Leaderboard

Popular Content

Showing content with the highest reputation on 06/26/15 in all areas

-

Fantastic Nad!! This is why I make these walkthrough, and to see posts like yours makes it all worthwhile.2 points

-

I don't know whether this has been seen by many yet but it seems like battle lines are being drawn against the choke hold being put on spare parts. Obviously Cousins has a vested interest but then again most of us have. Worst case is I can see a black market developing and the possibility of having to bid for every part you need on auction sites instead of buying from the shelf. Anyway hopefully it does not break any rules to put his message here for interest sake. Vic Breaking News: 27/05/15 We all must Contribute to the Future of the Industry - An open letter from Anthony Cousins The British Watch and Clock Makers Guild has set up an Industry Action Fund, and I am asking all of Cousins customers to contribute whatever they can to it. The fund is to initially be used to pay for a data gathering and research project on the current size of the UK industry, and its views and requirements on critical issues such as the forthcoming ETA Parts Embargo, along with Training and Apprenticeships. Once the research is complete, the fund will then be used to approach relevant bodies to obtain Government support for our industry’s needs. The recent Guild Conference (www.cousinsuk.com/page/news) demonstrated a strong desire to grow the UK industry, and a willingness to work together in a manner that has not been seen for many years. However it also revealed how the lack of basic data is preventing us from putting a credible case before the relevant bodies for the support we need in developing the next generation of Watch and Clock Makers, and from effectively tackling the anti-competitive practices that the Swiss are now imposing. The Conference was an event for talk, and it was a valuable first stepping stone in developing proper cross industry communication, but if it is not followed up with some serious action, then it will have been for nothing. Gathering that information is the vital first step, but equally important is the ability to demonstrate that those of us who work in the industry believe in a vibrant future. That is why it is so important for all of us to contribute something. If you are a self-employed out worker, I am sure you could afford to contribute £50, and if you are a large Corporate it should be many times more than that. We must all remember that it is the end consumer who ultimately pays our wages, and they are already suffering. The practices being imposed by the Swiss on the watch servicing market are drastically reducing customer choice, and pushing up prices to artificially high levels. The shortage of trained staff is resulting in unacceptably long repair times, with the resulting frustration that this delivers. It is the people who work in the Industry that are the Industry, and if we individually take the attitude that contributing to the future is someone else’s responsibility, then there is no future to be had. If it isn’t our collective responsibility to tackle these issues, then whose is it? We all take great pride in delivering high quality service and value for money to our customers, but are we really doing the best for them if, by our collective inactivity, we fail to counter the threats that we face, or ensure that there is a new generation of trained professionals to carry on our craft? Please take two minutes out of your day to send an email to [email protected] enclosing your contact details and how much you would like to donate, and the Guild will respond with how to pay in and obtain a receipt. Thank you in advance for your support. Kind Regards Anthony Cousins1 point

-

This is a 2 part series from Oklahoma State University of Watchmaking on the correct use of Oilers. Oiling a movement correctly is one of the most important skills you need to master, and these videos give some excellent advice. Part 1 https://www.youtube.com/watch?v=eMJiX0MA-Wg Part 2 https://www.youtube.com/watch?v=rlMW5qMHaNc1 point

-

Its funny how despite having handled and still handling so many timepieces i have never bought a watch brand new for myself. So with a few ideas in mind i decided to bite the bullet and say yes, treat yourself :) Whilst i do still love my Omegas,JLC's and Rolex's, they are all pre-owned and have always been someone else's first. My first watch which i bought myself was actually a Casio but that was well over 25 years ago now and i felt the need to finally have something i can happily say is mine, and mine first. The problem i had is likely the problem we all have as watch lovers, and that's choice, so with a few key factors in mind i thought about and searched for my perfect everyday wear watch. Its been a long tradition in the male side of my family to buy a Seiko, my great grandfather and grandfather both had Seiko's as has my own father ( in fact he has had 3 ;) ). I myself have owned a few good Seiko's, again these have been used, never new. So in keeping with a family tradition i set about finding one that was just right and ticked the boxes. Requirements > Good Looking - Both daily and Dress Reliable Quality Movement Tough & Waterproof Value for money Fully Automatic with day & date Comfortable This is what i found and fell in love with..... Seiko SNZF17 K1 - aka Sea Urchin It's still very factory fresh and running a little fast ( i expect it to settle down after a few days of wear ) but she fits like a glove. The watch is stunning quality for the money ( £90 with free shipping :) ) with a very good strap that is heavy but comfortable. It is still early days but i have to say im impressed with the quality, and for what i paid i think i have a good daily wearer. I may be investing in another Seiko in the future ;) Just sharing my thoughts :)1 point

