Leaderboard

Popular Content

Showing content with the highest reputation on 04/20/19 in all areas

-

Another nice one Mo. Personally, I think it would look better on my wrist but that's just an opinion.3 points

-

My recent restore of a 1984 Timex Diver style. Problem was that moisture had gotten in because someone had glued in the wrong size crystal. After several attempt to revive the movement I moved on to a swap which was also in bad shape but did comeback quite well. I added the band was to give it a full Timex look.2 points

-

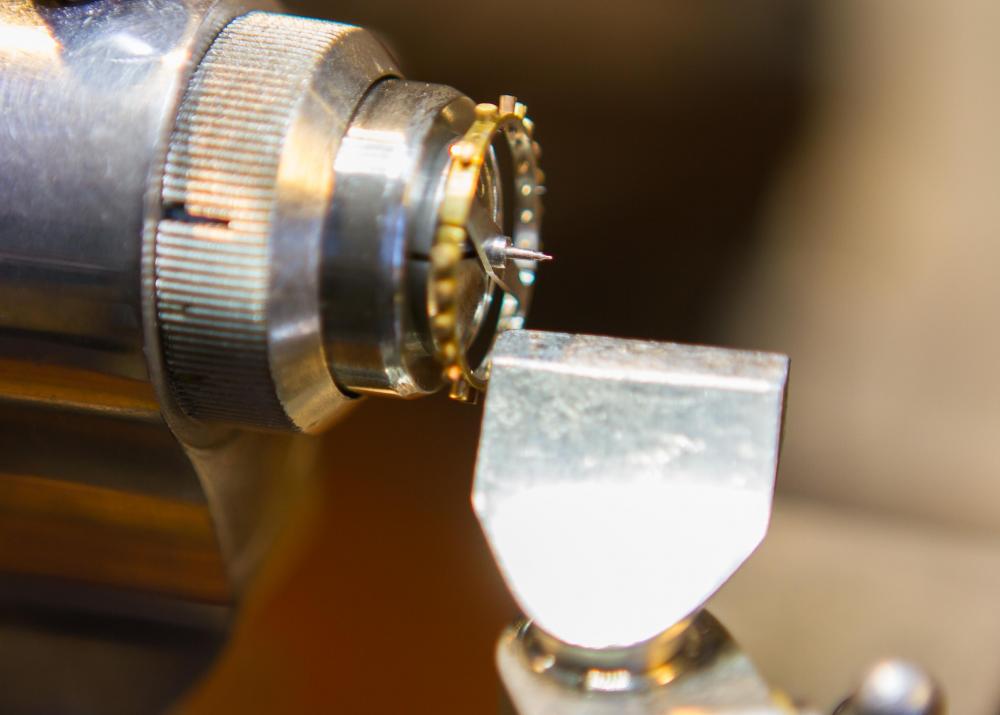

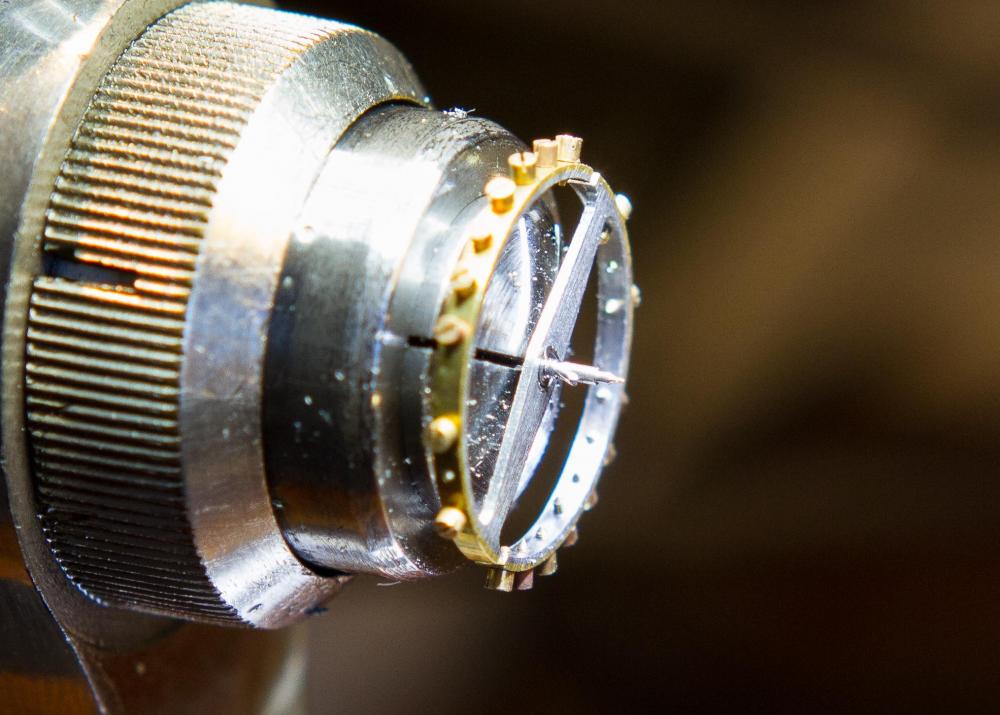

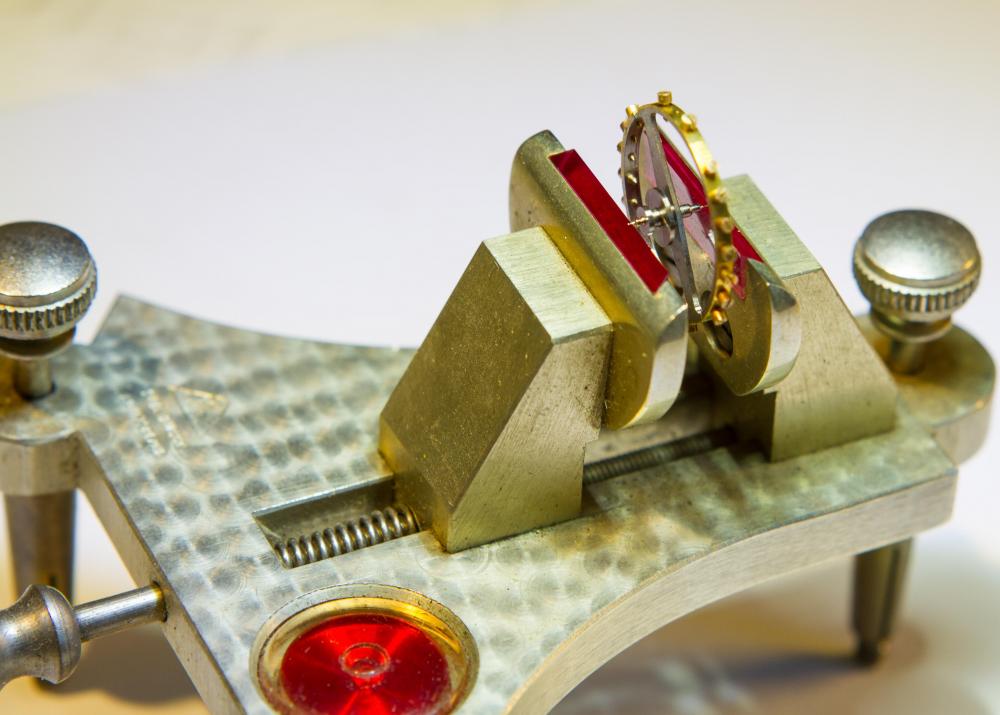

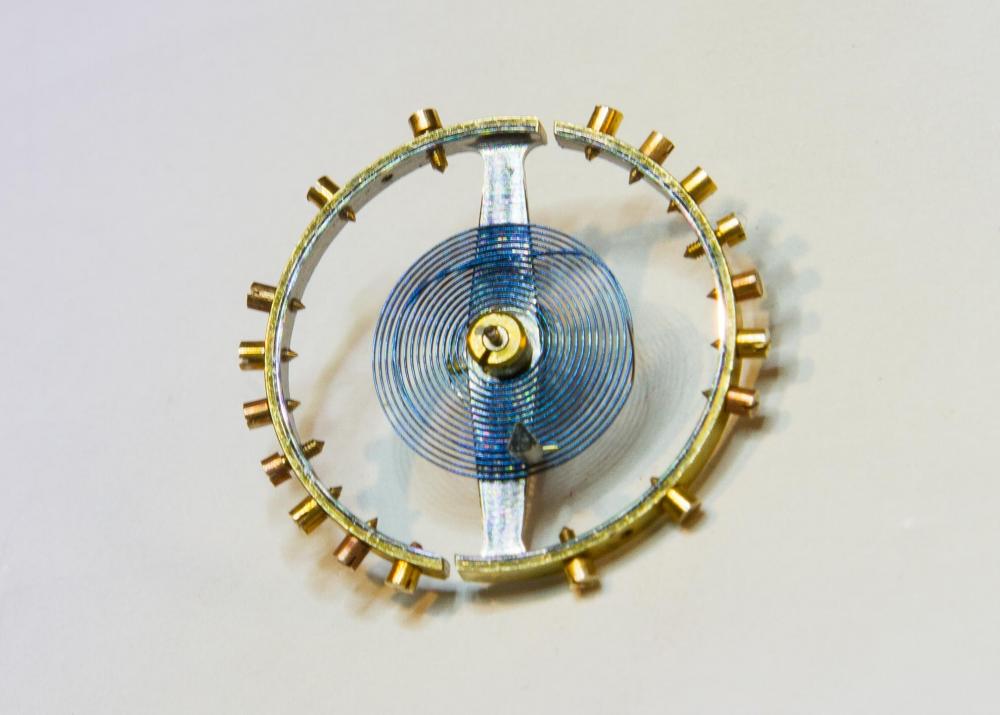

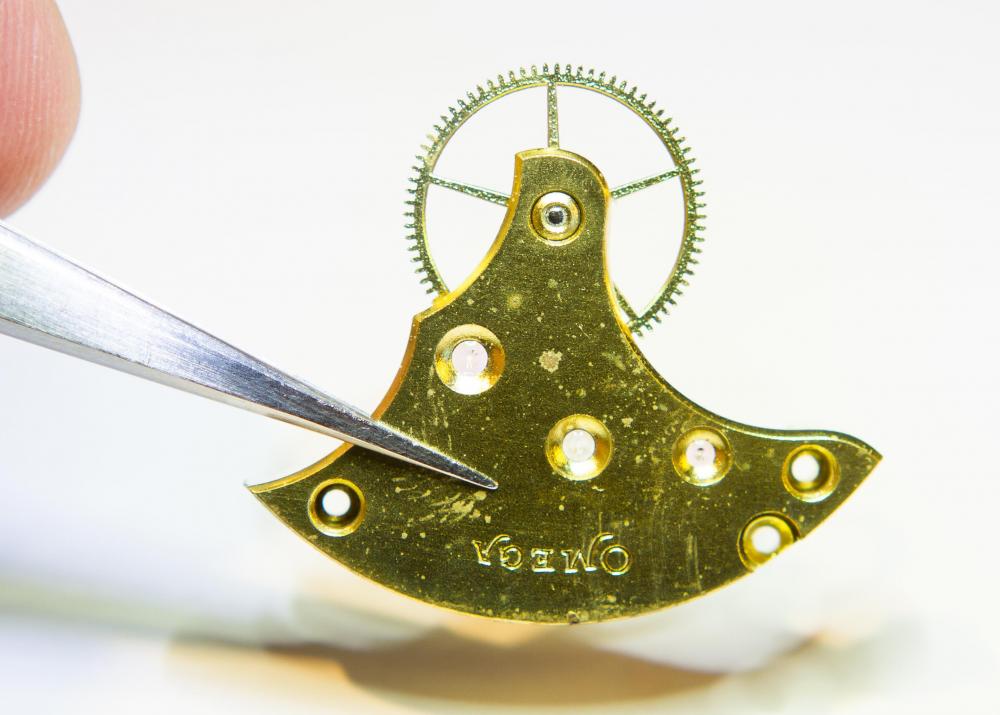

