Leaderboard

Popular Content

Showing content with the highest reputation on 07/12/20 in all areas

-

pictures and practice and patience, Watches are like a puzzle , they only go together one way.3 points

-

2 points

-

In simple three hand jeweled watch there really are not many parts. Each has a unique function and really wont work in any other spot than the one intended. Adding complications such as day and date, just makes them more complicated, but the same thing hold true. Other than screws nothing can really be interchanged.2 points

-

My guess is that they just have been subjected to chemical bluening .. there are some stuff at ebay one can use. Just search on "Cold Bluing Chemicals" or similar and you should get results like .. https://www.ebay.co.uk/itm/Bluing-solution-Cold-immersion-bluing-agent/224039720684?hash=item3429ced6ec:g:NfMAAOSwUd9afHHo2 points

-

Juniper is not used in carpentry (which I believe is technically framing houses and the like). In general woodworking, I think the small size and gnarliness of it limits its uses to very small things (i.e. pens) and decorative elements. It's a softwood (which refers to biological characteristics rather than it's physical hardness), and that's another limitation. I have a fairly large juniper in my yard between the house and the creek. I can't think of having ever seen or used juniper. A burl is an extremely figured feature on a tree that comes from disease or stress of some sort. Photo not mine, from Reddit via google image search for silver maple wood burl: It's too finicky and unstable to use structurally, but can make for some stunning accents. I'm sort of at a loss, because it's huge and riddled with burls, but it's a bit too gaudy for my style. I'll probably sell it to fund either watches or car parts... If you like the gnarliness of junipers, you should find your way up to this neck of the woods. At tree line, there's a type of tree called krummholz. It's not a species or anything, though I imagine they're all coniferous and I'm sure a few are junipers. It a tree that is heavily deformed due to the extremely strong and cold winds at high altitudes. Same source:2 points

-

Bought this one today. Don't know much about them but can't wait to open it and see what the movement is inside Sent from my SM-N975U using Tapatalk1 point

-

That's Simplified Cyrillic for the us the Westerners that can't read it With a coil over the regulator arm, that's not surprising! Who can do better, one extending outside of the (closed) case? Must have been work by the same guy - I can fick my zwuatch hiere in the tar factuory - oh, no, curva!1 point

-

I've found that having a practical understanding of movement function and construction (such as what you learn in Mark's fantastic course) is extremely helpful. If you know the parts of the movement and keep your screws organized, you should be good to go. Sent from my Nexus 5 using Tapatalk1 point

-

All techniques help but remember the most important one is good use of your eyes and brain. A good watchmaker is able to put back together a chronograph movement take to parts in a can, without much difficulties. Take out the screw, (or any other part) look at it, ask yourself why it has this shape / length / peculiarities? You will find that very rarely the manufacturer made illogical choices. What made sense to them, must make sens to you now. The difference between understanding how it works and why, and repeating without making sense of things.1 point

-

In the thread below I posted about "Seiko style openers". That is what one wants in most cases. I believe the tool you posted is meant to be a bezel remover, with the flat side of the blates being on the case side once the watch is placed upside down. Otherwise two blade would be always in the way of the lugs or band. Some examples in the thread above.1 point

-

No, what I wrote is that Nomos makes an automatic watch where the mainspring is designed not to slip. https://www.watchtime.com/featured/nomos-caliber-duw-neomatik-6101/ And I believe that like any other highly priced maker will not sell any part outside their official service points.1 point

-

Due to it's strength it exerts more force, friction, and general goodness. Even if the spring was to not slip, a robust winding mechanism wouldn't break. This type in now manufactured by Nomos IIRC.1 point

-

Interesting. I'll measure my Seiko spring and my GR spring (once I've taken it out of the barrel) and see if I get the same result. The big question then is how a twice as thick bridle affects the slippage!?1 point

-

I found the thread over on wrist sushi where I showed the difference in bridle thickness between an OE Seiko mainspring for a 6309 and a GR equivalent and the one on the Seiko spring was just under (by .01mm) twice as thick as the one on the GR mainspring. Sent from my iPad using Tapatalk1 point

-

for the most part like a puzzle the parts will only go one place. lots of pictures definitely help. Separating sections as you disassemble like all the dial components goes in one cleaning basket, automatic components etc. easier for reassembly if things are in sections. Then when I'm doing reassembly like the photograph shows I like to put my screws like this makes it easier for me to see if they're all grouped together. Even simple watches like pocket watches sometimes the plates screws will be different length this allows me to see which one is shorter if there is a shorter one.1 point

-

Sorting various parts that go together, like putting the keyless work together in mini baskets, so when you do put all your clean keyless work back in the same compartment together ready for replacing, you know only those screws are for that area of the watch and can't possibly go anywhere else. The more practice you get, you'll get to the point where all the screws and springs will go into a mini-basket together, because you'll know the movement intimately and where each screw and part goes, but that takes taking lots of photos first.1 point

