Leaderboard

Popular Content

Showing content with the highest reputation on 12/27/20 in all areas

-

Another £2.1 ladies TIMEX watch from 71. I know it has no value, but it is really special to me. It came with a bent hairspring - wasn't me this time -, and I UNBENT it!!!!!! ? It runs! It runs! It runs! ? Cleaned and lubricated. Even the bottom - opposite to balance screw - oil cup! Thanks @AndyHull!! ?3 points

-

Problem sorted ! I'll explain, as it may help others. I found the problem by checking the barrel with a straight-edge. The bottom was bowed in slightly, restricting the mainspring. When I wound with a screwdriver it gave me the impression of good spring resistance. You were right @Nucejoe when you said "possible rubbing in the barrel". It happened because I was using my new barrel closing tool. It has a concave surface on the bottom (black bit) so that the pressure is on the outer edge of the barrel. I hadn't spotted that the inside of the top bit is flat, and that this barrel has a raised section on both top and bottom. So pressing too hard (which I probably was) results in the barrel being pushed in. This explains why things got gradually worse every time I took it apart to check. It's something I should have checked sooner. But it's now something I won't forget. I have since used a drill to make a slight depression on the top surface of the tool.2 points

-

It happens, this club members even highly skilled folks. Everyone would agree with weasol, usually risks are higher when you are tired ...etc. Practice on a cheap scrap, twice a day for couple of months, at some point you,ll be feeling confident with the task.2 points

-

Alexandros, we are ALL capable of cockups, being tired, lack of concentration or trying to be more careful and in doing so slip up. The thing to do is to read up or watch videos if possible of the procedure you are about to undertake and be familiar with the correct tools and what you are doing and foremost take your time and think it through, but above all enjoy what you are doing. The members here are here to help. If you are not sure ask no matter how simple. I wish you a Happy New Year2 points

