Leaderboard

Popular Content

Showing content with the highest reputation on 03/18/21 in all areas

-

I enhance the picture of your regulator pin. Are you sure it actually had two pins? In other words was there a hole for the other regulator pin? Because looking at the picture it looks like one pin only? One pin will work fine if the hairspring never leaves the pin. Then what kind the timekeeping area expecting from this watch?2 points

-

You might find the discussions found at the link below interesting as it relates to your question. https://www.watchrepairtalk.com/topic/16140-tissot-27b-21-guidance/ https://www.watchrepairtalk.com/topic/17980-omega-234-sc-seconds-wheel/#comment-1542402 points

-

Another video I watched of his after polishing the plates of a English Longcase clock he coats them in clear plastic. I don't care how long he has been repairing clocks going by his videos he is a menace to horology.2 points

-

If you happen to bend the driver arbour the slightest, you have created a problem of depthing between the driver and seconds wheel, so if you have not yet mastered fitting the wheel on arbour with your staking set, I think twice ..... I have seen driver wheels get loose off the arbour specially in cases that driver wheel has previously been removed/ replaced couple times, even peening the center hole on the driver wheel doesn't gurantee much. In my neck of the woods, the wheel usually gets replaced with a new one on high end watches. So if side shake on the arbour isn't alerting and all else checks out alright, why bother or creat a problem for yourself, you can always go back if your TG said something is wrong. I usually inspect the hole arbour goes in, under good magnification for signs of previous removals. Regs Joe2 points

-

Greetings, I fell in love with this watch the minute I saw the dial (no pun intended) and bought it at auction basically without having any idea about its provenance. I’m not sure all the bits and pieces are original. I was hoping someone might have some thoughts about its history. I am fine if it’s some sort of bizarre combination of GP parts. I confess to wanting to replace the case with something a bit sturdier; but won’t do it if that’s the original case. (The crown is unsigned and the steel case just feels wrong somehow.) Anyway, here are some pictures (sorry (1) one photo is sideways and (2)I forgot to take a photo of the inside of the case back).1 point

-

1 point

-

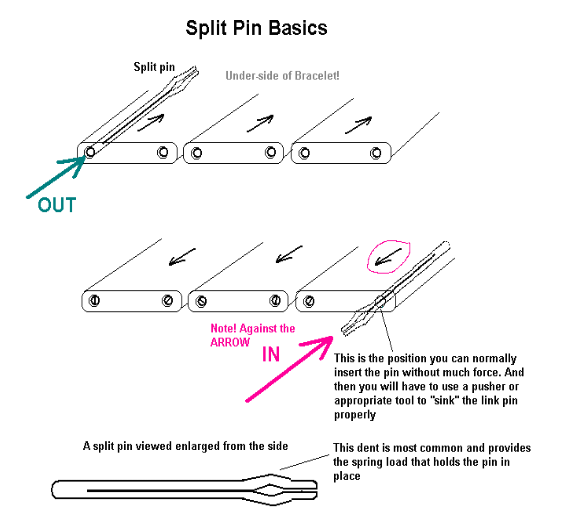

It might look like a screw but far more likely it's the end of a split pin. Look from the other side ... is it smooth? Whilst you could push it out with a thin piece of metal (e.g. a paperclip) it's best to use a proper tool. They're pretty inexpensive; look on ebay for 'watch bracelet pin remover'.1 point

-

1 point

-

I'll look into that....thanks....although I can't guarantee it will be great quality. You mean with the regulator in different positions right?1 point

-

Agree...that is essentially my point. The noise performance of the electronics is kinda moot for this application.1 point

-

1 point

-

Hi It’s quite probable that the clothes we wear contain man made fibres like nylon rayon etc and the atmospheric conditions were intensified leading you to charged to a degree it has affected the oil. Not knowing te composition of the oil I suspect It is synthetic which would likely make it worse. Tho only way of stopping it is use a grounding strap and mat, that way both you and the watch will be at the same potential and hopefully sort the problem. When I was at work servicing Mainframe computers, as the machine was running tests I walked across to replace a side panel and killed the machine had to replace the whole cabinet. Found out later from the factory it had blown some components on the base board. Static can be deadly in more ways than one.1 point

-

1 point

-

1 point

-

Thanks Nickelsilver but it's a three arm balance . I really enjoy that old school eyeball method and can get a great result at Plus or Minus 50 degrees !?1 point

-

Hi Suggest you take a look at Ranfft for the 255 and its family models and then check the family with the watchguys lift angles as All the sites I checked out did not have the 255 listed on is own1 point

-

If your putting your work up to public scrutiny you should ensure your methods are sound, I can only judge what he has presented as his work in the video, it is not good, I'm a learner I known some things I do are wrong or unsound but I endeavour to improve, I wince at the method he uses to remove the pins in the clock he rives them out with a pair of pliers that are far too large, I know that those plates will now be scratched on the edges, he bangs the barrel arbors on a metal vice to release the caps, I know the ends will now be dented, he tells people they do not need a mainspring winder and yanks them from the barrel he then puts them on the table and they are clearly out of shape, and coned. He separates the plates holding the movement at an angle with no regard to the wheels and pivots. Any criticism is of his own doing by presenting bad working practices as an example of his work and telling people this is how you do it what can he expect.1 point

