Leaderboard

Popular Content

Showing content with the highest reputation on 03/07/20 in all areas

-

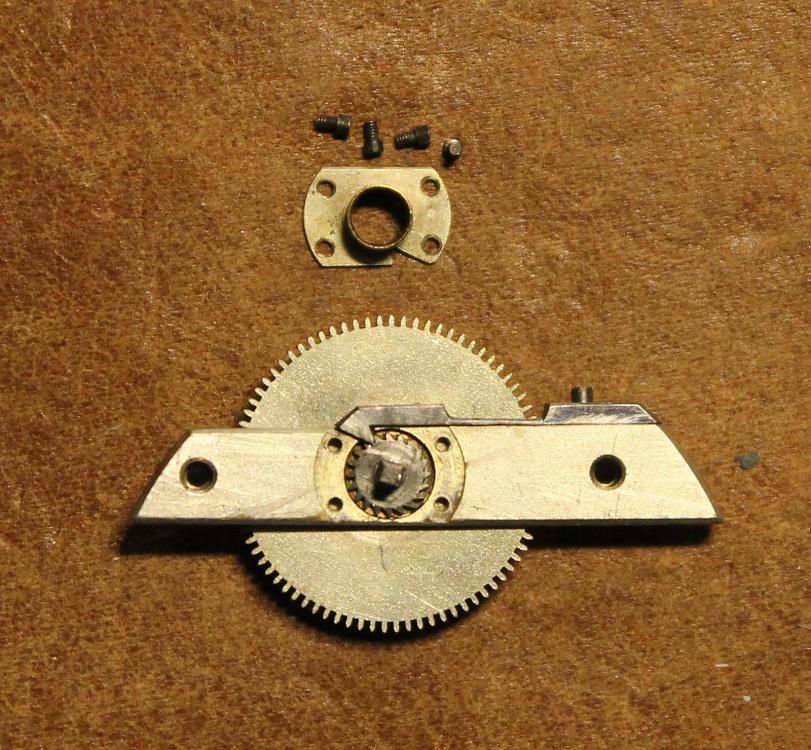

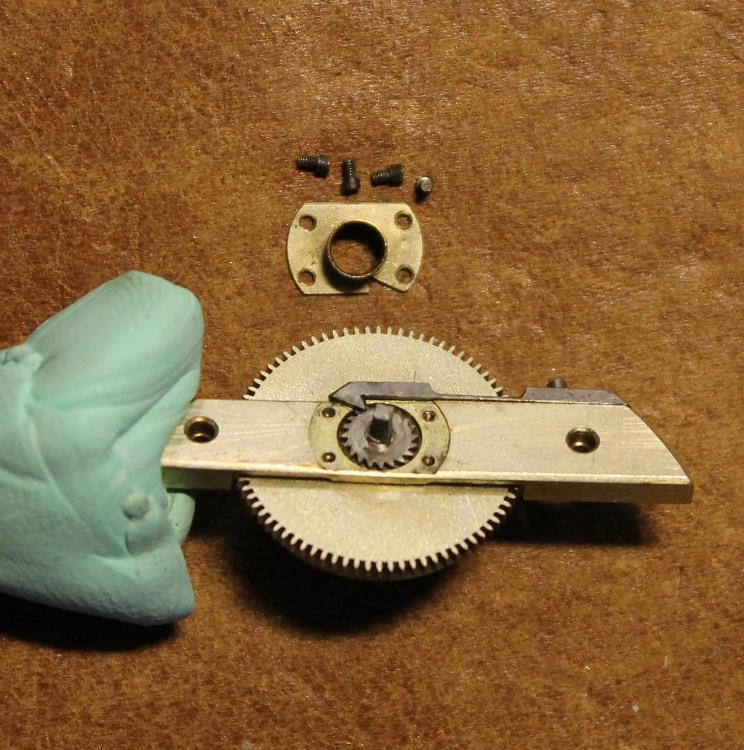

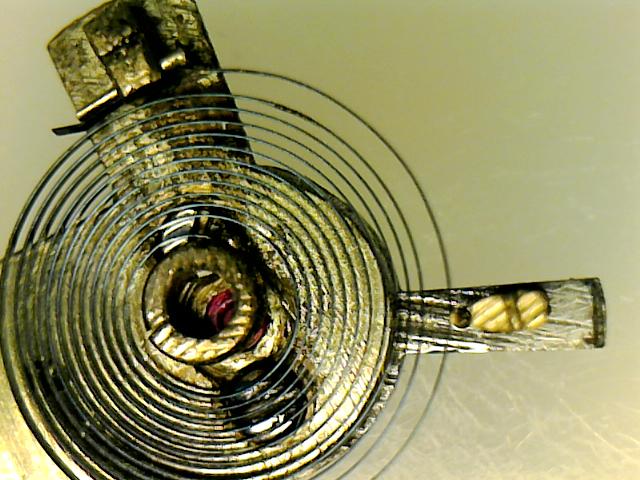

Hello All; Today I was handed a key wound pocket watch, or rather what was left of this none-runner, with the question if I could fix it up again ..... It's a cylinder movement, damaged porcelain dial with both feet intact, has a partial hour hand, a replacement seconds-hand , no crystal and a silver case. Two watchmaker marks in the back lid; Megol '84 and 15/8/'66. Looking at the state of the watch, I don't think the Megol '84 was 1984, but more likely 1884 (?). Currently I'm stripping the movement to assess the damage; The main-spring was fully wound and seems intact. The balance-staff pivots seem intact, however when lifting the balance-bridge only the hairspring came up, the hairspring-collect lost (probably due to too much play) grip with the balance staff. (Needs to be looked at at a later stage) Once the balance wheel & cylinder were removed, the wheel-train seems to rotate fine. Currently I'm trying to open the spring barrel, but encountered a system which I haven't seen before and don't know how to open the barrel ? The arbor seems to go through the bridge and is connected to a ratchet; both ratchet and arbor seem to be one piece ?? How do I open the barrel and remove the spring ? Top-view of the barrel-bridge with ratchet, click and winding pinion; Side view; Bottom of the spring barrel & bridge; Any help will be greatly appreciated ! If I were to proceed with the restoration, another question would be how to line up the balance-wheel with the hairspring so the cylinder is "in beat" ? Anyway, that would be a bit further down the line, first the damage assessment ...... Hope to hear .....2 points

-

Hi JJM tell her the dog ate it. A very generous offer SStakoff, My theory on oils is the same as food the date is a guide if it tastes ok smells ok eat it and at 76 and still going (just)2 points

-

I bet a shudder went down your spine when it came to settling the lube account!...... Best hide the receipt from the other half!2 points

-

I completed the job yesterday. I was able to snip the extra pivot length down to the right size and push down the second hand...perfectly. I was really worried about snipping the pivot as it could break in another spot without the absolute perfect tension on the pliers. It was a complete success. As well, I did not glue the new JD-Pivot to the remaining wheel shaft as there was enough friction where glueing was not needed. I reassembled the movement and case and it looks great. Sent from my iPhone using Tapatalk Pro2 points

-

Hi Graziano that tool does exactly the same job but uses a screw others use a small punch to do the job. I think your tool is better as it has micro adjust which is more controllable2 points

-

Well, I just thought it could possibly be an option to try in case the OP doesn't have a wife in his toolbox.2 points

