Leaderboard

Popular Content

Showing content with the highest reputation on 01/18/21 in all areas

-

Evening I thought I'd share my modest attic fresh finds less the nasty wrist bands. I bought them mainly for the Sekonda. Both not working, the Sekonda's balance was wrapped round it's rotor. But the Timex really surprised me as it started to work as I adjusted the time. Stopped a bit, and after a bit of shaking and a gentle warming on a radiator I've got it to go. Though it does , run a little slow. The self winding side of it seems to work, however when I go to wind it manually it the crown winds back when you let go. I guess this might be something to do with the click not engaging.2 points

-

Maybe not the best choice to learn on, from a financial perspective... Based on what I've read here so far, I am also leaning toward the keyless works as the prime suspect. But, since the rapid run-down of the mainspring, I'd also be very suspect of the pivots on the escape wheel and pallet fork; as well as ensuring the escape wheel is planar (flat) after that explosion. It was suggested the watch be fully torn-down and ALL parts be carefully inspected, and I fully endorse that. It's great you want to do this "yourself", but at the end of the day, it's STILL going to have to go to someone with the knowledge and experience (not to mention proper lubricants) to service it correctly. That said, what you are describing could be cannon pinion issues (how many hours did it run successfully?), or it is the keyless works. Based on the hack job that was done to this poor watch (broken dial feet?!? Really??!?), I suspect the keyless was improperly lubricated, if at all...2 points

-

I was under the impression that it was running somewhat during the interstitial assembly attempt. If that's the case, I don't think the cannon pinion can be seized. It's hard to tell without it in front of me, but my money is on something in the keyless works. What's the situation re: stem removal on a 3135? What are the odds the sliding pinion or some other part of the keyless works got goofed up a bit? Seized canon pinions aren't all that common (in these circumstances), but wonky keyless works are a dime a dozen. Horses for zebras. Fortunately, keyless works, while one of the most variable features across movements, is one of the easier systems to work with as a novice (at least in my opinion).2 points

