Leaderboard

Popular Content

Showing content with the highest reputation on 07/05/20 in all areas

-

I think we need to go back to the beginning and look at the exact procedure of everything involved with this mainspring plus any additional lubrication you're putting in the mainspring barrel? Something is not right when the laws of the universe seem to be going backwards for us My experience with the other breaking greases were more was worse. This is what makes the Kluber Different it's really really sticky and more is more sticky. Except for this watch where it's not? But that I also question sanding the inside of the barrel your changing the characteristics. Email auto watches the inside of the barrel has cuts to reduce the contact area to make it easier for the mainspring to slip this is why this is such a weird example here lots of surface area should have lots of stickiness and we don't2 points

-

Welcome to the forum. This should house a MST movement, produced in-house, its caliber is needed to get the relenvent datasheet. Shake the watch see if the seconds hand moves forward or rock back& forth in place or not move at all. Try to fully wind it, to see if it takes a full wind, or keeps dischanging power at some point. MST movements are fun to work on. Your watch will get fixed. Regards2 points

-

The screw on the crown wheel doesn't look central to the wheel, this normally indicates worn crown wheel bearing, if so crown wheel doesn't properly mesh with ratchet wheel and slips. Crown wheel screws are commonly reverse threaded, that is; you are to turn the screw in clockwise direction to unscrew it. To check for this I try to keep ratchet wheel from turning by placing my thumb on it as I wind through the crown, if faulty the crown wheel should slip and the slipage is not hard to notice, or you might remove the crown wheel and show all thats there. Regards1 point

-

This particular grease is recommended for lubrication of mainsprings provided they're not already prelubricated like a new spring. But it is very definitely not considered a breaking grease unless you like having very early slippage. Based on the other discussion on this group somewhere of breaking grease is not working I'm going to throw out a wild theory with absolute no physical profile.. So like so much other stuff on the Internet it's subject to a certain degree of it just may not be right a wrong or maybe it is correct? Normally the purpose of breaking grease is to hold the end of the spring until enough force develops that the spring breaks free and the grease Part provides lubrication so you don't destroy the inside of the barrel with all that force rubbing.. But maybe if Seiko's outer spring is considerably stronger basically very very strong then maybe it does not actually need breaking grease.. It just needs a lubrication when it does finally slip so maybe the breaking is part of the mainspring itself not relying on the grease? That would be another reason to supply a barrel complete if Seiko did something really clever.. They may also assume that the barrel wears out eventually and just needs replacement.. Unfortunately for us Seiko didn't count on the world liking their watches and trying to keep them forever..1 point

-

That incomplete work should not be regarded as if it is the bible of working on Seiko. The following statement alone is considered wrong by pretty much any experienced watchmakers And then he proceeds to hand fitting the mainspring to the barrel, problem is, that's a pretty strong one and the force required makes that you will leave probably some good amount of skin to add to the graphite loaded mess. Looks like Seiko and others had good reasons to only supply barrels complete.1 point

-

It will be more cooperative if you turn the barrel, just lift the movement retaining ring and some barrel teeth will get exposed. Looks like the mainspring is broke.You might get by with a quick fix, that is replacing what is broke and faulty or give the movement an overhaul. Regards.1 point

-

The question of Loupes and binocular visors has been discussed at length before on the forum, so I would suggest you use the search function at the top right of the home screen and have a look at the many varied opinions and make an educated choice on the data gleaned, all the best1 point