-

Do you have any photos of the movement? What positions is it running fast, and how fast? How did you clean the hairspring? Did you demagnetize it?1 point

-

I find it really strange. I went to his website to further research his credentials. He is a 3rd generation clockmaker, qualified horologist with over 40 years of experience. His family business is over 100 yrs old. He has customers singing praises about his work. I have not found any negative comments. Is it fair to judge him from a fews videos on YouTube. I would hold off passing judgment lest judgement be passed on me.1 point

-

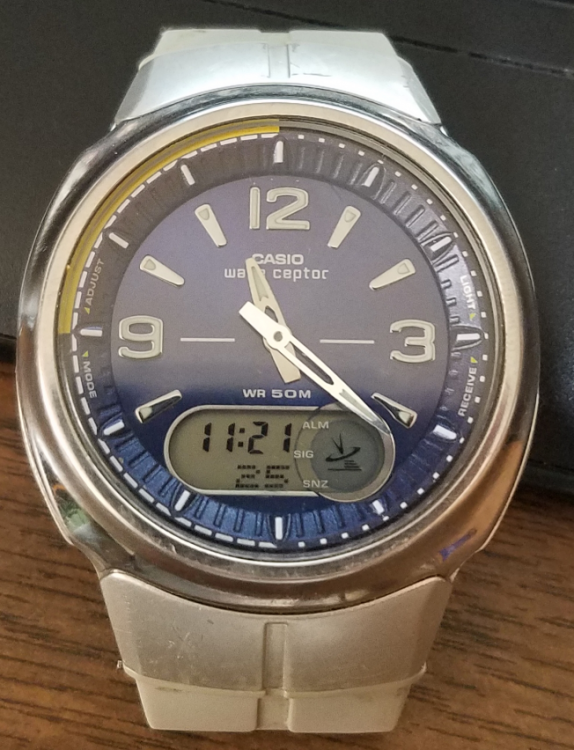

I got this watch years ago. Some time after that it quit working. Then I tossed it into the watch bench that ways dormant. Sat there for years. After I learned about accelerating hands using my demag, I decided to try spinning the hands on this watch. Yay...they spun. So, I installed a battery went through the setup procedure and set the time. Now it is working fine. Receives WWV and calibrates itself. Now I need to get a band for it. I do not know what I did with the one that was on it.1 point

-

Completely unrelated to anything to do with watches or clocks, but as you might observed, there have been a few hints about flying "toys" in this thread. I picked up a bunch of Eachine E58 drones. I blame covid related lockdown boredom. I wouldn't claim to be actually "dangerously" bored, but I've been sailing pretty close to that level of boredom. These are not what you might call "real" drones, but none the less they are quite impressive little gadgets. A quadcopter with built in multi-axis gyroscope, barometer, wifi camera and 2.4GHz remote control that has a claimed range of around 100m. You can also control them from your mobile phone, and watch the action on the camera in real time. They look a lot like a DJI Mavic Pro, but about 1/4 of the size. They are in fact tiny, as you can see from this picture. The real DJI Drone has a proper camera with gimbal stabilisation and GPS positioning which the toy lacks. It can also fly for around 3 miles and about 30 minutes on a charge, whereas the E58 manages less than 10 minutes. The E58 on the other hand doesn't cost the best part of a thousand pounds, and will fit in the palm of your hand. It even folds up really tiny to sit snugly in the small zippered travel bag it ships with. Here it is next to a 9V battery for scale. It doesn't use a 9V battery, I just had one lying around. In fact they uses a proprietary 3.7V LiPo battery in the drone and three AA batteries in the remote) Naturally, being me, I didn't buy a working drone, but rather a job-lot of four dead ones for around twenty quid. The Eachine E58 retails on Amazon for about £75 each including three custom LiPo batteries (and the bunch I got actually included seven batteries), so I figured if I could make at least one work, then I would have had my money's worth. As it happens I have three of them working and the fourth one, (which is actually a slightly different design, and claims to have a 4K camera.. I'll bet it 'aint really 4K) is awaiting a motor and some SMD transistors (and some minor brain surgery), so it looks like I've done reasonably well with this particular pile of junk. I'll probably give at leat one, maybe two away to my brother, so his kids can play with it/them. They are held together with lots of tiny screws, and my watchmakers tools are perfect for performing surgery on them. Surprisingly, considering they are mass produced toys, there are many sellers on ebay and aliexpress selling the parts for them, and the parts are dirt cheap. I replaced a couple of motors, a couple of gears, one battery connector, re-fitted a couple of loose motor connectors, and un-mangled the joysticks on one of the remotes. The total cost of all of the spares was probably just under a tenner, shipped from China. Admittedly I had to wait a while for them to ship, but I was in no hurry. Here is some random Youtuber playing with one. I also picked up a larger Syma X8 series and a tiny little Syma X12 series quadcopter too. The first for three quid, and the latter for a pound. So if you are looking for a little light amusement during lockdown, you could do worse than pick up a few dead drones to mess about with. Now place your bets ladies and gentlemen. How long will it will take me to knock some "important" trinket from one of the bookshelves and get myself relegated to the dog house. Maybe I am "Dangerously Bored" after all. ?1 point