-

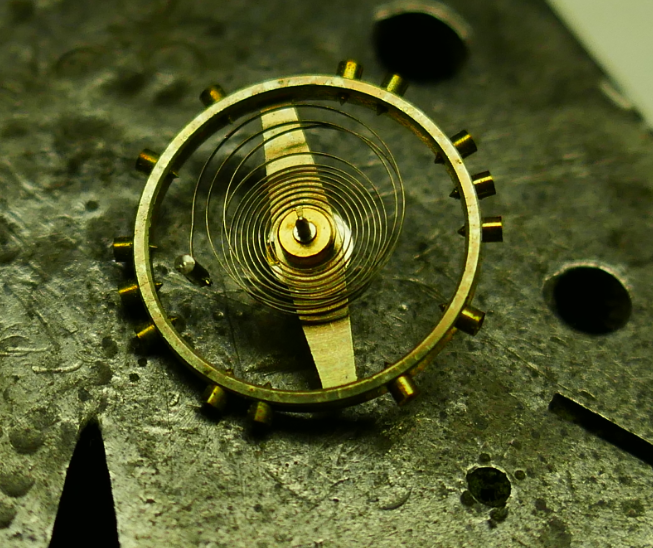

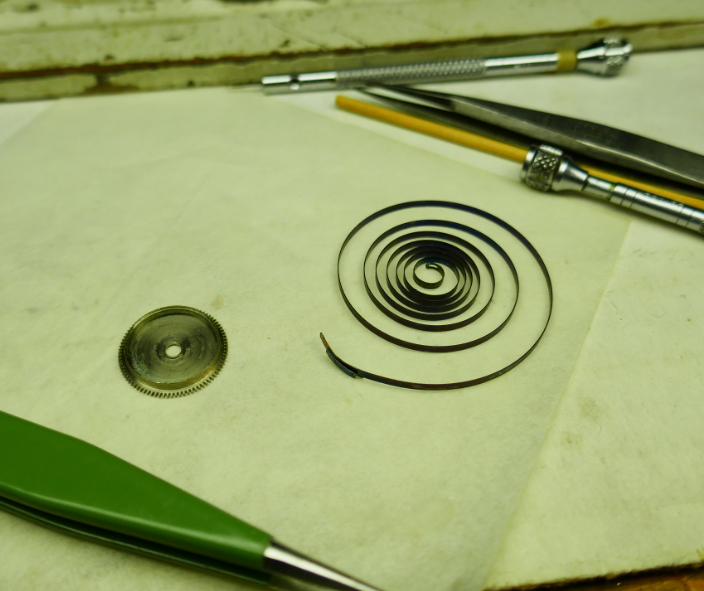

This makes for a good learning exercise. Especially since you're going to replace the movement anyway you have nothing to lose here if you try to fix the problem. The reason you want to learn how to fix the problem rather than replace it is this is unfortunately all too common of a problem for all of us and you can't always replace the balance wheel with hairspring it may not be available. This means an extremely important skill to learn is what does the hairspring look like in the watch and if it doesn't look right how would you fix the problem? Ideally when learning how to work on hairsprings you should have scrap ones that you don't care about to practice bending seeing what happened seeing how easy it is to bend etc. . I'm attaching a bunch of images some of them are yours enhanced slightly. I was going to object to something last night but I just let it slide. While it is nice to have all those pictures of the balance wheel out of the watch so we can see that they hairspring looked pretty good there's a problem. The problem is the problem is only a problem typically in the watch. This is where pictures of balance wheels out of the watch like the one that I have reattached makes things look really good. What were missing was a really good picture aimed straight down so we could see if they hairspring is centered in the watch and of course all important is Is the hairspring flat. Learning if they hairspring is flat takes a lot of time. The problem is if the hairspring touches the balance arms you lose heck of a lot of energy. This watch uses the etachron system for the regulator and stud. For the factory it makes it really easy to get things adjusted. But should you have to remove the balance wheel its a problem. Which is why typically wouldn't remove the balance wheel from the bridge even for cleaning. So basically this is a good and bad thing. What you want to do is look at the image then open up the regulator to its maximum open. This is so the hairspring is not caught up there to make it easier to figure out where the bend is near the stud or at the stud. As this is the probably the most common place where you going to bend the hairspring. Not that you can't get creative like one of the images up above and do other bad things. The first step is figure out what you're doing? This means you need to stare at the balance wheel and hairspring see if you can figure out where it's bent. I have an image where it looks like it's twisted. Someone above has an image a little farther down of where they think it is. They also show where they think you should push to fix the problem I would not do that. The band is usually in a specific place you want to fix that place. I'm attaching some images out of a book it will give you some ideas for how to fix the problem. Then ideally when working on hairsprings you need special Tweezers that you need to hide and not used for anything other than hairspring work. They have nice narrow tips to get down to where you need to be.2 points

-

One detail is not clear to me. Energy is being transferred to the mainspring barrel; you say it's turning. What's not clear is how far it gets away from the mainspring barrel. The energy that's going in, is not being regulated coming out, or is not actually being stored at all. When you wind it, do any of the gears turn? Do ALL of the gears turn? Sheared teeth is aiming at some number of gears turning with the energy being released fully through the opening created by the broke teeth. The escapement/pallet fork theory assumes all of the gears are turning freely as you wind it. The third option is that the mainspring is broken, and the energy is never being stored for release in the first place. Regardless, the movement is dirty, and a full tear down, clean, and inspection are a good idea; if for no reason other than to be able to fully and more easily assess where the actual problem is. On a side note, living very near to a major IBM facility, I'm curious which one you're near and whether or not there are any local jewelry shops I should be avoiding.2 points

