Leaderboard

Popular Content

Showing content with the highest reputation on 12/04/16 in all areas

-

4 points

-

3 points

-

epos originale 3420 A bit sorry but this slim boy will have to go. Too large for me even if just 40,5mm.2 points

-

The rest went pretty fast and well. I didn't take a picture of each assembly step, since I documented the disassembly well. The result was a success! When I got the watch, the movement stopped from time to time. At one point prior to service she did not run at all. This was what the seller described. After cleaning and proper lubrication (I use Moebius D5, 9010, 941 (pallets), 8212 (mainspring), and 9501) the movement behaves quite well for it's age between 40 and 50 years, maybe even older. This is what I saw on the timegrapher after minimal regulation. Note: the beat error cannot be corrected easily since the stud is fixed on this movement. I did not dare to fiddle around with the balance. Here are the results (° = amplitude, s = accuracy, ms = bear error): Dial up: +1s, 285°, 1.5ms Dial down: +20s, 306°, 1.1ms Crown down:+1s, 243°, 1.4ms Crown right (6 up): -5s, 250°, 1.7ms I am especially pleased by the amplitude of the fully wound movement. This tells me the lubrication went well. Next steps will be cleaning the watch as good as possible. I will clean the dial only very carefully, using no solvents whatsoever. I will just remove the dirt carefully with a pegwood. Any ideas highly welcome. Cheers Alexander2 points

-

My name is Shirley. I have been fascinated by watch repair since the sixties. My father was a watch repairman for over fifty years in San Antonio, Texas, USA. He was a railroad watch inspector for Southern Pacific Railroad back when they used to have their watches inspected. That was before quartz watches. He worked on a lot of Hamilton, Illinois and Elgin pocket watches. When Bulova Accutrons came out, he worked on a ton of those. In fact, he wore a Railroad Accutron for many years. For a decade or so, he did watch repair by day (in my uncle's jewelry shop) and worked on the railroad at night. Eventually, he retired from the railroad and bought the jewelry store from my uncle and did watch repair full time. When he got older he developed Parkinson's and his hands became too shaky to repair watches. I bought his tools and thought I might try my hand at it, but it wasn't as easy as my father had made it look. I decided to take a watch repair course, but didn't get very far before my father became too ill and I had to quit and move back home to help take care of him. In the course, I had learned just enough to strip me of any false confidence I may have had. I can take a basic watch apart and put it back together... I don't promise I could repair it. But I'm dragging the tools and a few old watches out and trying my hand at it again. Mark's videos have given me back the confidence to try. I really look forward to interacting with any fellow watch repair friends here. I hope not only to learn a bit, but maybe share a bit of what I learn also. I will definitely take photos...1 point

-

Thanks for the info, I've emailed all of the above. I tried again to remove the broken screw but without success. I've ordered a new lever from the USA. If I can't get a genuine screw, Cousins do a set of 100 various set lever screws - one should be close enough to use.1 point

-

Hi Richard. I'm new here, too, but I have been around watches for awhile. The videos from Mark are fantastic for learning. He actually services watches and explains along the way. Welcome aboard!1 point

