Leaderboard

Popular Content

Showing content with the highest reputation on 04/08/20 in all areas

-

3 points

-

Can't help you with the movement cal. but did you know that address on the Ad above is next door to Bravingtons head office in Pentonville Road? They were a importer of several Swiss watch makes from the 1930's onwards and 294 was almost certainly their import business address and workshops, 298-296 being their retail showrooms... I did some research on Rone watches when I had this pre-war Rone refurbished for my brother. It originally belonged to his father, our mother's first husband, who died as a Japanese prisoner of war..2 points

-

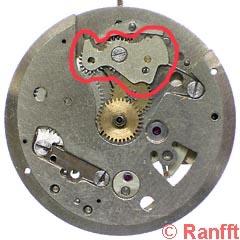

This is the rocker bar If the stem is correct and installed correctly, then the peg on the set lever (just above the rocker bar in the picture) should sit in the slot in the stem. When you pull the stem to hand set position, the set lever should rotate clockwise and the right hand end of it should engage with the cam shape on the top RH corner of the rocker bar, causing the rocker bar to rotate clockwise until the end of the set lever hits the stop in the rocker bar. The parts all need to move freely for this to work properly, so could be a lubrication issue. The rocker bar has 3 meshing gears on it - the centre one turns when you turn the stem, causing the other two to turn. In winding position, the one on the left winds the mainspring. In hand setting position, the one on the right turns the minute wheel. With wear or damage, any of this could jam up when you try to move it. Photos of yours might show where the problem is.2 points

-

2 points

-

2 points

-

2 points

-

Your clock movement is known as a rack striking movement. It’s a strike, the hour wheel with those ridges on it to determine how many times it will strike is called a snail. The strike side wheel next to the fly (that’s the flat one right at the end of the train, the wheel with the little pin in it, that pin needs to at about a quarter to or 10 to so it has good warning, make sure the hammer doesn’t start to lift in the warning passion. There is no easy way of regulating a clock it depends on the mainspring it is a trial and error, this sort of movement should go for 8 days on a single wind, if you can get it down to a minute a week that would be good.2 points

-

1 point

-

1 point

-

Using the magic power of the internet, here is the building next door, and yes, it too has Bravingtons on the signage. Sadly, like every other shop these days, it is now a MacDonalds/Pret/Starbucks etc. Click the link below to get a full view. https://www.google.com/maps/@51.5308053,-0.1220827,3a,75y,131.45h,93.33t/data=!3m6!1e1!3m4!1sO--wFeJNM_UxkLKqFE5rdw!2e0!7i16384!8i81921 point

-

Today I'm sporting a Denison cushion cased Rone Sportsmans 15 jewel with bags of character most probably from the late forties or early fifties. This had been lying for quite a while in the to-do pile, as I had assumed that since it was locked up solid and had a distinct rattle, it would have a broken balance. Fortunately this was not the case, and all it needed was a thorough clean and now it is ticking away quietly. It is sitting around +10 sec/day, all be it with a relatively low swing around 220 degrees (a slightly tired mainspring most likely) but a more healthy beat error of 0.6ms. The diminutive size of this Gents watch is quite a contrast with the recent trend for wrist mounted frying pans. I had no suitable strap for it so I had to improvise from one of the straps in the scrap pile.1 point

-

1 point

-

Hi https://www.vertex-watches.com/history This may help apparently they inported swiss movements and re cased them as Vertex Hence the resembelance between your picture and clockboys picture of an AS movement.1 point

-

Hi Seth, I think VWC, stands for Vertex watch company. If I am wrong somebody will come along shortly and correct me!1 point

-

I am afraid there is no magic wand with these movements just a great deal of care and patience. they are fiddly little things, Like one of those puzzles where you have to get all the little balls in the holes. always one falls out. best of luck. cheers1 point

-

It could be the depthing of the rocking pinion to the chronograph runner is too deep It could be the tension spring for the chronograph runner was installed incorrectly or is damaged and greating too much drag It could be the chronograph runner pivot (long one for the hand) is bent and causing the hand tube to rub It could be that the hand tube is damaged and rubbing It could be that the rotor screw is not the correct one, and the screw in place is touching the upper pivot of the chronograph runner The last one is the easiest to check, and the screw should have a bit of a "divot" in its end. It could be something else (just dirt somewhere for example). That it runs OK for a bit from full wind probably just means that it manages to go with that extra bit of kick the end of the mainspring gives. If you have a timing machine it would be interesting to know the amplitude with chrono off and chrono on, at full wind.1 point