-

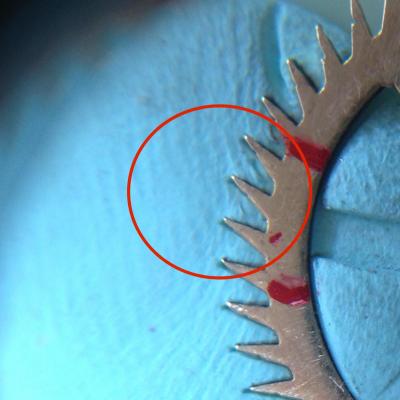

This 1920,s gravity clock that has a really simple movement required a lot of work to restore. Every bushing had to be changed with some of the bushes I had to custom make. The escape was very badly worn & the escape wheel was misshapen with many teeth out of true and all of the teeth had wear. I straighten the obvious teeth with small smooth nose pliers and every tooth was treated to a smoothing with a fine escapement file. Then see below I had to check all teeth where true, the wheel was true & all teeth where exactly the same height. See pics & short vid. Making a mould with Rodico to find them elusive mis aligned teeth Four tips of teeth mis shaped found Checking round & bending to get running true Running on the lathe with a gentle rub with a flat escapement file to get all exactly the same height Job done1 point

-

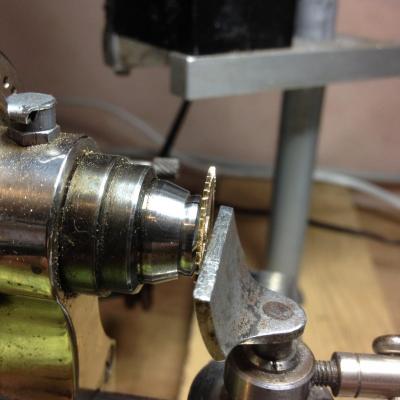

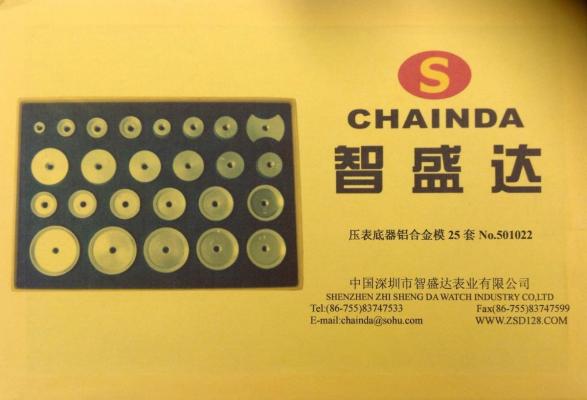

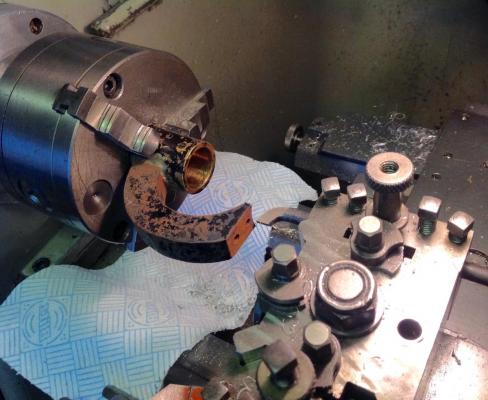

I purchased a cheap Chinese crystal press when I took up watch repairing/refurbishing a few years ago, this was one of the lever operated type with nylon dies. This has served me very well, but there are some jobs that a screw type of press is far better for because of the more sensitive control. Being a canny Scot, I kept an eye on eBay for a second hand Robur or Horotec and stumbled across this antique home made press for £14 delivered. The engineer in me immediately saw the potential, all it needed was stripped down, modified to take new dies and repainted. The other thing that was required was a set of new aluminium dies, so after a search on AliExpress I purchased these for £26 delivered from China. Right, down to business. (1) Modify the lower die holder to accept the 6mm threaded alloy dies. (2) Make an adaptor to fit the bottom of the ram with a 6mm thread to take the dies. (3) Machine the lower end of the pillar to give clearance for the largest die. (4) Accurise the dies to ensure that the faces are parallel. Many were slightly out of truth. (5) Remove paint and rust from press, paint and polish. (6) Reassemble. Total cost of complete set £40.................well pleased!1 point

-

Which of the following gives you the most ecstatic feeling? [emoji23] o "One more turn and it's all in!" - winding the mainspring into the barrel by hand o "Fourth wheel in... Third wheel in... Escapement wheel in... And they are all turning freely! Wee!" - aligning the train gears into their jewels o "swing please... Swing please... Yes!" - installing and seeing the balance assembly swing into action o "0s/day...0.0ms...270 degrees... Straight line... Not bad!" - after regulating the watch o "Such a pretty watch!" - admiring the assembled watch head without strap on wrist while still wearing finger cots o "You know what? I fixed this myself!" - telling your wife/children/friend your new hobby o "I can watch all these videos all day!" - gets popcorn and sit in front of the computer to watch Mark's videos1 point

