Leaderboard

Popular Content

Showing content with the highest reputation on 05/26/20 in Posts

-

Some might have noticed I started a thread first about buying, then about making my own. A friendly cautionary tale to those like myself who are just getting into this hobby and like the wonderful pictures of benches on Amazon and eBay. It seems that all who sell benches, sell the one I purchased. I was reluctant to note the manufacturer, but it's necessary for this post. Doesn't matter from whom you purchase, just be aware of a few things. The drawer assemblies are laid with the back facing down. Since the drawers are shorter than the compartments that hold them, they are hanging from the false front. Gravity/age/dropping causes the false fronts to stay put, as the drawers themselves drop, splitting, splintering separating the drawers from their fronts. The layout is classic (from what I've been seeing) but the quality is simply not there. ALL wood is veneer, and the backs and sides could be split by a stern talking to. Some list the manufacturer, many don't. Some have a nameplate, some don't, but Grobet is the manufacturer and it seems these were made by the hundreds, boxed, and sit on warehouse shelves. Lastly, the wood is dehydrated and shrunk to the point where the typical hardware holes no longer line up. You can certainly fix this, but as my wife said, "You're putting that $700 desk back in the box." (That included shipping). I could have made this work quite easily, but the low quality of materials didn't warrant "fixing" it. Last word: do not buy a desk unless you can put your eyes on it. Mark Twain's quote comes to mind: "Beleive nothing of what you hear, and 50% of what you see." Larry.2 points

-

Well... You guys got me inspired. You may be onto something with this "404 club" thing. I've been casually trolling eBay the past few evenings, and thought I'd give it a shot. I converted £4.04 to USD ($4.94), and started tossing around throwaway "Best Offer(s)". I actually scored one, and not even one but seven! A lot of 6 identical, and a seventh very very similar watches with 17J manual wind movements. They look like the cases are silver plated (no photos of where any telling marks might be found, so I'm going with plated) and thoroughly tarnished. What's more, they look mostly NOS and unworn; some still have bits of sticker on the back. No idea what the movement is, but I figure if I can't get at least most of them up and running and sold to make a few bucks for the next "404 club" buy, I'm doing something very very wrong.2 points

-

I don't recall running across an independent 4 jaw chuck for a watchmaker's lathe yet, though I know they exist. I do use a 4 jaw on my larger (102mm center height) lathe quite often.2 points

-

I use the Greiner GS concentrate. It's mixed 1:19 with distilled water, so 50ml makes a liter. The rinse is pure isopropyl alcohol, and my machine distills it so it's clean, 1st rinse, dump the alcohol then 2nd rinse in clean alchohol. Drying is in warm filtered air. Greiner recommends rinsing the balance and fork alone in the first clean alcohol bath for 30 seconds to a minute to avoid softening any shellac; the rest of the parts then go through as above. For clocks I use a water based solution that is a recipe from the Finnish watchmaking school; with that I clean in the ultrasonic, rinse in warm running water, then a final rinse in alcohol to absorb the water, dry in warm air flow. Both are fairly gentle cleaners, and I've never had anything rust with the water based cleaners. I like them as they are pretty environmentally friendly, and I'm never wondering is the final rinse is clean enough.2 points

-

What I would recommend doing is reading the PDF For the cleaning fluid it has detailed specifications. Basically what they're saying tap water to mix up your solution anywhere between 3 and 10 minutes for cleaning. I wouldn't go over 10 minutes and I wouldn't make the solution stronger that supposed to be it has ammonia. Ammonia is really good at making things bright and shiny and looking clean but if you go too long it Can frost the Brass parts. Basically starts doing the opposite of cleaning stuff looks not clean. Then you're supposed to follow up with the water rinse and their real clear on what that water is supposed to be distilled or demineralised. I assume what they're basically saying is the water needs to be clean. Does not specify unfortunately how long it should be in the water but you do want to remove the cleaning product. Then the last rinse is the Suprol . In this case is used to displace the water before drying to keep the parts from rusting as a guess. If you are using a non-water-based cleaning fluid then you would typically have several rinses so in each one could reduce the concentration of the previous solution more and more. Then it says error dry? But how do curiosity and looking at one of the watch companies recommendations which is three minutes in each of the rinses they are recommending three. Followed up by warm air drying. So basically off to figure out some of the stuff on your own like whether you really can error dry or not? You may find that a little but a warm air blowing across the parts helps. Then is there any reason why You're not using the non-water-based watch cleaner?2 points

