Leaderboard

Popular Content

Showing content with the highest reputation on 02/06/22 in all areas

-

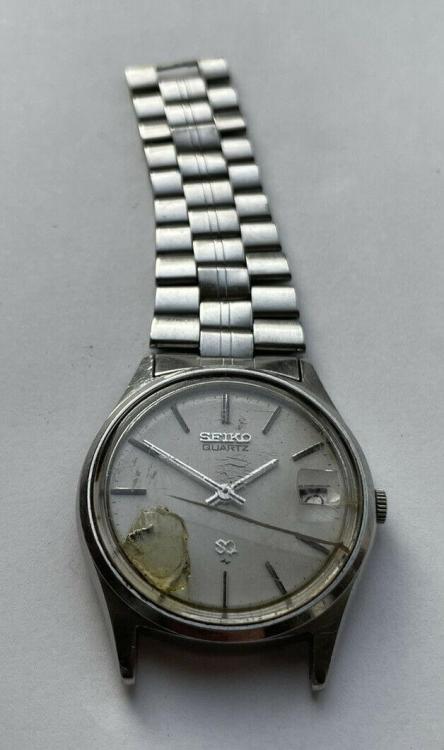

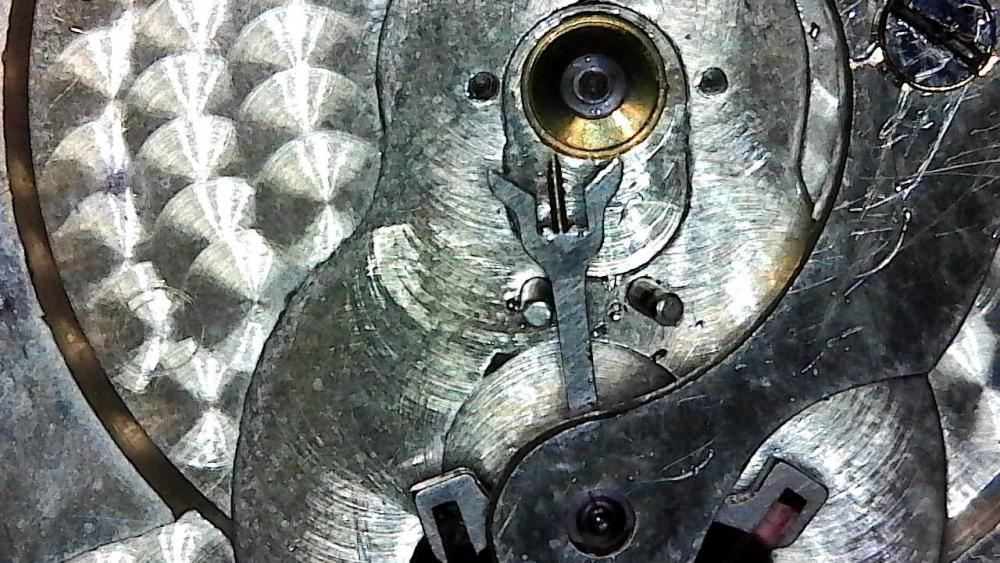

Watching the video, I see amplitude not good at all. Looks like about 130 deg. Should be at bare minimum at least one full revolution for a 180 deg amplitude. Remember, amplitude is half the total rotation.2 points

-

Sounds like you have a problem with the balance. The bad news is.... you have to take it apart to check. Firstly, check the V-conic pivots of the balance. They should be sharp and not rounded or flat. If the pivots are worn down, they can be resharpened on a lathe. Next, check that the V-conic jewel cups are clean. There shouldn't be any dried up oils or dirt. And remember to oil them before reassembly. Then check that the hairspring lies horizontal and flat. Make sure that it doesn't rub against the magnetic keeper plate. Lastly, the endshake must be adjusted to allow smooth movement without excessive vertical movement when turned dial up, or else the balance wheel may drop down until the contact wire may rub on the roller table or worse.... not touch the contact pin. Good luck and have fun!2 points

-

2 points

-

I do the same as @Plato, I use the handle end of a pair of brass tweezers. And as he says, even if it doesn't go in flat, you can push it down without too much force.1 point

-

I bet it's happened to everyone, don't get disheartened. I find the handle end of a pair of tweezers is a good tool to coax the mainspring into the barrel. It does tend to go in unevenly but it can levelled out without too much force. Brass tweezers preferably.1 point

