Leaderboard

Popular Content

Showing content with the highest reputation on 12/23/20 in all areas

-

If my dad were still alive, he would be 105 yrs old. When he passed, I got the majority of his gear--watch bench, lathe, staking sets, hand tools, etc. These are in one room of my house--I call it the lab...you see...I am an electrical engineer (Ph.D). The other stuff in the room are electronic in nature (soldering/desoldering station, parts bins, microscope, oscilloscope...etc.) My dad owned a business in Houston, TX for 50+ years. He wanted me to follow in his footsteps but I chose engineering. In addition to all of the tools, I inherited lots of old watches. Many were left at his business and never picked up for reasons unknown. Some, I think he may have bought from customers as an investment--mostly pocket watches. Not sure. So as time has crept up on me, I have felt this urge to return to my roots. I am retired (although I do sell some of my time as a consultant--expert witness). I have been digging through the old watches and finding a few gems. One, in particular, inspired me to open it up to investigate a problem with the date ring. The process has given me a deep appreciation for the life my dad lead as a watch technician. The problem is not solved yet, but I will not give up!! It is fun, though scary!! When I was a kid, my dad gave me all of his clock work. I would repair clocks to earn money to buy guitar strings, music, and other things a 15-yr old would buy in the 60's. Wonderful memories. Now I have discovered this forum and am looking forward to reading about the experiences of watchmakers and hobbyist on this site. Thank you for having me!!!4 points