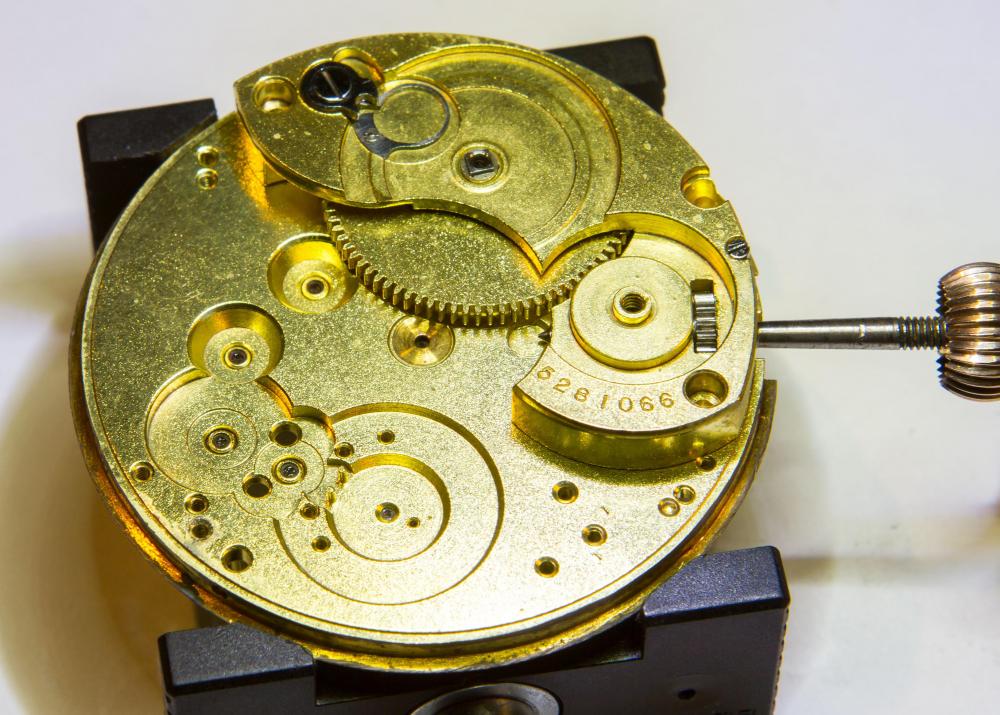

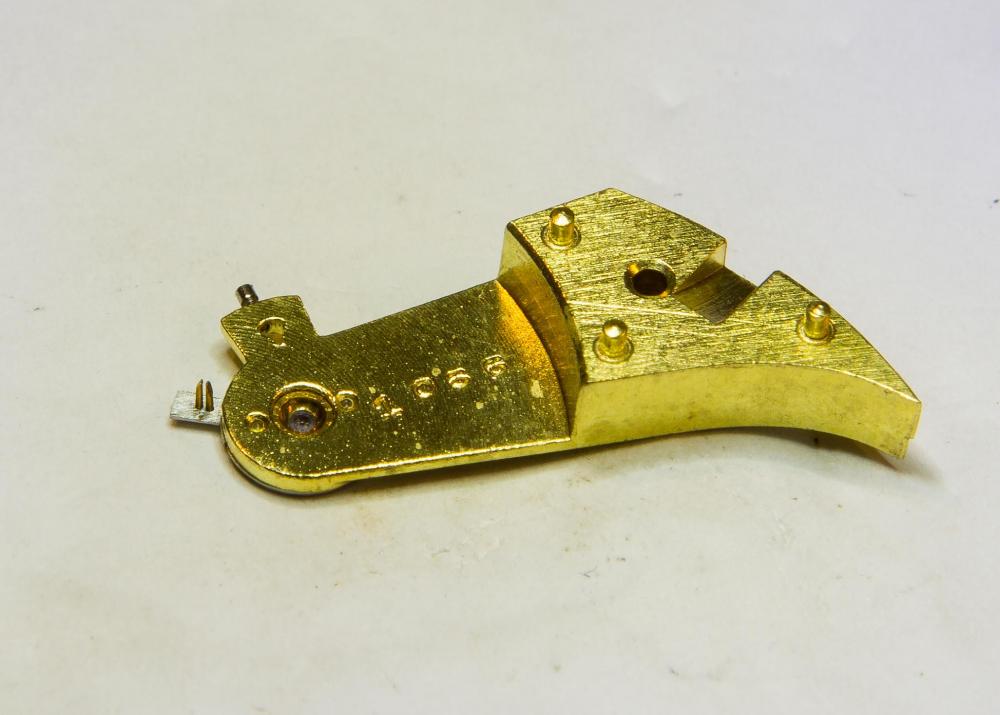

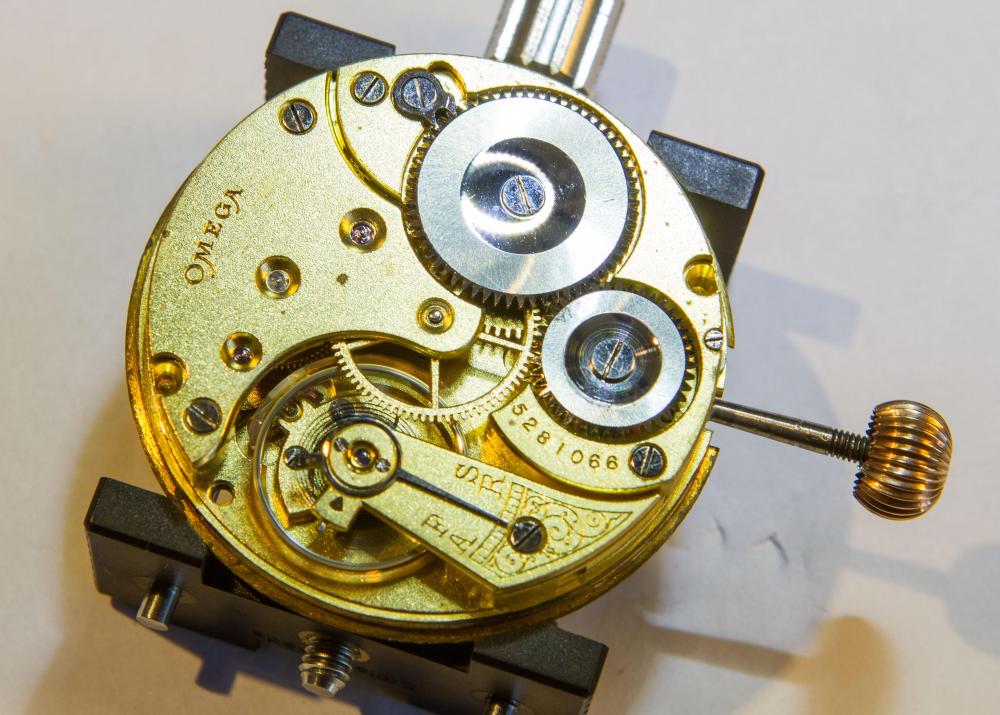

A friend asked me to take a look at a pocket watch recently which stayed in hand setting mode even with the crown pushed in. I assumed a broken yoke spring... but actually no harm done, other than dried up really sticky oil everywhere! Goodness knows when this movement was last serviced, but certainly not in the last 20 years I would guess. I didn't take any photos before disassembly as it wasn't really easy to see what the problem was just by looking. But this picture of the train bridge shows the centre wheel stuck in its bush with crusty oil Unfortunately, there are also a few fingerprints and