Leaderboard

Popular Content

Showing content with the highest reputation on 03/08/20 in all areas

-

Note: This is no cylinder escapement - its a pin pallet escapement - as Roskopfs had. Frank2 points

-

A picture could help. Some case backs are designed to look like screw back but are in fact snap backs. Looking at this one on eBay I might be correct. Looking at the inner rim of the case back is, what looks like a spring washer. https://www.ebay.co.uk/itm/Very-Rare-Zenith-Surf-solid-18ctl-Hand-Winding-Watch-with-cal-2572/274296780437?hash=item3fdd5cb695:g:SSsAAOSwUcteMuQP2 points

-

Hello and welcome to the forum, I guess we have all destroyed a few in our time.. jdm is spot on with the advise, In bag the errant part is captured and can be tried again . Saves your patience and your knees grovelling on the floor2 points

-

Thank you for your friendly introduction and welcome here. It's always better to read or watch before doing. You would have found that is better to lift minute parts with Rodico, and work inside a clear bag on anything that may ping away.2 points

-

This day dial is not kanji, it's chinese. If it is for a watch with crown at 3 then it will be misaligned with the dial day window in a case with the crown at 4.2 points

-

Remember watch, tools, hands in bag. Head outside bag.2 points

-

1 point

-

All- I've been inactive for a while, but starting up again. I just replaced some of my expired and expiring lubricants. I also replaced my 9010, 9415 and HP-1300 with the fluorescent versions. So....I have what are essentially full bottles of the following: Moebius 9415 - expires 12/2021 Moebius HP-1300 - expires 10/2021 Moebius 9010 - expires 12/2020 Moebius 8217 - expired 11/2019 Moebius 8200 - expired 08/2019 Moebius D-5 - expired 09/2019 I am happy to ship any or all of the above to someone that will be able to put them to use. I'm sure others here will be able to offer opinions as to whether or not the expired lubricants can/should be used. Please be considerate and only ask for what you are truly in need of. This stuff is very expensive, so I am hoping it will not go to waste. I am happy to ship within the US for free. I can do overseas if you can PayPal me the cost of shipping. Stu1 point

-

Hi everyone, im ViolinDad. I tried to get my son to learn violin, and ended learning the violin myself. I love music but am also facinated by watch movements. However the thing that really gets me all cramped up is the balance wheel. Im both intrigued and yet also fearful of it. Fearful that I will muck up the hairspring. You known its strange, the thing u fear most somehows comes to bite you really fast. In my second attempt at re-assembling a 2824, due to poor technique in drying the hairspring, it got stucked together. I tot otherwise, in e process of unscrewing the balance cork, I "molested" the hairspring and its got a kinked in it............and so my journey begins. I'm hoping to just "sit at the feet" of this really good forum and learn as much as I can, so that I will be able to service my own movments ( and also the wifes), and really enjoy this hobby. I would like to mention Mark .L. for his wonderful videos tat have started me down on this journey. I never knew taking and putting back movements can be so addictive! So time consuming....but the night is my friend! I look forward to it....when everyone sleeps and Im hunched over at the desk, peering thru the eye loupe, fingers are almost craming up due to prolong holding of tweezers and a persistant slight pain throbbing behind my right eye, staring endlessly at the movement...what madness is this? Normal people look in the ads for great deals on fully functioning watches......i look for watches wif words such as "spoiled", "broken", "needs reapair", "may need a servicing" Oh wat Joys! Scratched cases, broken glasses, missing parts and rusted screws....... Well...thank you for reading. Too much rumblings I guess. But Im so glad I found you guys. Cheers!1 point

-

1 point

-

1 point

-

If it makes you feel any better I've just done something unspeakably disgusting to a poor defenceless Timex. I dropped the entire mechanism, dial and all into a small jar of WD40... However given the fact that it looked like this at the start of the process, I hardly think it can make it look any worse.1 point

-

Hi The clock has been dismantled and the wood work treated with boiled linseed oil to feed it all the gear work has been hand cleaned and is now back together just running the time train for a few days. The chains are black and I have one soaking now to see what happens, more to do.1 point