-

In preparation for the repair of my own chronograph, I found this one amongst the watch graveyard and decided to take it down and put it back together. These are the photos of the disassembly. After disassembly, I put forth an effort to clean the parts with Ronsonol. I was not passionate about the clean because the purpose was to validate both disassembly and reassembly. I am happy to say that everything went off without a hitch. I even removed the mainspring and found the appropriate mainspring winder among my dad's tools. No problem. The hairspring was quite gnarly due to the watch's misadventures among others in the scrapyard! I did my best to straighten it. It tic'ed a few strokes when I realized that it was way out of beat. So, after watching some videos, I rotated the hairspring until it was close. It tic'ed a little more, but the hairspring was just not playing along. That is OK, I accomplished the goal of tear down and rebuild, and I also got to experiment with hairspring adjustments. No springs, and no screws were lost!!1 point

-

Hey y’all, I’m 16 and have been working on watches and clocks for roughly 2 years now. My father got me interested in watches, but I never got into the art of watch repair until I stumbled upon Mark’s videos! I have been watching them for 4 or 5 so years and have gained much of my knowledge from them. I created an account on WRT in hopes to further my knowledge from the more experienced repairers! I hope to engage with the other members of this forum! -Josh1 point

-

1 point

-

1 point

-

I'm attaching an image from the book. You can Google title you can find that it's on Amazon and it seems to come in a variety of versions? It looks like the link below the hard cover is what you definitely want at that bargain price. Even the paperback seems pricey but it does have a really nice section on fixing up hairsprings The book I have is 260 pages so the link is correct sort of. If you go down the page notices a reference to another book same title same author reproduction of the 1954 edition. Notice it's much cheaper and it has way more pages? The last time I remember somebody trying to purchase this book whatever edition they ended up with was missing they hairspring section? Which is always troubling if you recommend a book and it comes in too many versions which makes for confusion. https://www.amazon.com/Bench-Practices-Watch-Clockmakers-Henry/dp/096562191X1 point

-

I really don't like the term spinning freely as that would indicate a problem. The canon pinion has to have friction on whatever it's attached to. Then pay attention to the posting above By spectre6000. The problem is probably not the Canon pinyin itself it's somewhere in between. Removing or disassembling a watch under power as you found out is not good. All that energy released and went where? The problem with this section of the watch is in order to get here basically the entire watch has to be disassembled. you took your watch to these people to have them butcher the watch did you complain about it afterwards? Most people who pay usually a lot of money to get the Rolex serviced expected to be perfect not destroyed seems more like this would be a warranty issue except of course they're incompetent which would be a problem. Do these people advertise that they service Rolex watches? I'm going to disagree? Often times in watch repair you need a dramatic lesson to grasp that watch repair isn't really this easy. It takes a lot of time and practice learning to successfully to service a watch. For some people they need to start with a Rolex and destroy it to grasp that. Others need to start with a prized family watch and destroy it. Having the entire family criticize you every time you meet them might actually sink in perhaps. Really nice when I can quote other people that have my thoughts. Now we come to the it should be the end but? Where do you want to go with this? Normally people on this group learning watch repair one a learn all of watch repair of unlike just how you can fix my Rolex quickly when this Rolex was butchered before and need to complete servicing. So even if we can help you find the problem and you fix it this watch still need to complete servicing. That's because it's now very dirty from you taken apart and putting it back together and the lubrication has been hopelessly destroyed by taking it apart and putting it back together. Plus whoever serviced it before was incompetent so that alone means the watch needs to be serviced again. Then the cost of sending a Rolex anywhere to get it serviced is expensive because it's expensive watch the components are expensive. But if it's had prior to DIY servicing the cost will go up considerably. Then where do we want to go if you want to continue to fix your watch? He can't really service the watch and you find a problem anyway. There's really no good way to do this and yes we really need the pictures of your watch.someone else's watch because their watches running yours is not. We can't trust your eyes and diagnostic skills as you're a newbie. But in the absence of anything up like to do why did she put the balance wheel and pallet fork back in. Mina to verify that the watch runs and more than a few minutes would be ideal. Make sure the winding works don't worry about the setting. I suspect the problem is on the dial side but it's anything and everything is possible with this watch1 point

