Leaderboard

Popular Content

Showing content with the highest reputation on 04/16/19 in Posts

-

You could also use something like silicon carbide or boron nitride, if hardness was the only consideration, but there is a trade off between price, hardness and ease of manufacture. The steel should in theory wear out long before the sapphire does, but that does not take in to consideration the ingress of dirt, which may include tiny particulate matter from the environment, the watch manufacturing process, and any cleaning that has been done over the years. If a tiny piece of silicon carbide manufacturing dust, or an industrial diamond shard from a cleaning cloth was impregnated in one of the teeth of the escape wheel for example, or was introduced in contaminated oil, it could slowly, over many years eat away the surface of the palette stones. Dirt, as you are no doubt aware is one of the major killers of watches. You can find highly abrasive dirt pretty much anywhere in our modern industrialized world. You may find this interesting.2 points

-

When it comes to the pallets, the only part that should be oiled are the pallet stone faces. Never oil the pivots of the pallets as it will cause drag and the movement will fail to keep time. You must use the correct oil for the escapement, if you are not sure which; look for one that specifically says for watch escapements. Some watchmakers prefer to oil the teeth of the escape wheel and let the combined action of pallets and escape wheel to distribute the oil. Pallet stones should be smooth on their face, any marks, chips and they should be re-placed. The stone is harder than the escape wheel so it is most likely it also is worn.2 points

-

Place an @ before his handle. E.g. "@nucejoe" without quotes. Sent from my SM-G950F using Tapatalk2 points

-

2 points

-

If the pallet stones are worn then the escape wheel is probably worn as well, changing one without the other doesn't make much sense. Have you fitted a new mainspring? If not that is what I would replace first. Anilv2 points

-

The triangle is to vote up an answer. In the topic index there is a 'pinned' post explaining the Vote Up function. Anilv2 points

-

I'm really into machining and making my own tools (generally I spend more time doing that then the actual hobby itself...), so I thought I'd start a topic about DIY tools for watch repair. My first success has been making a watch winder on the 3D printer. Winders are one of the more expensive and difficult to find tools for me, so it really made sense to start here. Here's the watch winder, it consists of three parts (from left to right): the pluger, spring barrel, and winding arbor. The only non-printed part is to drill a small hole in the arbor and put a piece of steel through it to catch the mainspring. It's certainly more fiddly than I imagine a proper tool would be and will not last as long. But it gets the job done and you can make it any size you want! You can find the CAD files on thingiverse:https://www.thingiverse.com/thing:35406601 point