-

Personally, with a screw-down crown like that, I’d just re-use it as is. It may be thread-locked in place. I always aim to keep them in the inner stem position when removing, but it’s not essential. Gently twist the stem when you insert the new one.2 points

-

In the event you need a time-sensitive answer, I'd guess that watchweasol did mean to use the stem that came with the replacement movement. Perhaps that is because it will not have wear on it that the old one will have. It probably won't matter much though, providing the watch it was in was winding and setting well before replacing it. If you use the new stem you will likely have to cut the stem a touch and fit the crown. "Set" position means with the stem pulled out in the position to set the hands. Good luck.2 points

-

I’ve always been really impressed by the lapping machines that are used to achieve flat faces and crisp on cases. Although I don’t do enough case refinishing to warrant the price of a machine, I though maybe I could achieve a similar result with something home built. The impetus to try came when I bought an Omega Chronostop. The case came with a sunburst case finish that was long gone and would require precise brushing. I figured I could replicate the multi-axis adjustment by using a telescope head. Found one on eBay for $125. Then added a 3 jaw Chuck for $50. My only issue was that I needed to adapt the two together. Because the stress won’t be so high I figured I could just 3D print some adapters and it worked perfectly! The great thing about the resin printer is that the resolution allowed me to actually print the threading! Because the case is a top loader, there was no good way to hold it properly so I printed an adapter to screw on the back. All ready to go: I am really happy with the results! The case has some dings that I wish I could laser weld but alas I can’t built one of those on the cheap. Lol. My next step is to find a way to fasten everything down so I get more consistent engagement with the sander and recreate the angles consistently between checking my work. - Craig1 point

-

Hello fellow watch lovers, I have just completed a build from part sourced from various sellers. It turned out to be the best build for me yet and I have really amazed myself and the skills I had to exercise on this timepiece. I have impressed myself with this one and it is a stunner with a salmon dial. The NATO strap is very lovely on this timepiece. I apologize for the lack of details on this beauty, Enjoy1 point

-

With anticipation and excitement my new, not inexpensive bench showed up last night. I'll mention no names, no vendors. Let's say the bench looks absolutely amazing on the internet. Much like the difference between the bacon double cheeseburger pictured on the menu, and the one you get in the paper--the bench's wood was old and dry, split, filled here and there with "wood filler" that was terribly off-color, warped, out of square, and indescribably unsatisfactory. A refund is forthcoming. While that gets sorted out. . . I went to a store today and bought materials and tools to get started on the drawers and their encasements. I'll start uploading pictures as the project progresses, but I'm going to make a bench that's about 3' 2"high, 4' wide, and 21" deep. The top will have rear and side rails. I'll have 9 drawers on the right, a few on the left, and a large, felt-covered pull-out "shelf" area in the middle, which will be covered by the bench top when not extended. I'm going to give box-joints a go for the drawers. I'm no carpenter, but with the information available I should be able to make something I'll be proud of, and will last a lifetime. I'll keep a diary here as things progress. It will be nice to get off the kitchen table. The wife will be pleased.1 point

-

hi guys, my obsession is early Timex watches from the 1950s, 60s and 70s with a particular focus on 1976 birth year watches, Dundee made pieces and early 50s pieces. what attracts me to Timex is how disposable they were and how they shouldn't have lasted as long as they should. there's a UK connection and a wide range of mechanical pieces produced in 1976 when the quartz crisis was at its height. unfortunately i have the money but not the time to restore many of these pieces so for now stick with m24 (no date) restorations with others being helped out by the timex community on fb and ig. (@timetrope) my current challenge is getting date wheels on m25 movements back on. theyre tricky. and getting crowns to stay in place on m21/22 movements which im hoping some new antimagnetic tweezers will help with. if your looking to sell or trade pieces then my goal is to collect them ALL and even at 200 im short quite a few1 point