-

Cheapskate that I am, I can't resist picking up a cheapie on eBay now and then and, for not much more than the price of a round of drinks, got this watch from the 1940s - which arrived this morning. The make is "Olma", a Swiss brand registered in 1926 but now obviously owned by an Asian company. Olma was probably in the lower half of the Swiss watchmaking hierarchy, using good, dependable movements. The one in this watch is an AS 1287 - pre-incabloc, with a typical 1940s, quasi-military dial.1 point

-

1 point

-

1 point

-

That is a cracking job Geo, you are a master at restoring! I particularly like what you did to the press and trueing the dies! Cheers, Bob1 point

-

I love this topic, here goes my 2 cents: To paraphrase Geo: "I always think of "calibre" as the the designation for the movement. A bit like bra's, they are all an upper feminine lingerie that is used on boobs, but the caliber designates the "cup size" of the bra that fits the boob." I may add it is easier to work on larger calibres. :) Maybe this is not accurate but nice to imagine! :D Cheers, Bob1 point

-

1 point

-

1 point

-

Thank you. You are most kind. I think I'm settling in. For what it's worth I have been adding my little contributions. There's not too much activity with the clock side of things, but its all very enjoyable.1 point

-

I agree! And I should have added that aspect of watch repair. At this stage of acquiring skills, I tend to focus on servicing the movement. But I guess knowing how to handle crystals, watch cases are just as important... And satisfying!1 point

-

Purchased some tweezers recently just for hairspring work. However I have been very disapointed with them although they grip the hairspring the slightest touch and the coil slips. Wishing I had purchased more Dumont tweezers I searched the internet to see if I could make them at least work better. Many sites talked about dressing tweezers and when I found this vid I realised I was not dressing them correctly. Just another one for that big learning curve.1 point

-

Hi Dave. If you remove the clamps that hold the movement into the brass ring and given the position that the stem is in just now, you should be able to separate the stem by carefully pushing down on the part of the stem that is in the movement. It may be quite stiff, but it should slide apart. If you now use a small screwdriver or pin punch and press on the pin or lever in the hole marked with an arrow, the stem should release. You might have to pull the stem to the setting position first to get access to the release mechanism.1 point