-

Very comprehensive! Glad I did not fell in the trap, also price offer was suspiciously low, as well as shape totally off. Now I have *solid* information to choose a proper one, once I will set aside the budget for such historical timepiece. Thanks FLwatchguy73! -Ascanio1 point

-

To the best of my knowledge, NO actual US Government/miltary issued GG-W-113 watch EVER had the manufacturers name on it. These were always sterile. What you have here is a Vietnamese copy / fake! I've seen these with Brietling, Hamilton, Bulova, IWC, and Rolex branding among others. Authentic Vietnam era GG-W-113's were front loading, one piece cases featured hacking and manual winding. If a watch looks like below, it's guaranteed to be a fake!1 point

-

Hi Judging by the methods used up to now this is a real sticker. I had a screw back that was cross threaded but it Gave in to the glue / nut system. I would have thought if it was a snap back it would have moved a little. It is conceivable that the case back gasket has perished and glued the back on. The only chance is to soak the back of the watch in some acetone/spirit in the hope it will soften. wish you the best of luck on that one Cheers1 point

-

The bright red casing and 70's aesthetic reminds me of a quirky German made sport timer/ wrist watch that was made for the 1972 Olympics. It came with either a snap on stopwatch casing molded in bright red plastic, or it could be put into a wristwatch casing, also in plastic. I have this on my radar to add to my collection someday.1 point

-

Hello. Good day. When I was a child I used to service my parents' clocks as a hobby, most of the times always with disastrous results I have to say. 45 years later I'm going to return to my old ways. Yesterday I discovered that those tiny incabloc lyre springs like to fly far away when grabbed with the tweezers. Shouldn't have been out of its hinge to begin with, I know. The tweezers make a tiny "click" sound when it escapes and... oh well. I love Mark's videos, everything seems so easy!1 point

-

Two fine looking watches you have there. I'm not quite sure that "fine" would be the best description of the one I have just been working on however. By a bizarre coincidence I have also been looking at an oversized pocket watch, but not one with quite the same gravitas as that one. A Dax (Westclox) made some time between 1973 and 1979. -> https://clockhistory.com/0/westclox/series/series-20-1/style-147-1.html This one also keeps the neighbours awake at night with its ticking. Here is a comparison with a Timex from around the same period. The Timex is positively dainty compared with the 50mm case of the Dax. As you can see it shares more of its pedigree with alarm clocks than fine Swiss timepieces. It came with all of those apprentice marks, so obviously someone else has already had a crack at getting it going (without success I might add). It is now running reasonably well (as compared to an alarm click, rather than an Omega Chronometer obviously). The beat error fluctuates more than I would like, due to the poor tolerances but following a clean and service it is sitting +/- 10 sec per day or so, so long as you don't pay any attention to the wild variations that will no soubt occur when you actually carry the thing around. It polished up nicely and a little T-Cut restored the factory shine. It has a certain charm, but I certainly wouldn't rely on it to catch a flight.1 point

-

That is just the day/date corrector wheel and it does not affect alignment in any way, otherwise, it would have mentioned to you. You can try lifting and gluing the gear on the back of the day disc. Maybe it's just me but I don't get the importance of having a particular 2nd language on a day wheel. In fact many modders like to use a dial without day at all.1 point

-

Plating on a small scale is possible, but there is a bit of an art to it. Google/YouTube has a bunch of videos and articles on the subject. Watch/read some of these first to see if this looks like something you would be tempted to try. It has also been discussed on this forum a number of times, so try a search here too. Removing chrome is also possible, but bear in mind that the process either produces chrome salts if chemical stripping or reverse plating, or chrome dust if using a mechanical process. Chrome compounds are generally petty toxic, so should be handled and disposed off carefully (see your local disposal laws). You are producing relatively small amounts, so evaporating/drying off the waste, and disposing of it at your local waste facility would probably be the best route. Stripping chrome from brass can probably be done with household bleach and various acids. The exact method would depend on the underlying metal. See the following link for some basic tips. https://www.wikihow.com/Remove-Chrome-Plating Once stripped, the work piece should then be bright polished, and I would suggest that a relatively heavy copper plate should be applied to help fill the pitting, before a second bright polishing is done to give the base for the nickel finish. Be aware that any threads, drilled holes or other features on the work piece should be preserved by coating in wax or whatever, otherwise you may have issues re-assembling after the plating process. Take safety seriously when doing this, always wear gloves throughout these processes, and avoid breathing in any vapours as much as possible. If you do attempt this, don't forget to let us see the results (even the failures), as this will assist anybody else who is tempted to try this.1 point

