Leaderboard

Popular Content

Showing content with the highest reputation on 06/10/20 in all areas

-

After the Timex setback at lunchtime, I decided to take a look at a couple of first generation LCD watches. None of your fancy Casio G-Shocks here, these are watches with "LCD Processors" in them. Well that is what the PCB silkscreen on the Odyssey says any way. A Citizen Chrystron LC and an Odyssey Executive 25 Alarm. The Citizen is the Rolls Royce of the two, and the Odyssey is more of a Ford Escort, but none the less they now both work. Battery corrosion was causing issues in both, and the Citizen needed a new quartz crystal. A little TLC, consisting mainly of some light rubbing with a fibreglass pen, cotton buds and some denatured alcohol was also required. The light in the Odyssey seems to be dead, so I may have to address that somehow. White LEDs wont work directly on the 1.5V cell, so some "magic" may be needed. I'll have to have a think about that.2 points

-

Folks. I have been interested in being able to build and machine a watch gear for some time now. I would love to cut one on my lathe, but the vintage addins are really hard to find. I am good with designing the gear and getting it CNCed by someone else or even printing the gear and filing it by hand. That said, I ran into a program called Gearotic V3 where you design a gear and a gear train and send the file to a CAD program. Have any of you tried to do this or used this program for that purpose? It does have clock escapements it the designer but not watch lever escapements. Thoughts, suggestions, etc. the program was 120US, but no issue as I love learning and an adventure. Sent from my iPhone using Tapatalk Pro1 point

-

I guess a few silversmiths could handle the job.. there are a few people who specialise in making watch cases. https://www.watchcaseworks.co.uk looks like a good option but appears not to be taking on work at the moment.. I'm not a friend or associate of theirs and haven't had work done there.1 point

-

I really don’t know, but it could be, but a different “version” of it. I believe some watches have the same name and look but are offered with different case sizes.1 point

-

1 point

-

So, better then to replace it. Please keep us informed. There’s always something to learn.1 point

-

Here is a site which gives chapter and verse on the manufacture of hair springs https://monochrome-watches.com/technical-perspective-manufacturing-process-hairsprings-explained-with-videos-e2o-innovations/ cheers.1 point

-

Hi Unfortuatly not , It is usual practice to do that in order to encourage subscribers. Is there anthing specific you are interested in regarding hairsprings or is it just a general overall knowledge you are looking for. cheers1 point

-

1 point

-

I don't suppose you have a picture of the dial side showing the setting parts? Then the website below you can enter in dimensions see if anything matches or if anything's really close because then you can just modify it. Like very first one on the list Buren (BAA) Looked relatively close. Another place to look is the bestfit book Which also has a listing of balance staffs by size. https://www.balancestaffs.com/product.php?dim_A=5801 point

-

A good watchmaker should be able to help you out. I’m sure he or she would have a contact who repairs silver items.1 point

-

Hi, sorry to be annoying but I would get hold of a Caliper (or borrow one) there not very expensive and very useful then I’d head over to https://www.cousinsuk.com/ you can choose a Crystal by size and dome.1 point

-

Before you clean the fork, see if you can find where the pallet was seated in the slot before, try to find the old signs left by dirt or shellac on the slot.1 point

-

The pallet stone needs to be re-seated. You need to clean the stone of everything that is on it, this includes the part of the pallets that the stone fits in. This is not a job for someone that has little or no experience. Watch/clockmakers shellac should be used to set the stone. It has to be the correct angle, this includes depth and height. Do not use any of the quick hardening glues that are available as they act so fast you will not be able to adjust the stone. If you intend to undertake this work I can list the tools you will need.1 point

