Leaderboard

Popular Content

Showing content with the highest reputation on 08/05/19 in all areas

-

A couple of tricks from industry guys, not Brand approved but proven at the bench: Uhu Patafix, the yellow one, is a decent Rodico substitute that doesn't leave visible residue. The white one doesn't work. You can't touch it with your fingers, only cots or the pegwood trick from above. The other one is contact cement. When dealing with black polished steel parts, in a new watch, they have to be impeccably clean. The trick is to dip toothpicks in the contact cement, so just a little bulb is at the tip, and set aside to dry. When casing up, any small marks or bits of stuff that won't blow off can be picked up with the tacky cement (it stays tacky a long time). It won't leave a residue on the steel. The fellow who told me this one used the cheapest contact cement he could find, it was some offbrand stuff. I tried Continental tire glue for bicycles (the one for gluing on racing tires, not patching inner tubes) and it worked fine.4 points

-

Ëven fingercots leave a trace. A tiny hair from your eyebrown or head an then it's great to just lift it up with some rodico. I use it all the time. For all sorts of things. Like lifting the balance jewel or holding the inca jewel to take the endcap of. Or chewing it when i am out of candy3 points

-

2 points

-

One big problem with Rodico is most people manipulate it with their bare fingers. So all the oil, dirt, sweat, etc, end up in the Rodico. Then it get's used to "clean" a part, leaving a nice film of skin oil and sweat and who knows what else. If used for cleaning a jewel, the film can promote the oil spreading, like an anti-epilame. If used on a steel part or a dial it could lead to rust or oxidation down the road. If you really want to use it (not for picking up a stray oil drop!), like for a little piece of dust on a dial or whatever, the best method is to stick sharpened pegwood into fresh Rodico (I leave it wrapped in its paper, in a baggie), twirl it and you'll pick up a little blob of virgin stuff. Use it, then add it to your big dirty blob. It is indeed handy for getting stubborn cap jewels out of settings and many things, but should be kept off clean parts and dials, away from oil/jewels, and when used to "clean" already clean parts, use fresh stuff. If you need to handle it with your finger, do it with finger cots. In a professional setting Texwipe products get used a lot. Their pointy swabs are excellent, and cost about 12 cents/piece.2 points

-

Just curious where you have seen these opinions? It's OK to post links. Normally the advice from this forum is well based on reason, and best practices.2 points

-

An escapee from my watchmaker’s bag of Horrible Dead Things, the only polite description for his parts stash of old broken pin-levers which he’d hoped never to need again until, to his undisguised horror, I introduced him to my old nonsenses some years ago. I always tell him that instead of just sitting there changing batteries and re-sizing bracelets on fashion watches all day, he should be grateful for my helping him maintain his traditional skills. By way of witty riposte, he tells me to “@&*# off”. So, a forlorn Ostara which, although having lost the jaunty looks of its youth long ago, was willing to run with a little encouragement. The display back looked as time-worn as the rest of the watch so may well be original as I somehow can’t imagine anyone retro-fitting it to proudly exhibit its 15j EB 1344. The case and bezel topsides had lost their plating but have now been brightened up a little. With that and new crystals fore and aft, new crown and the missing seconds hand replaced, it now looks almost presentable. Oh, and it’s also had a new balance staff, because when it fell from Mr Grumpy the Watchmaker’s grasp, he expertly managed to dropkick it the length of his workspace whilst attempting to cushion its fall with his foot. Cue Mr Even Grumpier the Watchmaker. The watch was by Walter Ris of Grenchen, founded in 1945, with the Ostara brand following in 1950. They were making watches certainly into the ‘70s before liquidation in 1997 and eventual dissolution in 1998. Regards.2 points

-

Experienced watchmakers/repairs: Rodico - Yes or No? I see many varying opinions and want to know. Thanks, RMD1 point