-

So I found myself in the same situation with the same movement (albeit the 1 jewel version.) I was excited to find this thread in order to figure out what kind of shock protection spring this was in order to find a replacement for the one that jumped off my two sets of tweezers and landed far, far away. Unfortunately I didn't have a parts movement, and couldn't find a 1 jewel version anywhere and I'd like to keep the signed bridge that I have that matches the watch. While the watch that I'm working on isn't terribly valuable, it's too nice to turn into a parts movement. So dejected, but determined, I stared at the guitar cases next to my desk, which serves as my watch workbench. What the hell. So I cut off the end of a 1st E string and went to work. An E string is 0.010 inches or 0.25mm in diameter. Far too wide for this application. so after several failed attempts at shaping the new spring, I finally got one that was the reasonable shape. I then used a combination of a file and a sharpening stone to file it down. Finally I clipped it to the correct length. It isn't pretty but appears functional. I'm still waiting on another part so I won't know it works for a few more days. Thanks for the suggestions and ideas.1 point

-

@KarlvonKoln - Thanks for the response. There is no obvious scuffing on the inside of the case, so I don't think that is what is causing the issue. Regarding the alarm. I now see the catch that controls the alarm. Appears that it is just barely catching the alarm hammer and there is just enough play in the hammer that it is escaping the catch with even a slight movement. So, either the catch is not extending far enough or the hammer has too much play and is just slipping out. I've attached a picture of the catch. Guess I'll take it apart and see. @LittleWatchShop - Thanks for your input. Same orientation on or off. I now think that it has nothing to do with the back being on or off. I let it run down and stop with the back off and then wound it up again. It still wouldn't start running again until I tapped the "anchor", or pallet. (I looked up a diagram of clock parts so I'd hopefully be using the right names, guess I chose poorly). I think you are right that it needs a good cleaning and lube. Possible it just has enough gunk in the works to cause it to stick. @HectorLooi - Thank you. I think you are all on the right path. Clean and lube first to eliminate the simplest issue. Not sure if clock lube is as bad as record player lube, but I've seen the effects of 50 year of grease before. Must not be horrible since once I start it up it will run for days and seems to be accurate. Appreciate the quick input all around. Glad I found this forum.1 point

-

Keep in mind that the fact that a pin fits doesn't mean that's the size of the collet. They are usually sprung slightly open as made, and you can fit say a 2.1 pin in a 2.00mm collet- but it won't close correctly, run true or securely.1 point

-

Maybe photoetching? I've never tried myself, happy enough with a label printer and clear tape.1 point

-

Right. Any approach with no risk of damage to the dial is good. Slippage usually happens when we apply force , burning a hole is to do without any forcing. Someone might have glued the crystal on, as result tension ring might also have received some glue. tension ring is made of polymer, so if it comes to it, I would forget about saving the tension ring and remove it in pieces, save the dial.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Start on something big. If you have never worked on watches or know very little start on a pocket watch (not the fusee type) just practice taking it apart and putting it together you don't even need to get it working, this will help you to get to to use your tweezers and watchmakers screwdrivers properly and your eye glass. Here is a document to help you to learn the names of the parts that make up a watch movement. 1033305402_TZIllustratedGlossary(1).pdf1 point

-

1 point

-

There you have one of reason why Timex watches are not recommended to beginners, of course that will not prevent most people to pick these fights anyway. At the factory a jig was used, but none has ever appeared for purchase.1 point

-

One dial screw is the tall head one, in the middle on 3rd pic by the brass wheel, the other should be the same. These are eccentrics not screws, observe how they clamp the feet and turn half a turn the most, it could be either direction.1 point

-

Watch some of the videos from Esslinger. They expain the basics quite well. You can also check out the videos in the resource section of this forum. But anyway, breaking things is all part of the learning process. We learn from our mistakes. Whenever you break something, find out what went wrong and don't do it again. (Yeah! Right!) I just broke a mineral glass crystal moments ago.1 point

-

That would be the pallet. They used to be called "English anchor". I don't think there is a simple solution. It sounds like the clock would need a complete disassembly, cleaning and oiling. You can test if it's a problem with lubrication by using a small artist brush, dipped in lighter fluid, and dab around the pivots to clean and loosen any dried up oils. Watch the balance wheel as you do this. If there is a significant improvement in amplitude, that would be an indication that the clock would need a thorough cleaning. If not, re-oil the pivots and check for worn out holes and pivots. If the hole looks oval and not perfectly round or if you detect a lot of sideshake when you hold the wheel and move it about, then you have a worn out hole that needs rebushing. Anyway, our resident clock deity, OldHippy will advise you soon.1 point