-

Dear Mikepilk, jdm and John(s), Thank you so much for these elaborate responses. You guys are correct where exactly the hairspring is bent. Seeing that replacing is not an option I have tried to fix it still attached to the balance cock. During this the balance detached from the balance cock. Now I see that where the regulator pin for the beat error adjustment is, the spring wire is almost vertical. I must have hit it when I adjusted the movement. I'm suprised that it is that way since I didn't know I hit it. This proves how much of a novice I am. Still I have tried to flatten it following JohnR725's advice. This has worked so much better than expected. It's almost back to normal. However I am unable currently to reattach the regulator pin to the balance cock. I am looking for documentation on how but currently can't find any. Again thanks so much for the help this is a huge learning experience (and curve). I didn't expect so many time consuming an nice responses. Jasper1 point

-

Other's answers are perfectly right when it comes to trying oneself to repair an hairspring after having somehow damaged it. I'll be blunt, for a total beginner chances of bringing it to a better state are very low -- ask me how do I know. While at it look at the section circled in yellow too. Anyway, the point I want to make is that an hairspring bent like this does not stop a Seiko mov.t, especially not all of a sudden without apparent external event. So also consider and investigate another cause, e.g. a piece of debris (a minuscule piece of scalp skin is plenty enough) went in between gears, etc.1 point

-

1 point

-

ط Sound like a faulty pivot or excess end shake so pivot can jump out of jewel hole or its shoulder rub on jewel housing. Do you know how to feel the shakes on staff?1 point

-

Only the Chinese ones are cheap, but do not have a good reputation based from the few people here that used them. An original Seiko balance complete is maybe 5USD less that a new SII mov.t, which makes buying the mov.t complete the most logical choice. Last time this was discussed was on another occasion of an owner damaging the hairspring.1 point

-

It doesn't turn freely, there is some resistance. A definitely noticeable resistance, but not super hard. Could you set the hands before you took it apart? Judging from the earlier photos whoever did its last service wasn't very competent, if they cleaned it assembled they may have left out lubricating the canon pinion, and if its run dry is can seize up.1 point

-

The link to the other thread above is about a Zodiac barrel, which you very definitely don't want to open unless you want to search for another- or make a new cap. As I recall the Longines "do not open" can indeed be opened, it's been a while since I did one but I think the cap fits "over" the barrel, like a 7750 cap, and it's good to lift it off starting with a thin blade working around the rim. If you just push the arbor the cap has a tendency to actually grip harder as it bows.1 point

-

I think the theory behind sealed barrels is the fact that the parts, barrel and spring take quite a lot of stress during operation so therefor if you need to change the spring then also change the barrel. This in effect eliminates any problems just putting a good spring in a worn barrel and it is a one step operation. Not only that you have to buy the barrel and spring (greater cost). The barrel can be opened as poljot says and done carefully would probably be ok, but bear in mind some of the longines barrels were greaseless and greasing them lowers the power reserve due to excess slippage. so in effect you take the chance.1 point