-

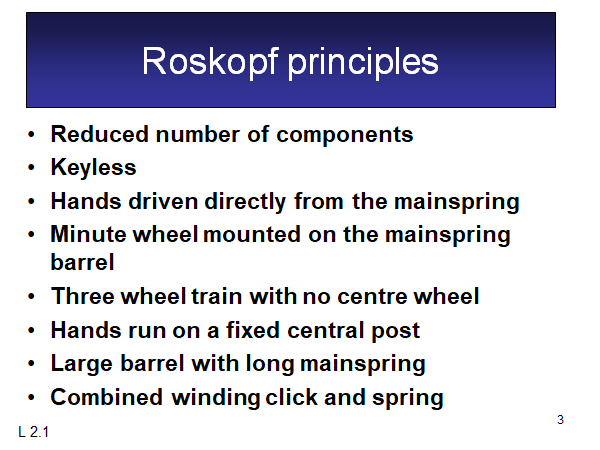

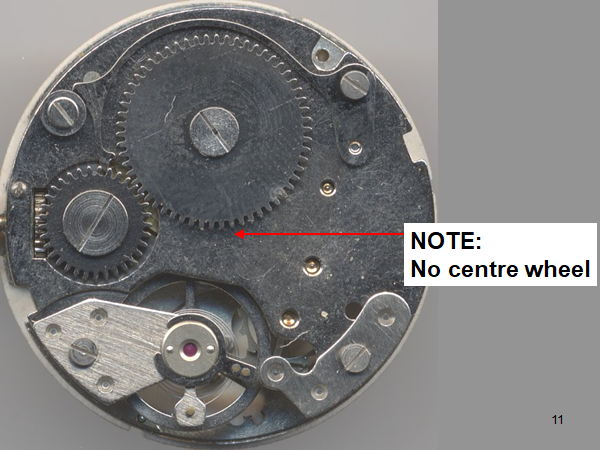

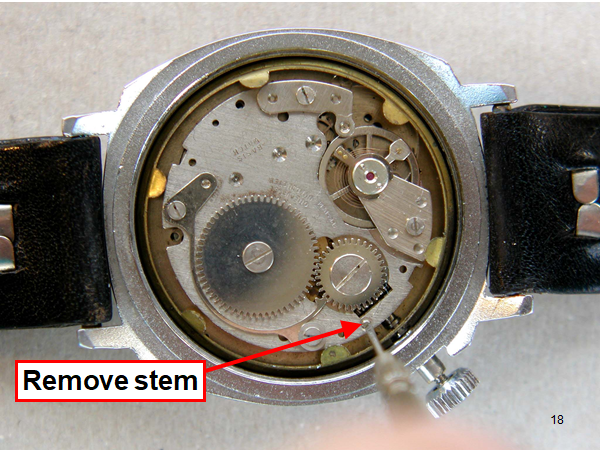

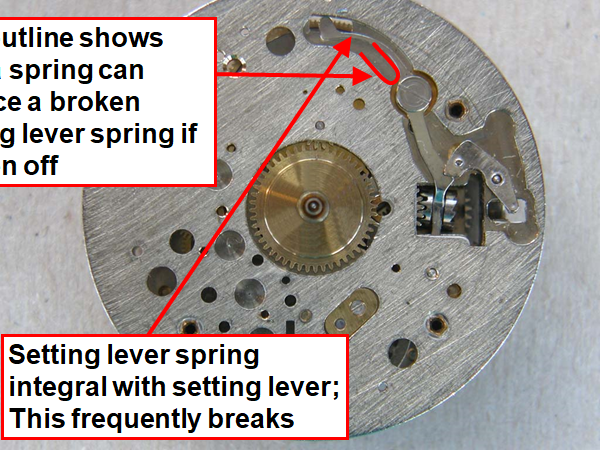

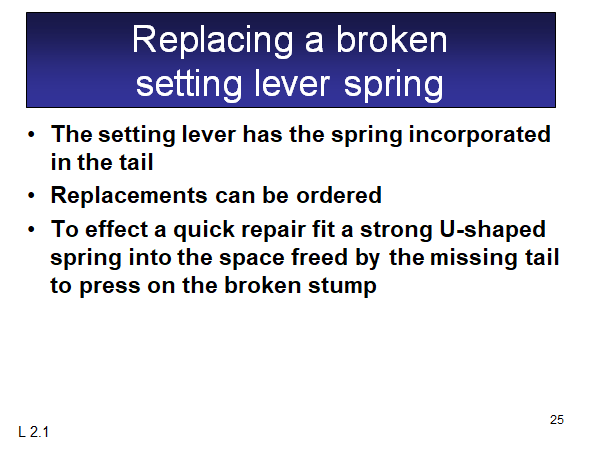

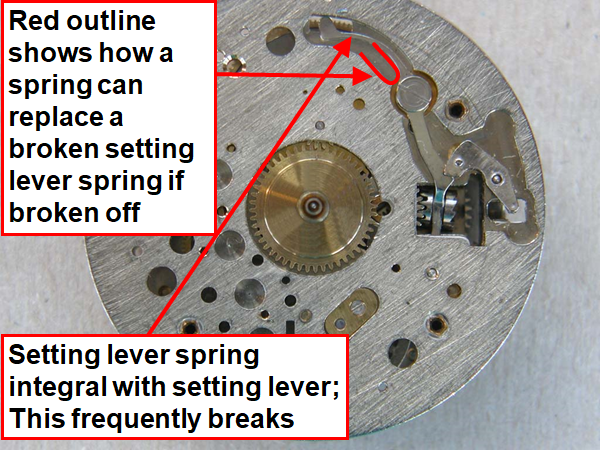

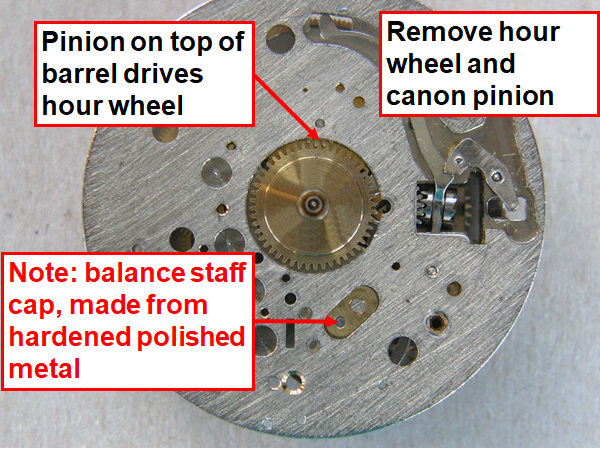

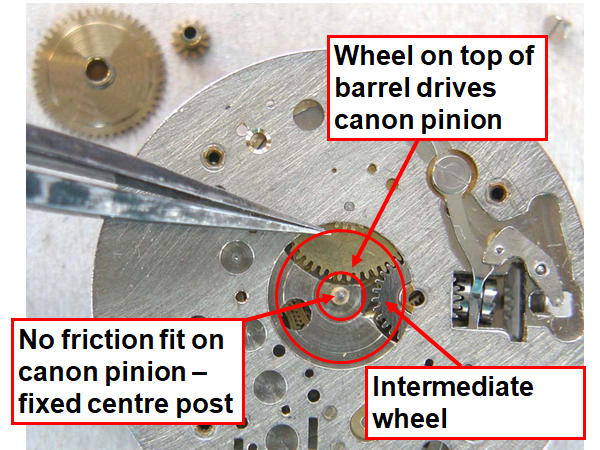

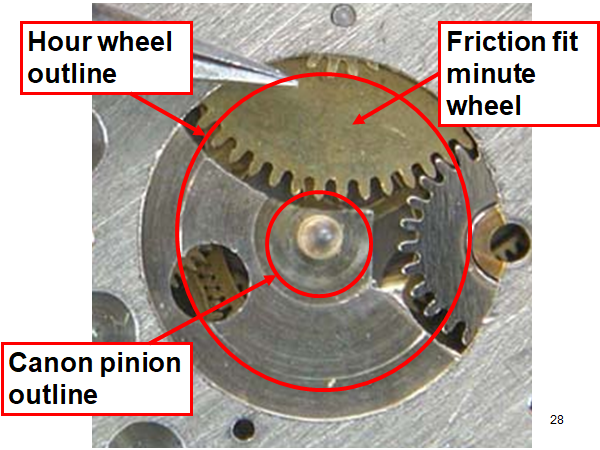

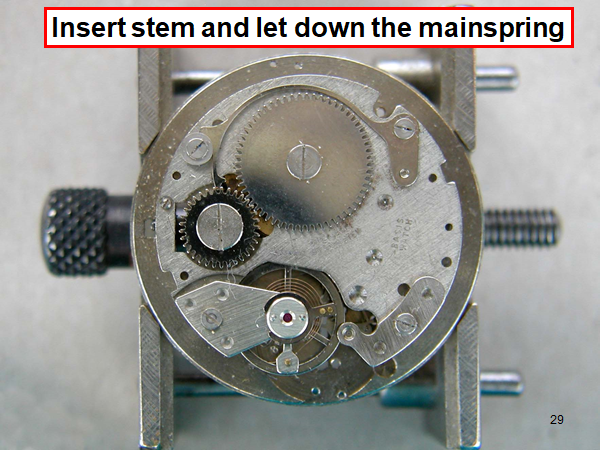

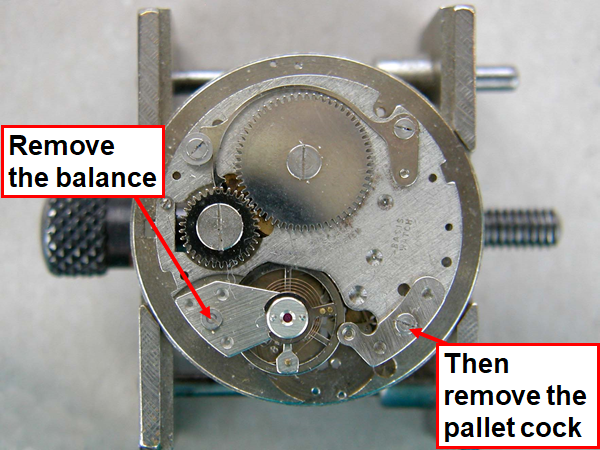

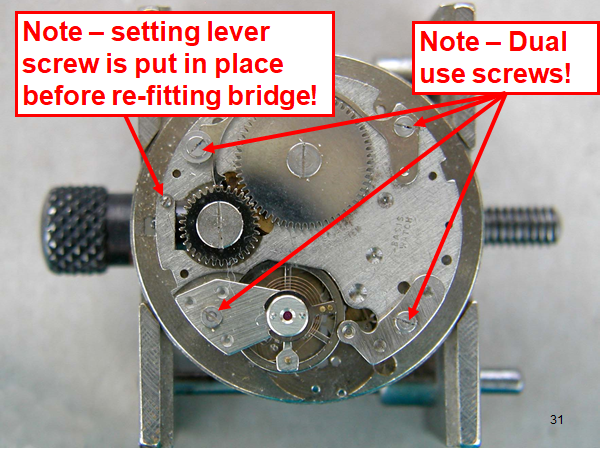

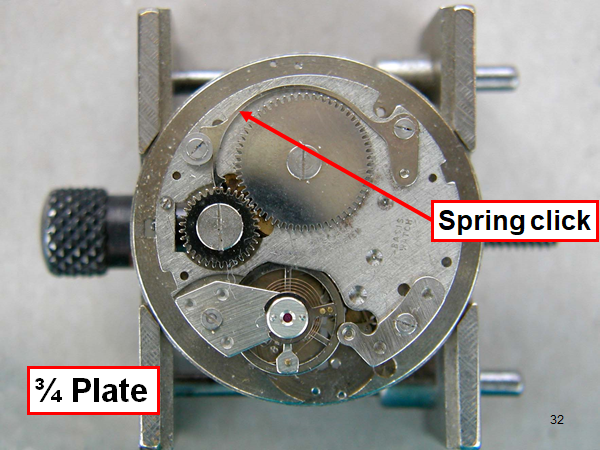

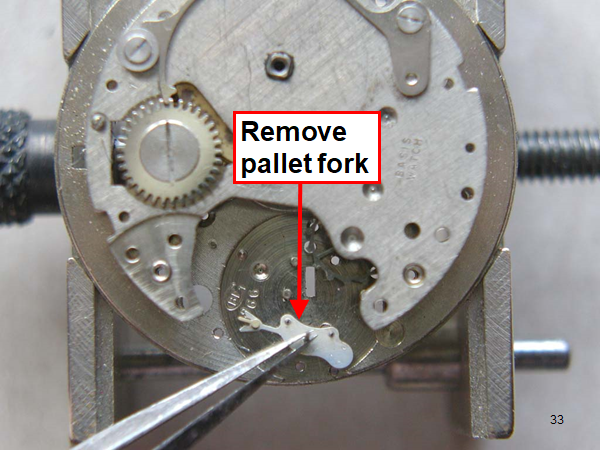

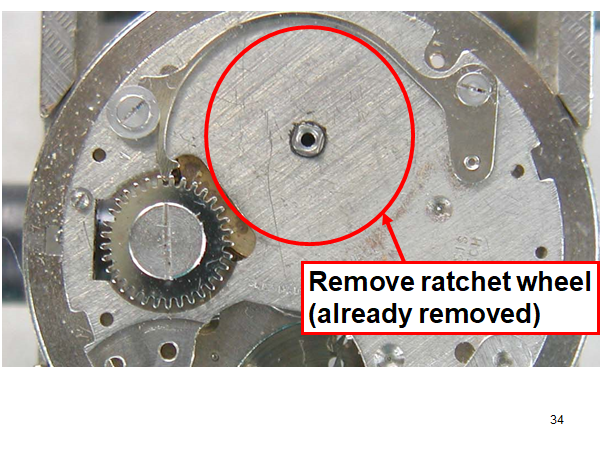

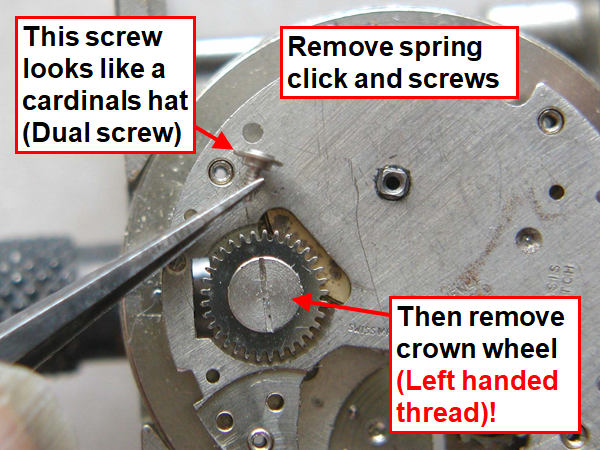

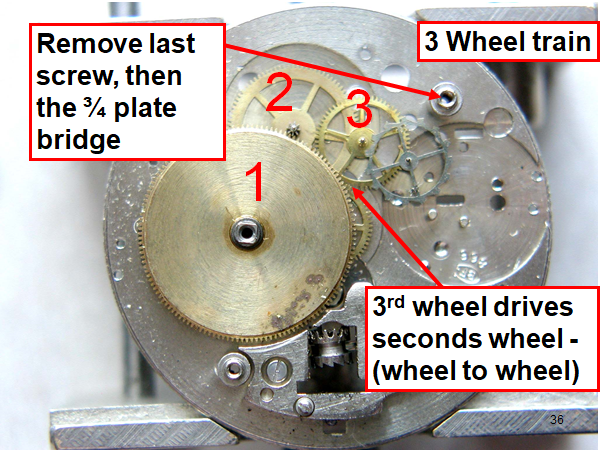

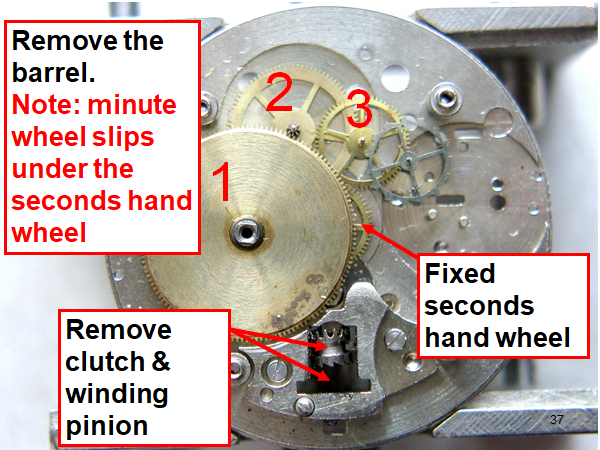

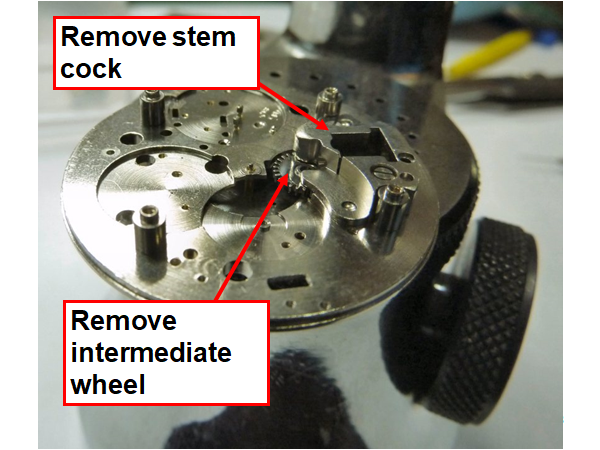

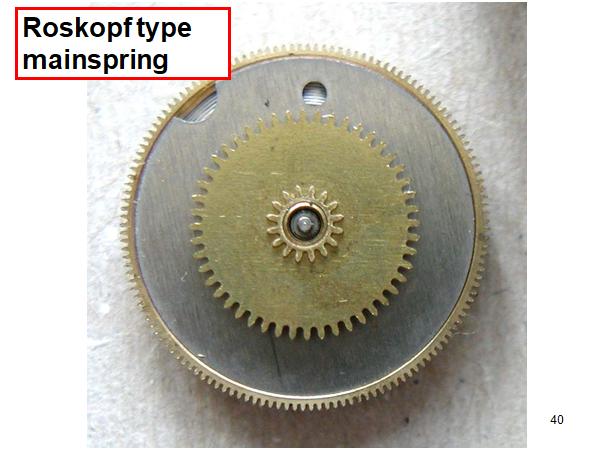

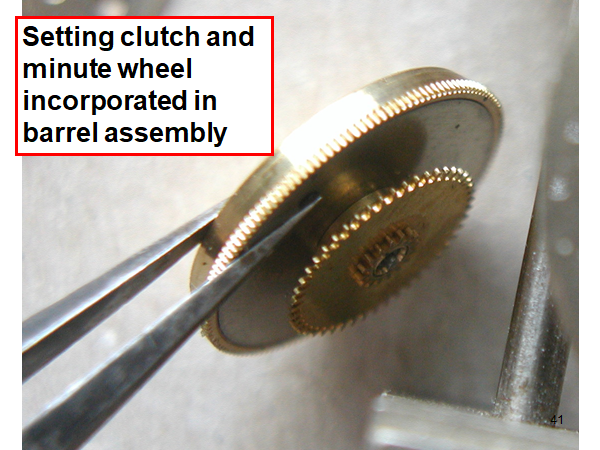

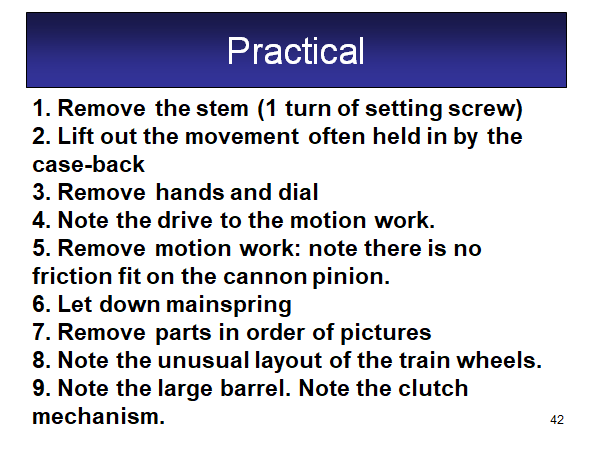