-

If you can get it within say 2 minutes a day with a cylinder movement, that would be acceptable, as you know it is not compensated so the weather will play its part.1 point

-

Hi Guys Flwatchguy, No you did right to question it its all to easy to cock it up. Checkout Kirk Fassbenders project on dialfoot soldering machines they are all read only and will not allow down loads although I have seen some of his stuff up for grabs. If anything mentions copy write I read it and leave it. By the way Keep the soapbox you might need it again some day. This is a brilliant site with equally brilliant contributers covering a multitude of watches, clocks and things in between, long may it continue. there I have got off my soapbox now all the best and thanks for policing the content.1 point

-

To take macro pictures with a common phone just place the eyeglass in front of the lens. The reason why I was asking for a picture of the screw is because there are actual screws horizontal to the plate, and dial retainers that are actually eccentrics, these are mounted vertically. It would be perfectly normal to loosen an eccentric in a clockwise direction, but it would be very strange to meet a left threaded dial screw, because there would be no reason for that.1 point

-

I don't know how good these mobile phone apps are, I have generally steered clear of them. I'm not convinced that the phone mic is entirely suitable, or that the app can filter out sounds that aren't the watch. Have you tried the app with a different watch to see if you get a more stable reading?1 point

-

Just look what is the smallest hole size that fits. For the seconds hand the pointed. It is not difficult but I recommend that you practice well first on watches of no value and for each hand pay observe that turns horizontal after having set it. Also, there is no "mechanism" made for crown or calendar in a given position. What changes are the case, dial, and wheel(s).1 point

-

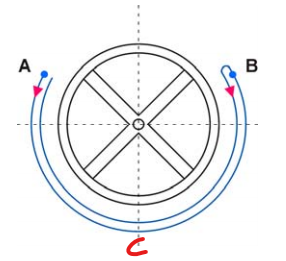

Nope.... Amplitude is the angle of rotation from the balance point of rest to the furthest point it reaches from it's point of rest. So amplitude = A to C, or B to C. A to B is amplitude X 2. Your video seems to show an A to B rotation of about one full turn, or 360 degrees, which equates to an amplitude (A to C or B to C) of 180 degrees.1 point

-

Soft solder a tiny shim of brass so the end just covers the pin and file to shape. Or you could just bend the pin so it touches the other brass part of the regulator. After all the hairspring should be part ways up and not at the bottom so it could slip out.1 point

-

Hi there not as accurate as a timing machine but it would surely give you an idea how its going , you should be getting about 250-300 degrees any more is a bonus ,yours looks like about 310 degrees .However positional error ,amplitude in different positions would be a bit more challenging . Then you've got beat error which you can't see .But I think it's ok for a general idea. Hope this helps1 point

-

A picture would help, however most material houses carry a good stock of hands.1 point

-

Hi there , what movement or watch is it ? some pics would help as many types of hands are available from material house1 point

-

Today's wrist watch has again already been featured, so today I'll showcase my huge Roskopf Messagero pocket watch. I dunno what size it is, 20s maybe.. Bigger even. I love the dial and the bold Roman numerals. It ticks so loud people have randomly asked what was ticking. I don't know an awful lot about it, other than it's Swiss, pin set, pin pallet, possibly 7 jewels, did I mention it was huge? 66mm to be exact. The barrel bridge reminiscent ofthe batman symbol. The little one is an 18s Waltham, it measures 55mm and looks tiny1 point

-

With a name like Graziano I think I'd look good with a godfather watch ,and the jerky tourbillon could rock in time with my machine gun1 point