-

I have found this, so the method I used stem in setting position seems to hold some water. A word from Mark our leader may clear this up or at least give us more (hopefully) confidence in the future. http://forums.watchuseek.com/f6/winding-stem-postion-stem-removal-eta-2801-2-a-675689.html1 point

-

We are the Borg, you will be assimilated...... Welcome by the way & really like clock 3.1 point

-

Thanks Geo. The camera output is S-Video so the video resolution is limited to SD video. Judging from the amount of electronics in there devoted to the video feed I do expect the quality to be about as good as SD gets though. I don't think the video camera is magnified in the same way as the stereo optics but I haven't hooked it up yet to see if that's the case. I'm intending to get a USB video capture device and see what it looks like soon. Even at SD resolution it might be interesting to see a movement disassembled from the perspective of the person doing it so it's probably worth getting the camera up and running. This isn't my first foray into horology. I've designed and produced a few electronic clocks in the past. This has what has led to an interest in mechanical timepieces. They are beautifully made and I'd like to learn some of the skills involved. Some of my clock making efforts so far are below: - Cheers, Tex1 point

-

1 point

-

1 point

-

1.495 hour hand 0.895 minute hand 0.2 second hand When listed on sale sites I see them adv as 1.50 0.90 0.20 Try Dagaz for aftermarket. http://www.dagazwatch.com/apps/webstore/products/category/832274?page=11 point

-

Agreed - the lube required for the correct friction is 9501 Do not tighten the floating canon pinion (the one under the hour wheel) - it is supposed to be loose.1 point

-

1 point

-

I have been doing some repair work for a local jewelry store and Monday I took the owner a Zodiac Seawolf that I had restored for him and he had a pile of watches that someone had brought in and offered to sell him. He didn't want them but thought of me and asked me if I wanted to make an offer. Evidently a former watchmakers wife is selling off his estate. I thought I might get some to sell and possibly keep a couple. Almost all of them need cleaning but all of them do work. I wasn't sure about the accutrons when I made my offer but I have now found that they do run. I offered $250.00 and they said ok. The picture of the 214 was not included in the deal but the owner of the seawolf asked if I also wanted that one for 250.00. Since it is 14kt gold I said ok pretty quick. In the other picture there is a Zodiac and Hamilton tank, Bulova snorkel, Longines automatic, Tissot seastar (1 piece case), Waltham divers and a Hamilton that is puzzling me as to what it is. There may be another or so in there but I just got them and can't remember. Anyway hope you all enjoy the pictures.1 point

-

Thanks for the comments, folks. In the end I just used very fine steel wool and elbow grease. The movement was drowned in oil and caked grease, but really only needed cleaning - all the pivots were, remarkably, fine! Almost all back together - not too worried about the staining The clock - unusually elegant for a Vienna regulator, I think. Poor thing has had a hard life. Here's a quick youtube movie of the striking mechanism in action: https://www.youtube.com/watch?v=72og4a_EL_01 point

-

Just a touch of loctite on the thread of the screw. When it dries it like a plastic & it might just give enough bite to hold. If you use loctite 243 it will still undo with a little force. However a bit of a bodge really but it might be worth a try because if it does not work no damage has been done. However as they say the quickest way is normally the correct way i.e. re-tap the thread & if it does not work go up one size and fit new screws. Have you tried new screws with the existing thread because that normally works.1 point

-

Yes, it is indeed possible to use an ETA 2836-2, or 2834-2 movement, and transfer across the Chinese GMT parts to it, and have a functional GMT ETA Movement.1 point

-

One of the easiest ways of telling a fake from the real thing would be the hands. The fakes always had cheap looking hands, not refined, if it came with a bracelet that would be a giveaway rough around the edges not a nice finish not what you would expect on high quality watches. I don't know about today as even with fakes I expect things have improved.1 point

-

1 point

-

Looks a lot like my "Swiss army" watch... Maybe a Ronda 515 movement or equivalent (takes a 371 battery) ?1 point

