Leaderboard

Popular Content

Showing content with the highest reputation on 12/29/19 in all areas

-

Decided to take a shot of the pocket watches I have repaired. Sent from my iPhone using Tapatalk Pro4 points

-

I was unable to remove the end cap jewel without risking breaking something real bad and I don't have an automatic oiler so I did as good as I could with cleaning and lubricating. The jewel had almost like a cup on the other side of the plate so I put some oil there after pegging. I'm pleased with the results I got from the watch timing machine so I will let it be for now. I think it is a nice looking watch !3 points

-

For those that don't know the Shortt Free Pendulum clocks were made from the 1920s to the late 1950s and were the most accurate clocks made between the 1920s and 1940s. Only 100 of these clocks were made and they were sent around the world to observatories and anywhere else that needed the most precise time keeping. Very simply describing the clock it had a master unit that ran in a vacuum and a slave unit that synchronised to the master free pendulum unit and then could send timing signals to any number of other slave clock units. The Perth Observatory which is now run by volunteers has 2 of these clocks Number 11 that was made in 1926 and after serving time at the Royal Observatory, Greeenwich to 1940, then it went to Edinburgh in 1941 for the duration of the war and then back to Greenwich in 1946 and then to Perth Obervatory in 1960. The other clock Short clock that is at the Perth Observatory is number 94 which was ordered by the observatory in 1956 and delivered in 1957. Besides these 2 clocks the observatory has a number of other significant clocks that they are wanting to get running after decades of static display. The president of my association had been in talks with them for some time to service and repair these clocks and started doing so a few months back, but has only just in the last few weeks started working on the Shortt clock. It had been 'fiddled' with by people he didn't know what they were doing and besides being gummed up solid for reasons only known to the person that did it they had put paint over the ends of the friction plate on the centre wheel so it could no longer slip. On boxing day he got the slave clock ticking after fabricating a new gathering wire and jewel and stripping and cleaning the whole movement, but it still needs some adjusting. I went to visit him yesterday to have a look and bring my reference book 'Synchronome Masters of Electrical Timekeeping' by Brober Miles that was only just published to help him out with some of the items he was a bit lite on with information. Whilst I was there I took some photos which I thought may interest people. Dials of Slave Clock Couple of the inside of the slave unit Apologies for this photo but I couldn't get a good picture with the sun shining through the window, but this is the vaccum chamber for the free pendulum Stand alone slave dial. I've got more photos and a slow mo video showing the pendulum being given its impulse but this is the limit I can upload to one post. This is a very special rare clock, but once it is finished then number 94 will get the same treatment. Number 11 is a type A model whilst 94 is the simpler type B model.2 points

-

The first bend after the stud looks it has a little to much bend . Maybe that makes the coils touch .2 points

-

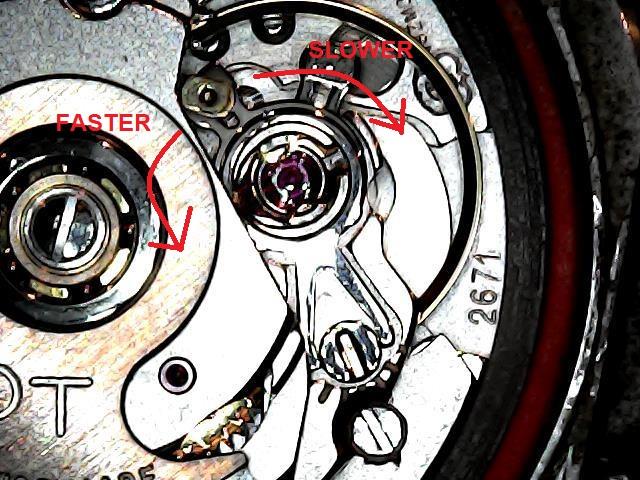

Hi having looked at the photo there seems to be no + or - marked, so to increase the rating of the watch shorten the spring length, conversely to slow it down lengthen the spring. So working from the point where the balance spring is pinned moving it away from the pin shortens it speeding up the watch , and moving it towards the pin lengthens the spring slowing it down. Be very careful in this adjustment as a slipped screwdriver can cause much damage to the balance spring.2 points