-

I agree with @yankeedog. The way I do it is take lots and lots of pictures using my iPhone 6S with a $10 clip-on macro lens. That way I really don't have to care how I organize the parts in my trays and on a coffee filter with a glass bowl in top. Although I do place all screws together and large parts together, and keep track of which cap jewel and goes into the balance and which one goes into the main plate (they are sometimes different thicknesses). I guess I've developed a system, but more out of experience than out thinking it through. Here's and example of what I mean by lots and lots of pictures:1 point

-

Make sure this part (red arrow) isn’t damaged and can lock and be freed. Some types cannot be moved so check for damage. You need to have the most pointed stake and see it it lines up center to the holes (black arrow) make sure none of the holes are damaged and not blocked. The black arrow part must be able to be un-locked and locked. All punches should be able to fit into the stand with ease. Keeping the stakes in good order and the plugs will also help in the work you will undertake when using this type of tool. It is quite easy to clean the stakes/plugs with very emery cloth or the sticks, if you have a lathe it’s even better. Don’t forget this type of tool is used a lot for watch work such as b/staffs, jeweling and riveting just to name a few. Yes if you do not have a jeweling tool but you have the right punches with a stacking tool you can use it for that. The main thing is make sure things line up.1 point

-

1 point

-

There looks to be many missing stakes and plugs. New stakes/plugs can be bought from good suppliers. Have a good look at what you might buy, Do the stakes line up with the holes in the bass, make sure there not blocked, the same goes for the stakes. Looks like it all needs a good clean, this can be done and it should then look fine. You can also find second hand stakes on ebay. The price is fair. Just make sure it all works and moves free.1 point

-

If canon pinion is not rubbing on mainplate or depthing with the minute wheel, then it is sitting too tight on center arbour, first thing to try if you haven't is to apply some grease to ease the friction.1 point

-

Here are some threads from other forums that had a ton of great information on hand bluing, including a discussion of the plum color. I'd need to refresh myself on the specifics, but I believe one of the American pocket watch manufacturers used that purple as a signature, before getting hands to blue-blue became the standard. https://mb.nawcc.org/threads/bluing-pocket-watch-hands-marty-b.156600/ (I really recommend this link -- lots of great photos and trial-and-error progress photos from someone. https://mb.nawcc.org/threads/how-to-blue-hands.33823/ https://mb.nawcc.org/threads/illinois-plum-hands.71211/ Here are a couple photos of "plum" and "wine" hands:1 point

-

I wouldn't even have a clue how just the heads of the screws have color? Induction? Physical barrier? Hmmm..another mystery to uncover.1 point

-

Ah yes. The downside of mass production I would think. Kinda like the military-you don't have to taste your chow, just get it down and in. Another reason to do your own, right? Illinois Plum, eh? Well now, I'll just be looking that up here in the next few minutes if I do say so myself. Thanks for the tip! Never heard of it!1 point

-

Format photog....you are in. Yep right up your alley. You'll be less that satisfied at a couple for sure, I did. But once you find your groove be aware of your face-I caught myself grinning like a little kid and ain't looked back. I screwed up I thought, and then kept looking at it at different angles under my light-came up with this almost deep purple/straw color darker pink...I don't even have a name for it. So I tried to duplicate what I had done on the minute hand and although not identical, came up very close. They look great but I don't know where to put em! Not sure where we can purchase-hands I've discovered to be inherently spendy. Blued hands even more. If you find a place let me know. I just bought a fair size lot of pocket hands coming for future projects. Keep us posted and have fun. Oh yeah-I find screws even easier because of more material. Gives you more time/less stress to get to the desired shade of whichever. Not as touchy! Just remember-use that easy flame. My favorite shade I call electric or ocean blue.1 point

-

1 point

-

1 point

-

What amplitude are you getting? The beat error is relative to this figure, and 3mS is not necessarily “bad”. There are other parameters which are more important. Remember you need to regulate the watch across positions, so at least test it in pendant-up position as well as dial-up.1 point

-

I've got some brass sheets & a nice handle on the way to build a heating tool. I've also got some nice cheap brass scarf on the way, and I'll be picking up a propane torch today to start learning how to blue hands. I just need to find a nice supply of steel hands to practice with ... and I think that "grab bag" of hands from eBay is going to work for that. Thanks for the tip and encouragement @MechanicMike1 point

-

I have been contemplating doing this for the last five years. Happy to see someone jump in and just get it done... Nice job!!1 point

-

Well one guess would be an ETA 956.112, these pops up now and then in a ladies quarts professional 200..1 point

-

1 point

-

Ricoh 61 finally completed today. Feels great. Love the winding sound, Zip zip zip. Sent from my Moto G (5) Plus using Tapatalk1 point