-

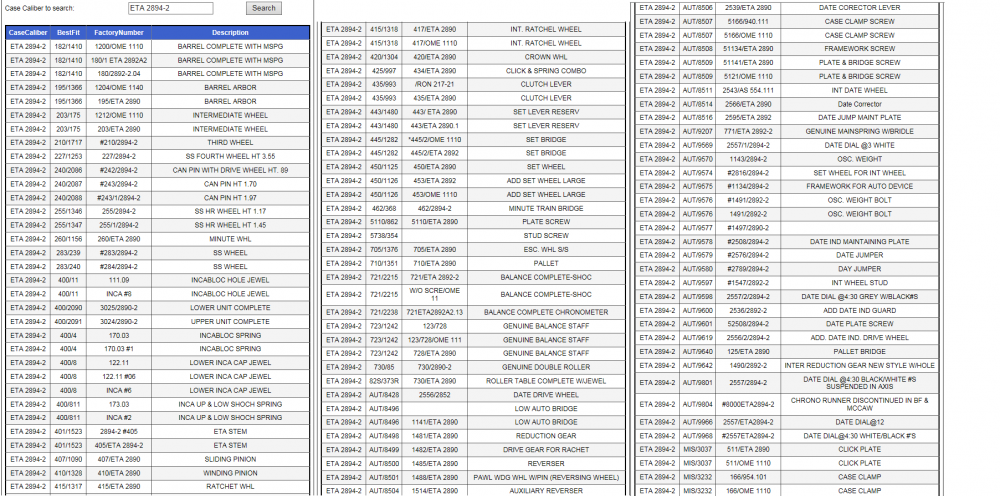

Unfortunately JDM is partly right the chronograph module has part number 8510 and is only sold as what ETA calls an "integrated part". You have to be authorized by ETA to buy it from them but even then it comes with an hefty prize. At Cousine you will find it as a "Restricted" part. I think the best chance is to buy one "Second hand" but there isn´t any parts for it out there. Used module: https://www.hhcdsjstore.com/index.php?main_page=product_info&products_id=486718 New: Cousineuk Chronograph Module Assembled, Height 1 ( 8510 ), ETA 2894.2 ETA289428510 (Restricted) https://www.boley.de/caliber/watchmovements/eta/4873 http://www.startimesupply.com/merchant2/merchant.mvc?Screen=PROD&Store_Code=1&Category_Code=1H-Parts-Movt-IntParts-ETA-07&Product_Code=ETA2894-8510-H1 And a tech sheet with the correct partnumbers for everything except the chronograph module. 2894-2_Tech_Com.pdf1 point

-

As mentioned above the module is made by Dubois Depraz not ETA, unfortunately you will not get help from them, that's the standard Swiss business practice.1 point

-

Hi Guys Like Frank I remember using a smilar product known as TYPE CLEAN when I was a typewriter mechanic years ago and it worked. Rodico is of the same ilk and is very good at what it does, It will leave a residue when contaminated, usually with oil at that point use it for something else. I use it and have no problems with the product. As with type clean when it got too dirty to use effectivly bin it it does not cost mutch.1 point

-

I use Rodico too just like Rogart63, I sometimes make magic wands topped with Rodico to pick out the balance jewels in a safe way and also to pick up persistant dust and other debrie. I sometimes take of dirt from the pallets with it and it seems to work fine. I guess some also use it to clean the movement with which probably isn´t the intent with the product. Some also use it to take away spillage of oil which is OK as long as you don´t reuse the Rodico anywere else. But I wouldn´t take away excess oil from a jewel with it since you probably just will push the oil through the jewel hole to the other side and by that get the movement bathing in oil instead, it doesn't have very good sucktion capabilities. I am also less keen to use it as chewing gum1 point

-

It is the same stuff that was known as "type cleaner" in pre computer times, I suppose. Frank1 point

-

To clarify a bit, It seems from what I hear, rodico is so effective that it has allowed watchmakers to cut corners at various steps. Examples are oiling; if you get a mini drop on the periphery of the jewel, careful rodico can correct it rather than cleaning up the whole jewel and reapply. Also not using the finger cots that someone mentioned here already, doable because at the end you could remove the marks with... rodico! So, my interpretation is that there is really nothing against it other than people getting into bad habits. It’s true, if Rolex or Omega don’t allow it, it’s so that in principle you will take all actions and precautions not to need it in the first place. Cheers! Sent from my iPhone using Tapatalk1 point

-

I must admit, I use Tesco supermarket brand "Bluetac" in place or Rodico (but then again, I'm not doing this for a living). Tesco's stuff is an off white colour, and I would say slightly less refined (i.e. cheap). The name brand "Bluetac" tends to leave a sticky residue, but the cheap stuff doesn't. Not sure why this is the case, presumably they are formulated slightly differently. It does pick up oily fingerprints, and it is very useful for picking up and holding small items. I haven't tried leaving anything delicate attached to it for prolonged periods. I'll give it a try and report back. If you are doing this for a living, I would suggest use the genuine Rodico since it is made for the purpose, and may well be formulated differently again. The Tesco stuff doesn't taste great, so think of it as diet candy. (*) * Other brands are available, the poster doesn't endorse the use of (blah)tac for diet purposes or as one of your five a day. Pleas read the small print before putting anything dubious in your mouth etc.1 point