-

1 point

-

Now managed to get a thin piece of steel wire to which I filed a taper and polished it and which now fits in the cannon pinion for a ladies watch. I mounted the tool in a small bench vice so that the screws end was upwards. This leaves 2 hands for turning the setting and pinching screws. It also made it much easier to fit the cannon pinion in position as it is fed downwards into the pinching slot to get the starting set point, and allows the wire to be manipulated to feel a good pinch status and allow removal of wire. I did note that the pinching screw can still be tightened beyond the stop screw setting due to flexibility of the arms, but this actually allowed a bit more control over the pinch !! The cannon seems to be working fine now.1 point

-

Hi Redwood find attached the pdf of the spec sheet for finishing powder and how to use it, hope its informative. Cheers finishing-powder.pdf1 point

-

Hi Moose It matters not the value of the clock , It had a fault which prevented it from running properly and you addressed the problem and in doing so you have learned a lot in the workings of a clock, far different than a watch but similar. They both achieve the same result in telling the time but do it in a different method and as such require a different approach, so you can be well pleased with your self in attempting the unknown and winning so a big pat on the back for that.1 point

-

When silvering a dial you are depositing silver salts onto the surface of the brass, this can look quite matte and dull grey the finishing compound is a very fine abrasive it lifts the lustre of the silver and makes it look brighter, usually the silvering salts come with a tub of finishing compound from most sellers on ebay. I have found that the silvering salts available on ebay are quite variable in quality the finer powders work better, some are quite gritty and not very good. I have found this to be the best not cheap but it has done a fantastic job on many dials for me: https://www.ebay.co.uk/itm/Clock-Silvering-Powder-Trade-large-500g-PLUS-500g-Finishing-Powder/324107918063?hash=item4b76565aef:g:NwwAAOSweW5VBpzI. The finishing compound can be applied when the dial has been washed and dried use a soft cloth or brush and lightly rub in much the same way one would use french chalk.1 point

-

That is escaping a few teeth at a time. A good way of testing platforms to see if you have the correct depth is to test the complete movement in all positions, for at least a minute, that way you know the contrate wheel has made a complete turn, even test it upside down. I always did that with any platform clock, if all works well you know it will be OK and the depth is right. Always remember to check the screws are tight.1 point

-

If that was wear, they would all look like that, this has been done by force due to the platform being moved while power was still on. Lucky it didn't break the escape wheel pivot.1 point

-

1 point

-

It works! I got the pallet depthing sorted after a couple of attempts and then got it acceptably into beat. Then got the chime sorted out, so it was bonging the correct number of bongs when it should. Then back into its case. Finally, a bit of “rattle can” gold paint for the hands and a final polish on the Bakelite case. I now have it running for an extended test to check timekeeping and also to see what sort of reserve the mainsprings give me. Very pleased with the result. I know it’s on only a cheap Smiths Enfield, but it also represents new skills picked up, new tools experienced and new knowledge obtained. Many thanks to all those who commented and provided hints and tips.1 point