-

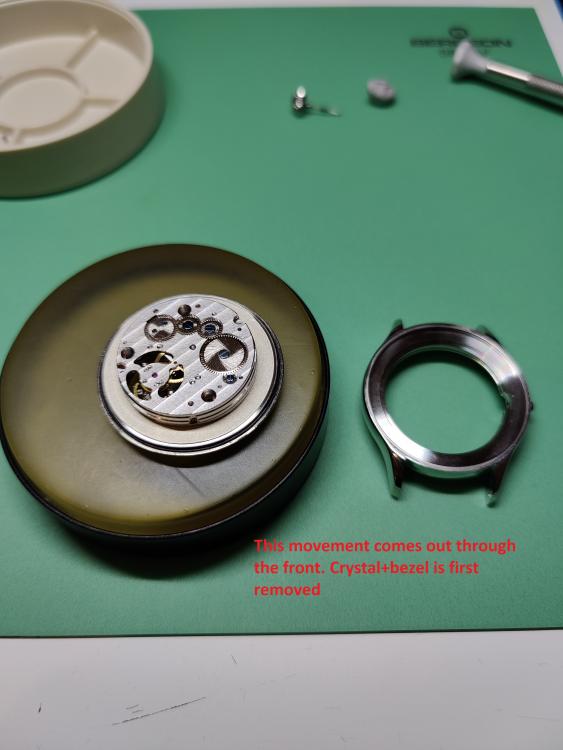

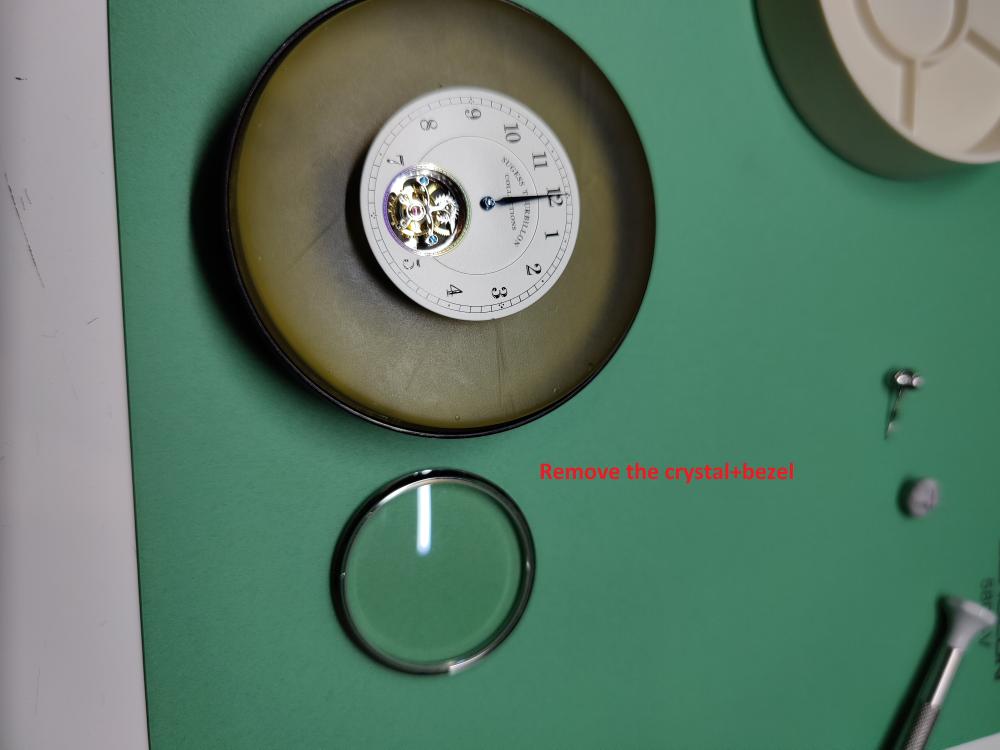

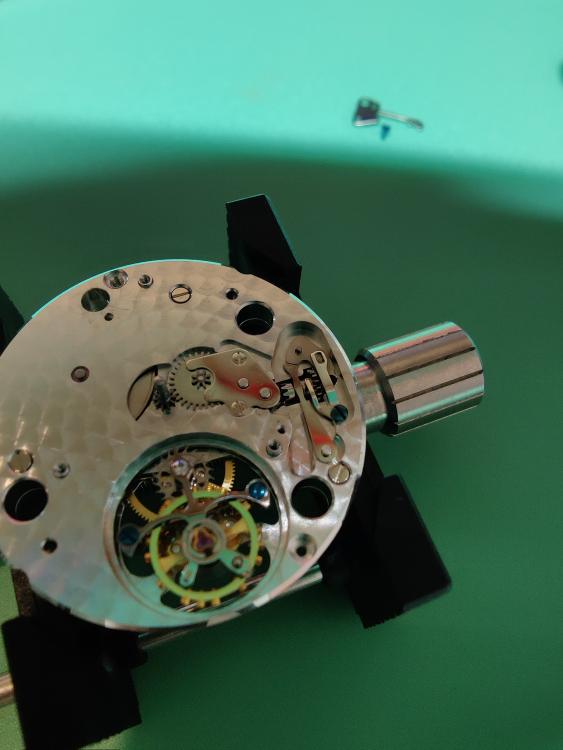

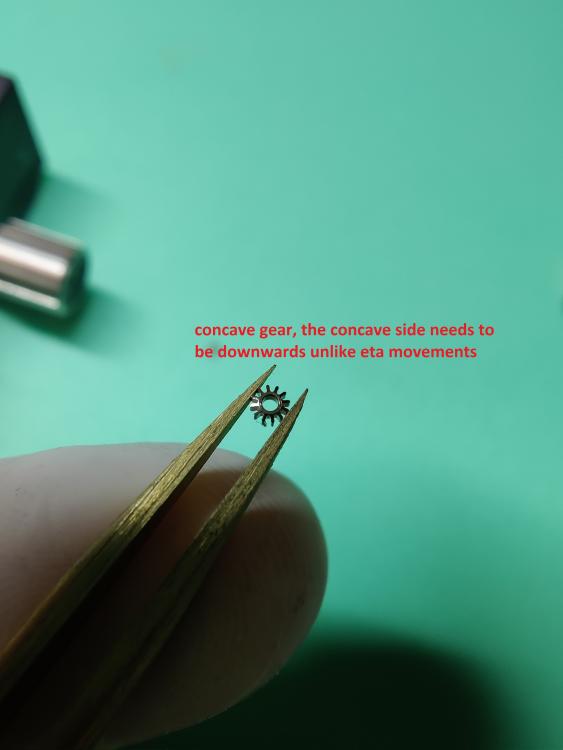

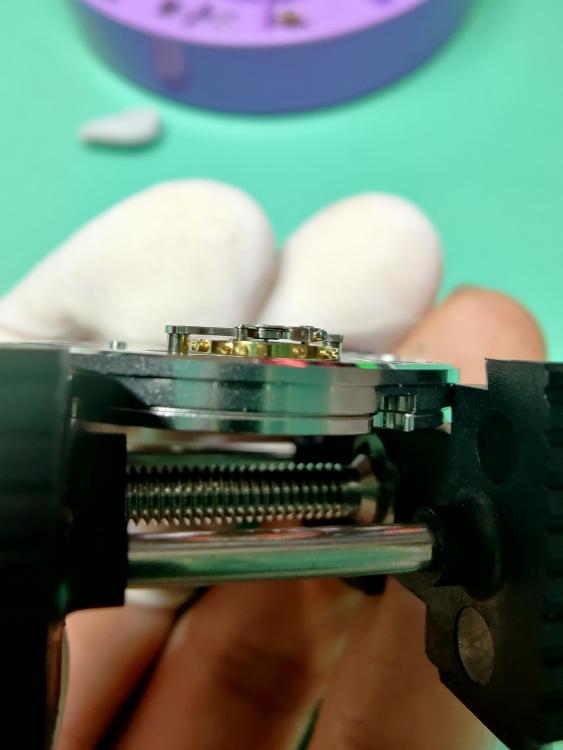

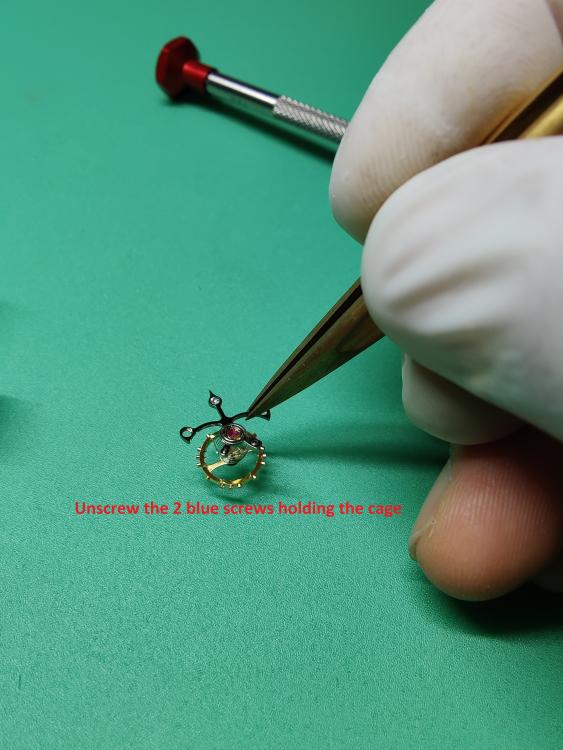

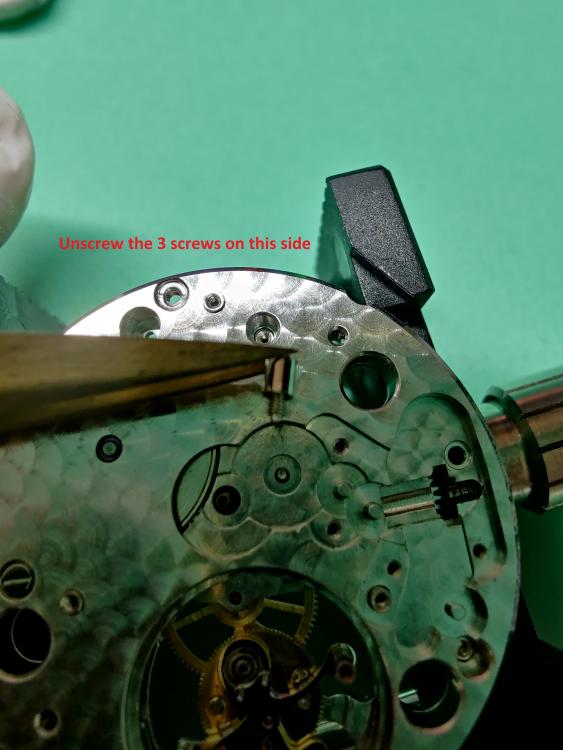

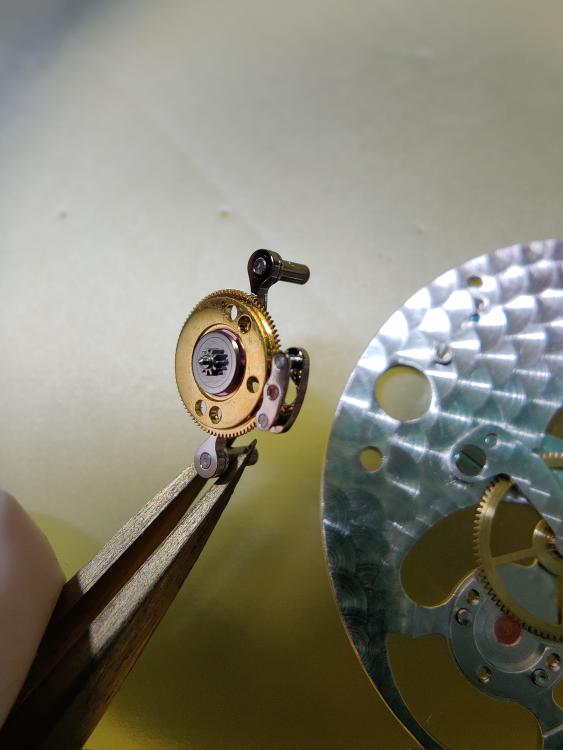

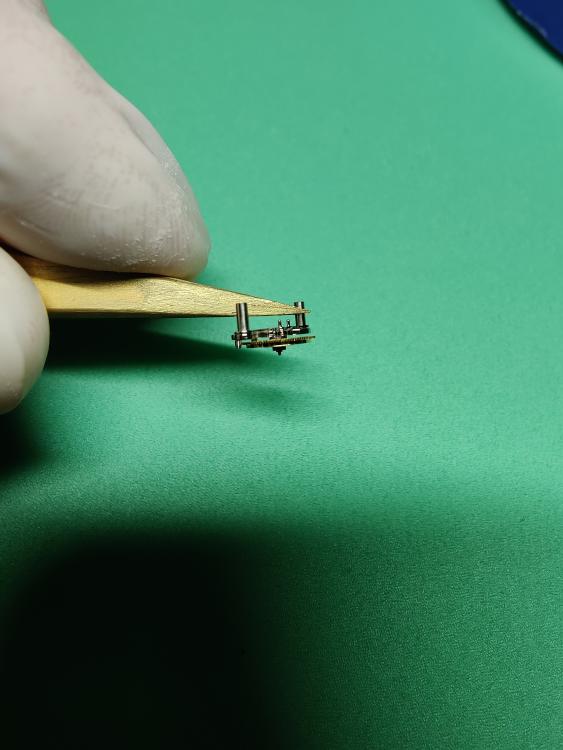

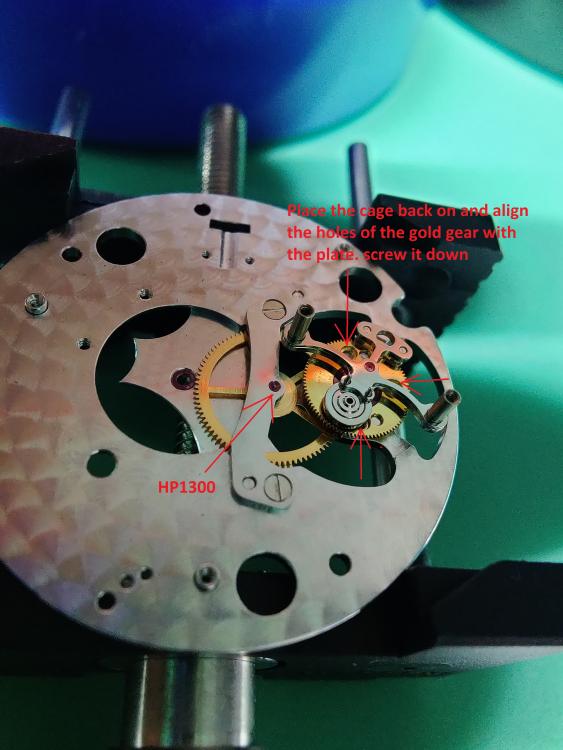

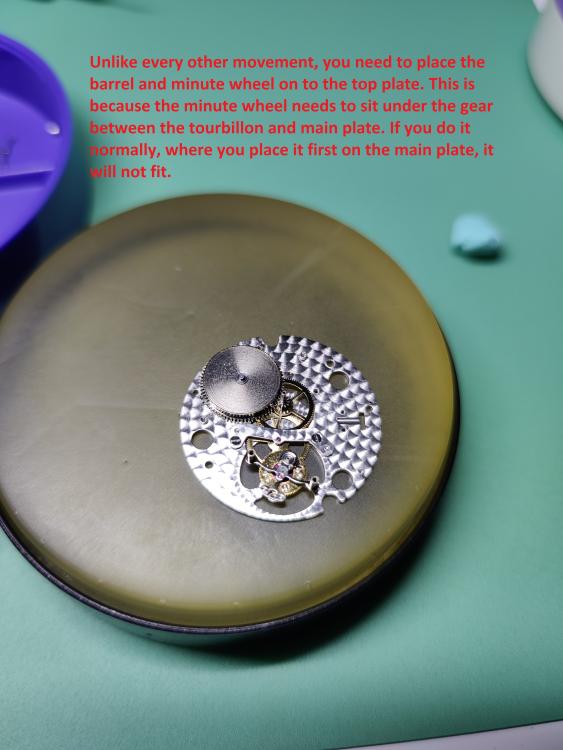

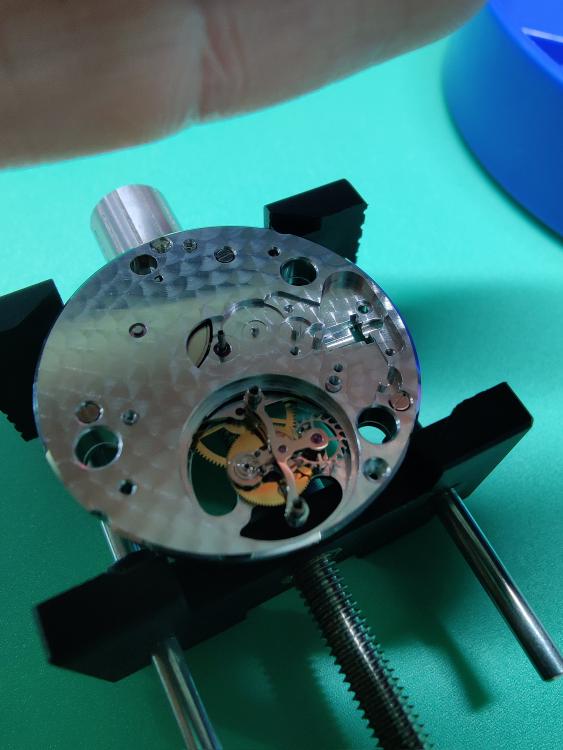

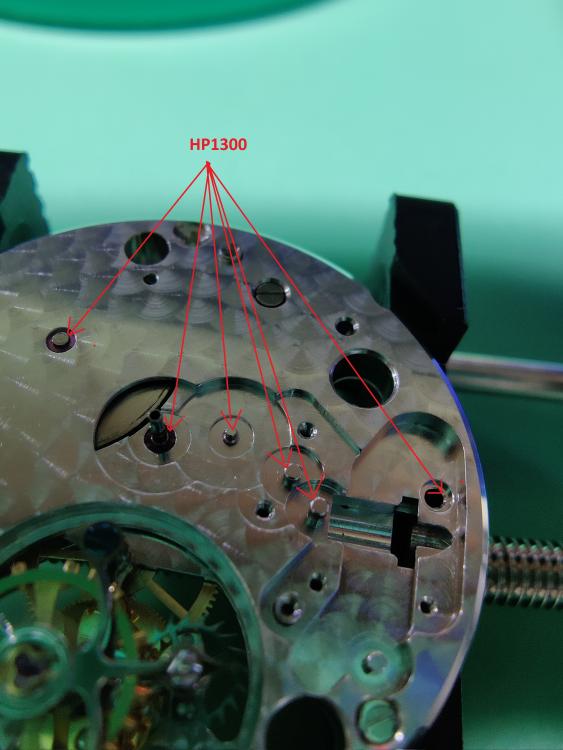

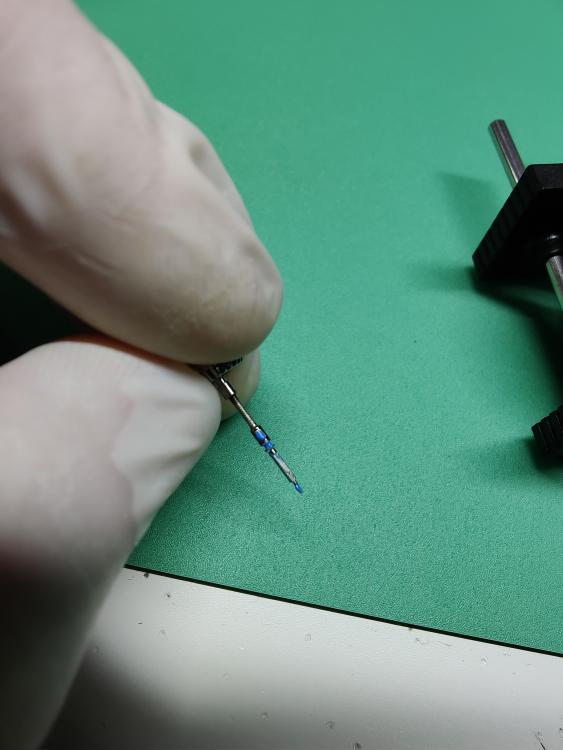