-

1 point

-

For $8.16* including shipping I'd get another watch, take links as needed then gift it to someone. https://www.aliexpress.com/item/32970333621.html *new AliX user get $3 coupon1 point

-

My lovely wife is in the medical profession and she brought me a couple hypodermic type needle things that are thinner than anything I had on my bench. I use them for oilers and although I'm no professional they work very well for me.1 point

-

I'm with @vinn3 ... assuming it's used for its intended purpose and that is a cleaning product to dab away residues, particles etc. I say this because I have learnt the hard way that Rodico has properties that in some cases may not be welcome. I once disassembled a watch that I found needed some hard-to-find part so left the disassembled watch in an air-tight box with easy-to-loose parts (screws; springs) gently placed on clean Rodico. When I came to reassemble the watch I found that a bridge had also rested on the Rodico and it had completely discoloured the bridge where it was touching. Sure you could say 'my bad' as I'd created this situation but then again Rodico is advertised for use for picking up parts (holding them) and wiping across parts (cleaning them) along with words like 'harmless to skin' and 'non corrosive' so I was a little put out! I'm still a user of Rodico but now you realise the caveat in my first sentence!1 point

-

That's actually very nice. Surprised that no Asian has bought the name yet, as commonly happens, maybe the holders ask too much. Even re-making it verbatim would sell in the lineup of a microbrand or Kickstarter.1 point

-

You are just talking about a mov't not pimping counterfeiting. But, these are pretty bad to start with, one should be happy as long they run at all.1 point

-

Just in reading various fora. Many say that it leaves residues and many also say that manufacurers will not allow it's use. I'm just trying to gather a snapshot of your views on it. Thanks, RMD1 point

-

In my experience it leaves a residue when used to dab away fingerprints/smudges on plates, best to use fingercots and save the hassle. I just use it to remove balance jewels prior to cleaning,1 point

-

1 point

-

I’m still learning and certainly it’s been emphasized that the use of rodico has been abused. There is a push to keep it off the desk and only to be used for selected procedures. I love rodico and it certainly helps me cover any tracks I may leave behind [emoji39] which is why I guess it’s frowned upon. So, I have it there on my tray and honestly try to minimize using it but it’s always handy. Sent from my iPhone using Tapatalk1 point

-

1 point

-

Just to place things in the right perspective, technical information and parts availability aside, working on chronographs is definitely an advanced watchmaking task.1 point

-

Well it depends .. ETA themselves have this movement listed on their chronograph selection nowdays. https://www.eta.ch/en/our-products/mechanical-movements/mecaline-chronographs/eta-mecaline-chronographs-2894-2 If you push the technical Communication button on the site you will find the Tech sheet for it too. If your movement is looking anything like the one above then getting the parts from a third part dealer I would look for them at https://www.cousinsuk.com I attache a Picture so you can try to find the correct part. Hope this helps you on your search..1 point

-

Thank you for your introduction and welcome to this friendly forum. I'l have a look for you and see what I can come up with. Do you know the make of the watch cleaning machine? A photo would be handy.1 point

-

The module is manufactured and serviced by Dubois Depraz but I believe they only accept work from the dealers.. ie Omega or other brands that incorporate this module in their watches. Also they are not serviced per se , but replaced on an exchange basis. Anyone else can confirm this? Anilv1 point

-

Now you are getting a bit disrespectful. I have around 30 years experience as a watch/ clock maker, not just a repairer. In my days I could make watch parts and clock parts. Watching someone working is a good way of learning. It is not the same as doing it yourself. That is why learning on a practice piece is safe and as I have said it doesn't matter if mistakes are made.1 point