-

T sounds to have enjoyed using his No 1 tweezers to shape an end curve on the tics ass so it never tocs again.2 points

-

2 points

-

Dose the post mention item location? Mumbay technology? Normally If I can,t get a pic of whats under the hood and return option. I am done shopping.2 points

-

Hi, my wife has a Tissot PR50 which runs +3 mins or so a day. I would like to try to regulate the watch but I don't own a timegrapher. I watched the tutorial below but I'm not sure where the regulator arm is located in a Tissot PR50. And I can't find any markings that say + or - (or anything else). Can someone please point out how to regulate this watch? I attached a picture of how the watch on the inside looks like.1 point

-

To be sure youre right. Ill do that next time. Thanks for the advice. Sent from my SM-G950U using Tapatalk1 point

-

The stud doesn't look vertical to me in the middle pic. Is it just the weight of the stud making the spring cone downwards ?1 point

-

Hi I have down loaded the tec sheets for the ETA 2671 which I think is your watch and will give you a bit more insight into what is required. As jdm mentioned it is always a wise precaution to de magnetise any watch when working on it to eliminate any out side interference . The files are the same I think one just updated. 27_ETA2660,2671,2678.pdf 2803_ETA2671(2010update).pdf1 point

-

1 point

-

Hi Underneath the balance there is a logo and a number which denotes the make and caliber can you please quote these Ithink the logo is ETA, I might be able to find the technical sheet for the watch for you which will help. From the picture it looks like the spring anchor is the one on the left the right one being the regulator. When the screw is turned only the regulator block will move. Do Not move the balance spring Anchor point as this will upset the beat. When the balance oscillates it has to be equidistant i.e. the same both sides of the oscillation. Its the balance spring anchor point which sets this beat the regulator just alters the spring length by beating between two points which when moved radially around the spring effectivly lengthen or shorten the spring governing the rate or speed1 point

-

You got a good coil there, unlikely to foul itself, just gentle... gentle. Give top view from the cock side.1 point

-

Hi I normaly use a pair of round nose pliers to avoid kinking the spring and have had no problems. I would check that the anchor point will actually fit in the spring slot if not no amount of re forming will make it fit, In such a case the answer is to open the spring slot with a jewelers file or needle file.1 point

-

Check the stud that it is straight. Sometimes the coil have been twisted near the stud. I often have to remove the coil and check that the stud is pointing straight . Also check that the hairspring is sitting horisontell . As it look now the hairspring is going up from the stud. Try very gentle to press it down and see what happens to the rest of the hairspring.1 point

-

1 point

-

Hi I think Joe is on the mark. The balance spring is running out of flat. The coils are concentric and beating ok but the spring is not perfectly flat, If it is clipping the center wheel during operation it will need adjusting around the stud point to bring down the outer coil slightly.1 point

-

Center wheel 224.086 is the same as on 4R series and despite the different number I believe is also interchangeable with the 7S26 B or C. Seiko is not detailing or distributing fixed jewels anymore, but again I believe it's common with the above. Cousins UK should be able to order at least the wheel, or if you PM me your address I can gift you the 7S26 parts.1 point

-

Now it's a bit too close, I needed to see the whole balance/hairspring area. You have to rotate it by just a bit. The regulator is sensitive. There are 2 tabs/pins near that jewel. When rotating the screw one of the pins will move. If that pin moves towards the beginning/exterior of the hairspring then it slows the movement down, if it moves closer towards the inner coils then it moves faster. Basically the regulator sort of shortens or lengthens the hairspring.1 point

-

1 point

-

Hey Mudos, the regulator you are looking for is this one. That screw should be turned depending on whether you want it to run faster or slower. Unfortunately I can't figure out from the photo which way you should turn it. Can you provide a closer photo ? I believe it's clockwise to slow it down but not certain. There's a pretty good app called Tickoprint which can help you regulate it. It's sort of like a timegrapher.1 point

-

Yep, going with glass cutter. https://www.hobbytools.com.au/assets/thumbL/BK8098.png?1560322947 https://www.alibaba.com/product-detail/Top-quality-six-wheels-glass-cutter_382983976.html1 point