-

A long time ago they used to be companies or individuals who would vibrate hairsprings to your balance wheel. I don't know if there's anybody left doing it they were slowly dying out. One of the problems is not the skill set necessarily because most students of a modern watch school get a basic training on how to vibrate hairsprings so the knowledge is out there. The problem is for vibrating hairsprings that the Swiss no longer make packets of CGS hairsprings. In the BHI Journal August 2007 is a rather nice article on hairsprings. At the very beginning they talk about where at one time you could buy packets the hairsprings but that's a thing of the past. The Swiss keep trying to figure out better ways to do things so they hairspring companies or company I don't know how many there are left. They make hairsprings for specific watch manufacturers. Then either the manufacture of the watch vibrates the hairsprings themselves or they hairspring company will do that as a service. Then if you just have a slightly mangled hairspring good book to get is Bench Practices for Watch Repairers Paperback by Henry B. Fried Then the version I have says copyrighted 1954, 1974. It's a little cryptic as to what got revised in74.. The reason I point out the years because I think there's a variety of reproductions and the reproductions might not have everything C need to get the right version of the book and it's hard to tell online which is the right version. In any case the version I have the first 64 pages is on hairsprings. Then probably the most important aspect of the book is about 20 pages in the hairspring section is on how to fix bed up hairsprings put them back the way they're supposed to like.1 point

-

Mine is close but no cigar - it’s the sub seconds version! I’ll keep an eye out for more.1 point

-

There is always a better way to do a simple job. You may take the steps that better apply to your situation Remove the band and clean it separately. If leather apply a specific product. Clean the case carefully before opening it Use a good and proper opener so to have zero chances of the tool slipping Clean the gasket groove and any other trace of dirt around Check voltage on the new battery, you want a bit more that 1.55V Check well if any screw need to be losened to ease the battery out Handle the battery with plastic tweezers or finger coats only Some modules have an AC pad to be shortened to battery to get restarted Some modules require a lot of button pressing and perhaps reading the manual to reset sundials correctly Set date one day earlier, then set time so to be sure that it changes at midnight Check the gasket, if any wear of deformation replace it with a new one which fits perfectly even if you have to order it Mark the date on the caseback Apply a little silicone grease before reinstalling the gasket Remove stem, clean it all carefully, apply hp-1300 to all contact areas and silicone grease to its gasket Blow air to module before closing it Do a pressure testing Brighten the case by hand with cloth and a touch of Dialux bar more suited to the case material Present to owner with a proud smile Now you know how to turn a 2 minute task into a one hour one.1 point

-

1 point

-

Yes, it's a mess, but it's NOT a disaster, despite what my wife says! I know where everything is. I have had a helluva time finding a nice cutting mat to put down as my work pad, so the lovely green pillow case is temporary. Good lighting is a must, thankfully the newer LED bulbs are bright and generate almost no heat. Decent storage is my next quest. That will help free some space and make things less cluttered looking.1 point

-

Amazing is an understatement. Here is what I got accomplished last night... I got the entire motion works back together. It actually runs great. The oscillating weight spins nice and free. The mainspring barrel is only supported on one side, but it really doesn't seem to have any adverse side effects. Everything was mostly surface rust. I scrubbed everything with a bit of peg wood and it all came off. Any pitting was very shallow, just barely under the plating. I dug out a screw from an older junk Seiko I had to replace the missing bridge screw. I'll work on the keyless works and the day/date components tonight.1 point

-

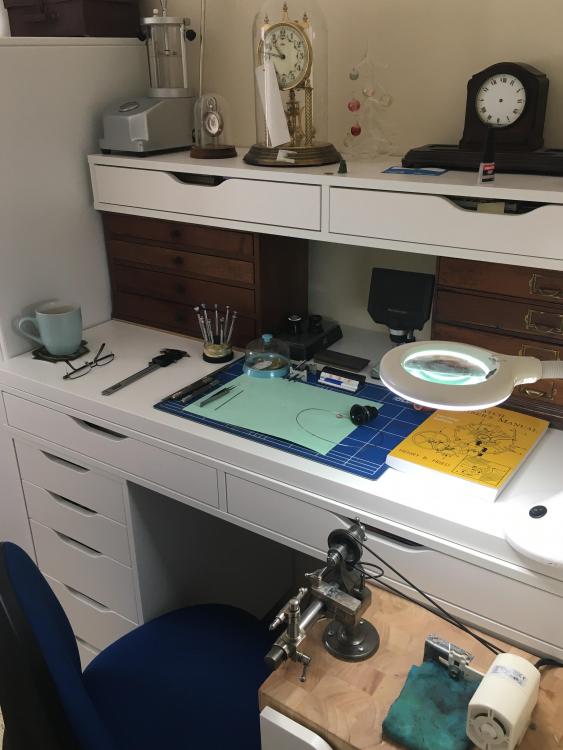

Well I might aswell jump in and join this one, here’s mine, I had a thread running in it, all from Ikea total cost just over £200 inc delivery. Bench sits at 1mtr high and add another 45cm to the top. It’s 1.2mtrs wide and 60cm deep. 2 vintage engineers chest hold tools and spares from jewels to gaskets and gravers to movement holders to pith wood. The top drawers above the chests hold books. The left hand chest holds wrist watches and spares for numerous movements, also pocket watch spares and projects awaiting attention. Also extra tools and oils. The right hand side has my staking set and cleaning fluids and some odds and sods.1 point