-

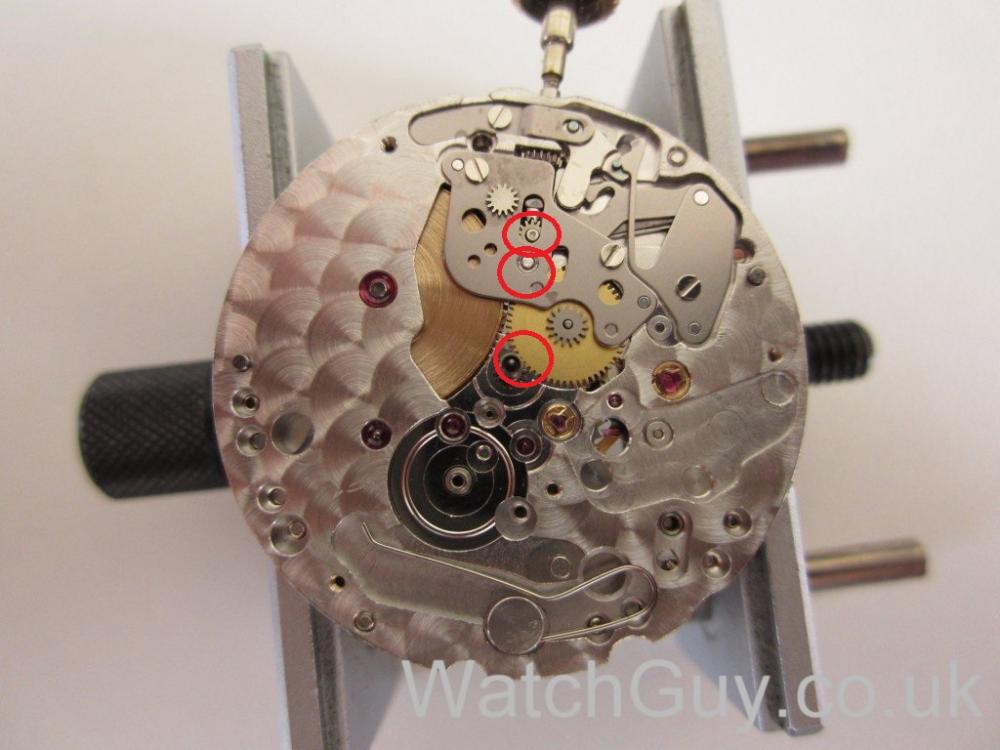

The piece in the center of the dial side, where you fit the minute hand, is the canon pinion. This has a light friction fit on the corresponding gear in the gear train, it snaps onto that gear's extended arbor. When you set the hands it slips on that arbor; when the watch is running the arbor drives the canon pinion and thus the minute wheel and then the hour wheel and date mechanism. If the friction is too light it might slip when driving the date mechanism- if it's too heavy you might damage parts in the setting mechanism. But nothing "disengages" or engages except for the sliding pinion, when you pull the stem. It is under the plate just above the top red circle in the second picture.1 point

-

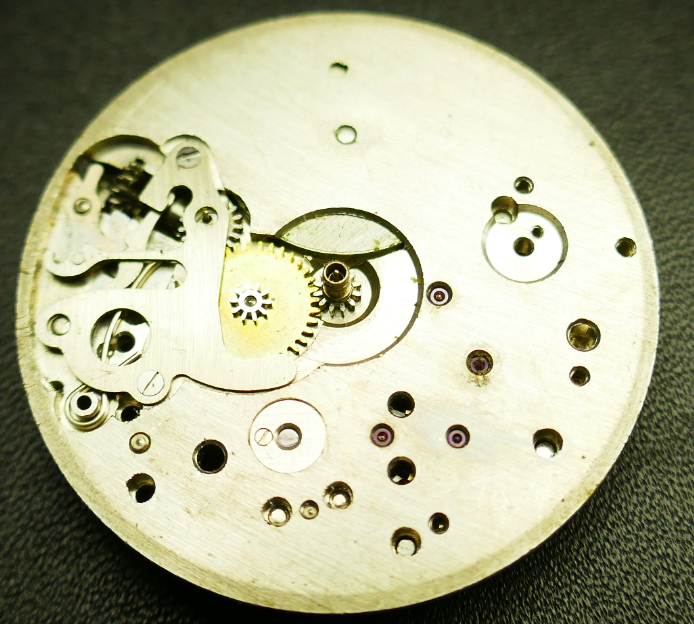

Using the pictures that you provided in the link above since I didn't have exactly the right pictures during my disassembly I'll try to explain it. In the picture of the front of the watch I circled the little gears that work together when the stem is pulled to position 3. They all line up to turn the minute sprocket (silver shaft in middle of watch). I am using the picture of the back of the watch to show that when the balance and pallet fork are removed and the stem is pulled to position 3 everything turns and nothing is binding up. But when I install the balance and pallet fork and try to turn the stem in position 3 the stem will not turn as the pallet fork is holding the escape wheel from moving thus keeping the whole mechanism that once moved from moving. When the stem is pulled to position 3 I assume that only the minute hand and hour hand should move and the second hand will stay stationary. Therefore, when the stem is pulled into position 3 something should be disengaging the train wheels from the minute sprocket (the post the minute hand mounts to on the front circled) and the hands should spin independently from the train wheels and the main spring barrel. But that isn't happening.1 point