Hi, I teach watchmaking to complete beginners at Epping Forest Horology Centre, close to Epping and this is one of the lessons on the BFG 866. I wanted to show my class a classic pin pallet (Roskopf) movement and how to service it, as many watchmakers won't touch these watches as they hold no monetary value. Turn the setting lever screw 1 to 1 and a half turns to release the winding stem A piece of watch paper or small plastic jiffy bag to protect the dial, whilst removing the hands The driving pinion is part of the friction fitted minute wheel on top of the barrel. This work in a similar way to a friction fitted canon pinion to set the watch hands Remove the keyless work: setting lever, held in place by the setting lever screw, screwed from the other side of the mainplate, then the yoke, which sits on top of the clutch (castle) and also the winding pinion. I have three other lessons on this movement that cover bringing the watch 'into beat' as well as taking apart the friction fitted minute wheel from the barrel, lubricating and staking back on to achieve the correct friction setting and finally how to remove the centre seconds wheel safely and refit using a staking set. Many people leave the friction fitted minute wheel on top of the barrel, not realising the amount of old grease that can't be cleaned out from it, as well as not removing the wheel of the centre seconds arbor and again not cleaning out the pipe which has old grease inside. Hope you enjoyed the tutorial? More to come....1 point

-

1 point

-

Do you have a photo of that piece of brass. I've come across some Russian watches with a brass shim placed under the balance cock to raise the height to give the correct amount of end shake. If the shim has fallen out, that would explain why the balance wheel is tight.1 point

-

1 point

-

1 point

-

1 point

-

Looks a little tired. You can buy a new spring and put in pretty easy. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&FHF_175 Here you find find the size of the spring. I thought cousinsuk had it but it was obsolete. You can maybe find a newer FHF 175 movement pretty cheap. And use that mainspring.1 point

-

1 point

-