-

I also found a suitable crystal for this rather tatty 8270A based Citizen (probably from 1978 or perhaps as late as 1988). There was a bunch of trouble inside the thing, including a rusted up stem (actually snapped, and rusted in place). A collection of lard masquerading as watch oil, which took two fairly in depth cleaning sessions to remove, and a case and face that despite my attempts to pretty them up, are still fairly rough. I repaired the stem using the slightly dubious method of sleeving he two halves together with the 1.2mm tubing from a spring pin, over the remains of the 1.0mm crown stem and fastening the whole lot together by dripping a tiny quantity of superglue down the sleeve. i.e. the two broken halves are inserted into either end of a short length of 1.2mm tubing and held in place with superglue. A better method might be to silver solder the three parts together, but given that there is as much rust as there is stem, this seemed a more likely route to success. Time will tell if this holds up, but if not, there is always the more sensible option of replacing the stem, but, predictably, I don't currently have anything suitable. After the cleanup and some delicate tinkering, it is running surprisingly well, at around 0.2ms error and +/- around 5s/day I'll let it run overnight and check it again tomorrow, as given its general level of grime and corrosion, there may still be a few hidden gremlins I've missed.1 point

-

Yes I was talking about the balance pivot. And roller table is the same as impulse roller. John is right with the terminology, stumps and anvils are the same, stakes are the "pushers" in a staking set, and pushers are pushers. The bottom right 6 pieces in your Seitz are stumps. You'll definitely want more. Horia sets often come with a stump for every pusher. A nice thing with Seitz (and Favorite and Chatons SA) is the spindle that carries the pushers has a 4mm hole, the same as the locating diameter of the stumps (also most staking set stumps), so the stumps can be also used as pushers. I do this all the time. Including a pic of "some" of the stumps and pushers I have around. The middle rack with 50 or so stumps are the ones I use the most. Also a Horia with a stump in as pusher.1 point

-

1 point

-

Ive been TAD and on vacation for the last few weeks so I havent had much time to spend. Im also having issues with the new 3D printer which will need to be addressed as I plan to use it to make some of the tooling necessary. I also have a mini cnc vice on order that im waiting to get in. Itll be another week before we return home then i. TAD again for two weeks. I will be sure to post as soon as I have made any progress. Thanks a bunch for following. Im eager to get this column wheel 7750 varient in a case. Sent from my SM-G950U using Tapatalk1 point

-

That dial is perfectly aged. Anything you do to it is likely to make it worse1 point

-

So finished reassembling and lubricating my grandfather's ETA 1080 today and took a couple of pictures of it before putting it back into its case. For anyone interested I assembled the movement in the order shown by these pictures (000A.jpg, 000B.jpg, 001.jpg to 073.jpg). The pictures were taken during disassembly so the parts in the pictures are somewhat dirty. The pictures were intended for my personal use, so some of the text and coloured arrows might seem somewhat cryptical. And finally, a slow-motion video of the balance in motion can be seen here. This watch was last used some 40 years ago or so, so just wonderful to see it tick again! This was my first ETA movement and compared the Vostoks and Poljots I've been working on before I must say the fit and finish is indeed a notch or two better. I really enjoyed doing my first Swiss watch (except for the Unitas 6498 in Mark's watch repair lessons).1 point

-

So, I’ve started to reassemble my grandfather’s ETA 1080 and went about it as I always do, with the train wheels. However, when mounting the train wheel bridge I just couldn’t get the pivot of the escape wheel to reach into the cap jewelled pivot hole on the bridge (seen in the first picture in my first post above). Scratching my head, I removed the escape wheel and inspected it, suspecting the pivot might be damaged. It was not, it looked perfect. So, I tried it again and by holding down the bridge with some peg wood, I could get the pivot to just barely reach into the jewel hole. Yet, as soon as I tried to secure the bridge the pivot would fall out of the hole. Having struggled with this for probably more than half an hour, I began to feel pretty frustrated. I’m not a very technical person, I don’t have a lot of experience of watch repairing, and in all honesty I guess I’m not too smart, but all of sudden I realized, or rather remembered, that the jewel hole on the dial side has a cap jewel as well and that the escape wheel pivot on the dial side probably fell too deep into the jewel hole as I hadn’t mounted its cap jewel. Said and done, I oiled the cap as instructed above (it worked out perfectly, thanks!), mounted it on the dial side and then tried to mount the train wheel bridge again. Bingo! This time around the escape wheel pivot reached into to the jewel hole on bridge perfectly. At this point, I felt pretty proud of myself! Well, just thought I’d share in case someone else who’s new to cap jewels happens to find this thread in the future. I'll try nickelsilver's method the next time around which would have eliminated this problem. Thank you all for helping out!1 point