-

I've been watching this from a distance. I have done quite a bit of fine wood working, mostly of a luthiery flavor, but also some fine furniture. If all you're after is a gentle curve on a single piece like that, and you're not interested in repetition across multiple components or production run, you would probably find yourself best served (and best enjoyed) with a curved sole hand plane. Assuming you don't already have a profiled router bit ready to go (and your router is powerful enough to do such a large cut in the first place), the setup time on the router is about how long it would take to just bang out the same operation with the plane. You could just freehand whatever comes to mind in the moment, and it'll look great. As a bonus, if you can't keep it clean and don't want to follow with a scraper (same relationship as the plane to the router as below, but with sandpaper), your worst case scenario is very in vogue right now with the "hand scraped" look (even though that's not what that is). Additionally, planes are quieter to save your ears (I saw those amplifiers on the side of the photo, so you likely care at least a little about your hearing), and the shavings fall directly down and are easier to clean than the router dust which goes EVERYWHERE for DAYS. Just a suggestion. Do not try to plane plywood... It'll ruin your iron, the plywood, and your sanity. Practice on a piece of scrap wood at least to get your iron set properly, and generally try to avoid low grade pine (the alternating hard/soft of the wood combined with it never being dried even halfassedly makes it especially challenging, and no one really likes pine much in the end). On the tiny probability that you're in the Denver area, you're welcome to come up here and I'll show you the ropes. https://www.lie-nielsen.com/products/convex-sole-block-plane?path=block-planes&node=4072 This is a new, high quality curved sole plane. It's a little small, but it'll get the job done. This is one of the first planes I bought, and I use it to carve archtop plates. Lie-Nielsen essentially reproduces antiques, so a used one can be found and rehabbed for less, but it's a hunt and a project unto itself. If you wanted to go convex instead of concave with your trim, you might consider a plain old block plane. Good to have even in a power tool shop. A step from that, if you're really good at sharpening chisels, you can make an ad hoc plane (there's a guy on YouTube that shows this... Something Sellers... Peter or Paul?). If you're even better, you can use a chisel freehand in a plane capacity (I did something like this just yesterday). Over a long distance and a large piece, you REALLY need to be good since there's not much keeping things straight.1 point

-

Motorcycle references tickles me too, as one needs to make them right . The Ducati Monster is just (like a watch model) name for their popular naked bike style. They come as small as 400c with power adequate for a beginner and the related license. Monster was ever meant to deliver big power, not even in it's 1200cc declination, or track use. 20 years ago the overused reference for a top performance bike was perhaps an Hayabusa, more modernly maybe Ducati V4, or a Ninja H2R.1 point

-

This should do the trick, spare pins available. https://www.cousinsuk.com/product/oilers-3-in-1-incabloc-specialist?code=O494861 point

-

Morning all. Thanks for the kind advice and warm welcome. @Nucejoe I've tried to give the watch a shake and the second hand remains in the same place (just before the 45 second mark). It's had a full wind and it certainly feels like it's not holding any power. We'll have to see what it looks like when I can get the back off it. I'll let you know what movement is inside so I can take a look at the datasheet and get cracking! Bring on the postman!1 point

-

I presume OP is sure slippage isn't at arbour, a new mainspring is generally presumed as the right one and pushe againt the wall inside barrel as it should.1 point

-

I'm not sure that's the intended purpose for barrel notches. I rather think it's to gain more positive control for the slipping rather than relying on friction and specific lubrication quantities/qualities, like demonstrated in this diagram: Putting some watches next to my ear as I wind it I can hear this. For example on my 7750 it is always exactly 8 clicks of the ratchet wheel between each time the sound of the end of bridle slipping into the next notch is heard. You can't expect this kind of consistency relying solely on friction with a smooth barrel wall.1 point

-

What do you think. Being delivered in 2 weeks. Sent from my iPhone using Tapatalk Pro1 point

-

so it looks like i don't need the 423 core part, but only the part that has the teeth, which i hope is part 421 since thats what i'm trying to get quotes for. here is the link for the patek video1 point

-

Yes, those Esembl-O-Graf booklets/DVD, etc. would be very handy indeed. I remember seeing them being sold at NAWCC marts. But since I was only interested in pocket watches at the time, I never snagged any. I do remember a friend buying a bunch of them. Good thought. I had forgotten about them.1 point