-

I think your lift angles definitely wrong. It looks to me like you're going well over 180° he should look at the video on how to figure out lift angle and figure out what the lift angle for your watch is supposed to be. But it's still not super superhigh it still it's better than whatever it is indicating now The last Elgin that I took out of pin I held it in a lathe collet really really tight and it actually unscrewed it was threaded in. But seeing as how yours is missing you can look and see if it looks like it's threaded or whether it was friction Doone. Otherwise you sent to grab the existing one was something really really really tight and twist. Then I've attached a picture always hard to tell with over coils you have to look at them from multiple angles and this angle doesn't look good. Notice where circled it looks like it's touching the top of the bridge if it is that's why you're running fast. Also look like your stud was up may be a little bit if you lowered at her hair down then this problem might actually go away. Then the balance wheel looks nice and round sometimes the arms get either been in her out they look fine. Unfortunately don't have any timing screws to change the regulation. But you could move the regulator toward slow and see if it slows you down enough. I'm attaching another image looking at this and looking at their balance wheel you're well over 200° amplitude your amplitude then looks fine nifty video is right. Developed the arm that goes under the bridge it goes all the way up around it goes past 180 and looks like it's really approaching about its past 220 5C amplitude is probably fine we just need the proper lift angle. This is one of the minor problems of relying on a timing machine is if the lift angle is wrong which yours appears to be if you're slow-motion video is correct then we get all bent out of shape over your low amplitude that doesn't actually exist. Then we can start the worry about other stuff and you do need to check to make sure they hairspring is not touching the bridge at the point I indicated1 point

-

I know we've had this discussion before somewhere? The reference to the tool is a clue for how to take the crystal off. I have a link that shows the tools they are supposed to have but you'll probably never acquire No notice also at the link below the other way to take the crystal off is with the crystal lift but there might be a problem which is exactly what you have? If somebody got carried away with the crystal lift Or if it wasn't as close to the case as it could be you do probably break the crystal basically exactly what you have now. But it looks like you do have some crystal left you may be up just grab that squeeze and then Gently try to rotate the crystal lift when it's grabbing really tight and you may a bill just pop it out but you do have to be as close to the cases you can get otherwise you end up breaking more of it off http://www.old-omegas.com/tool107.html1 point

-

Thanks, that's very helpful. I am refurbishing my second one of these now. On the first one, I didn't mess with this part because I didn't know that the wheel could be removed. That watch is running nicely. The current one went together much easier (owing to my being more familiar with the movement) but the hour and minute hands wouldn't turn. I had originally put the minute on so that it turned freely with almost no resistance after seeing that the wheel could be removed. I'm not sure if installing it so loose would cause this problem. I've disassembled it again and armed with this information, we'll see if it makes a difference after an adjustment. The finished first watch is below. The second has a nice case but the dial has been relumed and isn't quite as nice as this one.1 point

-

Cleaning in an ultrasonic is great, and what a lot of us use. It's a midway point between naptha in a canning jar and a purpose built watch cleaning machine. You probably wouldn't want to just toss the movement in one though. You still want to disassemble everything, clean, then reassemble and lube.1 point

-

So, yeah. Spoon drill. I'm often amazed at the extreme duality of high/low tech in horology...1 point

-

1 point

-

There are watch repair tools you just can't work without, on which you should spend the budget you have considered, in a case like this alternative approach works, so we save.1 point

-

There is always a specific tool! https://www.esslinger.com/horotec-watch-bezel-remover-tool/1 point

-

Hi Ross I have attached the tech sheet for the 2789, used in conjunction with the one Mikepilk sent you should do alright, just in case you need parts the numbers are on the sheet cheers ETA 2779, 2789 (2).pdf1 point

-

An ultrasonic is absolutely fine, it's what I use. Even hand cleaning is OK. Do a search for the thread on cleaning fluids. Cheapest is lighter fluid, or buy pure Naphtha from ebay. Then I use isopropanol (cheap enough from ebay) as a final rinse - naphtha leaves an oily residue . I use just a little in glass beakers floating in water in the ultrasonic. The attached PDF isn't the correct movement, but it's similar, and shows you the order to strip/rebuild and the oiling procedure. ETA_2836-2_FDE_481924_15.pdf.pdf1 point