-

Hi all! My name is Alex, product designer with great interest in watches. Always liked them but since I inherited a vintage Omega Seamaster and got into the process to have it repaired and sliiiiightly modified by changing the strap to something more contemporary, I really want to get into the world of modifying Seikos. Added to the fact that I just had my first child, I wish to develop a hobby, a skill that perhaps could pass to him as well. If not, all is good, I can give him any watch I will be modifying. I just received my toolset(s), some from China some from more reputable brands like Bergeon. Shall I have success, ongoing interest and time to modify watches (as well as budget!!! hehe), I will try to enrich my toolbox. I got a case from CrystalTimes, some parts, as well as a seiko snk807 to practice on but I need to order more parts. I joined the forum to share my future creations as well as start asking some questions. Here is my vintage Omega1 point

-

1 point

-

Guess who makes parts for such prototype pieces? Our own Nickelsilver , isn't this something?1 point

-

Salutations fellow noob: I would take a walk through the flea markets & hit up the stall holders for non runners!... Market stallholders are a unpredictable bunch, maybe if you looked the part.... Just a thought1 point

-

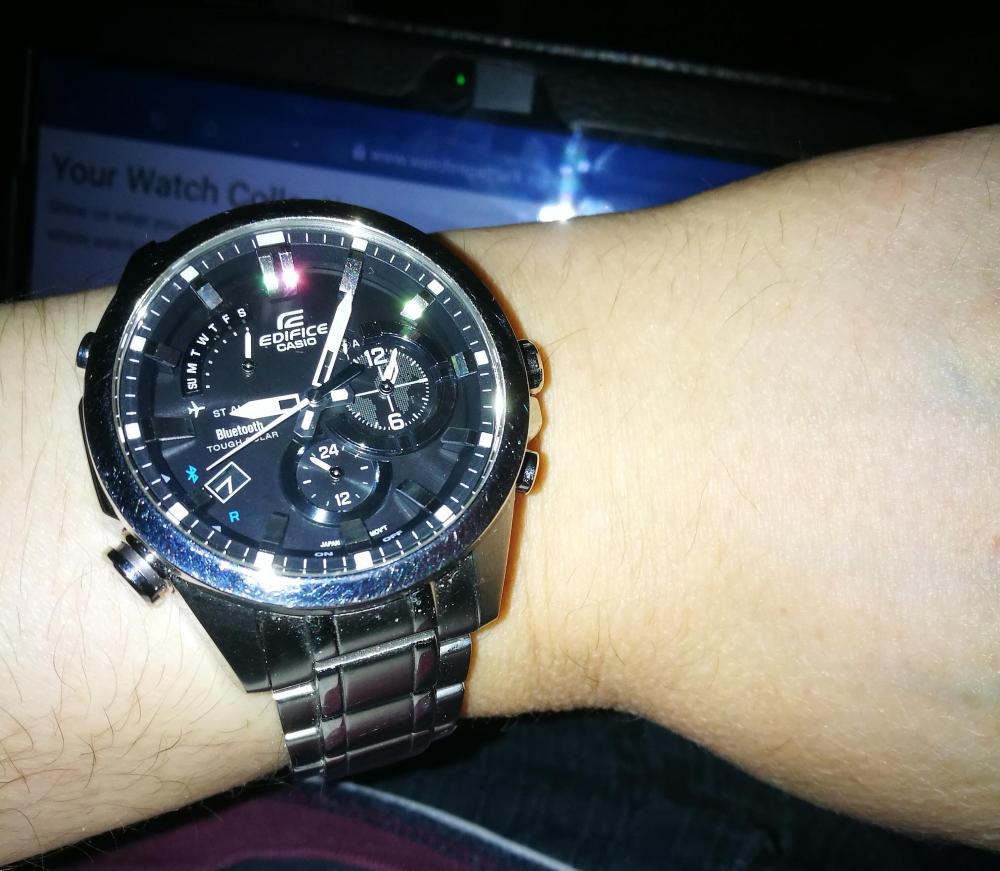

Today's 'Beast From The East' is a quite well worn (Read Scratched) Casio Edifice EQB-510D its about three/four years old & to date has given no issues whatsoever, a tad chunky I suppose, but you certainly know that your timekeeping needs are being catered for at almost 200grams & 45mm on the case diameter.... Its a good 15mm thick, however as you can see its complication rich, so I guess they needed a lot of space to shoehorn the 4529 movent in.....1 point