-

I think you’re referring to a comment I made in your post about Seiko mainsprings. I did not say he was the master, I said something along the lines of I think he has a bit of experience with the Seiko 7S series of movts. I’ll add my experience with the 700x series which is the basis for the 7S series and beyond: - The GR springs are close but not exactly equivalent to the springs I’ve extracted from 7002 barrels - they were slightly thinner and not quite as wide. I found, and your experience may be different, that the original used MS worked better than a new GR equivalent. - I’ve had terrible difficulty cleaning and re-greasing the barrel and mainsprings for these movts. I’ve used 8217 and found using the same quantity I might use in a 6309 allowed the spring to slip too soon and too dramatically. If I cut the quantity in half it worked better but still not great. I have not tried using a lot more nor have I used Kluber. - I eventually stopped screwing around with splitting these barrels open since Seiko never intended for them to be and started using factory new replacements which come complete and ready to install. - BUT, and it’s a big but, while I can get expected reserve out of the factory new replacements when wound at the ratchet screw I and some members on one of the Japanese watch forums have experienced issues with building reserve when worn. Not certain if it the reduction wheel being worn down or the hooks on the pawl levers not quite being sharp enough to wind the watch efficiently. Or maybe sitting at my desk during the day isn’t enough activity for these movts. Sent from my iPhone using Tapatalk1 point

-

I found a couple of videos of interest Mark repaired one in one video so how complicated could it be? The second video is interesting in that it's giving you a quest to slowly acquire spare parts for the future just in case. The third link the Amazon book is a good book on chronographs just a lot a general information. Then the eBay link a must have if you're in to chronographs. In particular Volume 21 57 pages of how to service a particular chronograph. https://youtu.be/pFOQm9sAzE8 https://youtu.be/AVISmI8r-5Q https://www.amazon.com/Chronograph-Its-Mechanism-Repair/dp/B0058NJFVE https://www.ebay.com/itm/Esembl-O-Graf-Chronograph-Watch-Course-Vol-1-28/402295131097?hash=item5daaa88bd9:g:TuwAAOxy3NBSdB801 point

-

In watch repair there are several methods of determining what the problem is. You can ask like he did in this group but this assumes that were all familiar with your exact watch. Personally I consider every single watch unique which means are all going to have unique problems. But maybe it's a common problem for the watch in which case the manufacture possibly with tell us providing you have access to current information? Then the next would be a better description and pictures because the only real way to troubleshoot a watch is to physically look at the particular watch preferably the components. I don't suppose you've serviced the watch yourself? Omega's an interesting company for technical documentation for instance I'm attaching the parts lists. The 1012 parts list has a few parts but refers you back to the 1010 for the base caliber. Then Omega has a common technical sheets with instructions but they assume that you're familiar with the watch and there are no pretty pictures. Then Omega got paranoid in their later years and all the technical documentation is watermarked every single corner has the name of whoever downloaded it. That means anyone that has one of those with never posted on discussion group because conceivably Omega would get pissed off and terminate their account. But if you've just service the watch I can probably snip some things out because I do see some cautionary problematics stuff if you service the watch were definitely some things you need to watch out for that are not necessarily common to standard watch. Then if for just diagnosing a watch because we like diagnosing sealed watches we don't have any pictures we didn't get a proper description I'm really go for rust. This is what happens when a watch hasn't been serviced in a long time lubrication can break down moisture can go past the crown it can rust the rust would be a good option in the absence of a better description. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_1012 Omega_Omega 1010-1.pdf Omega_Omega 1012-1.pdf Omega_Omega 1010,1011,1012,1020,1021,1022.pdf1 point

-

Practice makes perfect, in this case lots of it. Apart from its sentimental value, your watch is rare, collectible and not cheap, I'd entrust it only in a master watchmaker's hand. Good luck.1 point

-

First thing to do is to unpin that hairspring off of stud.( most important). (Your search show should a similair advice I gave, OP didn't listen, spent ages like thisand ended up buying a new HS. ) To unpin I insert the stud back in the stud carrier even instal the cock, then unpin. Next remove the HS and put it on a white sheet of paper. No tac is needed. Run an oiler through the coil, start form collet outwards, to untangle any circle stuck under another, each time all the way to the end of HS, then you will see a much less tangled coil that is not hopeless at all. Good luck.1 point