-

If you are in the UK, then Cousins is the biggest supplier. They sell to public as well as trade. They have a library of PDF files, which is where I got the pdf from. For your movement, enter 2789 in the search https://www.cousinsuk.com/category/filter/eta-movement-parts1 point

-

Due to space constraints, the manufacture identification is typically via hallmark. <= click the link, peruse the many, many images, lists, and charts.1 point

-

If you look just to the right of the numbers, you will see ETA, the manufacturer. So you have an ETA 2789, a good movement. A good reference site for movements is Ranfft : http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&ETA_2790 I've attached a parts sheet. ETA 2779, 2789.pdf1 point

-

OK. So, business mind kicking in here... A [b][i][u]SUBSTANTIAL[/b][/i][/u] percentage of the market price of a number of the name brands, i.e. Rolex, is tied up in the logo (I'm intentionally oversimplifying, but not by much). What's to stop someone from making an exact copy of the same level of quality, and selling it for a more justifiable price? You're just as deep in the manufacturing costs, but engineering/R&D is effectively just the cost of getting your hands on one to reverse engineer it. It wouldn't be an homage or anything. Hell, be transparent about it: "We copied [such and such caliber] to the last detail with the same level of quality, and just didn't put the badge on it." Completely legal according to the above. Why would that not sell like hotcakes? Faux exclusivity, marque chauvinism, etc. are certainly selling points for a lot of people, but for what I imagine is majority, it would be a no brainer.1 point

-

I picked up the ST3620 (6498) and, now that you mention it, I can’t remember it being lubricated, or rather, obviously. Maybe it was properly lubricated and not overly so, as you’d think from a Chinese clone. Truth be told, I used it in Mark’s course and the first step was stripping it, so it was neither here or there in my case. I did put it on a Timegrapher prior to stripping, and after assembly, and in both cases the movement performed the same amplitude wise. I’d guess it was then lubricated? Not an overly helpful answer I know, but maybe a good idea to strip, clean and lubricate anyway? We can all use the practice lol1 point

-

1 point

-

You could use protective plastic sheet like when removing hands, possibly?1 point

-

Or the Bergeon set if you're loaded!! https://www.cousinsuk.com/product/press-die-set-bergeon-5500a1 point

-

Plenty of cheap aluminum dies sets on AliX, e.g. https://www.aliexpress.com/item/Free-Shipping-New-25pcs-Watch-Back-Case-Metal-Aluminum-Closer-Press-Dies-Watch-Repair-Tool/32345297702.html1 point

-

The Robur is a great tool but the weakness is the plastic/ bakerlite dies.1 point

-

Lots of people says exactly the opposite, no much feel on a screw type press. Anyway in the context of the question above it's unrealistic to think that a watch owner will spend more on the tool compared to the crystal he's replacing, which possibly will be the first and last.1 point

-

Top die must not turn. If it does, the press is faulty. FYI, we have a dedicated section where it's considered polite for new members to introduce themselves first.1 point

-

Hi Chrisd, I have recently bought the exact type of press shown in the picture after also breaking a die on my cheap lever press. I have then used the screw down press to mod my SKX007 and scratched my sapphire crystal, because the top die turns with the wheel and a decent amount of pressure was needed to put the crystal in place. Is a piece of cloth between crystal and die really the intended solution for this problem or am I using the press wrong? It's a pity, because otherwise the press is so nice and sturdy but if it leaves marks on every crystal and bezel I use it on, it's somewhat useless. Best regards Daniel1 point

-

1 point

-

Has anyone tried one of the Girard Perregaux "Presto" hand-held crystal press, or a similar one? The design looks like it would be resistant to flexing or getting out-of-square, but as I've never even heard anyone discuss this type, and no one seems to make a modern version, I wonder if it's one of those things that just didn't work that well and was consigned to the ash-heap of horological tool history.1 point

-

From what I have heard those cheap types do not line up correctly and you are more likely to break the glass and damage the watch. Buy the best you can afford, a good one if looked after will last a life time.1 point