-

I make gears all the time, I use the norms in the swiss NIHS book which gives you all the math to draw the profiles for any module of cycloidal gear. Does the Gearotic do cycloidal or just involute? While several watch companies have moved from cycloidal to a highly modified (and proprietary) involute derived tooth form over the last decades, cycloidal is the standard. It won't mix with involute. Well, it can, but- Gearing is a pretty huge subject. You can get an involute to mesh with a cycloid and they might even seem friendly together, but the efficiency will be diminished and they will self destruct over time. If you reverse engineer geartrains in watches you'll find that they rarely match perfectly to theoretically correct numbers; this is because they were modified based on experience or testing. All that said, if you make a gear train for a watch "by the book" it will perform well and last. If you need to replace a gear or pinion there is usually the original to copy, and if not, a reverse engineered one will perform well. The larger the more leeway you have. A pocketwatch escape pinion can probably be off in diameter by as much as +- 0.02mm and still function; in a small wristwatch you will be cutting it close at +- 0.005mm. What's really a problem is getting cutters. There are several companies in Switzerland who will make you one to your drawing for a couple to three hundred bucks. If for a wheel of say 70 teeth, that cutter will probably be OK for any wheel of that module up to a rack, down to around 35 teeth. For pinions it's much trickier, a cutter for a 7 leaf pinion of a given module will cut that and nothing else. One does find cutters secondhand, but 99% of the time they are marked with some arbitrary number and you'll need a profile projector to trace the profile and compare to drawings. That's all said not to discourage, just to illustrate a little bit what's in store. I'll be the first to say that making even a theoretically terrible gear on your own is a really great feeling when you get the last tooth- it's like you're a wizard. Put it on your keychain and get ready to do some math then.1 point

-

1 point

-

Very interesting, I'm familiar with most of the processes there having worked as a design development engineer for an automotive fastener company for 11 years, albeit everything on a smaller scale. What the film doesn't convey is the noise, smells and general foggy atmosphere in such a manufacturing plant, that has to be experienced to appreciate it. About 40 odd years ago I used to go metal detecting on Hamstead Heath and regularly used to find the nose cones and pieces of the bronze driving bands from these shells, that fell back to earth, after being fired at German aircraft during the blitz....1 point