-

Hello to you all. I am unsure where to begin here. I guess I will start with basics. I go by Karl. I have too many hobbies, most of which involve antique and mechanical things. I live in Indianapolis IN currently, but I used to live in Cleveland OH and miss it terribly. I have been fascinated with timepieces since I was very little. Having steady hands and mechanical aptitude, once when I was seven I took apart my mother's alarm clock to see how it worked and, thank heaven above, was able to get it back together and futz with it until it worked as before. She still doesn't know and I'm not going to tell that story in her presence yet. Since then, over the years I've gone from just changing batteries to actually stripping and cleaning and repairing and replacing the parts of mechanical clocks and watches. I've sifted through the internet always in search of the right way to do things, or the best way, depending (for a given watch, sometimes those concepts are different). I learned there are quite a few hacks out there too. But this site is one that always seemed honest and straightforward. I am much like a number of struggling collectors with very modest income who visit little "antique malls" and flea markets, and Etsy, and rescue beautiful watches, snatching them up for a song before the scrappers find them. And then I do all I can to restore them, carefully get them running and regulated and polished. I own a late-1880s Elgin in a Keystone case, a little Waltham "Seaside" also in a Keystone, a size 6 Hampden in its Dueber case, a much newer Public Watch "Louis XIV" alarm watch with a Baumgartner 222 movement (cheapo, but more accurate than I'd have expected and heaven help me but I love the thing for it's utility) and I have my Longines 18.5 in its proprietary case. At some point I could post pics, if there is interest. I've worked on a handful of others recently. I am currently working on a silver-cased "Jacques" which has a no-name "Remontoir a Anchre (ligne droit anchre) Swiss movement. It has multiple bridges, and that is so blessedly easy to work on. It's face has a BAD divot from where it was damaged by a previous "technician". I must try to repair it if I can, as well as can possibly done. That watch belongs to a good friend. It was his father's and grandfather's and has become part of his history, so the weight of his burden of trust in me is very consciously felt. I hope that is enough about me to go on for now. I adore "time machines" of nearly every kind. I have looked in on this forum before a few times and feel I am in excellent company. I am here to learn. I am still learning all the proper terminology, all the riddles that some less common watches have, so have patience with me. I may have a number of "dumb" questions to ask now and then. I am better at doing and learning than I am at articulating questions. So, that said, hello everyone!1 point

-

The reason why The repair is so expensive is several reasons. If you take the watch to a jewelry store and they send it out for repair they mark up the repair cost considerably. Ideally you want to find the repair shop yourself you'll get a better price. But no matter what this watch is going to be expensive to get repaired. If the shop really was a Rolex shop they nearly double the cost of anything that's a vintage watch. Then if it's complicated like a chronograph it will go up again. https://www.hodinkee.com/articles/bring-a-loupe-nov-29 Then Nucejoe was kind of kidding about a decade of experience. For instance depending upon where you're located their schools teaching professional watchmakers two years there would put you in a much better position the service a chronograph. But Mark does have chronograph videos I have a link below for one of them not the same caliber as yours unfortunately but don't give you a clue is only six parts should bill a breeze through that no time. Okay here's the problem it's a chronograph with some stuff on the dial side it's a little more complicated. There is a service manual for it but it's really big file size so I'm not going to attach it. In order service this yourself you're going to need to learn how to master servicing a watch without breaking it probably service several of them without breaking them. Then I would find one of these movements on eBay to practice on before working on something that you prize. Because no matter what in watch repair things happen and breaking something that you value is actually a really good lesson in watch repair to teach you why you shouldn't be repairing it in the first place. It just depends on how much pain and suffering you like. So it's not impossible that you can repair it yourself it just isn't something that we would advise you to do at least not right now until you get lots of experience. Then as you didn't say where you're located it makes it hard to make recommendations of where you might look for repair shop. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Valjoux_72 https://youtu.be/EI3T-IR3AgM Valjoux_Valjoux 72.pdf1 point