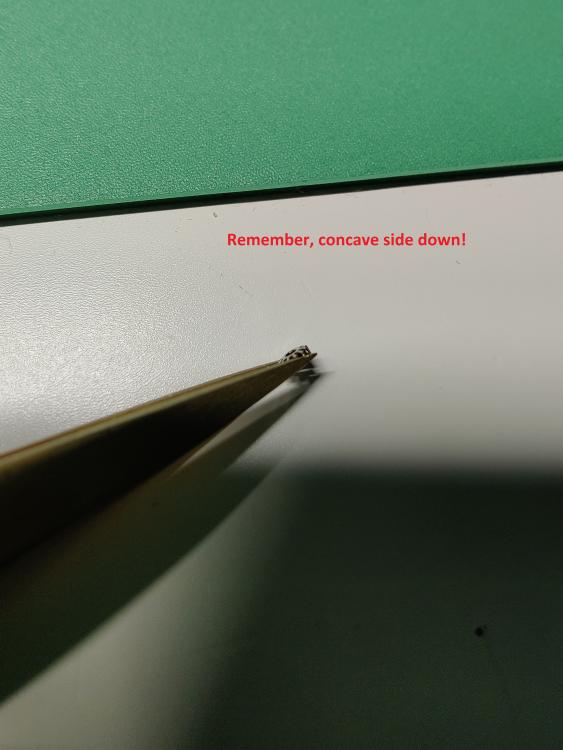

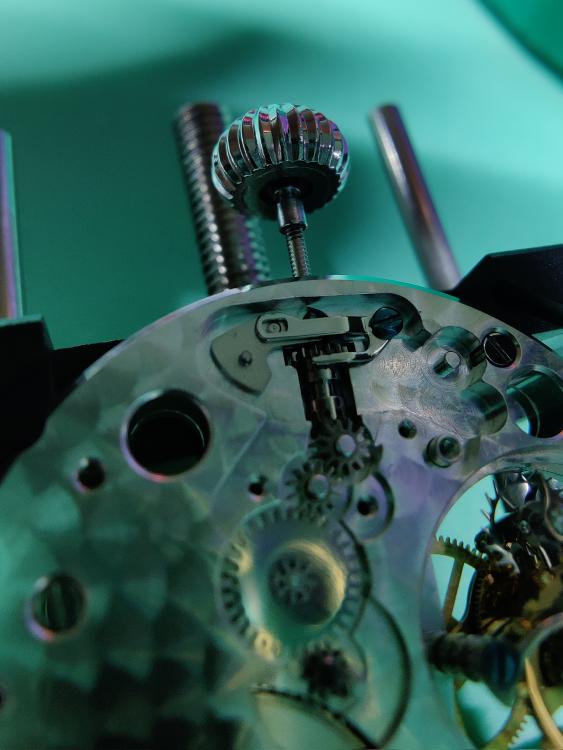

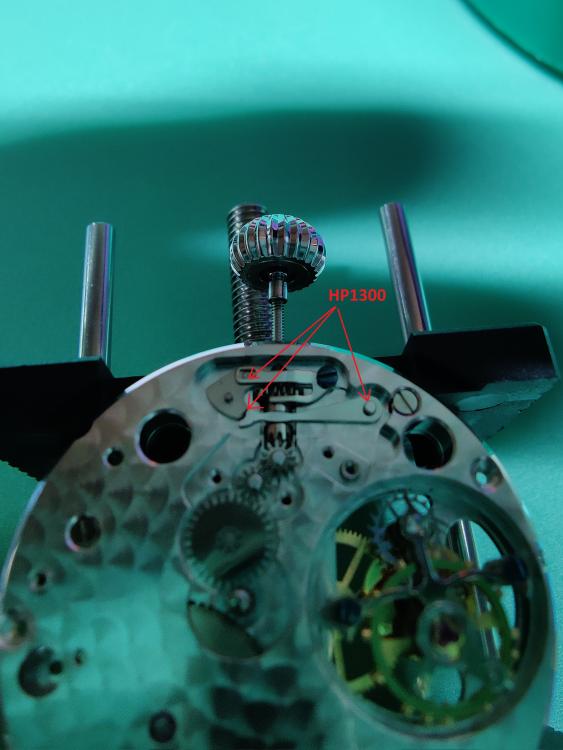

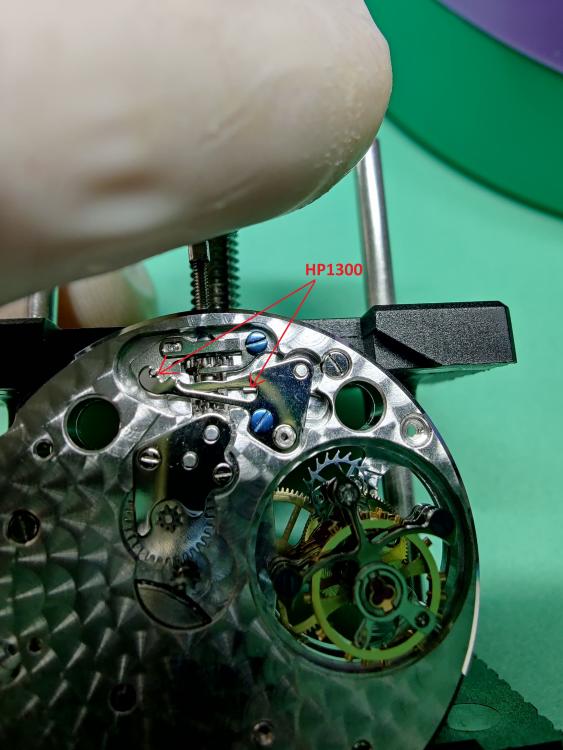

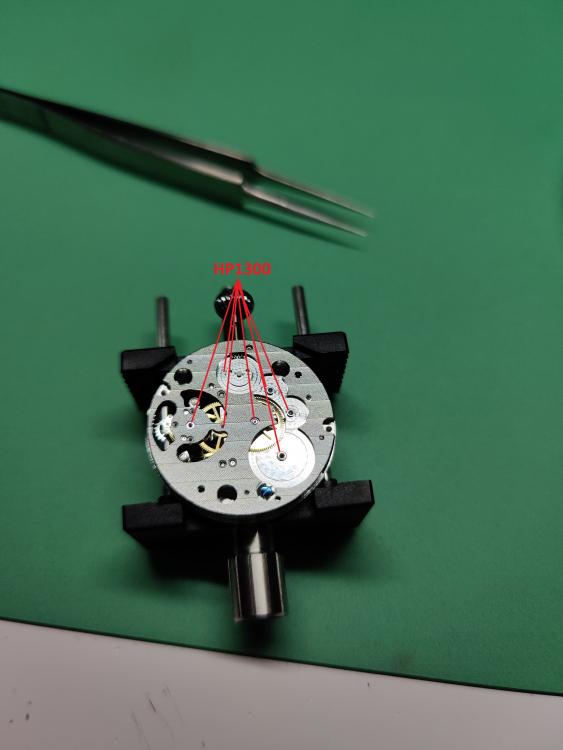

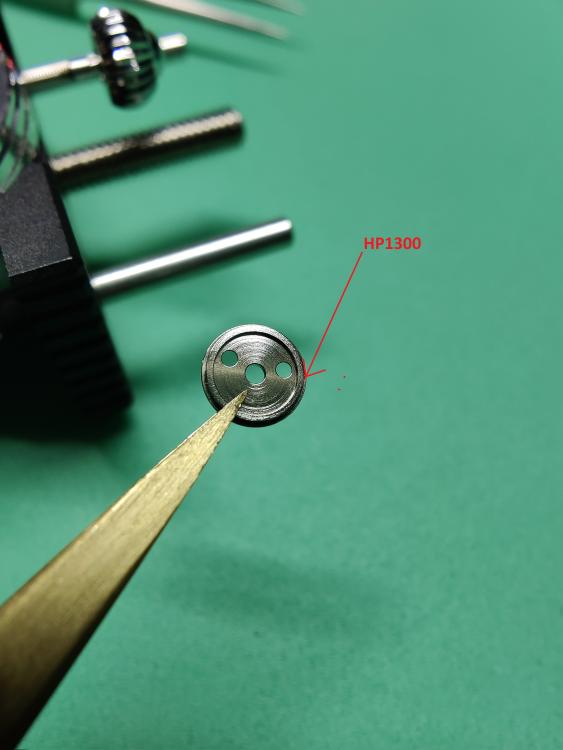

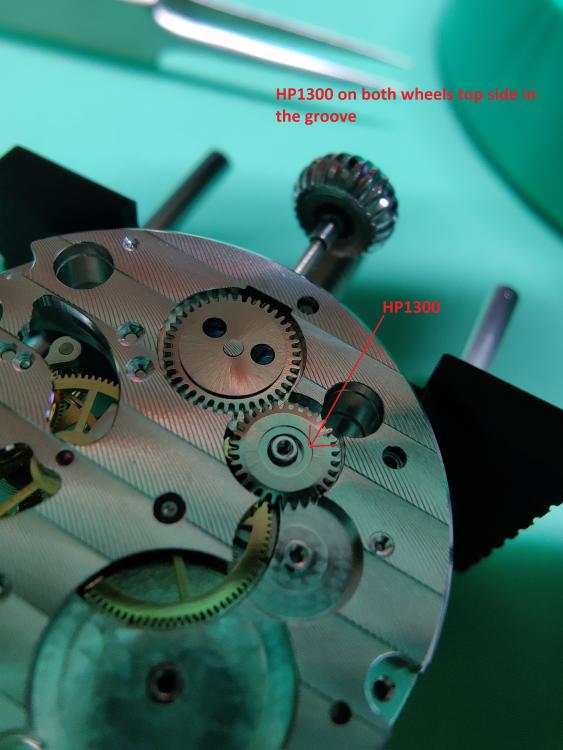

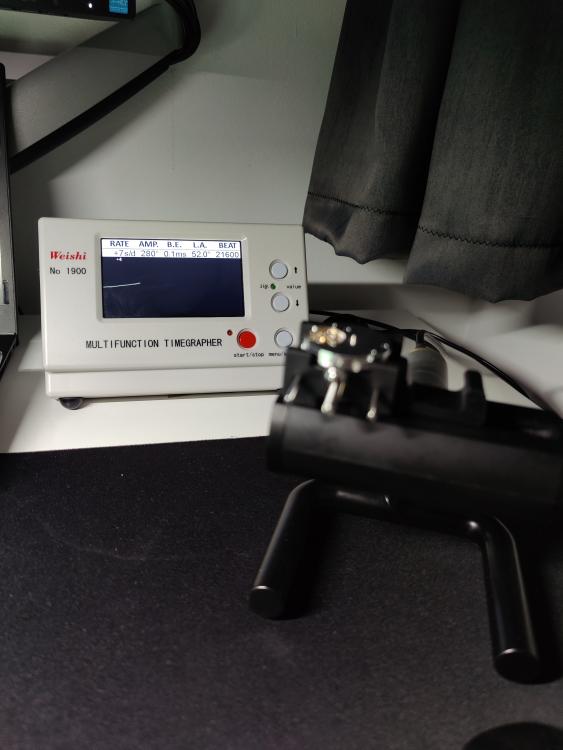

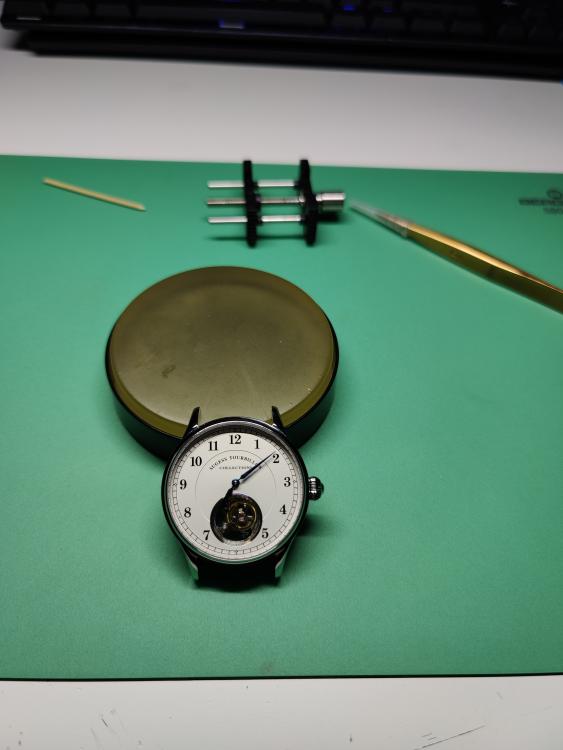

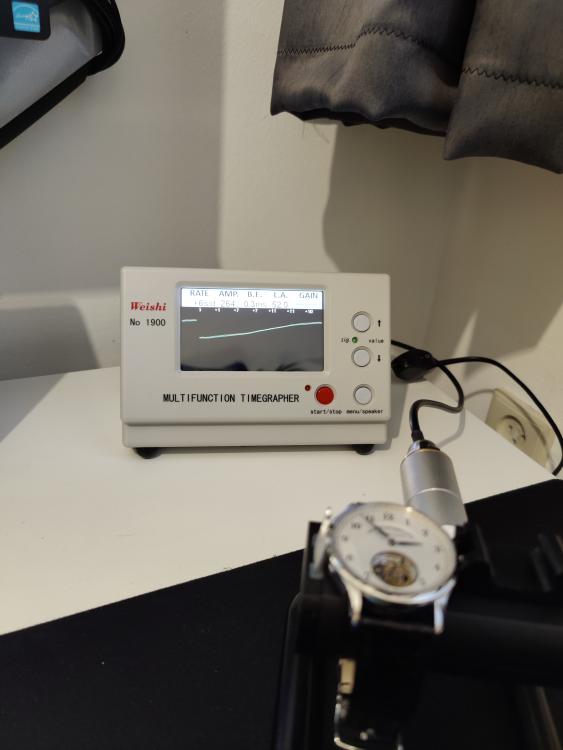

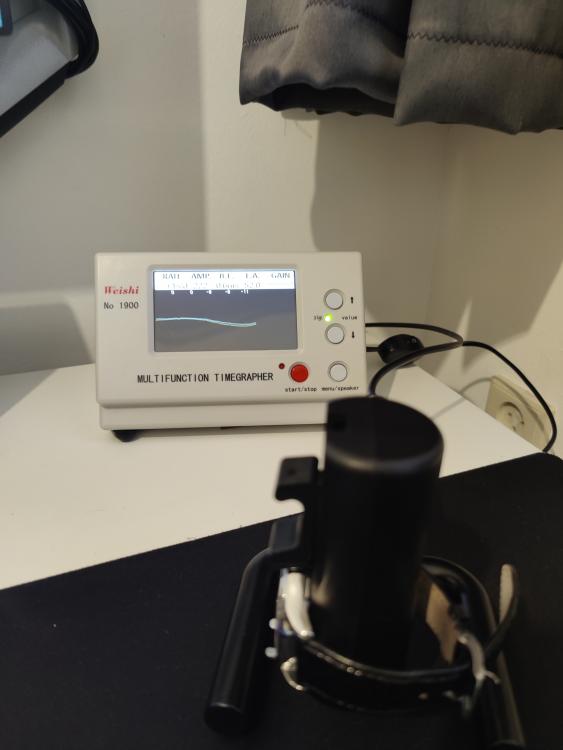

Hi all, Since it was impossible to find a how-to guide for servicing a tourbillon (in this case the seagull ST8000) on the internet, I decided to create one myself and share it on a couple of places on the internet. I hope you guys enjoy it and it will help you in the future. There are basically 2 types of tourbillons (other than multi-axles ones) 1. The brequet carroussel type (big balance wheel, turns 360 degrees around his own axle in 1 minute) 2. the blancpain flying type (the whole escapement and balance turn 360 degrees in circles like a planet in a minute) This is the blancpain version and is made by Seagull. I purchased this watch myself, both for the beautiful looks of an tourbillon and to do a service Conclusion: The tourbillon cage can be tricky as it requires balancing multiple loose parts before they can be screwed tight. Timegrapher cannot be used on tourbillons as the moving of the cage+balance will give readings going up and down at the same time, same goes for amplitude. Current timegrapher are just not made for tourbillon timing. It can only be timed in an old fashioned way, after 24h's checking. The ST8000 is very well made, be it Chinese. Finishing of gears and plates together with the thickness of materials makes it sturdy and built to last.4 points