-

Hi all I have put together a couple of pics of a recent project. This was my first pocket watch. This is my first post in this section of the forum, so I feel slightly intimated by all the knowledge around me! Limit was a British company, established in Lancashire in 1912. The 15 jewels movement in this watch was swiss made, and from my research I gathered that it was probably supplied by Thommen in Switzerland, and cased in the UK by Limit. It turned out to be very easy to work on. My previous projects have all been wristwatches (mostly Seikos!), so the slightly larger diameter here definitely helped. It also turned out easy to put it back together. Here is a summary of what I did with this watch, I hope you enjoy reading this! First the “before” picture – I bought the watch on an ebay auction for spares or repairs, not really knowing what to expect. Upon receipt of the watch, the first good surprise was that the watch was running after my first attempt at winding it. The mineral glass dial was very cloudy, so this needed to be addressed. I also wanted to completely strip, clean and lubricate the movement. Upon opening the case of the watch, the movement looked very grubby, with traces of heat having been applied to some parts of the movement in the past. I am not too sure why this would have been done, perhaps to heat up Shellac for a repair of the balance jewel? Or to burn dust residue in the watch. I was quite puzzled by this because the marks are definitely not localised to one area of the movement. I proceeded to strip the movement, no snags were encountered during disassembly. After a bit of manual cleaning, all the parts went in the ultrasonic machine for a good clean. I was not quite happy with the look of the visible parts of the movement after the Ultrasonic clean, so I gave some of them a polish, and back into the machine. I did not want to achieve a perfect result, but just wanted to make the movement look a bit more presentable. The superficial heat marks came out. Note I did not polish the balance cock as I did not want to interfere with anything there! I put the movement back together, and lubricated it. By that point, I had received a new crystal from our favourite supplier. I would normally use my crystal press to push out the old crystal, but I did not have a suitable die for this diameter, so had to do this manually. With a bit of persuasion, the old crystal came out, but not without a minor injury (cut on my thumb from the bezel edge, it was quite **BLEEP**!) so I will definitely wear gloves next time! And here it is, the watch completely re-assembled. I did not do anything to the case as I like a bit of patina, I think it gives this watch character. I put it on my timing machine, and with an accuracy of approx. 10sec/ day I am very happy with this, so will not do anything else to this one. I hope you found this interesting, comments welcome (positive, negative, or advice!)1 point

-

Hello from me. Start with a pocket watch, there just very big watch movements, just practice taking it all apart and putting it all back, get to know what the parts are called. Doing this will help you to use your tweezers and screwdrivers correctly and how to hold your eyeglass, with out screwing up your face. Stay away from fusee pocket watches there not like watch movements.1 point

-

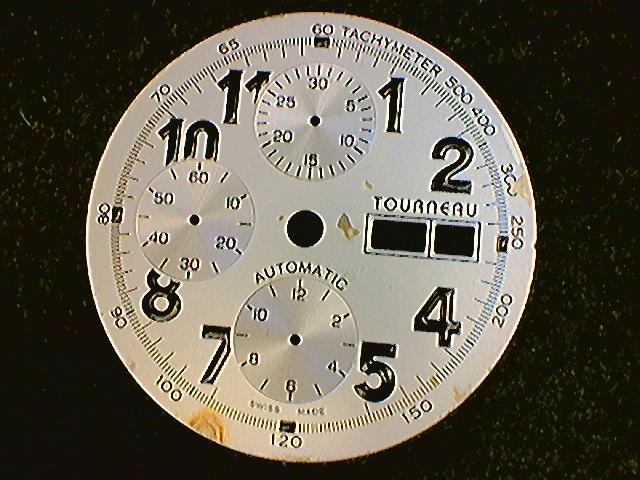

I purchased a Tourneau 7750 a while back on eBay. The watch was a mess. For one thing, the dial was glued to the main plate - missing the dial feet and it has some discoloration. Here's how it started. I finally got around to having the dial restored by International Dial. They didn't have the exact die, but they did find a suitable substitute. While they could have created a die to match the original I didn't want to incur the expense. Some pics of the dirty movement... The watch also had a Rolex crown (I think it's a fake) and the stem was soldered to the crown. You can see it in the following pic: Here it is on reassembly - preparing to attach the hands in my Bergeon movement holder: And the finished product - note I have a new crown on order - so the fake Rolex is still on there for the time being. This watch is a gift for my son.1 point

-

1 point

-

A crystal lifter is for platic watch crystals it works because it compresses the crystal around the edge and the crystal has enough give to compress to a smaller size allowing removal the same tool is used to replace the cyrstal. A crystal press is used for cyrstals that are friction fit and have no give such as amoured acrylic or glass and have to be pushed into the watch case or bezel. For your watch a crystal lifter will allow removal and refitting of the crystal.1 point