Its repairable, remove the two little screws to detach the rotor from the axel its mounted on. The two pieces were not pinned, the inner part fits in a groove of the outer part, the groove is to be closed a little for a fit tight enough to keep both pieces together. If you don't have the tools, you might can get a local repairshop to fix it for you, you are sure to ruin it all if you try it free hand. Some watch destroyers glue which is not a standard practice and will eventually rust.1 point

-

I would be curious as to whether that actually occurs today? The Swiss American Watchmakers Training Alliance (SAWTA) Which replaced wostep in the US at least at some of the schools as far as I know still is teaching vibrating hairsprings What's interesting is not all schools teaching watchmaking hand vibrate hairsprings. here's an interesting video of a school there making a watch and then we get shortchanged on the hand vibrating. At five minutes 39 seconds that does not look like hand vibrating at all does it? https://youtu.be/KJQIw8Az1Xk I really like the description it says is for manual counting? https://www.greinervibrograf.ch/en/Spiromat/Spiromat-Classic.htm Here's an interesting video showing how to do a Breguet hairspring In a school so there's still teaching it sort of? You normally wouldn't do it sort of the way they're doing it because that is a really big heavy hairspring. In other words that's not your normal hairspring. But there's still learning the concept. https://youtu.be/4ddWRl_NVTE Then I found a few links related they hairspring vibrating http://www.bobinchak.com/watchmaking/2017/4/26/hairspring-week-vibrating-the-hairspring https://watchmakingjourney.com/2014/12/23/second-semester-final-project-vibrating-a-hairspring/1 point

-

1 point

-

This type of snail regulator was used by many Swiss watch company's, it is sometimes referred to as a Wilmot regulator which is not entirely correct, as a Wilmot regulator incorporates a amplitude limiter that was designed to keep a constant rate when the watch was not being worn and laid face up, but the snail cam part of the Wilmot design found it's way into many watches Zenith, Omega, Longines, Lecoultre and Patek have all used snail cam regulators at some point.1 point