-

Good morning Folks. I hope everyone is staying healthy and occupied in these difficult times. I'm going to write about skilled tradesman a bit here. If I get a bit wordy, pedantic, opinionated, boring or generalize too much, I apologize in advance. Some of what I say here are solely my opinions and observations based of the experiences of myself and others I've known. There was a time in the world when skilled trades were respected and revered. During this time, If you weren't born into wealth or royalty, a trade was one of your only opportunities for a better life. Master tradesman would only take on a few new apprentices every few years, so the opportunity to be accepted as an apprentice was a great honor. Apprentices worked long and thankless days learning their craft from their tradesman. Master tradesman could be demanding, stern and harsh to their apprentices but they knew that people who needed the expertise of that tradesman would accept nothing less than the best. An apprentice would learn every aspect of the given trade and in most respects become an expert. An apprentice was bound to their master for the entire term of their apprenticeship which could be as long as seven years or more. When the apprenticeship was completed, they would become a Journeyman. They had enough skill to work for someone, gain more experience and were worthy of being paid for their work. As the name implies, a Journeyman could travel to many places and work for many tradesmen to gain experience and knowledge. In time, that journeyman could apply to become a Master Craftsman/ tradesman by applying to a Guild and creating a "masterpiece" If this masterpiece was accepted by the guild, the journeyman has now become a master. He could own his own business and take on new apprentices and journeymen thus continuing the trade. With industrialization and the advent of Trade Unions in the mid 19th century there was a modernization to the process. Unions organized trade schools that gave many more people an opportunity to learn a skilled trade and earn a living along the way. Worker health and safety began to become a valid concern. During this time new trades were added to the world specifically geared towards the many new industrial and technological achievements. Machinist, plumber, electrician and our own venerable watchmaker were added. All trades were still respected and valued and it was common to know families with multiple generations of tradesmen in one field or another. This system worked well and served society up until the late 20th century. I'm not sure anyone can pinpoint the exact fall of trades, but in America, many agree it began to unravel in the mid 1970's. Trade and labor unions gained a lot of power over the years and had exerted that power in excess. Pay and benefits were skyrocketing and the workers were safer and healthier than ever before but potentially excessive labor disputes and strikes began to cripple many of the industries that depended on the tradesman. Mildly skilled, non-union workers began to slip in and fulfill the tasks of skilled tradesman at a lower cost. Many unions were inflexible or too myopic and resisted the need to adapt to this "unskilled labor infiltration". In some areas, especially the southern states where trades and labor unions were never really strong, unskilled laborers out competed and underbid for jobs. The inadaptability of trade unions nearly led to their complete extinction as a viable entity throughout the Southern United States. Corporations and the government, which had generally stayed out of labor disputes other than to expand labor unions began to take advantage of this change and in 1981, culminated in President Ronald Reagan decisively firing over 11,000 striking air traffic controllers. I was fortunate enough to be accepted into an apprenticeship program in the late 1990's. It was a 4 year program that focused on several aspects of the machinist trades. I chose a specialization in machine repair. I had some difficulties during my apprenticeship but fortunately I was able to complete my entire apprenticeship before the program fell apart due to a corporate culture that had lost the understanding of the value of skilled trades. I have been very fortunate to work as a Journeyman for several good employers to help further my education in my trade. I currently work for one of the worlds largest defense contractors and it is truly a blessing. But, as with most good things in life, I earned my way here, I worked hard and learned a lot and became an asset for the company. I can absolutely relate to the value of a skilled trade. Many here may be aware of the television presenter Mike Rowe. He was the host of the Discovery Channel program "Dirty Jobs". Mike also narrates many science and history channel programs including Deadliest Catch, Ghost Hunters and How The Universe Works to name a few. Mike has become an outspoken proponent of the skilled trades. He travels the country promoting trades, apprenticeships and craftsmen and has spoken before congress on the subject. Mike speaks of the skills gap, where employers cannot fill positions in their companies because of a lack of skilled workers.I believe it is because there is a pervasive attitude here in America that the skilled trades have no value. He points to the removal of shop classes from high school curriculum programs. As an example, the state college near me invested millions of dollars to build an advanced technology / trade school that now sits barely used. My high school dropped shop class a few years after I graduated. This has happened all over America. The failure in this is multifaceted. Schools aren't providing opportunities for kids to be inspired though a shop program. States are gutting education budgets to the point where school systems that are willing to provide opportunities are simply unable to. Add to that a general apathy by many employers to actually invest in skilled labor and the culture and infrastructure required to build it. It seems many companies have always expected there to be an unlimited supply of skilled labor that they would not be required to invest in. Now that it's drying up, they're baffled on what to do about it. Generally, there is a lack of interest in trades in america. We pushed college so hard that we lost sight of this need. Generally speaking, kids have been lead to believe that computers and technological savviness will be the only skills they'll ever need. They're sadly mistaken. It seems many of our young adults assume that if they can do some coding that they'll be hired by giant tech companies like Amazon or microsoft or others, reality proves otherwise. The US government has invested nearly $700 million dollars in apprenticeship programs in the last 10 years which is great, but recently they have begun to restructure the standards to the point where the integrity of the system is being called into question. The article in this LINK goes into detail on this subject. Everyone from the government to corporations have to understand the reality of investment. You invest in money and time to produce a skilled tradesman or craftsmen. They are not simply created. And if you want Tradesman who meet a set of standardized criteria that you can count on their education and training being thorough and complete, there has to be cooperation with state and national programs like the US Department of Labor. Other countries have not forgotten the value in that investment. Japan for example has a terrific trade and craft apprenticeship infrastructure and culture. Manufacturing companies offer 7 year apprenticeships. The companies provide for many of the needs of the apprentices including healthcare, food and lodging. There is still honor and prestige in being a skilled tradesman and craftsmen. I feel this is one of the reasons Japan is outperforming America in terms of manufacturing prowess. In Japan, our own venerable trade of watchmaking has a few devotees and a very small number of watchmakers and apprentices still ply the trade. Here is a link to an article that tells the story of 2 generations of watchmakers, one old and one young. Even there it is a very slowly dying skill. I do find it fascinating to know that there are women as in the article I linked to, who are expressing an interest in watchmaking, even if they are hobbyists. Several women have recently joined our forums here. Diversity is key to our future I feel. In conclusion, I think it's a shame how we have lost sight of how valuable tradesmen and craftsmen are to the strength of our future. Hopefully, in my lifetime we will see that shift back the other way. If your'e interested, here are some watchmaking educational rescources https://www.awci.com/educationcareers/careers-in-watchmaking/ http://www.nghayekwatchmakingschool.org/The-Schools/miami/General-Information.aspx https://www.britishschoolofwatchmaking.co.uk/ http://www.wostep.ch/fr And many others from all over the world here: https://www.eternaltools.com/blog/27-of-the-finest-clock-and-watch-schools-around-the-world Thank you for taking the time to read this, I really appreciate it.1 point