-

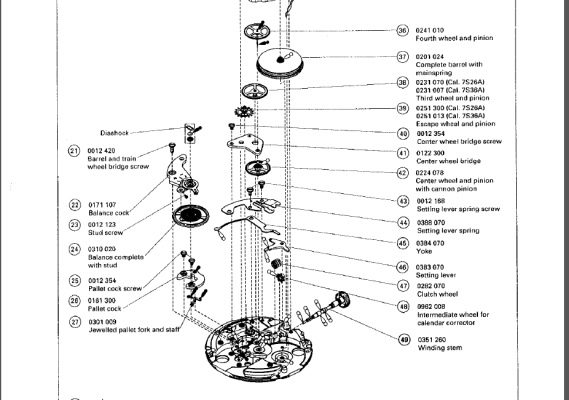

An assembly tech sheet for a Seiko 7S26 , NOT your 7625 , but they will be similar in the setting lever components layout . Also from Ranfft's watch movements webpage , Info on a 7625D ...yours is 7625A . The difference may be the jewel count or the next generation , etc. [ Taken from Ranfft's Watch Movements ... You can Google the page and in the search box type "Seiko 7625".... Seiko 7625 D.html1 point

-

1 point

-

No - there is a distinct difference. A watch "movement" is the total mechanism which drives the hands around the dial. There are various designs of movements by different movement makers - and each maker has their own set of designs, known as "calibres". So, for example, Arthur Schild was a maker of movements, and his movements are known as "AS" movements to indicate that he was the maker. Within the complete set of AS movements, there are various designs or calibres, each with its unique number - such as "1287". The movement in my Olma watch from the 1940s contains an AS 1287 movement - the "calibre" AS 1287. The movement in my Hamilton Khaki watch is an ETA movement - calibre (or "cal.") 6497. In the US, American watch movements were known as "grades", rather than the more usual Swiss (mainly) "calibres". So my Hamilton railroad pocket watch has a grade 992B movement in it. Hope that helps. Will1 point

-

Get a copy of this book The Horolovar 400-Day Clock Repair GuideIt is invaluable for anyone who is going to attempt to repair a 400day clock, although the name 400day clock had to be changed here in England, it was all to do with the trade description act, because some of the clocks could run more or less then 400days when fully wound, so technically it did not run for 400days so they changed it to anniversary clocks. There is also a very good tool that you can buy that helps to adjust the beat of the clock. I found it to be tremendously good and because of its long handle you can adjust the beat extremely finely. I'm new to this forum. I've uploaded a picture of the beat setting tool for you. I hope it shows up and its not to big1 point

-

It is known as an 8 day goliath travelling watch. If the escapement is a leaver escapement and the full train is jewelled it is of good quality. I have never seen one where the barrel is jewelled. They were mass produced so it's highly unlikely that a watch makers name would be on the movement. I can't see what's on the dial of yours, sometimes the shop that sold the item would have their name put on the dial for advertising. The travel case is I would think silver, I would say there should be a hallmark somewhere, if so you can get a good idea of the date. If it is a really top of the range the watch case will also be silver. The dial is white enamel. If yours has no cracks or blemishes you are very lucky, as I've seen so many that have even had large pieces of the enamel missing. I can tell you the hands look correct and I would think original. Some of these movements are silvered so if you are going to take it to pieces and clean it be very careful so you don't remove the silver coating.1 point

-

1 point

-

I have been off work for two weeks on holiday, and apart from doing odd jobs around the house for witch the list is endless as supplied by my other half. I have been buying a bit on Ebay and looking for reasonable priced watches for the collection one is a rather nice 1930's gents watch in a deco style which I am waiting for delivery, the other was a total gamble. A pocket watch so badly listed with out of focus pictures and a scant description. My interest was aroused even though the pictures where very bad the pocket watch appeared to have a 30t2sc movement, I have been collecting watches for over 30 years since a teenager with a love of watches, carboot sales and charity shops thay all went hand in hand and started a bug that no doctor can cure, in all that time I have never seen a Omega pocket watch with a 30t2 movement other than in books. The watch arrived this morning and has been ticking away merrily, the watch is as follows, Stainless steel case marked acier *inox* with the the usual omega triangle mark and the following reference number underneath " 1 c 418140" and measures 45mm across and is in a lepine style case. The movement is a 30t2sc with the serial number " 10093198" The dial has Omega with non magnetic printed below and has a separate second track around the outside. I have a number of question about the watch so am appealing to any Omega experts or collectors if they have ever seen one before and know anything about it. There are probably plenty about I'm just looking in the wrong place so cant find any info, many thanks, Wayne1 point