-

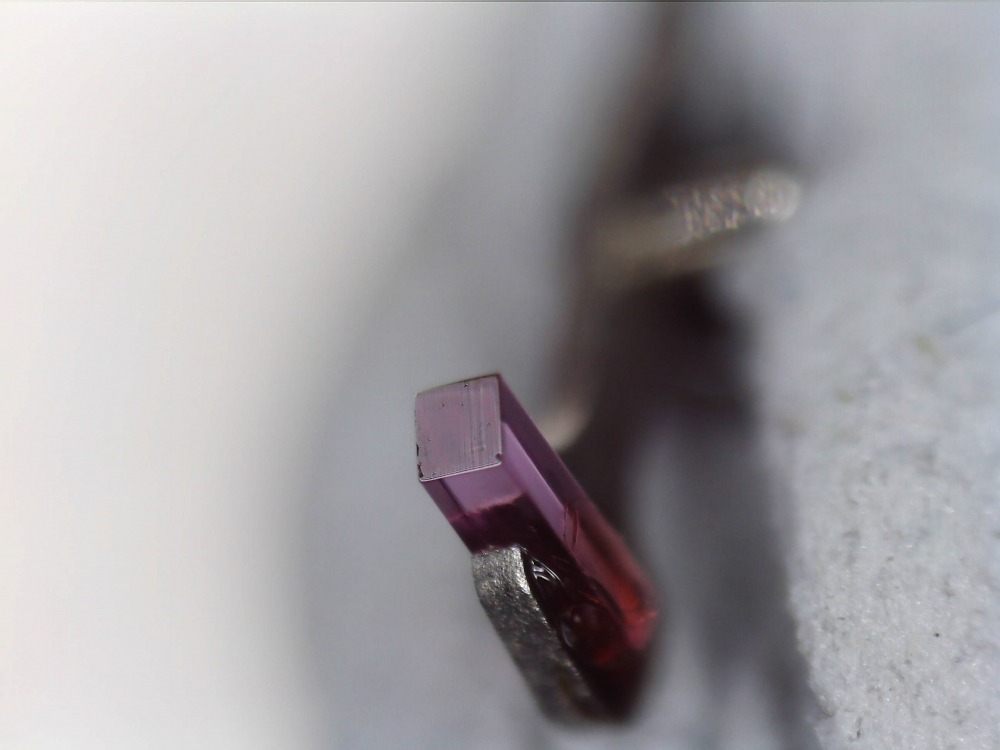

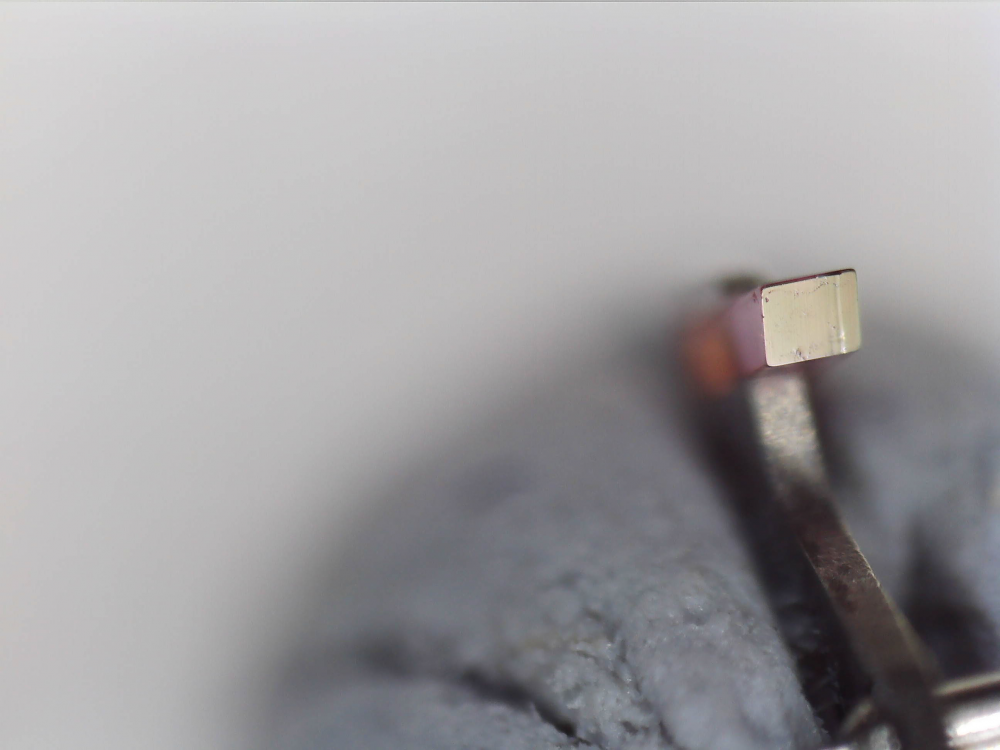

Hi folks. Ive got an Omega that's showing occasional beat errors in certain positions and only on one side. It's very intermittent and I can't work out what's causing it. Because it's just on one half of the reading (lower) it made me think one of the pallet stones could be damaged or dirty. I just put them both under the microscope to see how they're looking. Is this a normal amount of wear for a 50 year old watch?1 point

-

Not sure what is on main computer, I rarely use it jd, mostly use my Hudl. Will check in the morning as I don't want to wake grumpy up to ask lol. Many thanks.1 point

-

You can buy a software computer Timegrapher which should be good enough. I bought etimer. Not cheap but really good and all you need is a computer. Sent from my iPhone using Tapatalk Pro1 point

-

I got some watches where we tried to fix it . But ended up scraping it as it did run very well. Can have a look when i come home .1 point