-

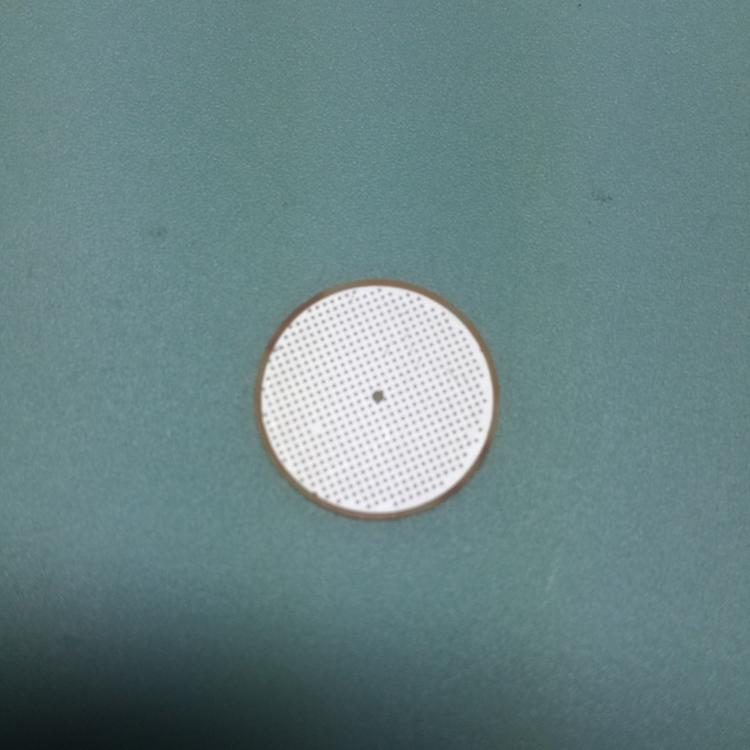

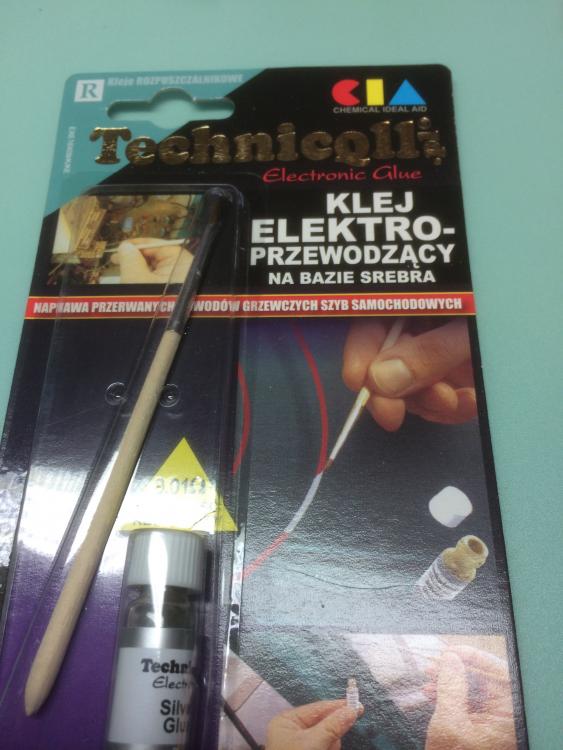

I can report the issue has now been resolved although not conclusive. I ordered a new movement which is supplied with a new Piezo disc. I found if you look closely the disc has some heat glue already attached to it's underside I therefore removed the old disc cleaned and attached the new disc applying a tiny amount of heat. The dots are heat glue Heat being applied. However maybe I applied too much heat or the disc was damaged when applying a little force,I don,t know BUT it did not work. I had a delivery of 50 Piezo discs fro China that come surrounded by a brass disc. I applied a little heat to remove the disc and attached it again using conductive glue. Conductive glue used. However this did not work either. So I removed & attached the whole disc + it's surrounding brass disc with the conductive glue & yippee it now works. I have read that this style of Piezo does not need conductive glue but it now works. I am not going go play any more but is a bit of mystery why the single disc did not work. Disc attached to was back1 point