-

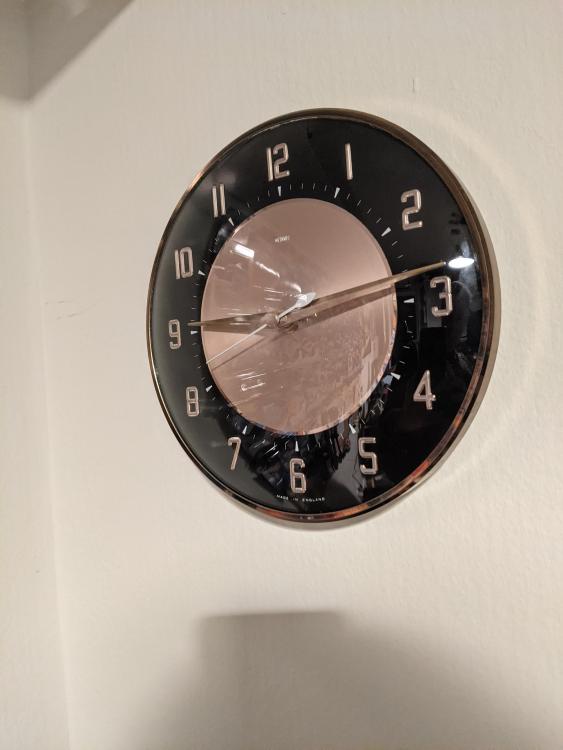

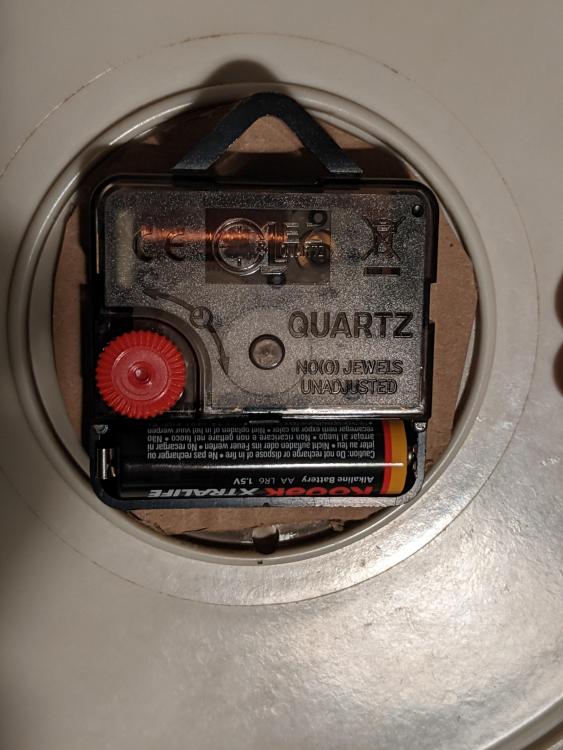

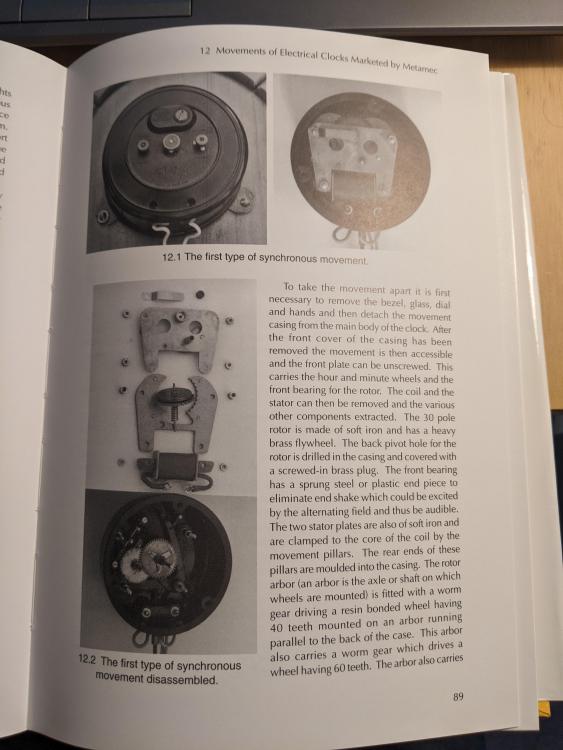

Nice to see a Metamec here ? I've got a couple of dozen Metamecs of various types, many mains synchronous, but also quartz and clockwork. My Metamec habit pre-dates my interest in watches by about 15 years!, even have a book about them somewhere. Many rooms in my house have a Metamec. I have a fair few wooden ones, but I like the 'mid century' plastic and metal best. Selection shown here (including a crazy 'eye' clock with built in lamp), most would fit the '404 club' rules (having been bought very cheaply 15-20 years ago). Mains synchronous is a clever method, basically, you allow the power generator to keep the time for you ? (they are required to keep the average at 50Hz in the UK, there can be a little drift depending on demand, but they put it right again later in the day if that is the case) there is little to go wrong with the movements (most you pick up will still work) and the clock will stay super accurate (especially compared to clockwork or pre quartz battery movements) Easily within 60s/year. Also, they are very quiet, and you get a super smooth sweeping second hand as the movement doesn't 'tick'. British houses in the 50's and 60's often had outlets for them high on the wall (about 1.5" square) which would be hidden behind the clock. This went out of fashion as clocks became cheaper and quartz came on the scene. The technology still works just fine and for a 'sideboard clock' is still useable, but for wall clocks you end up with an ugly trailing wire from a normal socket. Which isn't so good! For a few years I have been modding the mains synchronous wall clocks to use generic £3/£4 chinese quartz movements to get them back into use, the ones I use are smooth sweeping despite being quartz to keep the original look as best I can. The spindles are not compatible with the old hands though, so I select hour/minute hands that match the originals as well as possible, the original second hand can be reused by replacing the tubes with one from a new hand.3 points

-

I am in a serious you or me fight with an M21 movement at the moment. It seems that the movement is going to triumph over me - a clean and lube action i hoped for turned into sleepless nights, with hairsping bending and unbending, and i put the mainplate back now as easy as other ppl eat porridge for breakfast, a task i thought is impossible before - , there is still hope for me to win though. Whatever happens, there is a love between the two of us and it will stay there forever. ?2 points

-

The 404 club membership committee (me) debated long and hard, well in to the night and have decided to allow clocks under the extensive 404 club rules and regulations, so here is the first new member under the new rules. A relatively early Metamec synchronous mains, brush finished brass and mahogany mantle clock (serial number 60). I would guess its age as anything from the late fifties to the mid to late seventies, as this model had a long production run, even sporting a later quartz variant, which looks almost identical other than the Kienzle quartz mechanism and a "Quartz" designation on the dial. The mains synchronous motor and gearbox mechanism got a good clean and lubrication and the case, woodwork, plexiglass and brass all got treated to a bath and some polish. I had to re-finish the brushed brass as it was so heavily darkened and the lacquer so badly stained that it looked terrible. I should have taken some pictures of the works of this thing as it is a little more interesting than your average quartz mechanism. Maybe I'll take some pictures of the interior when I get around to lacquering the brass. it is virtually silent and has a nice smooth sweeping second hand, on account of the 50hz "tick" from the mains. It should be fairly accurate apparently, but that all depends on how well my local mains frequency is maintained. As you can see I added a modern two core moulded plug mains cord in place of the slightly dodgy looking existing wires (which were black and red, suggesting the thing was originally wired before the early 1970s). I should really use a 1A fuse, but I only had a 3A. I'll pick some up next time I'm ordering stuff.2 points

-

1 point

-

My 13 year old son is very much into computer coding and has moved so far beyond my coding ability that I don't understand half of what he is telling me he is doing now, but I thought I would post a picture of a project he did over the weekend. But first I need to mention he is a big fan of aircraft clocks and very quickly took my Russian AChS-1 'MIG clock' to sit beside his computer and then when I restored my WWII German Kienzle aircraft clock he very quickly grabbed that one too. But back to my son's project. He has always wanted an analogue dial in the style of an aircraft clock to display the CPU temperature of his computer, so he decided this would be his weekend project. I found him a micro servo in one of my drawers left over from my RC plane days and gave it to him. He then wrote a C# sharp program for his computer that runs in the system tray and reads the temperature of the CPU and passes this value out on one of the USB ports to an Arduino he had programmed to read this value and drive the servo with a PWM output. He then designed a dial inspired by the 'Mig Clock' at half scale on Fusion 360 which he made sure the dial size would fit one of my larger spare watch crystals. We then 3D printed it on Sunday and he then designed a dial to fit it and finally I fitted the watch crystal to it for him tonight and here is the finished product. He now has the C# program running on his computer passing the CPU values to an Arduino driving his analogue CPU temp gauge. He has plans to expand this and create another gauge for the GPU temperature now and is talking about changing the case design to incorporate an RGB LED, so it can shine blue, green or red depending on how hot it is. When I was 13 I did enjoy coding in 'BASIC', but never did anything that complicated. How times have changed. Tony1 point

-

Hi you could try a dedicated Omega forum, Its the most likly place to find such a document.1 point

-

I need an exact replacement, no dial spots or anything. I didn't think it was possible, just checking! the 1L02 would need 1 dial spot. I appreciate the help!!1 point

-

Hi @Tmuir, I'm a professional computer games programmer with over 27 years in the industry and 36 years of programming experience. I volunteer in schools teaching coding, tech and trying to inspire young minds. If your kid needs any coding advice or has questions about the industry PM me and I'd be more than happy to help.1 point

-

1 point

-

1 point

-

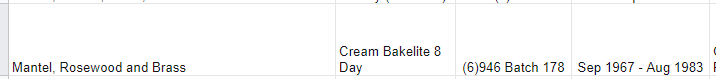

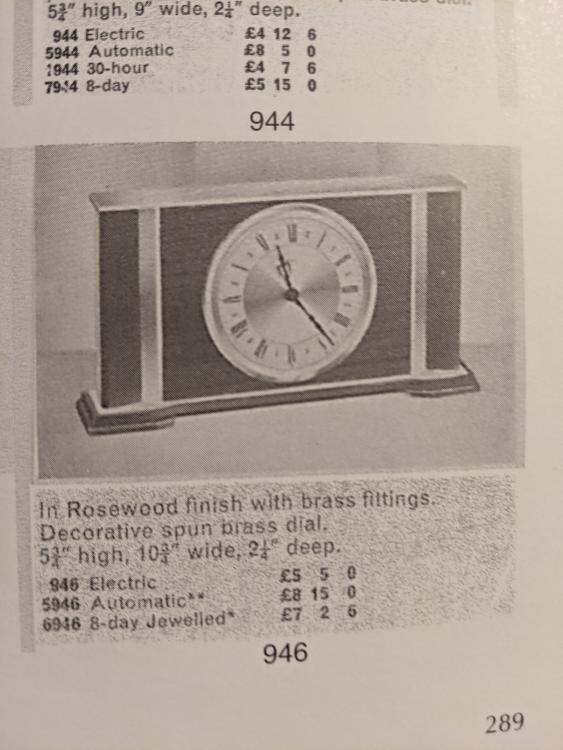

Yes, datewise, I was puzzled by the fact yours had an older bakelite cover version of the movement too, you are quite right, I thought they were using plastic covers on a more compact movement revision (like the one in my picture of the wall clock) by the mid sixties, so maybe yours isn't a '946' as described but a preceding variant, I don't think it can be just '60' though as so far as I can tell, they never used 2 digit model numbers at any point, they were always at least 3. I think the stamped 60 is more likely to be the number for the 'pattern' of the wooden case parts. Another possibility is that the book could be wrong on start date for the 946... the data I think is compiled from loads of annotated sheets saved from the factory, but this often relied on cross referencing descriptions to pictures that weren't directly linked, and I think the running dates for models is just done by seeing when they appear/disappear on the sales sheets. I have found mistakes or irregularities before! (and clocks that don't seem to be in the reference at all). I have (or at least had!) one the same as yours, I found its picture and entry in my spreadsheet! My Picture is from January 2004, it might be in the attic... possibly... or maybe I moved it on, but mine was clockwork (so a '6' 946)1 point