-

2 points

-

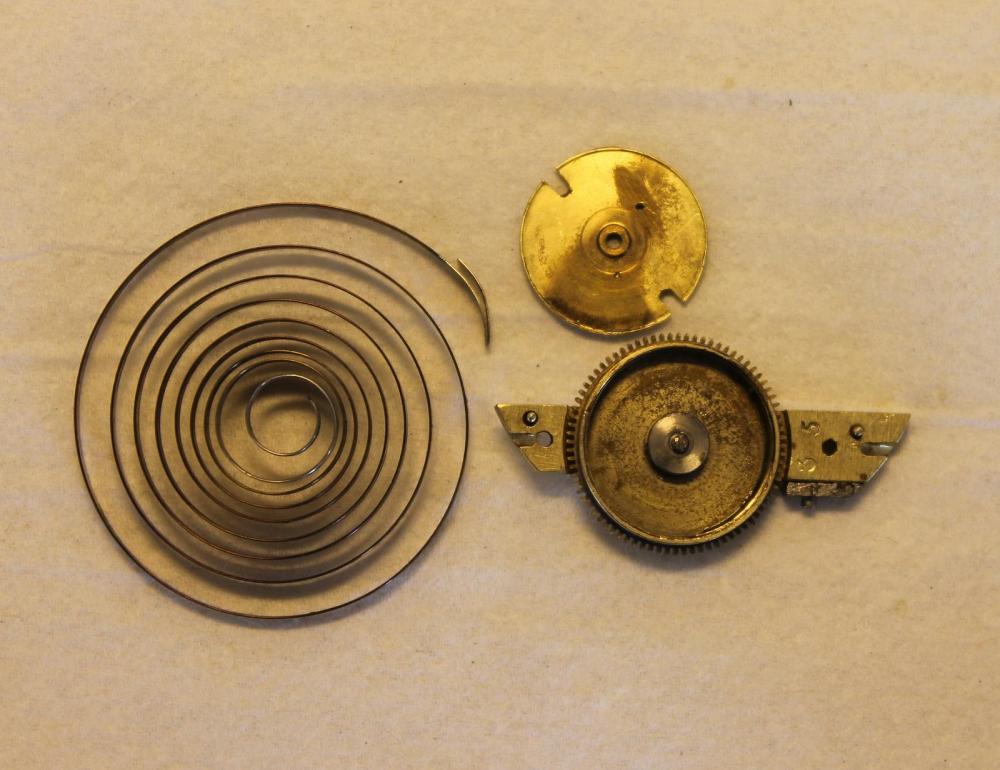

This is what as known a 5 bar p/w movement about 1880. With the barrel cap removed the arbor should unscrew from its center part. Some can be very tight so be careful when under taking this, some refuse to move and you might have to clean it in your machine partly dismantled.2 points

-

This is a suspended barrel, held only by the bridge. What looks like a screw slot on the lower end of the arbor is what's left of the hole that took a pin to hold the stopworks finger in place. The lid snaps of, pry in one of the openings. The hook is screwed onto the arbor, it will have two holes to take a spanner. Hold the square, and unscrew the hook. As the adjustable pin spanners are hard to come by, you can grasp the hook with flat pliers lined with paper tape or wrap paper (or copper even better) around the hook. Sometimes they will unscrew just with stout nickel or brass tweezers grabbing the hook; at least in wristwatches.2 points

-

MetalX makes strippers for different metals, I use the solution on nickel plated cases. It will remove the plating and leave the brass. I then polish the brass so it looks like gold then I replace with nickel using electrolysis. Then I polish again. Doing your own plating is very easy, chromium May require other steps in the plating process but I never dealt with it so iam not sure. But many videos on the tube in regards to metal x and electrolysis.2 points