-

So, the result from my best performing movement, a newly serviced ETA 2824-2 running perfectly, is in. During my workout the extrapolated rate goes up to 252 seconds per day.That is, during my 40 minutes of work out (walking, jogging, running) it gains 7 seconds. In each test I have manually fully wound these automatic watches (ETA 2772, Vostok 2416, and ETA 2824-2) 12 to 18 hours before doing my workout and not wearing them in between. I should also mention that during normal everyday use of these watches the rate is very consistent only varying a few seconds depending on my normal everyday activity. I think you're spot on. Well, I got rid of my hair, or rather my hair got rid of me, years ago so I would only be able to simulate such a "test", and that would make me feel really silly I think we can now pretty safely conclude that mechanical watches in general are affected by quick changes in gravity. I'm pretty sure that would include prestigious tool watches from Rolex, but if anyone wants to send me their Submariner or Explorer for a workout I'd be happy to take it out for a test. This, IMO, absolutely gorgeous "STOWA Flieger DIN Professional" (unfortunately way to big) is advertised as "in no way affected by any physical stresses and strains in air traffic". I don't know if that includes the Swedish designed and built fighter jet SAAB Gripen NG, but in that case I'd want one1 point

-

Mike, thank you so much for the thoughtful response! I'm particularly happy to hear that it's not necessarily impossible to resize a hand with a staking device and stump. I'm definitely looking into this more. I'm also just about sold on learning how to blue hands (and maybe screws) myself. I did quite a bit of research, and this is right up my alley. I'm a large format photographer with experience in quite a few touchy and potential dangerous alternative processes, and the bluing process sounds like a lot of fun. I'm certainly more "visually" inclined than I am mechanically inclined, so this seems like a good fit. Thanks again for the great information! I'm still interested in knowing if there are any good sources of blued hands that are cheaper than what I've found, but I don't think there are beyond doing it oneself or finding vintage hands. Cheers, and stay tuned!1 point

-

No just Japanese, that is the Etachron system adopted by Seiko also. The adhesive is applied with a controlled temperature. Now, cleaning a balance is a bit different than other parts, there dedicated solution but I believe that they are nothing else than hexane.1 point

-

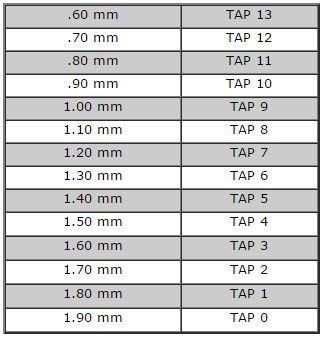

That screwplate appears to be metric. So the sizes listed are the thread size, 20 is 2mm, 13 would be 1.3mm. So you would want to start with 1.3mm as your diameter. But- it might (probably) not cut the thread so much as cut and form the thread by displacing metal. I say that because it looks a little dubious in quality. So try a little smaller and see if you get a good thread form. You can turn a taper from say 1.15 to 1.3, and then thread that, and see where along the taper you get a full thread. Make a note of it for the next time you need to thread that size. The old Martin screwplates had a screwy (haha) numbering system. There were two main designations from Martin, L and B; both seem to have the same thread diameters regarding their numbering, the difference is the pitch of the thread. Martin G plates were for left hand threads. Funnily enough, the "backward" numbering system for watch stems and crowns corresponds to the Martin sizing, I guess it was taken up at a time when Martin screwplates were the primary threading tool for watchmakers. 99% of the time I use industrially made metric taps and dies for threading, but sometimes for an old piece I will use a Martin plate. The threads are a little more rounded on their crests. I find that for a given size I need to turn a little undersize, as mentioned above. With new "real" metric stuff I turn to the nominal diameter.1 point

-

1972 Timex Marlin. This is a bit of an experiment. Having discovered that some (all?) of the ingredients of the secret sauce in Moebius Classical Oil "8000" are light mineral oil and neetsfoot oil, I decided to see what would happen if I brewed my own. This watch was treated to a 80%/20% mix of scent free hypoallergenic baby oil and finest saddlers neetsfoot oil. The former can be bought by the half litre bottle and is intended for oiling delicate infants. The latter I picked up a litre of from ebay and is meant to be used on equestrian tack. In total I paid the equivalent of around $12 USD for the lot, which should make roughly 600ml of my open source watch tipple. For comparison 600ml of genuine Moebius Classical Oil "8000" would set you back around $3540 (and last you approximately twenty life times). I mixed up enough to fill a 50ml hand sanitizer bottle, as for some strange reason I seem to have rather a lot of them kicking around these days. I chose an 80/20 mix for no other reason than it looked about the right colour. The watch was serviced, and lubricated in the usual manner, and so far nothing has exploded, and I haven't had a visit from the Swatch finder general. As a side note, it also appears to be keeping good time (for a 1972 Timex), keeping perfect pace with the Timex Big Q on my other wrist (which has NOT been similarly adulterated), so the viscosity is in the right ball park. Note: I am in no way advocating the use of random lubricants on precious time pieces, but this did seem like an experiment that was worth doing. I may make up a batch with a whiff of Chinese Molyslip knock off, as I have about 200ml of that sitting here crying out for a similar bit of probably unwise fun. EDIT: I forgot to mention, the strap (which came from another basket case watch) is also fairly ancient. I used the neetsfoot oil neat on that, and it has brought it back from a hard, cardboardy and twisted mess, to a supple, clean, wearable and comfortable piece of leather. If nothing else, I do now have a plentiful supply of leather softener.1 point