-

So I traded my jack stands in on the entirety of Horror Freight's watchmaking tooling. I didn't get the spring bar set, or the "watch repair kit", which IIRC was just crappy tweezers, screwdrivers, and quartz battery replacement stuff. I took home the crystal press, the case opener, and the 3x/5x eye loupe. The crystal press, as FLwatchguy73 brought to our attention, appears to be identical to the discount model sold at the horological supply houses, but at about half the price (less if you have one of the ubiquitous 20% coupons, which I just realized I forgot, and a set of recalled jack stands that came with some long forgotten project car or engine or something). I used it to replace the crystal on a Seiko. Meh. It worked reasonably well. I had a helluva time getting it to press straight, and the crystal is a fraction of a mm high on one side if you really look. Still, it seems good enough to keep water out (I left it submerged in a bowl for a half hour or so one night, as that's considerably more water exposure than I'll ever subject it to otherwise). For $15 or whatever, it's good enough. The opener tool is probably also identical to a cheaper model at the horo houses. It's a bit more janky. Tolerances are high enough that the anvils will bow out, and there are other less than great aspects. I wouldn't put it on something I care about scratches on, but for farting around like I'm doing now, it's fine. I have an old brass two point wrench that I'm sure was even cheaper, and I probably prefer it to this one. The eye loupe... That might be the belle of the ball! I have a 4x/7x Bausch & Lomb, and the clip spring is stronger, and it's shaped such that scratching my eyeglass frames isn't likely to be an issue by comparison. The HF version has rubber shrink tubing on a cheap clip with a weak spring. If it's even lightly disturbed, it'll all but fall off. If you can avoid bumping it though, the optics are actually pretty decent. I've gotten some use out of them for the working distance afforded by the 3x lens in comparison to the 4x. Just another inch or two for me to be clumsy in. Worth the $5.1 point

-

I am not sure what are you talking about. Japanese never bought largely in the Swiss industry. Just recently some Chinese and other Asians bought dead brands, and one smaller Swiss movt manufacture. If you want to learn how things are evolving have a read to the below and other articles from the same magazine https://www.europastar.com/watch-knowledge/1004087450-mechanical-who-will-succeed-eta.html Again I am afraid that you have ignorance fueling prejudice. Seiko makes large SS watches because that's what the market demands, last time I checked that is the same other brands are also making. Then if you care about learning one thing or three about Japanese manufacture I suggest that you have a read about past and present Grand Seiko offering, and the long gone time when they were giving the Swiss an hard time at the Chronograph competition using a flat hairspring, before the nice hosts of the venue changed the rules to avoid further loss of face.1 point

-

Depends what type you intend to get. I use the screw down type like the pic. Seems to give you more control but the princible is the same. The smaller die presses down on the inside of the crystal and contracts the outer rim. The watch front is then pressed down onto the crystal. Hold down while undoing the the large wheel. Hopefully the crystal will then be in place. Takes a bit of practise. A small circle of linen will prevent the top die marking the crystal.1 point

-

Currently working on a Gruen Guild, Semithin, 16 jewel, 12s that is in nice shape for it's age. Seemed like it was just dirty and dry but I've found what might be a problem with the banking pins. One of the pins is bent over quite a bit and has a gouge on the pallet fork side of the pin that pretty clearly shows it was bent over on purpose. The other pin looks a little bent too but not as much. I don't know if I should clean and lubricate the movement and see how (or if) it runs or try to straighten the bent pin while reassembling. The roller jewel seems to line up between the pins but the fork swings much further on the side with the bent pin. One thing I've never done, as I've pursued learning watch repair at my hobby level, is try to adjust banking pins on any other work I've done, and I have very little knowledge of checking the run to banking. The pins appear to be pressed in to the plate and not adjustable. Any help is greatly appreciated.1 point

-

I don't recommend that one, because the pressing force is not in between the pillars, so it tends to flex. Better to have cast strong body as others that were featured before.1 point

-

I have the following one at link, or it's similar—lots of knock-offs from China. It beats spending hundreds if this is a hobby like it is for me. This is a cheap alternative that works very well.1 point

-

We have a lot of people here using hand held and bench Chinese presses. No reports of breakage or other problems, generally these are great for beginners. Isn't always necessary to spend a lot on tools. I have an Anchor copy of MKS screw type, works good and has a sturdy build, link is a previous posting in this thread. For the ease of finding info I have merged various threads in a pinned topic. Some generic postings moved to another thread. Please stay on topic: Crystal press advice1 point

-

I wish I could help you Jim, but this is one I have never seen never mind come across. You do get ten out of ten for the best description of losing a part yet, it describes my reaction when this happens perfectly! Just as an aside, I haven't lost a jewel cap or retaining spring since I started using a jewel "Picker Upper".1 point