-

the c/p needs to be tightened OFF the center wheel. its a friction fit so it will not tighten when in place, it needs to be tightened on preferably a brass tapered wire. Dont forget to apply a smear of grease or thick oil on the center wheel post so that the c/p does not seize or wear loose. especially in calendar watches were there is no rapid date setting. john1 point

-

Thanks for all your responses and ideas. I am only a hobbyist and rarely encounter loose pinions, so expensive tools are not really an option. I have been through the sewing box but no needle fine enough, will have a look for one next time I,m out shopping. I have made a tool from an old pair of nail clippers. The sharp edge has been taken off and a screw (8BA) fitted, with locking nut, into one of the arms so that the gap can be limited and fine adjusted. It works OK with about the same care as needed for similar tools. I am trying to improve its rigidity for better control (cost so far zero !). As I asked in my original post, would it be ok to crimp onto the centrewheel shaft whilst it is still in the movement?1 point

-

As you turn the balance wheel to the point that escape wheel starts to move, where clock-anticlock turns shows you the interval within which balance wheel should receive impulse energy, the midpoint of this interval is your TDC. Immediately passed TDC, balance wheel is in beat. To sustain oscillation, this is where all escapements, regardless of the design, are to deliver energy to the balance wheel. I mark both ends of the said interval on main plate or bridge with respect to the point on balance wheel, where you saw impulse got delivered. Manufacturers normally mark the wheel with a dot.1 point

-

(1) On tension spring side of center pinion, what lubricant should we use on it's pivot that sits on T spring. (2) what about lubrication of the dial side of center pinion? Which sits on center jewel. Tension spring is there just to keep center arbour in place, should not push on it's pivot, a .01 mm free play is required for seconds arbour. In pendent up or down position, you should see no effect caused by T spring, installed or removed. I have seen this type of movements start loosing amplitude a month after service. Just have culprits at center pinion to blame.1 point

-

Yes, it's possible. The proof is in your own two hands, so to speak. If there is not seconds bit (separate circle) under the center of the dial, you have a watch without a second hand. It will have been designed like that. This was often done to house a hunter case watch (winds at 3 o'clock) in an open face case (winds at 12:00 o'clock). It's quite common on ladies sizes, which the 6s is generally considered. I'm not familiar with what the grade "W" is. They ran anywhere from 7 jewels to 17J, I believe. I don't recall seeing a 6s Waltham with more than 16-17 jewels. Enjoy.1 point

-

Just got this Sprite the other day had to service movement and give it a new crystal came out pretty good. Sent from my SM-G975F using Tapatalk1 point

-

1 point

-

As the usual you're on the spot exactly. I wanted to clean my set which is like 50 pieces, and stupidly put them in a cookie box with alcohol and let it rest for the night. The box plating left for to the stakes in form of a sturdy black! I was able to restore completely with green cleaning pad on a rotary tool, but it took forever! That to say that is not just just about cleaning and the time involved, but also knowing how to do it, something which not everyone is supposed to know well.1 point

-

It's not a bad idea to clean it up but bear in mind you have something like 200 pieces there. As said above you don't want to affect the original functional surfaces, so a gentle method like steel wool and oil to remove rust. Any pitting will be left but that's better than digging deeper. At 2 minutes per part you're looking at 7 hours of work and fairly well beaten up fingers, so ask yourself if it's worth it for 50-75 bucks more when it sells, if it even makes a difference. Personally I prefer buying equipment grungy but original rather than shiny but less functional.1 point

-

If it is nice and clean, buyers will more likely buy it, also you can ask a good price, its even better if it is complete.1 point

-

1 point

-

1 point

.jpg.91b3d69f686ed46788f6c95c3406494f.jpg)