corrosion spots on the plates, which I couldn't remove during cleaning. I found a couple of other interesting things during the disassembly. The bridle on the mainspring has a little Omega symbol stamped on it. Sadly, I don't think the spring is correct for the watch - it should be a double brace and hole spring, but only has the lugs to fit in the barrel slots, not the hole. It may also be a little short, but on the basis that it must have worked once, I thought I'd clean it up and give it a whirl. More problematic was that the balance staff was missing a little off one of the pivots - enough that the pivot wouldn't reach the end-stone, so I figured that had to go. Of course, not easy to track down a replacement balance staff for a 103 year old watch, but eBay was my friend on this occasion. New staff on the right, and what a beautiful blued Breguet hairspring Set in the lathe ready to turn off the hub Hub removed so I can punch out the staff Old staff out Punches at the ready to rivet the new staff in to place - one domed to spread the rivet and one flat to set it. The staff was a little loose in the balance arm, but it riveted down OK. Finally pushing the roller table back into place And checking the poise. It was a little out, but there was some dirt in a couple of the screw head slots and removing that seemed to do the trick. Hairspring back on and ready to go Keyless works back together and now moving freely Barrel bridge on Train wheels and jewels all cleaned Train in place One of the lovely things about old watches is the serial number popping up everywhere. It had been scratched inside the barrel and I didn't take a photo of that. but here is the marking on the back of the pallet cock. and on the back of the balance cock Quick wind and off she goes The case is stamped EWCCo (English Watch Case Co) and is hallmarked for 1927 so is therefore just over 10 years younger than the movement. It also has some case screw marks inside which don't line up with the Omega movement so obviously a later marriage. And just for kicks, alongside my Omega PW from the same year. I think I know which one John will want me to give back to him and anyway I'm still in love with those Omega hands!1 point