-

Found my book, yours looks to be a '946' made from September 67 - August 83, for the wooden clocks, the number stamped into the base, is sometimes, (but often not) the model number. Interesting the photo from the catalogue shot in £ s d shows that the mains synchronous ones were way cheaper than the clockwork ones when new.1 point

-

Very good and nice clear photos. Just one thing you forgot to mention and that is make sure you have all the power off before dismantling the movement . We don't want parts flying all over the workshop do we. Happy Christmas and stay save.1 point

-

It's it possible that the centre second wheel upper metal bush has been moved slightly and reduced end shake? I personally have encountered that on a 7006 where that bush also doubles up as the arbour for the winding weight. I pushed down too much when tightening the winding weight screw and dislodged the bush slightly causing the watch to stop running. I removed the bridge and could see under a microscope that the bush had moved very slightly. I pushed it back flush to the bridge with the flat handle of my tweezers and has been fine since.1 point

-

1 point

-

Hi @JohnR725, you make some interesting points, and I agree, I need to step away for a few days and ponder. I am fairly confident the amplitude was about 270° when it fell off the timegrapher. I was using the service sheet you posted from and was surprised the amplitude listed was only 180 deg. That was what I was testing when it fell off ! (The lift angle is 58.4 for this movement, and I was seeing about 240 deg). In these situations, stepping away and thinking is the best option - tinkering can cause more problems.1 point

-

This is actually a problem with the discussion group as a whole. We can't see the problems at all because we can't hold the watch in our hand. We rely on the original posting person to give an adequate description of whatever they are seeing. But the problem is if whatever you're seeing isn't registering then none of us can see the problem. Then unfortunately with watch repair we do get problems like this. I tend to have a different view of microscopes then other people. It's a common feeling in watch repair the microscope allows you to see things better and it does not. It allows you to see things bigger and bigger isn't necessarily better? You still have to understand what you're looking at. Perhaps another way to think about this looking at the forest with a microscope you can see the needles on the pine tree. The problem is you can't see the tree or the forest for that matter. Sometimes I'm amused with my reading skills lacking. Yes I read that but for some reason I kept thinking it fell a greater distance. Probably because when I was timing my own personal pocket watch on the timing machine at work it didn't like the pocket watch And maliciously tossed it off the microphone and it hit the floor and broke the balance Staff. Here just being thrown onto the desk you're right that shouldn't of been that bad not for a wristwatch? What was the condition of the watch before you serviced it? In other words how was running and did you have it on the timing machine? There is always the possibility that there was an issue with the watch and you didn't have enough time to run it afterwards to find the problem. So you conceivably may be still dealing with original problem perhaps. Then a momentary distraction when I was looking for something. One of the things interesting about the 4006 watch is it's one of the few technical bulletins that actually specifies the amplitude that Seiko is expecting. So the minimum amplitude that's acceptable for this watch is 180° which is always amusing for everyone obsessed with more amplitude. Yes and action rereading everything for the most part it looks like it should run? Except for the minor problems with checking each of the wheels and checking everything without having the pallet fork in is that they will a lot of times feel free. More common and clocks were there is way more pressure on things if the bushings her oval in shape without pressure they will feel fine but under load they will not. With just the pallet fork in it and the watch wound up gently push on the pallet fork doesn't snap nicely? If not then your problems in the gear train. Reading through it looks like it should work. There's another option here take a break Go away don't touch it for a day or two yes I know that's really really hard. Then when you look at it again you're more likely to see things that you just can't see right now. Those really obvious things like the elephant in the room that one day You notice has elephant always been here? This is a really long shot and it does not help at all but visually was the balance wheel going at 270? The reason I bring this up it's a common problem of all timing machines if the amplitude is too low or it's noisy the machine will read the wrong part of the signal and give you something like this. So it's not entirely helpful I'm pointing out that may be perhaps the amplitude wasn't 270 it only looked that way on the timing machine but as I said that's absolutely no help for the problem at all. I found what I was looking for was the tech sheet and it's been a long long time since I've worked on one of these as I remembered it's complicated. So obviously for diagnostic purposes right now all you want to have in the watch is just whatever you need to get power from the mainspring to the balance wheel and nothing else.1 point

-

From the pictures it certainly looks like a one piece case in which case either method should work, the old maxim is just be careful . good luck. and Merry Christmas.1 point

-

Now that you have the books from through them. There is a lot of interesting information buried in those bucks hidden in some ways beyond just looking for parts helpful tips and things. Yes looking at the book now pays 734 is where the pictures are of your part possibly. I know like in the fingerprint section of the book the section where you look at your setting parts of those are printed exactly to size. I never really thought about the other section so maybe they are? How do curiosity I printed one of the pages out printed the size and I will lean towards the probably not printed to scale they're printed so you can see them. But I did notice which I hadn't noticed before they do is specify dimensions sort of like the cap jewel diameter is mentioned except of course that's somewhat unhelpful? So for the two different springs the cap jewel diameter is basically confusing in a way so for part 461 of the stones has a diameter of 190 and the other one is 160. Then for the other one it's 140 although? Probably go to the beginning of the book and look up the specific calibers and you find that one am is smaller than the other perhaps. There is another option to try don't know what you're going to get though the material houses a lot of times have considerable more information than we have. You could always try emailing the company telling them exactly which watch you have by model number and asking if they know which spring would fit your watch if it would. But on something as obscure as this it may just be cheaper to buy one of each. Then the other thing is the website that talks about this watch asked them maybe they know. One of those other minor little weird problems of way way too many variations of parts. Seemingly simple tasks of getting something only a find out that comes in so many variations.1 point

-

To aid in your search try a magnet. Even though the Springs are usually a pretty gold color that's deceiving their usually steel. At least it's worth a try. It's amazing what happens if you're really obsessed because you misplaced one super tiny component. A nice flashlight and a lot of patience and it's amazing what we've all found That seemingly was lost forever but not1 point

-

As said by Bod the 10th Edition is the latest and with the correct Horolovar spring and set up as per the manual you will be ok. Hope fully the top and bottom blocks and fork are all there if not there seems a ready supply of bits, I guess Timesavers, Jules Borel etc can supply although there are plenty of bits on the Ebay. Enjiy the experience and keep us posted.1 point

-

Get the 10th edition of the Horolovar book, it's the most up to date version. The book will tell which suspension spring to get. ONLY use Horolovar springs, as they are matched to the book recommendations. Other makes of spring are available, but there is no reliable way of knowing which spring is needed, due to manufacturing differences. Likewise measuring the old spring for thickness, unless it is known for certain to be Horolovar, is not reliable. Bod1 point

-

1 point

-

1 point

-

There is a case section on Boley.de. I just typed in 087836 as the case number. Check if that is correct: https://boley.de/en/case-parts/citizen/7099.4-087836?q=087836&p=0&s=50&l=7 The crystal is a 54-L0303H There is one here: https://www.sapphytimes.com/citizen_crystals.html but you have to email them and check stock. Ebay don't have any. I'd just fit a generic flat crystal. I usually order 1 size down, 1 size up, 1 size correct. Watchmakers usually (break one, fit one, keep one). I use cousinsUK for crystals. They have more sizes than esslinger. To be honest esslinger dont stock a whole lot of anything compared to cousinsUK. You can't rely on one place for reference information. I use Jules Borel, Boley, Cousins, Seiko PDF's (search caliber + pdf), citizen PDF's, forums, etc. Sometimes CousinsUK will list the part number for a caliber such as 8943 that will then let you track it down even if out of stock. That's how I found my first replacement NOS 8944 circuit board and LCD.1 point