-

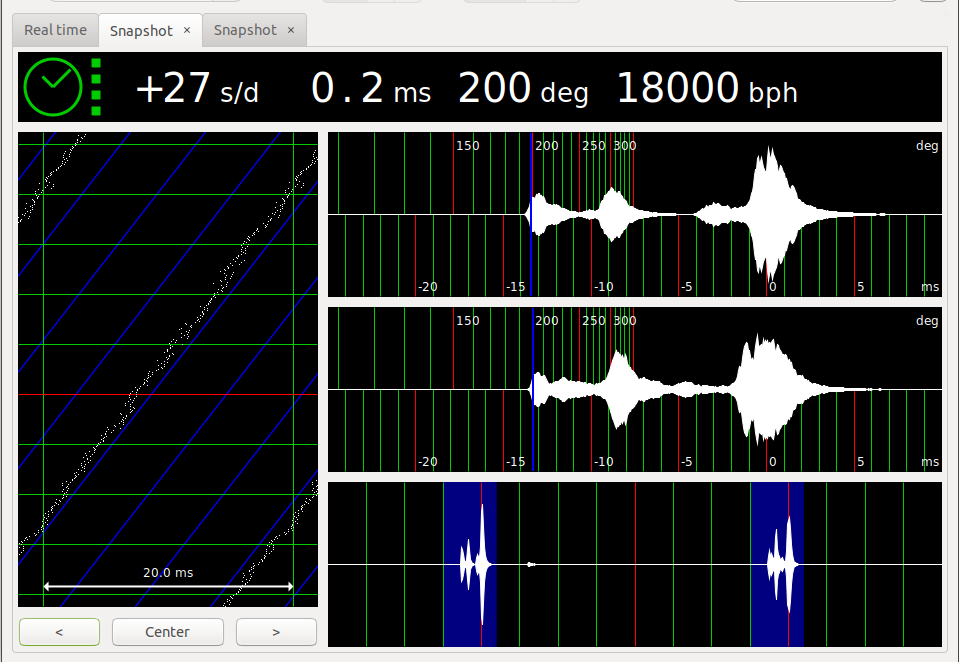

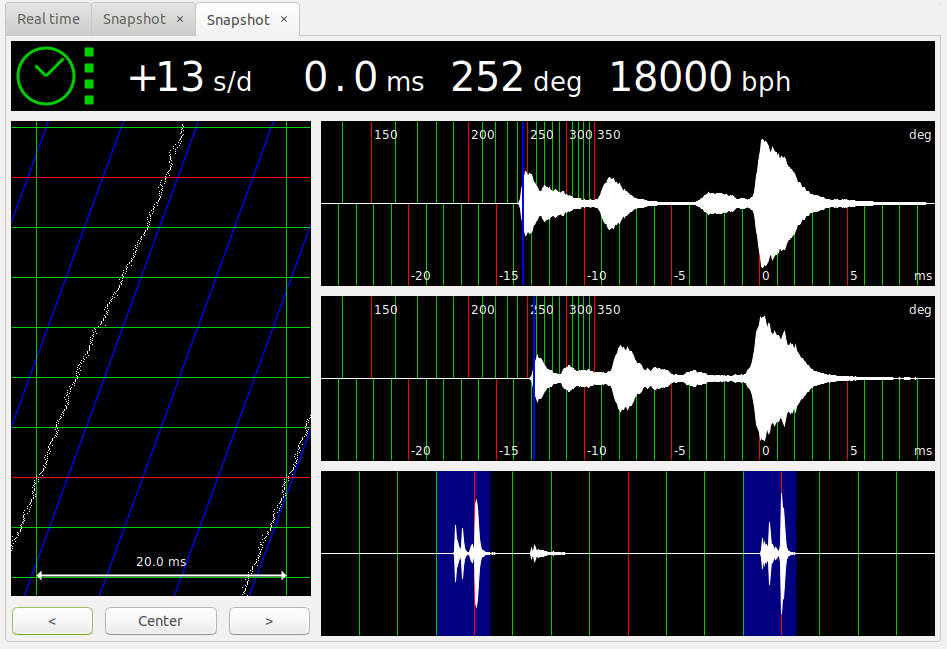

Continuing this theme, here is a Raketa 2609.HA from the mid 1970s immediately post-op, and the same watch some 12 hours later, both dial up. The big balances in these 1800bph movements make for some nice stable traces, and allowing everything to bed in has improved the picture immensely. Nothing has been done to the watch between the first graph and the second, other than wearing it on my wrist for a few hours, and letting it sit overnight. The improvement is entirely down to the fresh lubrication doing its work.1 point

-

@ffar, similar movement, it is just another model but these movements have a double balance. Sounds like a keyless problem?1 point

-

Hello Maciej, thanks for introducing yourself. With the crown pushed all the way in, when you turn it backwards and forwards, does it make a clicking sound? If it does, then you should be able to manual wind it. However, you say it does not respond. If it makes no sound and you can't feel a ratchet working, then it doesn't manual wind, only automatic. In your photo of the back of the watch, that plate with the stripes on it is the rotor. It is the movement of this eccentric weight which slowly winds the watch when it is on your arm, everytime you move. It takes about a day of wearing to wind the mainspring up fully. Does this weight rotate freely, when you tilt the watch back and forth? If you do this gently, but enough to spin the rotor, for about a minute, does the watch start to run? If it does, strap the watch to your wrist and wear it for the rest of the day, then let us know what happened. You say you have contacted the company for service. Is it a new watch? If it is still under warranty, and not working properly, get it fixed that way. As far as identifying the movement is concerned, HSL and Watchtime are right. If you follow the link Watchtime posted, it's the S-05 movement in your watch.1 point

-

Five sided cutting broches are the best for clocks. These are very good. https://www.eternaltools.com/clockmakers-cutting-broaches-set1 point

-

Some month ago I had a similar situation with a diashock cap jewel (I finally fount if though). Our fellow member Marc told about a tool mentioned in the thread I'm linking below. I bought it, it's very cheap, and I haven't had a problem since then. I even pick the cap jewel with the tool and oil it while it is stick there, then put it in the chaton that I have previously put on the balance cock or the main plate, and everything goes perfect, no nerves trying not to press the twizers too much or too little, no spreading the oil when putting the chaton over the jewel, etc. I really recommend it.1 point

-

The superglued nut works, have used this method in the past. Plus you don't mark the back.1 point

-

Try using a stick ball, it's amazing how often it has worked for me in the past, and I wouldn't be without it today. If your watch is as old as you say it is, the ball may not cope, but it's still worth a try. Here's mine! Failing that, superglue a 17mm nut to the case back and use a spanner, you can remove the nut by soaking the back in acetone afterwards to dissolve the superglue.1 point