-

It is indeed a capacitor, not a battery. The difference is that the capacitor can be recharged an infinite number of times where a battery, unless it's intended to be rechargeable, can't. Citizen would be a bit off the mark if they used batteries in an eco-drive. The whole idea is to present a package that is totally environmentally friendly. Seiko missed the mark with their kinetic drive watches. The original capacitors didn't have enough current flow to power the watch for an extended period. You never really see or hear Seiko referring to their kinetic line as "battery powered". Rather, they prefer to use the term energy cell. Semantics. The Citizen eco-drive watches are much more efficient at keeping the capacitor charged. No arm swinging required. I leave mine beneath my Dazor twin tube fluorescent light overnight and it's good for six months.1 point

-

Hi There there are references on this site for removing broken stems from brass buttons using Alum. you dissolve the Alum in warm/hot water and pop in the button. The Alum dissolves the steel but leaves the brass button intact.1 point

-

1 point

-

1 point

-

if you read the technical document found above you'll notice on page 3 there is reference to another document? This is the document you need which explains how to fix the problem of the new weight becoming stuck if it's not properly adjusted. The only problem is you're not going to have the tools. But in the absence of lacking of the proper tools I'm extracting out the text that you will find interesting "The new oscillating weight becomes stuck if it is not adjusted to the stud (pin). The new studs designed for the oscillating weight in the calibre 550 family are 0.698 to 0.701 mm in diameter." The reamer is described as "Hard metal precision reamer Diameter 0,702 mm Reference 516 0072" then even if you can find the reamer you need the spindle that holds it in the staking set. So what we get out of this is the axle is over size and you need to open the hole to 0,702 mm. I would suggest not using the old parts just replace both of them. then if you're careful you can use watchweasol instructions with a brooch which will work just be careful it's easy to go too far.1 point

-

1 point

-

Hi, clock sits on my table I let it run down, waiting for cleaning and oiling. Cannot put the whole thing together again as the dome is badly damaged. And it is a special one, not just the ones you could possibly buy. I am trying to figure out which acrylic glue to buy at the moment as now I have two domes needing a repair. ebay1 point

-

1 point

-

welcome Nigel ! pocket watches are a good start. the older the better. newer ones - not so. vin1 point

-

Hi Ascanio Broaching by hand is permisable remember a broach is tapered therefore cut from both sides to achieve a parallel cut the secret to work slowly with frequent checking of the fit. polish the finished hole with a sooth broach or use pegwood.1 point

-

We're probably saying the same thing. Centering the impulse jewel is done (on mov.ts having this feature) by moving the endstud of the hairspring, that will make the balance staff and impulse jewel to rotate accordingly. In doing this, the total HS length stays the same, but the since the regulator arm didn't move, the effective HS length changed, and so the timing. Once that is done you would then regulate rate, at this during which error should not change at all, or by 0,1 Ms perhaps.1 point

-

Very true ,Oris and FE look very much the same, if johnnie was HS ,Oris would be a close fit. Not dirct fit yes can be fly to resonate the ribht fit. Now that a part is found ebay there is no need to fly one1 point

-

1 point

-

The HS for the Ronda-matic might be easier to source than the complete balance, but that assumes the balance pinion pivots are in good order. BTW Ranf mentions the glued hairspring that you spoke about. As I said, I think mine has a screw on the HS stud.1 point