-

Look like the small push indeed produced different results from the intended one. Was this the first time you went hands on to a mechanical watch? Since I assume you have no timegrapher or equivalent application (these are practically mandatory to properly regulate a watch) the only safe step you can take is to post some high quality picture of the hairspring stopped, and high quality video of it running. A good audio would also help others help you.1 point

-

The suspension spring on these clocks have to be the right thickness and length otherwise you will end up with the problem you have encountered. Get a copy of this, it’s the bible on repairing these clocks. Take a good look around for prices. https://www.ebay.co.uk/itm/4024159721321 point

-

1 point

-

1 point

-

1 point

-

1 point

-

The only time I have seen a ratchet like this with no positive means of keeping it in place is on fusee movements, where it holds the pretension on the mainspring, and is thus under constant load and can't move.1 point

-

I've never seen this type of ratchet wheel held with a friction fit washer they are usually held captive with a ratchet wheel bridge or a pin through the winding arbour.1 point

-

Thanks Mark, as a student of your watch lessons I've been following your advice. In the level 2 course where you discuss lubricating various parts, In respect of the keyless and motion works video you lubricate the vast majority with D5 which I have adopted. However in this thread and in subsequent videos you recommend 9501 or Molykote for the keyless works. Can you advise which is generally correct? On a separate related note, the extended Seiko restoration video a oil/grease of purple appearance is used extensively, can I ask what this is please? Many thanks, I'm really enjoying the course!1 point

-

I made this for anybody getting started, feel free to share. Recommended Lubricants for Getting Started.pdf1 point

-

Just my suggestion, buy from Cousins UK, lowest prices and shipping fees, largest inventory ever, great ease and businesses practices. USA buyers will have to wait a little longer but they buy tax free.1 point

-

I think you might find their website Moebius below helpful.They even have a nice PDF lubrication chart To download. Then it would be impossible for any horological company not to have 9010 because everyone in the universe except me uses that for the balance pivots. It's just about the universal one that 99.9% of the world recommends is 9010. You could use the 8000 except it's a natural or mineral oil it's not synthetic. Although it's much cheaper you really want to get the 9010 so you can be with the cool kids of the world. Then you're right I've done a really thorough search because it's impossible but they really don't have any 9010? You really want to look at their website Moebius look at the tech sheets 9010 and 9020 are not the same thing. 9020 by Psalm is now considered obsolete. When I was in school it was the universal pivot oil of course yet 9010 up for the balance of light stuff. So it's basically just heavier 9010 and it seems to stay in place longer. As typically I'm doing pocket watches it's my oil a choice as the light oil. Then when purchasing a horological stuff it's very important to shop around prices can vary considerably. So I have a link to eBay below they have a variety of oils and the seller is in the US. There was another seller in France it might've been cheaper but I don't know what shipping's going to be or whether you even get anything from France right now. Then the D5 is a mineral oil The suggestion is to replace it with HP 1300 9104 I have a link below for that. Slightly cheaper than your D5 Then the last link is another seller and if their prices are up to date they look pretty good you'll just have to scroll down the page for the various lubricants. http://www.moebius-lubricants.ch/en https://www.ebay.com/itm/Moebius-Oils-Lubricants-Greases-for-Watches-Clocks-Repair/172671249074?hash=item2834022ab2:m:mXVxMGZkUfPs7aD9W88bz1A https://www.esslinger.com/moebius-9104-synt-hp-1300-synthetic-watch-oil-2ml/ http://www.ofrei.com/page246.html1 point

-

Hi some more information for your interest attached.. Moebius Oil_Chart.pdf moebius-specsbook.pdf1 point

-

Forget about wiggling & light pressure. All drivetrain wheel should drop straight into their pivots with zero pressure or friction. Go back to basics. Starting with the barrel, check that the barrel cap is installed correctly. Then start fitting one wheel at a time, installing the train bridge and ensuring that each individual wheel is seated correctly and rotating freely until you find the culprit. Once you find the wheel that is causing the problem, check its pivot isn't damaged or bent and that the jewel is in good condition and hasn't been pushed out of place. Good luck.1 point

.thumb.jpg.0a428591a4890374749e43b895c070f5.jpg)