-

I know, it's a serious issue. On another forum I frequent the average age is well above 50, and fairly frequently there will be a moan fest about "millennials" and one or more folks will always talk about how they paid their way through college and when they graduated they had no debt and in some cases even owned a house, but the kids today... That was possible 50 or 40 years ago, less so 30 years ago, and has become more or less a total impossibility from 20 years ago. I had the very good fortune to go to a college prep private high school (scholarship, we were anything but wealthy). I was the only kid in my class to not go straight to college. As I had zero idea what I really wanted to do and I would be on the hook for tuition I figured I'd work a bit and go when I knew. Ended up becoming an auto mechanic for a few years, which through a matter of chance encounters got me into watchmaking.1 point

-

So according to the link below the spring for the Hamilton 61 is a 2-3/KIF. Then if you possess the Kif cross reference catalog other than the nice picture below showing what the different styles look like there is no explaining all the variations of the numbers. So I'm assuming you that the first number is the type and the second number is probably a size. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=HAM_611 point

-

I bought a nice new roller table remover to aid in replacing roller jewels.I have some old Ballance wheels with tables attached to try my tool on. Then I watched a great video by our founder, where he used this tool to remove the table.I was very impressed & confident. I took the shiny new tool , carefully slid it between the balance wheel & roller table, checked (under magnification) , put the whole thing in a plastic bag (so not to lose ping the table across the room) , then gently squeezed. Nothing happened, so I squeezed a bit harder, still nothing. So instead of using my brain & watching the video again to see if I had it correct. I gave a mighty roar & squeezed like "Mean Mountain Dean". It popped right off the staff. I patted my self on the back saying "Your The Man". It's then I noticed the balance staff was cut in " twain " as they say across the pond. What could I possibly done wrong? Perhaps it was a faulty old staff ? So you have two more old Ballance wheels in the box, try again? Ping there goes another one. It doesn't take Alan Einstein "sic" to figure out it must be me, not the tools or staff. After re-watching the video It dawned on me, I had the tool upside down " (duh) " There I confessed & feel much better. You can bet, I won't make that mistake again !1 point

-

Hi Tim, I think the Bergeon winder sizes go up from 12mm (#8) to 19mm (#15) in 1mm steps. The ones I can be sure about are #8 (12mm), #11 (15mm), #13 (17mm), and #15 (19mm) as I have measured my own #11 and #13, and I have found the #8 and #15 sizes on Cousins web site. The others I have inferred as they seem to fit a logical sequence. #00 to #7 are a little less obvious. They can be found on Cousins site if you need them but as you are enquiring about pocket watches I assume you're mainly interested in the larger sizes. The sizes refer to the outside diameter of the winder drum so to work out the correct size winder for a given barrel you need to measure the inside diameter of the barrel and select the largest winder that will fit inside it. This will then ensure that when you insert the wound spring it is fully inside the barrel when it releases from the winder. Individual winder barrels do crop up from time to time on eBay and other online sellers so it's well worth keeping an eye out for them. Hope this is of some help.1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)