-

Of course you can open it simply by pushing the arbour and placing the barrel on a holder or tweezers.1 point

-

Most mechanical watches will tick a few seconds, some for up to a minute, when shaken as there will be some residual power left. If it ticks for more than a few minutes then it could be a sign the mechanism needs a service. Also a faulty watch (damaged pivot etc) pivot may allow the watch to run a while but will eventually stop and then restart when shaken. Anilv1 point

-

I've been trying to find a slotting file to cut the screw heads, but haven't found one fine enough. Nor have I found any under cutters. So I ended up using the balance screw cutters. As long as you don't cut too much, it looks OK (usually it's a very small amount to remove). I just hold it with a finger against a staking block, without taking the hairspring off - which is how I damaged the Omega hairspring ?. If you have one of the balance holders I mentioned above - it would be easy. Depending on the size of the balance, you might be able to use a staking set - press down on one of the balance arms with a flat ended punch ?1 point

-

Hi there JD, that is what you call a bumper movement A bumper movement is a type of self-winding, automatic movement. However, unlike a modern automatic, which has the rotor spins a full 360 degrees, a bumper moves back and forth at about 120 degrees.They are fun to wear. You can feel a slight thud as you turn your wrist reminding you that you are wearing a bumper. It is an interesting method to wind the watch that avoids infringing on full rotor patents.Hope that helps Cheers Graziano1 point

-

Was this the Rolex service center in Geneva or some other one?The reason I asked quality control must've really dropped since when I visited a very long time ago? Many years ago I Visited the service center and found out that they use powered screwdrivers. standard operating procedure was to replace all of the screws in the watch. This was to prevent the heads from breaking off. But maybe they ran out of screws or maybe it wasn't the Geneva service center. In any case because they do use powered screwdrivers you do want to be careful because there is the likelihood that the heads can break. Then two separate links to the same site sort of. It doesn't look like he's recycling pictures both flanks or servicing the same watch and he has pictures you might find them helpful perhaps. https://watchguy.co.uk/service-rolex-oyster-perpetual-datejust-16233-calibre-3135/ https://watchguy.co.uk/service-rolex-oyster-perpetual-datejust-16200-calibre-3135/1 point

-

Glad to help. You have to understand that "remote assistance with blind troubleshooting" is not easy. I just gave you some food for thoughts about wheel train & escapement. Without understanding the basic concept, you would be wasting your time on guessing (mostly incorrectly) on what should be your next troubleshooting step. But if you have a good understanding how things work, your guess will be an educated one. Makes your life easier and less stressful :-). Cheers1 point

-

1 point

-

IBM please be aware if you loose or break any parts genuine Rolex parts are expensive and often very difficult to source. Only attempt this service/repair if you are really confident.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