-

1 point

-

Hi @VWatchie From what I remember, I roughened up the wall of the barrel with a bit of wet and dry paper, and used a strong braking grease - 8213. I think the spring was performing OK in the end. I never did get great amplitude. As @nickelsilver suggested, this probably isn't due to the mainspring, but as it just sits in my collection, I'm not bothered. I'll have another go at it one day. It's an unconventional gear train, and the most complicated movement I've worked on - talk about springs ! Don't assume that new springs are OK - I've had several instances when I've repeatedly stripped movements to try and figure out why the amplitude has been so low, and it turned out that the 'new' mainsprings were dud - i.e. not springy Good luck1 point

-

Among others, Cousins UK and Boley.de let you search by case reference for Seiko and other makers. Very good, BTW I have broken my good share of crystals and other assorted parts too. Yes. That allows to delivery fine contours and details with ease of manufacturing. Below 1.2mm they break very easily, you can break a 0.8mm pushing it out by hand. Try to use only crown type dies on the crystal, and a lever type press if possible, as it provides better feedback.1 point

-

1 point

-

No, as mentioned above it's never so on that class of watches. And gaskets can always be re-used unless damaged messing with them as happened here. I'm afraid the OP is a bit ham fisted, working on crystals is delicate - just as everything else on watches.1 point

-

Well said SparkyLB Its only when things like this happen and some one posts the findings that others benefit from that knowledge, $700 worth of plywood is a bit much. I bought a computer desk from Ikea 20y ago still going strong and now used a a clock repair bench, no drawers though which is a bit of a bind. good speed with the construction cheers1 point

-

If you wish to use the new stem (not necessary if the one you have is undamaged) you can unscrew the plastic crown and replace it with the TAG crown. However, the TAG crown may be more or less glued to the threads of the original stem so that could possibly pose a challenge. You would probably also have to shorten the new stem using a cutter tool like this and you would possibly need to file the sharp edges after the cut (a simple flat diamond file works well for this). It's a bit fiddly... The battery should always be removed while working on the movement. Replace the battery (preferably with a new) just before replacing the case back. There is no "correct position" except the square section of the stem must be fitted into the square hole of the sliding pinion (AKA clutch wheel) so while inserting the stem, apply a little pressure on the crown towards the center of the watch while gently rotating the crown a bit back and forth until it goes in (into the square hole of the sliding pinion which you can't see). Unlike when you remove the stem, you will not have to depress the setting lever button when you replace the stem. Just shove it in! You can see exactly how the stem fits into the winding stem here. You might find my ETA 955.112 service walkthrough useful. I believe it is identical with the 955.412!? Good luck!1 point

-

Be very careful not to overdo it like I did. You may find this and this post interesting. Suprol Pro is some truly nasty stuff. Smells like death and has a narcotic effect. Be very careful with it. Have an open window or try to do your cleaning outside.1 point

-

1 point

-

Fantastic work so far. If you have the skills and tools to make it yourself the end result is always far more satisfying than a cheap off-the-shelf solution and you get something built to your specific needs. I commend you for doing drawers, they're fiddly and time-consuming. Sent from my iPhone using Tapatalk1 point

-

1 point

-

Hi Gary at all times unless testing the movement leave the battery out, whilst manipulating the stem into position . It will be best to use the stem provided with the module. some of the modules require you to put the stem into set position before removing as this keeps the clutch assembly and associated gears in place to enable an easy fit of the stem. Failure to do so causes the clutch to drop requiring re alignment before the new stem can be fitted. To do that you need to remove the calendar work to gain access to the keyless work. I have attached the tech sheet which covers this movement for you. good luck ETA 955.102, 955.112, 955.122, 955.132, 955.402, 955.412, 955.422, 955.432.pdf1 point

-

1 point

-

1 point

-

The answer "yes" given above is substantially correct but incomplete and hurried. For example, on the very popular swapping to a SKX 200m divers, one cannot reuse the original stem/crown combo, so a new one must be bought. Then, one must reuse the original movement ring, as well the day disc. But you cannot count on carrying over the date wheel, because that changes across versions. I wrote about that many times here and on WUS, it should be easy to locate my postings for those that desire to gain full understanding and do a perfect job.1 point

-

1 point

-

Picked up the Swiss case from eBay, brand new but from the sixties I believe. Unfortunately can’t source a 10 1/2 mechanical movement so fitted a Swiss Ronda quartz movement. The dial is a genuine 1963 uncirculated half penny which I machined down to .5 mm and then silvered. I made it for my wife's birthday who was born in 1963. She absolutely loves it Just normal dial silvering compound1 point

