members, in spite of access to the search function do not know the post exists. The proposal is a data bank created by members for all, Welcoming non-memebers traffic and more importantly an introduction directing all via a link, on the main page.1 point

-

Sometimes when buying parts it is useful to know the names in other languages or to know the standard swiss part numbers which can be found here https://www.cousinsuk.com/document/category/factory-symbols-trade-marks-ebauches-swiss-part-numbers1 point

-

Here is a link to P/W parts photos these came from IHC185 club by John D. Duvall https://www.dropbox.com/sh/27ej5vl7etzaqzi/AADuOsY6QNnl8heHIweN3OcGa?dl=01 point

-

I know what you mean, sometimes these things are pretty hard to find. It's probably a bit difficult to do this as each movement has it's own type and it's parts and you won't really find one movement to show all types of parts. Here's a couple of images that should help.1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)