-

OK I admit it isn't the next morning, but I hope this answers the question. The lens tube unscrews into various bits and the base can be removed from the turret using a set/grub screw. At least this is the case with the version I have. From what I have seen online, there are quite a few variations with similar designs though.1 point

-

Interesting. Could be static electricity? If you do get charged and are holding a very fine wire, all the charge will try and earth through the end of the oiler. It's like a lightning conductor in reverse! Is the weather dry, and are you sitting on a synthetic seat ? If so, every time you slide about you could be charging up. My seat is nylon, If I slide off and touch the bathroom tap I can feel a slight spark as I earth. Shocking1 point

-

There are different Bergeon Presto type tools for wheels with 5 and 6 spokes. They do a cheaper option : https://www.cousinsuk.com/product/wheel-hand-roller-remover-bergeon I have removed them by using razor blades slid under the wheel (and some tissue paper to protect the bridge) Or, as @Nucejoe suggests, leave them attached to the bridge if you can.1 point

-

Dr ranfft reffers to this as " independently driven minute wheel". Following the tear down, I put the train bridge ( with this wheel attached) back on the mainplate, give it four cleans in ultrasonic and call it cleaned. I do not remove this wheel unless there is a need to replace a faulty part. what kinda side shake on the driver arbour do you feel? Do you have a staking set?1 point

-

I think this is the driving wheel for the center second. It is friction fitted to the third wheel and can best be removed with a special Bergeon tool: https://www.bergeon.swiss/outil-presto-1857.html1 point

-

A nice watch! Replacement hands are easy to come by, as are replacement crystals. Bezels are a different story. You might contact Don Barrett at City Bank Antiques in Ohio. He has a good reputation among NAWCC members for his epic stash of hunter case bezels. (He would also replace the crystal if you wished, which is probably worth it.)1 point

-

I've had this happen. I cleaned out the oil pot, new oil, and it was gone.1 point

-

As OH says what type of oiler and what brand of oil are you using.1 point

-

That's really weird. It shouldn't be due to static because your other hand would be touching the movement and would have grounded it to the same potential. Keep us informed. This should be interesting.1 point

-

You have to have a very steady hand when working on watches. What type of oiler are you using?1 point

-

I'm more of a coffee drinker meself, but I have grown a marked fondness for Indian Chai. With honey and milk.1 point

-

Dear all, unfortunately I don't have a lantern in my Jacot set. But here is what I did (stupid enough I deleted most of the pictures of the arbour in the lathe). My lathe motor's slowest is 300 revs. That's still too much so I took my bow and turned the lathe by hand. I mounted the pinion in a 1.2 mm chuck very carefully. Instead of a pegwood I used a rubber polishing stick the jewellers sometimes use and put that in the tailstock. Here is a video I didn't delete VID_20210120_131627.mp4 For those interested they are called "EVE Pin Polishers" and are made by company here in Germany called ERNST VETTER GmbH. And here is the result: Not half bad. @Nucejoe: Altough I've never pulled off a wheel from an extended 3rd wheel before I thought "...that's what I call a loose fit, that is". Felt absolutely no resistance when levering it off with the Presto-for-5-spokes. I can see your point. Thanks and all the best Alex1 point

-

Joe, I know you have this feeling that drive wheels on an extended 3rd wheel pivot go flying around but I gotta say in 20+ years I've never opened a watch with a loose drive wheel and never had a comeback from taking one off and refitting it. The forces here are tiny, and just a little friction is needed. Hands are usually fitted much tighter. As to cleaning up that pinion, it could easily go in a jacot with an appropriate carrier (drive dog) in a lantern, and polished up with either a thin burnisher or polishing paste on pegwood. It definitely needs some cleaning up. If you have a lathe, try chucking the pinion in the headstock, the a piece of pegwood in the tailstock, run the lathe slowly and hold the long spindly bit true with brass tweezers while you bring up the chucked pegwood. Should bore into it, then provide enough support to do the finishing work near the pinion. If the far pivot end is also manky (looks ok in photo) just twirling some pegwood down it should clean it up. Continue pushing the tailstock pegwood in the above example should work.1 point

-

1 point

-

1 point

-

You could use tools like Bergeon # 3 which will do the work most of the times like on this one. If the pivot is slightly longer and thinner you would use a tool like the Bergeon 6016. With this you put the thin small points under the wheel while pushing and at the same time twisting the handle. Then we have the less preferred style, put two screwdrivers underneath the wheel and twist them around. If you choose this method just remember toput something underneath so you don’t scratch and make a mess out of the movement.1 point

-

New one to me. My first Seiko Ana/Digi Should be a fun refurb [emoji4]1 point

-

Scored my first Hamilton Khaki used for a decent price ! Should receive it sometime next week. Not the best pictures but looks in decent enough condition and will serve as a "plug and go" watch for me that I won't have to baby !1 point

-

1 point

-

0 points

.thumb.jpg.cdc9a547085e79d2a78650622e4edb82.jpg)