-

A few months back, I purchased online this Breitling Navitimer for a fair price despite the fact that the watch was non-functioning at the time. I did this without seeing the movement which was a bit of a risk as there was the possibility the insides were rusted out, but the price was right and the I figured I could resell the case and dial if the rest turned out to be a disaster. Things looked bad when I received the watch as it wouldn't run at all and the pushers were jammed. I noted on inspection that the dial didn't sit flush either which caused me quite a bit of concern. Removing the caseback revealed one of the case screws had broken off and gummed up the works. Extracting the screw head brought the watch back to life and allowed the chronograph to function properly as well. Knowing I would need to extract the remains of the broken screw from the plate in order to properly secure the movement and seeing that the watch clearly had not been serviced in a while, I added it to my queue. It would be a few months before I would have time to work on it, but I must admit to being anxious. I don't often work with watches of this vintage that aren't terribly weathered but the dial and hands here were in quite good condition. Removing these gave my heart palpitations but with a bit of patience and caution I was able to get to the engine without damaging any of the paint. The video Mark posted earlier of a Navitimer service was a quite a help also as I was a bit stumped when it came to removing the bezel. The watch movement is a Venus 178 which is a fine manual wind chronograph movement that was produced in the 1950's and 1960's. Contemporary chronographs movements would be the Valjoux 72 and Lemania CH27. Disassembly was pretty straight forward. The chronograph mechanism is bolted piecemeal to the barrel plate so each lever needed to be removed separately. I would remove each spring first to release tension then proceed with the removal of the accompanying lever. Each screw was then returned to its hole so that I wouldn't mix them up later. Pictures were taken throughout the process for reference. The dial side received the same treatment for the hour recorder and keyless works. I had assumed I would need to dissolve the broken screw in a bath of alum in order to remove it from the plate but found this not to be the case. Once the barrel plate was removed, enough threads poked above the main plate to allow me to grab it with my tweezers and slowly unscrew the remainder. I have an old L & R machine for cleaning movements, so the parts were separated and packed in small baskets before undergoing a cleaning in the appropriate solvent and rinse. The case, caseback, and pushers were cleaned separately in small ultrasonic cleaner. Since the shafts of the pushers are not the same length I snapped a pic before disassembly for later reference. Following cleaning, each piece was inspected under the loupe before reassembly. I can't stress the importance of this step! Reassembly was the reverse of disassembly. I referred heavily to the images taken during the disassembly process and also used the published technical sheets and representative Esemble-O-Graf. Before reassembling the chronograph the base movement was completed and properly adjusted. Despite having already procured a replacement, I reused the original mainspring as it seemed to have quite a bit of life still in it. My assessment turned out to be correct when I placed the base movement on the timegrapher and discovered the amplitude was fairly high. This is not a problem I've had before but since the watch had a full wind I felt there wasn't much need to replace the spring with a weaker one. The beat error was initially on the high side (3.1ms) but a bit of adjustment brought that down. I suppose I would be remiss if I didn't point out that adjusting the beat error was difficult as there is no beat corrector and the Breguet hairspring sits so low that it's difficult to see the position of the roller jewel. Assembly of the chronograph mechanism is laborious as each piece needs to be checked for movement and properly lubricated before moving on to the next. I had inadvertently mixed up a few screws on the dial said which added another hour of labor to the job as well. The toughest bit was the actuating lever for the hour recorder- it passes from one side of the plate to the other and likes to fall out when you try to thread the screw to secure it. Otherwise reassembly went as I hoped- no parts lost or left over! I cleaned the dial and slide rule with a bit of Rodico. The slide rule is set in the bezel before the crystal is dropped in. A new crystal was needed as well since the original was damaged beyond repair. Lastly, a replacement case screw was procured to reset the movement and a crystal press was used to reset the crystal and caseback. I added a black leather band as the expanding bracelet wasn't really my taste. For my next chronograph project I'm hoping for a Valjoux 72 movement or perhaps an Excelsior Park EP40. We'll see what comes along though.1 point

-

1 point

-

A squeegee ball($1) for opening can help but a good caseopener will in time prove its value($ 5-10). Ofco**BLEEP** a good knife for pressed casebacks. I used to have a very simple glass press to close also the casebacks. When doing quartz, a batterytester is useful and not expensive. a watchcusion($1), for dustcovering you can use jars. A good set of tweezers , maybe add a brass one. Handremovers will prevent you from damaging the dail. On your wishlist I think there also should be pegwood and maybe a $30 ultrasonic when you want to clean stuff. Have fun.1 point