-

Hi Rogart63, Do you have some spare part watches? that's awesome, I also look on eBay for cheap 5M63 watches to just get the parts, but I worry to get a watch with not working parts. Darak1 point

-

Couldn't find anything for Orient H9. Is that Seiko? If so, do you know the parallel Seiko movement number? J1 point

-

And there is my previous answer, making the both of us big duplicate posters I think that you certainly need the timegrapher but not the u/s cleaner. You can clean equally well without one, it may take just a bit longer. I had one and I don't consider it that much important. Beside, isn't recommended to use it with flammable solutions, that is the ones that clean good.1 point

-

I’m one of those ‘oddities out there’...LOL It needs a good cleaning and a new balance staff. I’m thinking it got dropped once too often. I hope I can get a balance for it; it’s a very well made time machine.1 point

-

It is possible to remove the Novodiac with a toothpick that has the point cut off, You oce the blunt end over the spring and apply slight pressure downward while turning. ...but you may have trouble replacing it with that technique because you won't be able to see it when it locks in place. I wasn't able to do it without damaging it. I would suggest you save yourself the grief and buy KIF or Novodiac tool. I bought mine from J Borel when you could buy a single tool (they come on three sizes) but now you have to get the set. KIF tools_J Borel NOvodiac_KIF tools_O_FREI Joe1 point

-

I got the front off. I used a very little penetrating oil on the rim and it came off quite easily. Thank you for pointing that out to me. Now to see if I can do something to make it work better.1 point

-

PaulnKC Glad you have found something your happy with. I use mine all the time now and rarely use a loupe. I sometimes wonder if I should have spent a bit more and got an auto zoom. Its ok when the watch is flat everything is sharp and in focus but when you stand the watch on its edge for say removing dial screws you have to wind back the focus. Ive also noticed that when using a loupe click springs fly away and you usually know the direction. Using a microscope they just 'disappear'1 point

-

I presume you mean 0.005 mm ( i.e. 5 microns) - 0.005 microns is pretty small, bearing in mind that the wavelength of light falls in to the 380 to 740 nanometers range, so adjusting to 0.005 microns would require super human vision. Shifting by 0.005 mm means a shift of roughly a third of the width of a human hair, but at the scale of small watch calibers, human hairs are like scaffolding poles.1 point

-

I'm sure there are some oddball watches out there with diamond pallets, Harrison's H4 for example had them (and Derek Pratt's replica of that piece) but that's really a unique example. Diamond is about 4 times harder than corundum (sapphire, ruby). That means that is can be used to fairly easily work corundum. But diamond can only be worked with diamond, and it's a slow process. Raw material wise the corundum is cheaper, and add to that the much lower manufacturing cost of jewels, and that generally corundum has a very good- almost indefinite- service life when used with steel, should explain it.1 point

-

I suspect because a synthetic diamond of that size would be pretty expensive. Small industrial diamonds used as abrasives are dirt cheap, but flaw free synthetic diamond is still rather expensive. Synthetic ruby (crystalline aluminium oxide) is much easier to produce, and almost as hard as diamond.1 point

-

I totally "get it" about not recognizing the old geezer in the mirror who's face I shave each and every morning. From this side of my eyes, the world still appears as it did when I graduated from high school. Full of infinite promise, endless adventure and far too many watches to even count that I haven't yet worn or owned.1 point

-

Hi Mark and thank you, I guess you expect a point for that.1 point

-

Jdm, I made a timegrapher report today, please take a look, thanks. Darak Timegrapher Report 04152019 SARX055.pdf1 point

-

1 point

-

My first watch was a Timex as well and recall getting it on Christmas, maybe 1965 or 1966. No idea whatever became of it. Maybe I actually restored it all these years latter without knowing. The sprite will always be smaller than a Mercury or any other of the made for men series. BTW: here is the 64 Marlin out for a ride on the wrist. Although not quite as interesting as a window blind, I added some "eye candy" to the photo for artistic impact!1 point