-

I have not seen one in a pocket watch case before but as the SC 30T2 is centre seconds then it lends itself well. I have just done an O/H on a 30T2 which went very well. Had to fit a new balance staff as the original had been replaced and a non-inca was fitted, was a huge amount of work to reverse all the adjustments done to make the non-inca staff work. The serial number on your movement suggests the watch was from the early to mid 1940's Did you take the picture with a low shutter speed - I see motion blur on the seconds driving wheel :)1 point

-

1 point

-

Hi guys, it's been a month or so since I last picked your brains. During this time I've been beavering away with a few projects & getting my workstation fit for purpose. As a few may remember, I picked up a sweat little longines that was gaining 1hr+ per day & would stop intermittently. After a complete strip down, service & regulating the beautiful little eta 2671 now runs like a champ. However, I'm wondering on the timegraph I'm still seeing 0.2ms beat error, but 0 s/d gain. Would you guys leave it alone now & say job done or try to get the beat error correct?1 point

-

If the seconds hand moves when you turn your watch it is a good thing: first- you have enough friction on your clutch (friction pinion), and second- if you need that small force to make it moving, then the wheel train is ok, the pallets are ok. All it needs is a bath and oil!1 point

-

If you post a couple of pictures and describe the issue you are having, someone might be able to help you.1 point

-

Was reassembling the keyless works on a Waltham Ruby movement, and it has a c spring that can be a bit of a pain to re-install, it took off, so the search began, the watchmakers desk was thoroughly checked, and the floor was gone over, finally ready to concede defeat, I started going through my parts movements looking for a replacement, so I was looking into the drawer I noticed my shirt pocket, when I wondered, could it have, so I checked my shirt pocket and there it was. Well I have learned my lesson, when I get a spring that has previously tried to escape the work area, I like to use a clear plastic large ziplok bag, I cut a hole just big enough for my left hand in the bottom and reseal the zip part around my right, try keep the movement in the center of it during the installation, it has saved me plenty of time doing grid searches. Also it is a safe place to practice spring installation, I would always try to pick the end of the spring I was installing, instead I found if I used the tweezers as a pusher and pushed the end it was so much easier!1 point

-

very recently I sold 8 watches to buy a pre owned Parmigiani , though some are left and I still enjoy wearing them . however some of my favorite are gone now : Oris big crown day date , Oris Sinatra chrono day date , Tag aquaracer date day chrono , link chrono date , Kiryum professional 200 chrono date ; Tissot PRC 100 grey dial chrono day date, Quickster chrono date blue dial blue strap, Bulgary bulgary date black dial . So I guess I will start slowly over , my first targets will probably be a Speedmaster and a Rolex dayjust .1 point

-

Ofrei has something similar I bought a year ago. I couldn't make it for the cost. Esslinger has similar: http://www.ofrei.com/page416.html1 point

-

1 point

-

A word of caution (& a slight contradiction to my earlier post). Upon further investigation it appears that the gentleman who is behind the video manufactures high end Rolex replicas/fakes (depending which side of the fence your on). Now I am not going to get judgemental as to if they are good, bad or indifferent, or the fact that the Rolex sub is the most copied, homaged, faked watch in the world, just an observation that a lot of these are reported to fall apart after a short while (not the gents in question I would add). Could the same thing happen with the new movement? I would suggest that a bit more rigorous testing would be in order, before any conclusion about the build quality can be reached.1 point