-

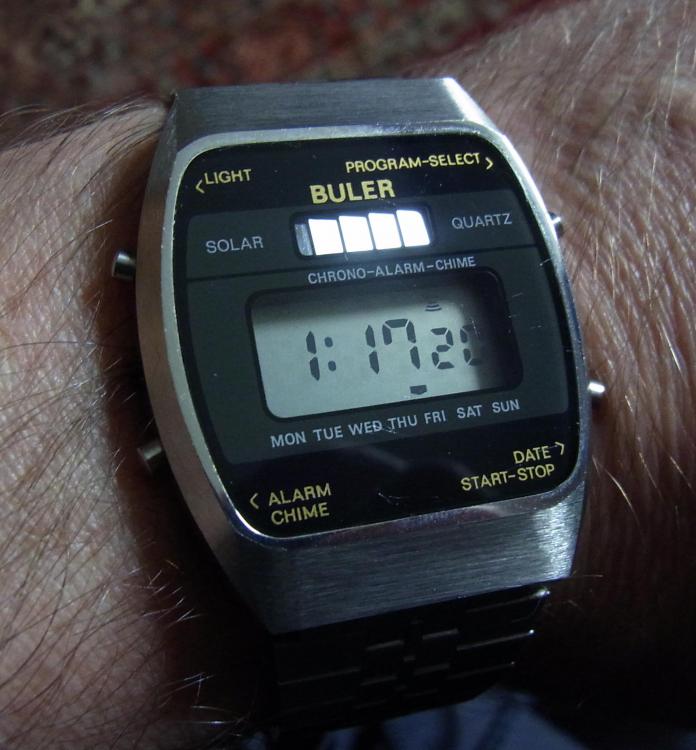

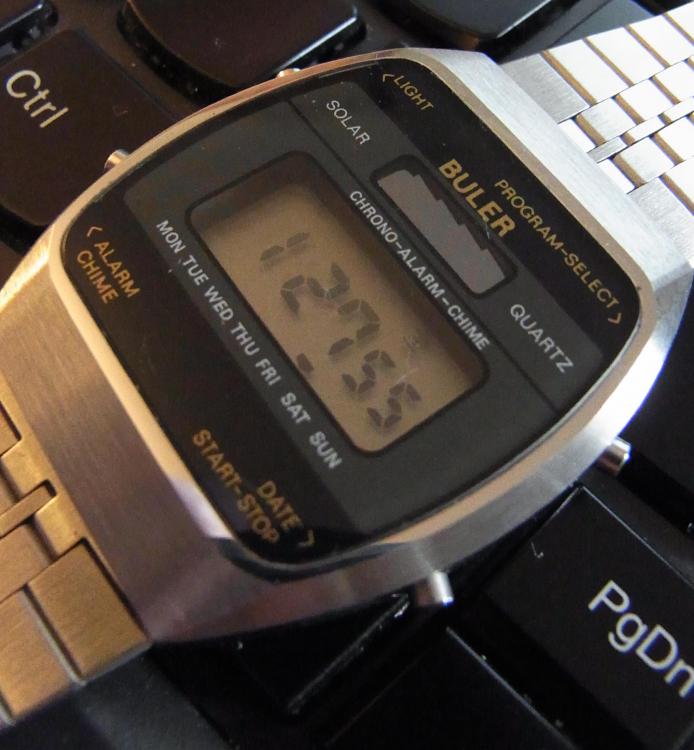

\ Buler Solar LCD Chronograph Alarm (3091-9003), circa 1978. This was presumably meant to compete with the likes of the Seiko LCD Solar Alarm Chronograph A156 produced the same year. It has all the look and feel of a quality watch, entirely stainless in construction. Very different from the 99 pence "Hong Kong specials" that you could pick up from a filling station a few years later.1 point

-

In my experience, kids have more than enough "springs" in them already. Perhaps a kid spring removal tool might be a big seller.1 point

-

Seiko Engineer today Yes, still haven't painted the bezel numbers https://i.imgur.com/uiTmZuP.jpg1 point