-

Hopefully a decade of experience after graduation from Mark Lovicks courses, you will have acquired enough skills to attempt servicing the Wittnauer complications. Let us enjoy watching its picture please. Meanwhile we can have fun playing baseball or with the seiko. Just a thought. Regards.1 point

-

Hey I hope I can help you. I live in China and there's a considerable amount of spare parts of 7001 taking out from the original movement including the whole barrel assembly and mainspring. Where do you live? I see if the selling can ship to you or not? As for the prize I guess one barrel assembly will be ¥100 that's around $14.1 point

-

I'm not going to say they are wrong as I've used sturdy tweezers to make light adjustments before. However, it is not ideal, especially when you need to modify the radius significantly. They will potentially cause acute bends which is more liable to cause fracture. I've been there and done that. It may have been worth trying to anneal the inner coil further on the second spring. But it's easy to say that now with hindsight. If you are in the UK then I can have a look through my spring selection in case I have one.1 point

-

There's a guy on daBay selling what he says are "Peseux stems for mechanical watches" that includes one for a Peseux 7001, which I believe is the same as the ETA 7001. If they are indeed Peseux branded NOS springs, you should be in luck. Not cheap, but should work if ETA 7001 = Peseux 7001. The seller is in the USA. Good luck.1 point

-

I figured out that I have the short version of this stem and I need longer version of this.. It is very slightly longer ( about 1 ,2 mm).. I think I should get the right stem. Thank you for your advice!1 point

-

you're in luck, the seller on eBay I messaged has a complete balance arm available. quoted message below.... New message from: remwatch (650) Hello.I have a balance bridge. But I also have jewel for it. HERE is the link to the original listing. Contact the seller and see how much they want for the Bridge.1 point

-

1 point

-

Is it one like the one below? That one is mine. Parts are difficult. You can get a new balance wheel or a set of hands, or a dial, even a nice display stand, easier than any other bits. Is it the jewel in the balance bridge? If so, you may find it easier but not financially feasible to purchase an entire watch and possibly scavenge the balance, though it would be a waste of one watch for another. I put in a question with a seller on eBay who is selling a handful of miscellaneous gears for one of these to see if they have a bridge available, assuming that is the culprit. Mine has an issue with the lower balance jewel Chaton. It had moved away from it's propper position and would cause the balance to overbank randomly. I seem to have it sorted now. They were built in a relatively robust manner, most bits are quite easy to disassemble. I suspect the reason there are so many available is likely because it was easier to replace a faulty watch rather than try to service one. Most were likely sent back to the factory but again, it was just simpler to ship out a new one rather than to bother fixing them. These watches were in military aircraft so they were certainly subject to vibration, impacts, shocks, and wild temperature swings to say the least. I would imagine it wouldn't take long before issues began to arise. The were usually placed low in the instrument panels to make getting at them easier when they failed. 2 thumb screws and two wire connectors were all that were required to remove these. As I said, mine is running reliably now as long as I don't fiddle with it too much while it's running. I would be curious to see photos of yours. I'll let you know if the eBay seller gets back to me. My AChS-1 watch There upper balance jewel. Here is a shot of one properly mounted in a Mig-29 Fulcrum.1 point

-

I know this might annoy people, but I have serviced 200+ automatic seikos and have used 8200 on the barrel walls. There have been no problems with power reserve or amplitude. I have a 40 watch collection that I have serviced as well in the same manner. I have applied 8200 to Rolex's and Omega's. My 1040 Seamaster is running on my wrist right now. Yes correct braking grease is ideal, but to say that "whatever you do" is a bit harsh. It all depends on budget and availability. I started off servicing with just Moebius 8000 for all pivots and some of the watches are still running perfect - albeit quite oily after 5 years. It is a matter of desired performance. Also regarding re-using barrels and springs - if they are in decent condition, why not? I had the first unusable barrel come on my bench and that was from a 7017 that came from Japan that was rusty and horrible. I swapped in a good condition 7002 barrel and bob's your uncle, it's running with beautiful amplitude and reserve. Out of curiosity I will buy some braking grease and give it a go.1 point