-

It's a glass cutter https://www.aceuae.com/en-AE/suki-glass-cutter/930206.html1 point

-

Ticks can have nasty side effects if you are unlucky. I think the tick that bit me was a paralysis tick Ixodes holocyclus But the government health website says as long as I removed it completely and promptly and don't develop any symptoms there is no need to go to the doctor. https://www.healthdirect.gov.au/tick-bites1 point

-

As mentioned a $13 dial is perfectly acceptable and certainly better than a damaged one. https://www.ebay.com/itm/SEIKO-AFTERMARKET-BLACK-DIAL-LUMINOUS-HOUR-MARKERS-FOR-SKX007-DIVERS-7S26-0020/193110703703 Cousins UK has the genuine item for £25.95 + VAT.1 point

-

Why an expensive tool and set when there so many affordable one that work perfectly. You can use a crowned die. Place some plastic in between the crystal to avoid marring it.1 point

-

1 point

-

Canon EOS 6D Mark II full frame CCD SLR camera so I can finally use my old film lenses again. Also Antique Watch Restoration Volume III by Archie Perkins . I also got a Begeon 30070 roller table remover in the post, but that's not so much a Christmas present, as I've been waiting nearly 3 months for Cousins to get it back in stock so I could order it along with new reamers for my second hand jewelling tool.1 point

-

Jewelers files are a must have in watch repair but i really don’t think its needed in this case since the problem lies in the MS and not the arbor itself. The catch looks fine and I have never came across a slipping arbor in which the arbor was the culprit.1 point

-

Nucejoe- I don't know a specific name other than vibrating tool. Back in the days watch companies might have gad their own proprietary tools, Greiner made industrial level vibrating tools too, but the bulk of sprung balances come out of Nivarox and they have their own stuff. For the bench watchmaker the "Luthy" tool is the standard, using a master balance. A member here is making an electronic master balance to fit these tools at a very reasonable cost which I intend to try out as soon as I can get around to ordering one.1 point

-

1 point

-

You can also carefully file the catch so the bite angle is deeper. Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

Hi I think a good bottle of malt is called for, I wont cure the cold but at least you dont care any more happy days enjoy1 point

-

I think this is original. It's not uncommon at all to have one or two cap jewels at the escape wheel. In many cases we see this in higher end watches but also in common grades. The jewel count of 17 was sort of a magic number and consumers wanted to see at least that to know the watch was of a certain quality. I think you'll find you have exactly 17 jewels in this piece, including the cap jewel on the escape wheel. Almost certainly there isn't a plate jewel for the center wheel. I can't really see from the photo but there's a good chance the retaining spring is removeable. In some cases they aren't; in those, if the maker was thoughtful there will be openings around the jewel usually on the underside to allow cleaning fluids to get in and out. Not the best design, but it works.1 point

-

Def a repair. Have seen this many times esp on old 7 jewel movements where someone added a jewel for the escape pivots or even the sub second wheel pivots. In this case the jewel was set In using a vintage tool set pictured below, this tool is used to remove and install jewels. Essentially they are openers and closers. The one half of the set (openers) spreads the metal out away from the jewel to allow for removal. The other half (closers) push the metal back over the jewel keeping it in place. This tool is especially used when adding a jewel that was not there in the first place and needing to use the metal of the bridge or plate to retain the jewel, rather than screws or setting. so in order to remove the cap jewel you will need to get one of these. You can lubricate this jewel by going from the bottom and using an auto oiler to insert the oil into the pivot hole deep enough to reach the cap, but if you don’t have one then you will have to use something thin enough to get in there and not make a mess which rodico alone wont be able to clean up, thus requiring you to re-clean and oil. I find that have a very small set of round smoothing broaches, like ,005-.015 work pretty well for this. You can essentially use them as an oiler, they hold oil pretty well. Not the best way to oil but when there is no other way you have to do the next best thing, its better than no oil esp on the escape wheel.1 point

-

1 point

-

1 point

-

Flu..... For both me and the boss (we share everything). Christmas is still in the fridge, looks like New Years is heading for a wipe out too given the rather slow rate of recovery. Here's hoping that every one did rather better than us.0 points