-

1 point

-

A classic Seiko quartz rises from the junk pile today. This was missing its crown and stem when it arrived, but otherwise it was in excellent condition, so I decided to trawl through my large pile of random stems to see if I had something suitable, and my luck was in. I then couldn't decide whether it would look better with a silver or gold crown, but settled on the silver one. Too much bling with the gold one I thought. Looking online, all of the similar Seiko watches with silver cases have silver crowns and gold cases, gold crowns, so I think I made the correct choice. A little bit of a polish and a fresh leather strap, and it makes a very handsome addition to the 404 club.1 point

-

I'm not sure if the phrase slightly worse is appropriate. Several years ago when I was in a teaching situation of teaching hobbyists watch repair. One of the students loaned me his small collection of pocket watches and his Chinese 1000 machine because he was concerned about the results he was seeing. this made for a really nice lecture with pictures. Then much later on one of the other students loan me his 1900 machine to do a comparison with. now of course I acquired a 1000 machine on eBay used for hundred dollars. You can never have enough timing machines. before we continue I turned both timing machines back on then I was doing something with the witschi you can't do with the Chinese listening to the ticking sound as I was still bothered by the issue of yesterday. Then I wrote down the numbers. Witschi thinks the watch is +3 seconds fast 222° 0.5 ms beat the 1000 machine thinks the watch is +3 seconds fast 226° and 0.5 ms beat. I'm not sure if it's going to answer your question or not but I have a link to the second page of this discussion it will probably give you some answers and bring up new questions then when you make comparisons between the differing machines other issues can come. Like what's the consequence of having a small graphical display like the 1000's? Or the Chinese machines typically do not display error messages they will always try to give numbers what's the consequence of that? The problem with a small graphical display is and we've done experiments on this group somebody had a watch that was perfectly in beat graphically but numerically the number did not agree? This is where on in a timing machine if the numbers do not agree with graphical results you have a problem. so what happened is the watches perfectly and beat graphically but numerically it was a huge number? This is because on the small display when you reach the edge to display it basically rolls over to the top and then you start getting goofy results. See you might have a watch that looks perfect but it's really not. Then my reference to always giving numbers? I have a saying which is garbage in garbage out relating to timing machines. If the graphical display seems to be random dots and you have nice numbers the numbers are wrong. this is one of the reasons I always ask for pictures of graphical displays because you can see things there that you can't see numerically. https://www.watchrepairtalk.com/topic/4124-chinese-timegraphers/page/2/1 point

-

Picked up the Swiss case from eBay, brand new but from the sixties I believe. Unfortunately can’t source a 10 1/2 mechanical movement so fitted a Swiss Ronda quartz movement. The dial is a genuine 1963 uncirculated half penny which I machined down to .5 mm and then silvered. I made it for my wife's birthday who was born in 1963. She absolutely loves it1 point