-

Hi The enclosed PDF's are from Witschi training bulletins and explain the tic/toc issue with the escapement regarding the sounds picked up on their timing machines. They may be of some use to you in understanding the action of the fork and impulse jewel on the roller Witschi Training Course (2).pdf Test and measuring technology mechanical watches.pdf1 point

-

You can get both for sure, definitely in a good kitchen supply like Williams Sonoma or something. Sometimes the N2O has to be asked for as it's a favorite among teenagers for huffing (it's laughing gas).1 point

-

Hi, you can replace the fork, but it is no must imho. There is a good chance then that you have to adjust the pallets, too. What I wanted to say, you probably have a measuring issue, no mechanical issue - my experience with developing timing machine software. In short: a tic noise consists of 3-4 single noises, the first being the weakest, but used for timing. More on tic noise you will find in the software TM threads on this forum. Frank1 point

-

Indeed so, if I were more knowledgeable Vin, at present I am an enthusiastic tinkerer, so Marks complete course must come first. Aim to subscribe in the within next few weeks !1 point

-

1 point

-

That's for sure Jdm, At present I have "the basics" my next three things have GOT to be are Mark's course, a timegrapher, and some sort of parts washer, my mind boggles at all the different tools required. The more I learn from this fantastic forum the more tools I need. Being probably one of the least knowledgeable people on this forum my head spins at times. I freely admit when I joined that I destroyed many cheap eBay purchases that have become my parts department but have been successful in rebuilding four Seiko's and that's given me enough pleasure to get more serious. (Now addicted)1 point

-

Hi and thanks for the welcome. tritto, it's always nice to hear from people living in far-flung parts of the world who know the Island. I'm thoroughly enjoying myself so far, and hopefully my knowledge and ability will build little by little as I aim to reach the "not totally incompetent" level of tinkering.1 point

-

I just thought I'd share this as it may be useful for another learner. By far the most difficult thing I've come across starting out in watch repair has been correcting bends in hairsprings. I've got the right tools, the right light, a powerful eye glass and a pile of scrap watches I've been practicing on. But I found time after time I was just making the hairsprings worse. I think part of my problem is that I'm slightly dyslexic and I find looking at the spiral really confusing sometimes. But I had a bit of break through last weekend which has dramatically improved my technique. Quite simply, I hold my eye glass up to my iPhone lens and take a close up picture of the hair spring. I then make a cup of tea and sit and look at the photo, zoom right the way in and really think about what I'm going to do. This is so much more effective than hunching over the hairspring and straining my eyes for long periods and losing patience. Once I've really thought about what I'm going to do, I go back to the hairspring with a clear strategy, ie, slight bend in, fourth from the centre at 3 o'clock. I apply the bend, take another picture and repeat. I know it sounds simple, but it's been a huge help to me and I'm finally having success1 point

-

Need to make a balance staff for a European picket watch. The old staff had both pivots broken off. First I disassembled the watch and removed the balance staff. Removing the roller table was the hardest part because it was a Three arm balance and my Magic Roller Remover would not work so I used the scissor type. I then determined the widest diameter of the balance staff and found a 2.0 mm piece of Blued Steel. I cut off 1 inch and sized the collet, and inserted in into my Boley Leinen Lathe. I then started to cut the Balance and Hairspring side by first using the old staff as a guide and marking the piece of steel with my carbide graver. I started cutting down the first diameter where the balance fits and simply cut and measure until it was snug but still room to stake it in place. I then cut the hairspring diameter next and fix and cut repeatedly until it was snug. I used a special gauge to measure as I went along. Once the part fit was good I worked on the pivot with the graver until I got it down to around 0.2 mm and then used a stone to get it to around 0.14. The rest I plan to do on a Jacot tool. I then flipped the part around with a different collet and started working the Roller Table side using the same technique. I Amos finished off the plate where both the rolled table on one side and the balance on the other side rest. Slight error in the description. I left the full part in and started working on the roller table side before cutting off the part and flipping it around...saves time. I worked on the other pivot as well and got it down to 0.14 with a graver and then a stone...on the Lathe. The final product looked great. I am waiting for a set of vintage pin gauges to get the pivot size exact. Will finish it off next week. Sent from my iPhone using Tapatalk Pro1 point