-

I made this for anybody getting started, feel free to share. Recommended Lubricants for Getting Started.pdf1 point

-

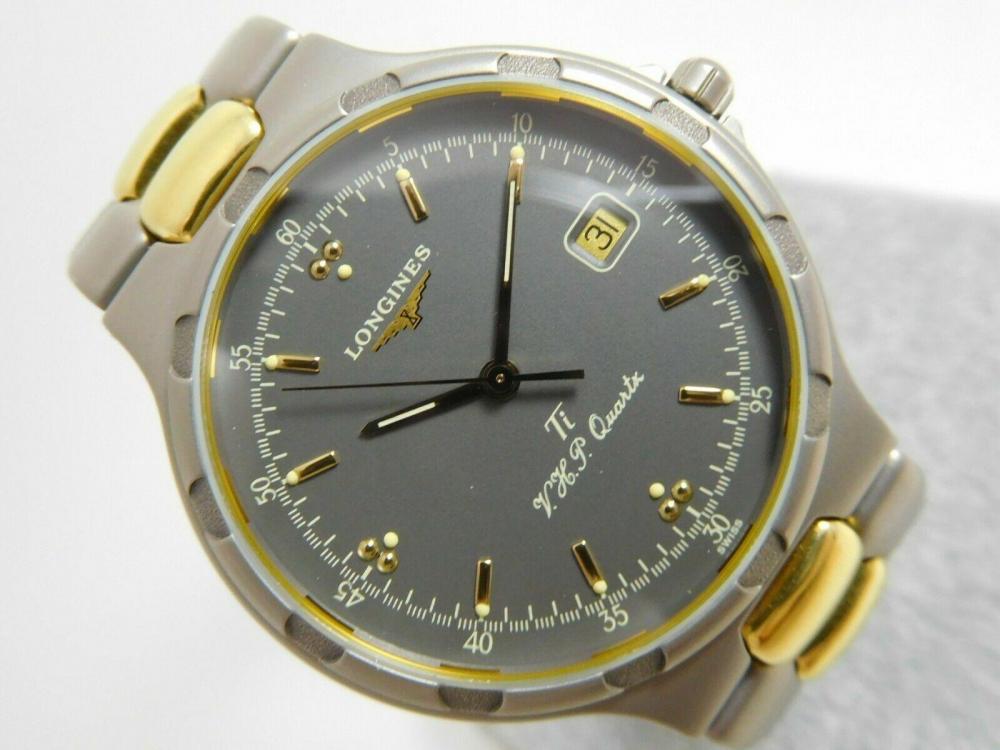

I'm not a watch collector but may become one. My Accutron 214 that I bought new in 1966 stopped working and after searching for repairers, I found it would cost about $300. So I started searching for good quality used watches and settled on Seiko and Longines. My first purchase was a Seiko Diver 200m 7n36-6A49 in near mint condition. I'm not a diver but it looked cool and was in great condition. After more than 1 month it is still accurate within +-1 second. I then started reading about HAQ watches and bought a Longines Conquest VHP quartz L237.2 L1.613.9 probably made around 1993. It has not lost or gained one second after 3 weeks. This watch looks like it has never been worn and it came with two extra links, extra pins, original outer box, inner box, instruction booklet in 4 languages including English, the warranty card with fields blank, another small card in Japanese and the jewelry store business card in Japanese. All these items are also in mint condition. Pages of the manual look they were never turned. Even the clasp appears never to have been opened as it is very tight with no sign of wear., So Maybe I've caught the collector bug because I continue reading about watches and have joined about six watch forums. henryr1 point

-

1 point

.thumb.jpg.c98cd0ea54a28ecfde0c346b58edacb2.jpg)

.thumb.jpg.fbb1e9e62d33760c306f601f037cc48d.jpg)

.thumb.jpg.62c7b0390ef06d72e83ead4b8a6ea369.jpg)