-

taking it on and off would add a new variation of having to wait at least 30 seconds for the watch to stabilize otherwise that's going to introduce a variation. the timing machine has a start/stop button. Each time the button is pushed it cycles between stopping which is freezing the display then starting a timing cycle starts over from the very beginning no need to remove the watch. that's an interesting observation which implies we would have to compare it to something? when the Chinese 1000 machines came out one of their selling points was the screen there were very proud of their backlit screen. At that time there comparisons were with the witschi watch expert II as it does not have a backlit screen. if we use their comparison then you're right the Swiss machine does have a nicer microphone considerably more more analog processing circuitry enhanced features plus a minor price difference. okay perhaps it's not a minor price difference comparing a professional Swiss machine that is just under $3000 to a Chinese machine that's under $200 is an interesting comparison isn't it? then how does the Chinese timing machines compared to the Swiss? I've already done that experiment couple years ago. I compared the witschi watch expert 2 with the Chinese 1000 and 1900.. for the most part they are very very close so close that I have no problems recommending either Chinese machine.. although I like the display better on the 1900 machine.. being curious about the start and stop problem I decided to try an experiment.. The benefit of collecting timing machines.. The witschi watch expert two and the Chinese 1000 machine.. Basically the 1000 analog and programming for the most part is identical to the 1900 at least close enough. The watch that I was timing is a Hamilton 992B pocket watch. Mainly because it was convenient and it's a lot easier to have two microphones attached to a pocket watch.. basically the exact same set up I had before just a different watch. but there seems be a problem with the 1000 machine not correct technical term but it's not happy? The LED is flickering but not in nice rhythmic way. the machine is having a problem figuring out the beats per hour it's just taking a long time. Once it figured out the beats per hour the rate was fine but the amplitude took almost a minute and was wrong.. basically the machine is not getting a good clean signal? this is a problem more common with wristwatches in their case.. A lot of times of the case is big heavy cases sometimes the movement is plastic a variety of things can cause the signal not to get out.. This is where the recommendation is rotate the watch until the crown is pressing against the part of the microphone where the sensor is located.. This should give you the best signal.. repositioning the pocket watch and the microphone the LEDs looking better everything is looking nice now. The witschi microphone is now clip to the side of the watch case it is working just fine. So there appears to be some minor signal problem with the pocket watch that the 1000 as having issues with the witschi is not. This is where in our oscilloscope feature is really nice missing from both of these machines. now that both machines are simultaneously appearing to work let's look at the numbers and see the difference between them. The witschi indicates +2 seconds 226° 0.5 ms. The Chinese 1000 is +1 225° 0.5 ms so other than the initial microphone issue which I still think it's odd both machines are basically tracking very very close to each other. I do curiosity I thought I would do a test where did I turn the machine off turn it back on and it's roughly 25 seconds to reestablish all the numbers then looking at the witschi machine it looks like everything is real close the amplitude is off by 5°. Some of this I think is because on power up it defaults to an averaging where sample time of four seconds and that's going to change things a little bit. now for the final insanity part? Were not exactly comparing the same thing in that the witschi is averaging over 20 seconds updating every two seconds. Watching the display I noticing a amplitude variation anywhere between 229 up to 240 something this is a very slow variation over several minutes and it's not exactly rhythmic or consistent. as a guess this is what happens when you have several variations in issues seeing as how I know the watch hasn't been serviced in a while. So with the Chinese machine I push the stop button right the numbers down the rates are very very consistent the same as the witschi machine so I'm going to ignore the rate for this test only look at the amplitude because that's the only thing that's showing any variation. So what I push the stop button I write down the number wait a moment push the start button once stabilizes right that number down this is why made a reference to insanity. Of and as a reminder the 1000 machine is set default sample time before seconds and we have no idea how the machine actually averages it would definitely be more stable if I would adjusted 20 seconds but the person who originally posted this never change the setting so I'll keep it where the machine would be for him. So stopped 237° it starts up at 225° compared to the witschi at 237°. Then running the test again 225° starts up at 236 and the witschi's 237. so the basic conclusion of all of this is the Chinese machines are relatively stable the microphone isn't quite as nice as the witschi the amplifier and so forth aren't quite as nice but it still doesn't really impressive job. For the original person posting we need more information? Like if you stare at the timing machine do the numbers change at all over several minutes? Are you seeing a slow variation. Because if there is a variation and you stop and start the machine up you going to see that where you had a number and it's going to jump to the variation number. If the graphical display is not a nice smooth line like mine is you're going to see a variation in the rate. Then if you change the sampling time to 20 seconds it will help to smooth things out.1 point

-

The spring is lubricated from the factory. Place the disc over the barrel (the right way up!) and push the spring down evenly using a flat object.1 point

-

Not just the build quality, but the intrinsic limits of geometry and tolerances. Since the driving element a spiral groove that is common to all jaws, which must also work reversed, some design compromise must be taken so keep it acceptably smooth. For example, on my Unimat 3 copy I have less than 0.01mm runout at the spindle chuck spindle register, but about 0.12mm with a precision 7mm round bar in the 3 jaws - which is the same as the Ebay example above. There are ways to improve concentricity on self-centering chucks, but in the end if precisions is needed either use collets, independant jaws, or turn between centers. There can be more ways also, as machining is full of ingenious methods. All that being said, here we are talking about hobbyist / non-precisions chucks only. I'm sure that watchmaker's and and professional machines chucks have a different precision class. Not all 4 jaws chucks are of the independant type, and not all sellers do specify. Look for square sockets on the body in line with the center of all jaws. Below an self-centering 4 jaws chuck, again for the Unimat 3. These are mostly used for woodwork where high precision is not important, but you need to grab square section parts often.1 point