-

1 point

-

1 point

-

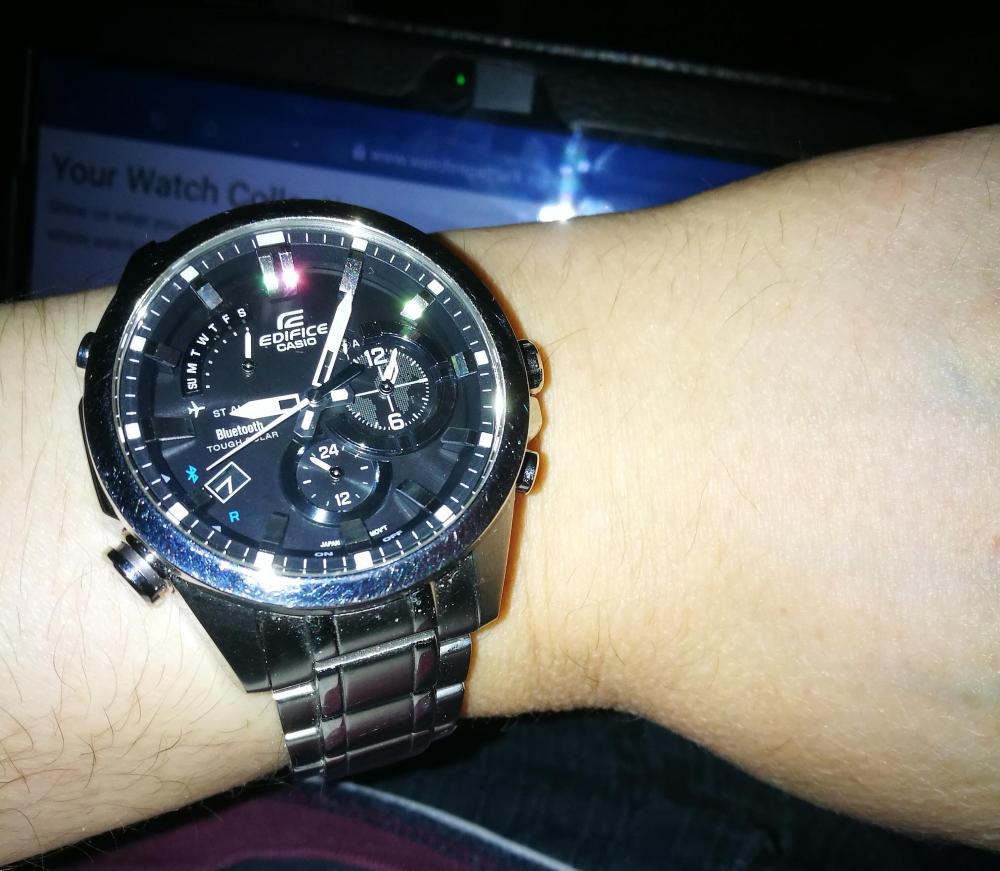

Today's 'Beast From The East' is a quite well worn (Read Scratched) Casio Edifice EQB-510D its about three/four years old & to date has given no issues whatsoever, a tad chunky I suppose, but you certainly know that your timekeeping needs are being catered for at almost 200grams & 45mm on the case diameter.... Its a good 15mm thick, however as you can see its complication rich, so I guess they needed a lot of space to shoehorn the 4529 movent in.....1 point

-

I am no legal expert but I believe that once an author leaves his work for 13 years in electronic form on public website where anyone can download, print or otherwise distribute it, there is little chances he can threaten if is re-hosted with full disclaimers about the provenience. In fact, this one is also hosted on a bunch of other watchmaking, or PDF archives. I believe it would be a bit different would be if one was to use an illustration or text portion in own work without permission.1 point

-

i lucked out. with a few military, vintage wrist watch cases "deeply pited" between the two wars, the US auctoned off a pile of military marked NOS cases. someone in New York got them, probably Freed. they are still trickeling out, some of those militaty marked cases modified for a proper winding stem and crown. vin1 point

-

I think you are about to open a can of worms. The base material is unknown and there may be layers of a kind of "filler" between the base material and the chrome layer. As said, High-Gloss chrome is not a DIY. Nickel plating is doable but you have to be prepared for any outcome. See this thread for further information / study; https://www.watchrepairtalk.com/topic/3831-design-watch-plating-project/ Suc61 point

-

Oh dear, not only bent but also worn. The cylinder is made up of 3 parts, two plugs at each end and the center part. They are very brittle, I can tell you if you try and bend it, it will snap. Finding a replacement will be very hard. Knocking the old plug out you need cylinder punches for that, stakes from an ordinary will not fit. I think you have an impossible task.1 point

-

the c/p needs to be tightened OFF the center wheel. its a friction fit so it will not tighten when in place, it needs to be tightened on preferably a brass tapered wire. Dont forget to apply a smear of grease or thick oil on the center wheel post so that the c/p does not seize or wear loose. especially in calendar watches were there is no rapid date setting. john1 point

-

I expect it is silver but not English, more likely to be French or Swiss.1 point

-

Than there is the pocket watch case ....... I'm not sure whether it is silver or (has been) silver-plated? There is a Hallmark in the back-cover, but Google searches didn't yield conclusive answers. I do have a silver-dip, but if the base material is something else, the results could be "catastrophic". I'll try to polish an edge, but won't go any further until I know for sure ..... Anybody seen this 2mm high hallmark and knows what it is ?1 point