-

Ok JD we do when spotted. There are a lot of posts every day and we do try to keep things tidy. We are not on the forum all day so some do slip the net.1 point

-

1 point

-

You never know what you will find but it could end up saving you a lot of time in the end if you catch any problems before assembling the movement. A while back I repaired an Omega Speedmaster and didn't notice that two gears on the barrel were damaged; this resulted in the watch stopping after about forty five minutes of running error free. Now I know to inspect the gear teeth on every wheel and pinion before assembly. In addition to checking the gear teeth I'll also make sure every bit of dirt and grease was cleaned off each piece, double check the jewels for dirt or cracks, and make sure all the parts that were run through the cleaner made it back to the desk.1 point

-

1 point

-

1 point

-

Howzit George , That's a nice looking watch , good job . ......uh,...that coffee and cake is looking pretty good too ...1 point

-

So I did it. Replaced my first balance staff. I also change the impulse jewel on this watch so it was quite the adventure. In the end, truing the balance was the toughest job. And when I had it all together the balance just touched the center wheel when turned upside down. So I needed to true the balance again whole attached to the balance cock. Just noted where it was touching and muscled it with my fingers.https://vimeo.com/194183442 Sent from my iPhone using Tapatalk1 point

-

The movement could well come through the front of the watch on a grand prize does it say anything else on the back of the watch such as " use wrench number ---" . The watch should set turning either clockwise or counter clockwise sounds like the crown is just loose.1 point

-

I'd recommend washing your hands before working on watches. I would aim for higher than 220 degrees amplitude at full wind on a movement like this. The +65s should be easily adjusted along with the beat error (as already suggested).1 point

-

It's the bushings that wear out. Mostly in the train wheel bridge. Not that often i the mainplate. And to much oil is no good either. A little HP1300 or D5 will be fine. The arbor usually is okay? Only the barrel arbor bushing is affected? Should be fine in your watch and use it as it is no good laying in a box or a drawer.1 point

-

Welcome Shirley! You'll get plenty of help from everyone here....and Mark's videos are exactly how I've learned to do everything from simple pin lever escapements, to the valjoux 7750 chronograph. I've only done one chronograph, but I did manage to get it working perfectly. I've only recently started working on Pocket watches and just finished a nice 1899 Waltham movement in a hunter case. I believe you have the distinction of being the first woman to become an official member of WRT. Welcome and look forward to your posts! Regards, JC1 point

-

Welcome from another newbie... Do they really say, "Howdy Doody" down under? In any event, Howdy Doody back to you! I bet we both learn a lot on this forum. Looking forward to it.1 point

-

1 point

-

I've been working my way through the various chronograph calibres over the past year and picked up this beautiful Favre Leuba off eBay just a short time back. The movement wasn't named but I figured it was a Valjoux VZH and I haven't had the chance to do a Valjoux service just yet. Turned out to be a Valjoux 71 which is the older bigger brother of the famed Valjoux 72. I couldn't be happier- this one is going to clean up nice I think.1 point

-

1 point

-

Nothing quite like slowly stripping down a little beauty and taking pictures as you go. At least as far as I can remember. Long nights are back - time to get back in the saddle again. Cheers, Vic1 point

-

1 point

-

1 point

-

Welcome from another aussie. I'm in Melbourne and mainly focus on Elgins, Elgins and would you believe ? Elgins from 1867 to 1973 with a kink for their electronic movements from the early 60s.1 point

-

I spent the day literally watching paint dry. I was using black lacquer to fill in the engraving on a pocket watch case to make it stand out. I will send pictures when it is finished. In the mean time I was looking for screwdriver sharpening stone holders on the net. The sticker shock was amazing. So i said to myself, "Self" your only watching paint dry, make your own, you have a sharpening stone and some wood. So I made this from scrap wood while watching paint dry. I'm happy with it & it cost nothing. It is perhaps not as pretty as Bergeon but they have enough money.1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)

.jpg.8a21c5bda26dd240cf8d9417ecce3edf.jpg)