-

A 3-jaw chuck is self-centring. All 3 jaws tighten in unison, so you are at the mercy of the build quality or wear in terms of how centred your workpiece will be. On a 4-jaw chuck, the jaws adjust independently. It takes longer to set up, but by using an accurate measuring instrument e.g. a dial gauge, you can centre exactly. You can also hold non-round workpieces, or set up purposely off-centre.1 point

-

More USSR keyless work repairing this evening. I've finally run out of spares for the keyless work on these, so time to start hunting for more donors. I actually stripped the necessary parts for this example from a basket case Raketa 2609A, which has almost identical keyless work, but I'm not sure if it has much else in common with the 2609HA. The 'HA' .. compared with the 'A' The strange pink lighting effects on the dials is just some weird digital camera artefact, they are in fact both white, although the one on the left did need a little bit of a touch up just above the 12 O'clock mark. Other than the dials, these two are virtually identical Raketa 2609HA engines inside.1 point

-

And i think it's the last one from this line(if anyone seen any other please let me know)1 point

-

Yes, remove the rotor and soak it in alcohol.1 point

-

Thanks for the reply, jdm. I'm not asking about "connecting" one of these devices to a PC - I see the manufacturers don't offer that option. Rather, I'm asking if anybody has opened the enclosure and interfaced with the electronics to grab data signals. My colleague is a wiz with electronics but if somebody has already done it and is willing to share the details, that would be great. Woody1 point

-

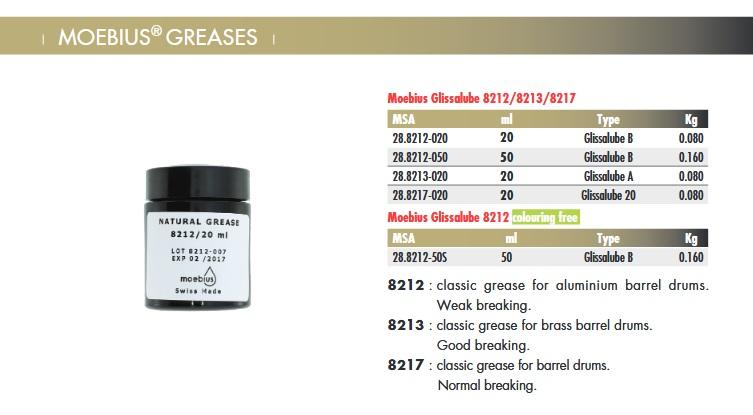

I don't think the spring is broken, that's just the bridle overlapping itself and is normal. If you try to wind a spring in a barrel with the lid off, the coils WILL jump out. It's not a sign of a deformed spring. And it's a common method to get "backwards" springs in to use a winder one size too small, and transfer to the proper winder then barrel. And if original is 1.2mm high, it's pretty certain that's the correct height. Many barrels will show signs of rubbing after years of use, see above about coils jumping out. The lid and barrel bottom keep them in, they rub. As to the slipping issue, it is probably a combination of a worn barrel wall and incorrect grease. The 8217 is from the old Glissalube line, which changed designation to fit the numerical system Moebius uses. The 8213 (old Glissalube A) is strong braking, recommended for brass barrels. The 8212 (old Glissalube B ) is weak braking and recommened for aluminum barrels. The 8217 (old Glissalube 20) is considered "normal" braking but Moebius lists it as "soft" for all barrels. Some auto barrels have notches around the wall, some are smooth. Both can get worn to where they slip too easily. If it's your own watch, a rub around the inside with rough emery paper may do the trick. Going to a more "braky" grease could do it too. Maybe both, maybe you just need a new barrel and the more braky grease.1 point

-

Ok I had a spare hour this afternoon so I thought I would have a go removing my Urchin bezel using a knife. After about 20 minutes using a whole selection of kitchen knives and being totally red faced I hadn't made any progress (The Mrs won't be happy with me when she gets home from work and sees the knives either) I even taped the lugs and tried leverage and twisting, still no joy, so I gave up. So I got the Horotec case grab out and removed the bezel in a couple of minutes. I don't reckon this tool to much as a case back remover but as a bezel remover, it's the BEST I've come across. So insert the jaws apply tension, the bezel pops and gently lift up with no effort with a Seiko type case back remover. See pics Sent from my SM-G920F using Tapatalk1 point