-

1 point

-

Hi Ascanio part 550.1451 is indeed the locking for the rotor, remove the screw and lift off the rotor removing the lock as you do so . I should put back the old axle and re fit the rotor and check for freedom again. number 550.1400 is the axle. I have attached the tech sheet for the 565 just in case there are different Numbers although all 500 series are usually common. The only thing that could have bent the axle is its had a knock. You could try straightening the old axle using a pin vise over it and gently reforming it checking the clearance as you go but be gentle. 377_Omega 565 NewLR.pdf1 point

-

One I restored for a lume-rot. I will be reluming it at some point to mount in this restored model as my eyes can't easily make out the hands on the gold dial.1 point

-

Glad I found this topic as I was going to order some head band style magnifiers. Definitely will be taking a look at microscopes after seeing that a lot are happy with it. I agree, the 'eye height' has to be taken in to affect with different work surfaces. With 10X plus your holding the parts in your hand, or your bending over looking at them on the bench. I'll post also if/when I find something that works for me. Keep the thread alive, we/I need it!1 point

-

1 point

-

If you look at the manufacturing information document it specifies that a serial number is placed on the mainspring barrel bridge which is what you have which means this is a chronometer grade movement. Then of course the 2892A2 Is the base movement. The other number is usually a date code possibly a location and a date code of where the movement was manufactured. When the watch is on the timing machine is it entirely reassembled? when you're having a problem like this I wouldn't put the automatic back on or any of the calendar components until you getting something decent on the timing machine.1 point

-

Let me put it this way, if you screwed up your cartier 49 you now got a 2892-A2 . The more new parts find their way into this movement the lower the quality is driven down to. I think nothing is damaged to find a fault by test replacing parts, eliminating suspects. The things changed are the lubricants so your assembly is not as high tech as cartier, but most of all magetization. I find it rarional to make sure your demagentizer is doing its job right and you managed to get a true demag out of it. Regards1 point

-

Hello Anthony. Here are some checks I would do: 1. With MS completely de-powered and the click removed, tilt the main plate to vertical. Does the pallet fork freely move to the banking stop? Now tilt to the other direction. Does the pallet freely move to the opposite banking stop? 2. Now remove the pallet fork. Using a buffer, gently blow a stream of air onto the escape wheel (this needs to be very light and repeatable magnitude which comes with a little practice). What you are looking for is the escape wheel to slowly turn with minimal puff. All gears in the train right back to the barrel/first (or great) wheel should freely turn with no snagging at any point in the full 360 degree turn. This eliminates any possibility of damage / contamination / lubrication issues. 3. Clean the escape and pallet fork. Inspect the faces of the pallet stones for damage. Reassemble un-lubricated for now. Rebuild and run on the time grapher. Have the spikes/anomalies been resolved? If so, suspect contamination or you lubrication of pallet faces. 4. My last check for now would be look for clashes / interference of the HS with the balance wheel, and balance wheel with the screw which holds down the pallet fork cock. Hope this helps Anthony. I’m watching with interest and hope the new MS resolves the issue. Kind regards Deggsie Sent from my iPhone using Tapatalk1 point

-

ok this may be a stupid question but, did you clean the movement before reassembling? if so how? the amplitude is on the lower end but still acceptable, i think you need to make adjustments to the etachron system since its your rates that are all over the place which means problem most likely lies in the high speed low torque area aka escapement and or balance assembly. The tools can be purchased from ofrei.com or esslinger.com. these tools are made specifically for the etachron studs and pins. there is many info on how to do this on this forum and youtube. i do nbot recommend chinese replacement they are not made with anykind of quality, yhou can actually see debris within the jewels from the factory! i would get a new eta if you can figure it out etachron tools http://www.tztoolshop.com/page212.html here is a good video1 point

-

I’ve noticed there are Seiko service manuals that call for oiling the pallet pivots as well, ranging from tiny vintage 2517 mov’ts to the recent 7s series. The only reason I’ve ever heard to do this was to suppress over banking Sent from my iPad using Tapatalk1 point

-

Obvious and simple things to check when the rate varies like this (plus it’s a newer movement so seems less likely to have an eccentric wheel): - magnetism - sticky hairspring coil, or coil fouling part of the movement.1 point

.thumb.jpg.b2d9433f9d45d2e4414929af0fb4f950.jpg)