-

1 point

-

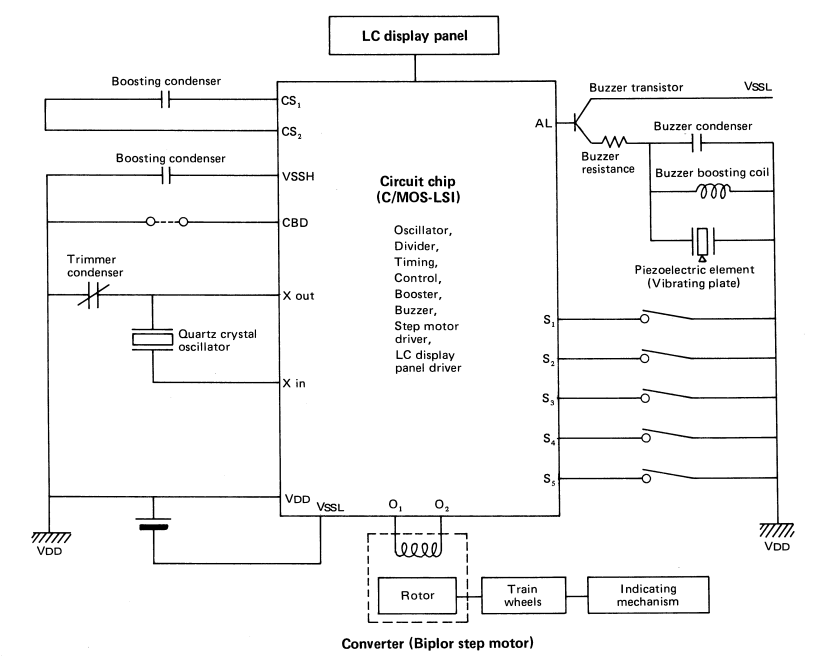

The "condensers" are about the only things you can suspect, and have a chance of actually changing. They are pretty important. The "boosting" ones probably generate the split supply for the LCD and possibly other parts of the circuit. They may also be used for a charge pump boost the voltage to drive the rotor. The chip is CMOS, so it is possible that it may be susceptible to damage by static electricity, but possibly impact and moisture are more likely candidates to kill the silicon. If you have a working external 32768 Hz oscillator (exact frequency for testing is probably not critical), and can inject a signal in to Xin (you may need to disconnect the crystal first) you might have some luck. Actually you might be able to just touch the X in input with one finger and inject a little random noise there the display may flicker in to random life. If so, the chip is probably OK. Without a working oscillator, I doubt if you wont see anything on the display, because the boost circuits for the LCD almost certainly rely on it and therefore wont work. Having a working board to compare with would also be a big help.1 point

-

I feel it is pretty unlikely it needs the coil to operate. The analog part of the circuit is likely to consist of a simple driver transistor for the coil, fed by pulses from the divider from the crystal oscillator. No feedback or anything like that. I don't have an exact datasheet for the crystals, but they are likely to be something like the above. The load capacitors are a faff, and they may be the cause of the problem. If you don't have 6pf or 12pf capacitors to hand, try using the stray capacitance from your fingers, or two short pieces of insulated wire as "ghetto" capacitors to see if you can tickle it in to life. Often once you get it started a crystal oscillator will continue to oscillate, even without the load capacitors. Once you remove the power it will die again obviously. You could also try removing the capacitor and injecting a 1V or so sine wave in to the oscillator through a 100k resistor or something like that to see if the rest of the circuit wakes up.1 point

-

My first watch was a Timex, 53 years ago this Christmas still can see the little watch now. Love vintage watches, I think it’s because of the size and shape that makes them comfortable to wear There was an Ingersol watch factory just up the road from me, it was locally called the ticktock. Sent from my iPad using Tapatalk Pro1 point

-

The very first watch I spent my own money on was an Indiglo model back in 1993. I was enamored by the technology. I was in the service then and for me it was a home run, stylish, functional and practical. I kept the watch until it broke one day about 7 years later. For nearly 20 years I got out of the habit of wearing a watch every day. For me they were a nuisance more than anything. I had always kept my eye on Timex's but was never really impressed with any of their offerings.2 years ago I picked up the habit again, which turned into serious collecting and then I applied my tinkering hobby to become a hobbyist watch maker. During this time I still wasn't paying much attention to Timex as a brand, until 2 weeks ago. I picked up 2 one electric and one manual Marlin at an antiques show and have been bitten by the bug. They're super simple in design and manufacture, They're robust in engineering and with proper care, can be reliable and fairly accurate time pieces. Their design was always stylish and trendy. The vintage models I have been looking at lately are very appealing. For me, they'll make great practice for my watch making skills. on a side note, I saw The Hitch Hiker's Guide to the Galaxy movie, one of my all time fave's!1 point

-

Couldn't agree more! Whenever I'm servicing or repairing a watch I wouldn't treat a russian Poljot any less than a Patek. I can certainly enjoy any watch as long as I can see that some passion went into it.1 point

-

1 point

-

They appeared to offer a 1 year warranty in the 1950s as standard, but I suspect as with most things, you could extend that. The Dundee warranty was likely to be similar, as the two Timex companies of the day (US Time Corp and UK Time Corp) were under the same umbrella as it were. More info here -> https://randomfootage.homestead.com/timexwarrantycard.html I did see some UK Time Corp warranty stuff while trawling the interwebz a while back, but I can't find it right now. If i uncover it, I'll post the details here. As I recall the UK warranty card required the watch to be sent to a PO box in Dundee, but the head office was listed in London (for marketing reasons no doubt).1 point

-

Today's "Watch of Today" - posted here, because.. Poking out from between my gloved hand and my fleece sleeve, about to venture out in to the wintry wilds of Scotland for the day. A fully serviced, fully functional piece of finest Dundee technology. A 1973 Timex Viscount Automatic day date (46850-3373).1 point

-

What sort of burnisher are you using? This is very important. If you are using a commercial one, you need one for left-handed use to use in the right hand on a Jacot tool. Would often be marked gauche or with a "g".1 point

-

I've got a Unitas 235 that has a cracked jewel that also damaged the pivot on the third wheel. Cousins still has replacement third wheels for this movement, so safe with the knowledge I can order a repalcement wheel I decided it was time for me to try and polish the picot with my Jacot tool. I've polished pivots on clocks no problem, but this is the first time I have tried on a watch pivot. I'm amazed at just how much harder it is to polish the pivot on a watch. I've butchered the pivot enough that I will be ordering the replacement wheel, but will continue to polish this pivot now just for practice. The few things I have learnt from my attempts so far are. Check the pivot dimension closely and select the correct diameter slot on the Jacot tool, don't just go 'close enough' Ensure you have set up the tool so there is no slop in the way it is holding the wheel, else the wheel will tilt by a degree or 2 as you move the bow and burnisher backwards and forwards making it easier to end up with a tapered pivot Take care on how you hold your burnisher to make sure its parallel to the pivot. Get yourself a few wheels to practice polishing pivots from junk movements before touching an important wheel Give yourself a break and go read WRT if you feel your pulse rising. I may of done a crap job on polishing this pivot, but atleast I can say that I've started to learn how to use my Jacot tool now.............1 point

-

Assembe movement and let it run 5 minst. Afterwards I do it using 9415 on every second teth tip of the escape wheel. Only on the tip of it not on the top or bottom of the wheel I check it under the microscope after 24hours of work if its not enough i do it once more Enough is when the escape wheel tip and the pallet jewel meet you shoul see a droplet of oil between them which is aprox. 30% of the pallet jewel tip length(its dificult to explain) And of course i use epilame as it makes this job a lot easier and the grease stays in place afterwards and does not travel along the surface which will leave the pallet jewels dry, at the begining i said let it run 5 mins, this will wear of the epilame coating and will leave the oil on that places. I hope i made it a bit clearer for you now br emso p.s: sent from my s****y phone so sorry for typing mistakes1 point

.gif.a670ee7538c0179d861f706a4066acc0.thumb.gif.43ba5ce8aa96fbdce358fd1c640dc0a4.thumb.gif.3d49446561727c1bb88677bdda098715.gif)