-

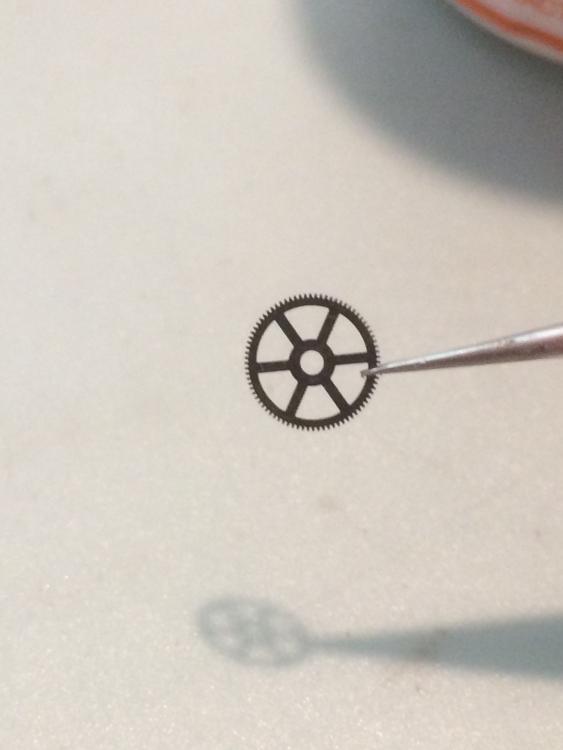

Recently I have been restoring a Roamer watch movement which had suffered from water ingress. The centre wheel was really badly rusted and although I have a donor part I thought I would try "Horosolve Rust Remover " Well the instructions suggest 10 mins or longer for badly effected parts. BUT I dipped it in the solution & because of family commitments I completely forgot about it for two days. ANYWAY see pics the centre part of the wheel was completely dissolved gone. I don,t know the formula/chemical in this stuff but it must be very powerful indeed. AFTER !!!!!! BEFORE (not the original,this is my donor part)1 point

-

Hi a chistle punch is a small screwdriver ended hard punch. the cannon is mounted on a fixed chistle shaped stump and the loose punch taps down of the nipping point to slightly indent the cannon for the friction fit. There are purpose build tools for the job, I made one years back, cant find it now it will be somewhere in a box.1 point

-

Thank you all for your suggestions and help The barrel-lid was indeed a "snap-on" and it was "snapped-on" well The arbor was perhaps different as from what I understood out of NickelSilver's description. It still may well be that the arbor is screwed onto the ratchet-wheel "driving-spindle", but it may also be that the arbor is "pinned" onto a spindle and that outer-end of the securing-pin also acts for the arbor-hook (?). The normal bridle spring was unhooked and removed. Instead of dismantling the barrel assembly any further, I'll stick to Oldhippy's advice and clean the assembly "As-Is" As for the cylinder balance; I haven't come to that part yet, but there are plenty of marks on either side on the balance-wheel rim and a pin which most likely indicates the center of the cylinder, to be lined up with the center-line of the escape-wheel (?) I'm sure that when working on and lining up the balance wheel, some of these marks will start to make some sense () and NuceJoe suggestions. The hairspring needs a tiny work, the first coil goes a bit tight around the collet, most likely the reason for the slight off-center. I was thinking of giving the hair-spring-collet a few small punch-marks around the edge to reduce the inner-diameter slightly. The bend regulator-pin sticks outside the regulator key, allowing the hairspring to come out of the regulator arm. I'll be back with further updates and / or more questions Thank you very much so far !!1 point

-

Another bargain bin Scotsman on its way, this time, not a Timex, but a Westclox from Dumbarton. This is pretty much all that remains of that once bustling factory. https://en.wikipedia.org/wiki/Westclox_Scotland1 point

-

In other words, first , find the position on balance wheel that escape teeth engages with the rest of escapements mech, be it pallet, cylinder or else. Principle are dynamically the same, only mech designs vary. The interval during which, escape wheel interacts with the rest of the escape mech, is bound by drop and lock ie: the wheel goes through drop and lock, the rest of that period it just sits there and cheers the oscillator do a good amplitude.1 point

-

Hi, this is only a discussion forum. Members are not allowed to offers goods or services for sales. You will have to locate a reputable repairer local to you. You can also check a Seiko forum like SCWF for recommendations.1 point

-

Hi there oldhippy , I feel for you .You still have all those great memories that you will never lose .Grief is like the ocean ,it comes on waves ebbing and flowing ,sometimes the water is calm sometimes it is overwhelming .All we can do is learn to swim .You are very fortunate to have loved Cookie as many people have not unlocked that part of their soul.Take care and keep on keeping on1 point

-

I collect (and restore) firearms mostly military and mostly vintage and antique. I do not invest hundreds or even several thousand dollars into a firearm that has no provenance. Last one I bought was an 1880's Parker double barrel shotgun from R. Lee Ermys gun collection. I did not buy it until his son Clinton contacted me and said a notarized signed letter would come with it and a Picture of Ermy with the gun with it. It came and I bought the gun (hangs beautifully above the mantle) This watch set off every red flag imaginable to me. Hooker died in 79' the movement is an 83' model and that was huge to me. I felt it to be a pile of (insert word of choice here). Thanks guys I figured this was bunk but I'm new to watch repair and to some extent collecting. I have been buying them almost all my life but just now taking time to know what they are and how fun it is to do this! I contacted the seller for provenance last night before posting here. He has yet to return my E-mail. Simon.1 point