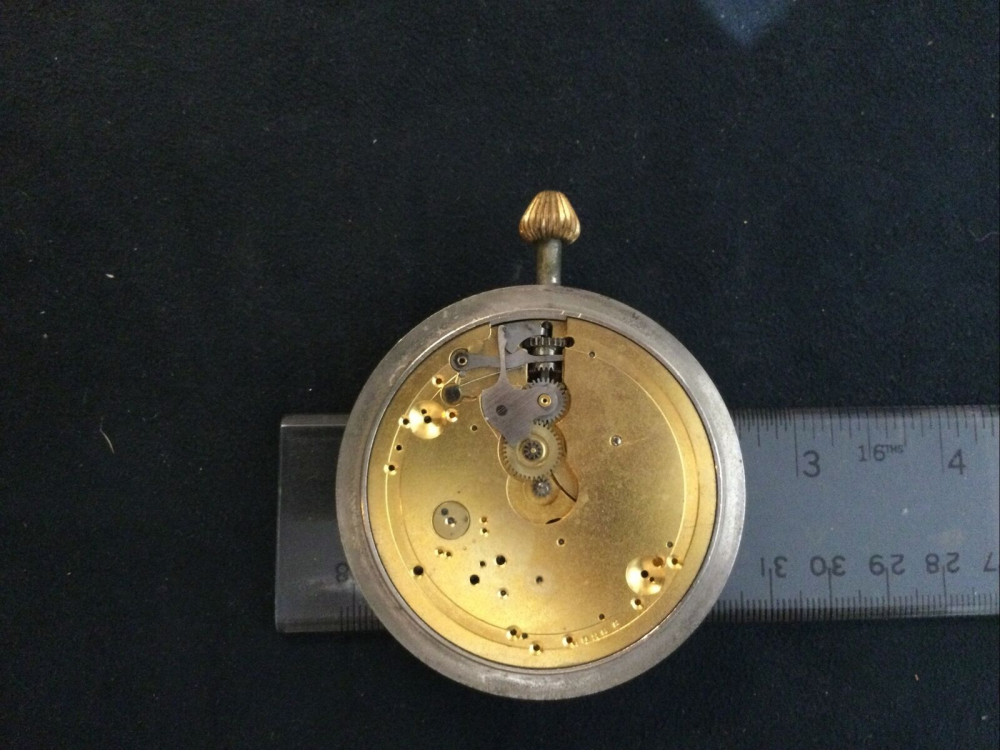

Sadly this is missing its balance, dial, minute wheel, hands, bezel and glass. It should look like this example. (Image source https://www.catawiki.com/l/5306421-bulia-depose-old-clock-ca-1930 ) Possibly a forlorn hope that I'll be able to make it run, but nothing ventured... Well actually £3.75 ventured, including postage, but at that price, I won't be crying in to my beer if it never runs. The inverted dial and long stem suggests this was possibly from one of those new-fangled automobile thingies. It might even possibly be from a heavier than air flying machine! Does anybody remember travelling in one of those ;~)1 point

-

Tough one. You're going to have to experiment, mix and match different colors to get close. Use hobbyist Testor enamel .1 point

-

Here is another watch found in my dad's collection of abandoned watches. When I discovered it, I saw that it would run fine but lost tons of time. After dusting off my brain and recalling what my dad taught me and with a little help from the internet, I set about to tighten the canon pinion. Whoooo...very scary, but I seem to have been successful. It keeps great time. After polishing the crystal, it is a real beauty.1 point

-

And us guys who are computer challenged appreciate people like you who have stuff and share it with guys like me. In other words, thanks John! It does not go unnoticed. I've been trying to get better at finding stuff on my own. Still is fun asking and meeting new people tho!1 point

-

I think what you see in that google picture is a movement holder for working on the movement. A caliber specific movement holder and very nice. It is easy to find Seiko part numbers in the Jules Borel database. http://cgi.julesborel.com/ type in CS#6349-xxxx replace the x's with the number on you case back. The problem is, the Mumbai specials don't always have the correct case back. The crafty devils at Seiko code their part numbers so you can derive the size and shape of the gasket from the number. Many of the dress watches use a flat gasket. Now that I think about it, you may only have to take off the winding framework and ratchet wheel to see it it is a real 6349. The barrel bridge will have a jewel in it if it is a 6349. Sadly it is the main plate that wears worst at the barrel arbor. Something is better than nothing I guess. The 6309 and 6319 use a bushing on this bridge. I would follow the tech guide and remove parts in the order given to get to this point. These parts are step 25-26 and step 38-39 of 49 steps total. May as well strip it down completely. I have done just the steps 25-26 and 38-39 to get a peak at the jewel or lack of. Nothing else is in the way. There is a nice tech guide, in color, on the internet. It is much clearer than the grainy scan most commonly available. Search for "Seiko Technical Guide hires and colors". It may be here but I have it saved on my computer so I never looked.1 point

-

1 point