-

Hi Regarding the glass Try bruce.davidson@btinternet,com I have ad a few cut by him Ships clock flat, thick with beveled edges. I sent him the bezel and he did the rest and a good job. In your case send the bezel and the glass thats in it so he can match,, worth an e-mail cheers1 point

-

Hi Have a rifle through the wifes sewing basket for a pin/needle to fit the bore of the cannon. I prefer to use a small chistle punch to close them as you can do it by degrees slowly and check after each tap. The use of blunt top cutters has less control. Have a look on the bay for canon pinion tools, might be cheaper than buying new ones.1 point

-

Hi From memory I think the ratchet wheel is a friction fit on the square and will tap through with a brass or plastic hammer... Setting the spring onto the cylinder there is usually a pip on the balance rim for alignment purposes same as the platform escapement version, I shall need to read up on that procedure. It looks a nice old piece and should come up quite well when polished.1 point

-

1 point

-

Hi Gary find attaches the pics. The problem with your spring is the rivited attachment on the outer end has broken off leaving the rivit stump and nothing to attach to the barrel see pic 3316 and 3313 enlarged. Without this attachment the spring will not hold on the barrel wall notch 3312. in short the spring is knackered and needs replacing.1 point

-

Have you disassemble the watch to verify what the problem is? What I've seen happen on other watches using this design is if the canon pinion part doesn't rotate the drive wheel will slip and eventually wear itself out. Occasionally flipping that wheel over and putting it back on again works. Tightening as noted above sometimes works if you're careful. By far replacing it would be the best if it's available. 925_ETA 2770, 2772, 2782.pdf1 point

-

Countless spare hairsprings were produced during the past hundered years, what dose that tell us?1 point

-

I have been watching this vid with huge interest. Why, well this job is more common than I would like as spares are becoming more and more difficult to source. Cousins sell "quick pivots" for clocks but watches/pocket watches are a real challenge. I don't know why but French clock pivots cannot be drilled even after annealing. Great job done JD another vintage watch brought back into life.1 point

-

In it's restored splender, running very nicely, on a 'Condor', flexi bracelet from the period..... Only downside is the bloody enormous seconds hand!1 point

-

If that's a '404 Club' candidate, what is this one that I got a couple of weeks ago for £0.02, yes that's right two pence....1 point

-

Chrome will be attacked by acid. The higher the acidity, the faster it will be removed. Perspiration, or sweat, has a slight acidity and therefore a chrome-layer will, in time, be eaten away. How fast and how much depends on many factors like the acidity of the persons sweat, the contact duration, the quality of the chrome layer etc , etc. I don't know how the front of the case looks like, most likely the "damage" is restricted to the back-side. If you want everything a 1000% perfect, the old chrome layer has to come off and the case needs to be re-chromed. High-gloss chrome is used and that is not a DIY job. Applying a nickel layer is another story, has another appearance and is not as per original. The watch has had a life and a story to tell. You can erase all the age/life tell-tales, but where do you stop? Re-chrome the case, remove all the patina, install a new dial, new hands and while you at it, a new movement? Also, it seems to be on the back-side of the watch, a place normally nobody sees .... Polishing too aggressive and too much and you will go through the chrome layer making things only (much) worse. Considering the fact that you may do more harm than any good, I would leave it "AS IS" is .........but that's just my opinion1 point

-

If it was a stainless steel case they can be refinished and polish to look like new. If you're dealing with chrome plating on brass as mentioned above not much you can do. Although you could try going to an automotive supply store where they have polishing supplies for chrome items found on cars maybe they have something.1 point

-

Hi, yes, it's pretty frustrating. These are base metal (brass) cases with a chrome plate over them. I personally have never found a satisfactory solution as the pitting goes pretty deep. Good luck with finding a workable solution. Maybe finding a junker watch with a decent case? I've had some luck with that. Anyway, the case back looks beautiful! Nice job!1 point

-

My thought is that you may have pushed the hands down too hard, pressing on the hour wheel under the Face. Just a thought. See if it runs with the hands of or the face off. Sent from my iPhone using Tapatalk Pro1 point

-

1 point

.thumb.jpg.1e0c8e712e274abf69e39fb770fd4b73.jpg)