Leaderboard

Popular Content

Showing content with the highest reputation on 05/17/20 in Posts

-

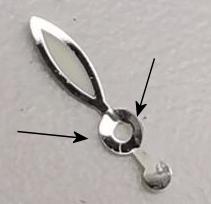

looking at the discussion I thought I would make some observations. so starting off with tweezers everyone makes the assumption that they're all the same. A lot of times people new to watch repair think the tweezers have to be super delicate super tiny fine tips which are really bad for watch repair. Super tiny tips can be good for fixing hairsprings. one of the most important characteristics of your tweezers and I'm attaching an image gently squeezed together the jaws come together parallel. Really important for holding round things. that a link to a good bad video. May be bad isn't quite the right word. For instance if I was cleaning a watch like this I leave the balance in whereas everything else comes off. So the balance stays on the main plate with its bridge and the jewel assemblies come out. Make sure you remember to put the springs back down so they don't go anywhere undesirable. Then the jewel assemblies will clean just fine in the cleaning machine the balance is protected the hairspring is protected. so he shows them in and of course his watches running which it really shouldn't be makes it a lot harder when it's running. Plus the jewels clean better if they're not in. So a difference between the procedure that you've outlined above is after you put your drop of oil on the end the stone what's left of the oil on the end of the oiler is applied to the hole of the hole jewel and yes he does point that out in the video. if you take the jewel assemblies out for cleaning just remember there probably not exactly the same sometimes. It's usually best if you keep the top and bottom separate. https://youtu.be/KpII8WDZnYQ other thing is helpful to have or equivalent. so for instance at the link below because it was the first one I found a small jar of rinse typically referred to as hairspring rinse. http://www.stsupply.com/tools/cleaning-polishing/other-cleaning-supplies/one-dip-hairspring-cleaner-2-oz.html then the suggestion of automatic oiler above? I was at a lecture once where the person brought up using the automatic oiler and he would a sold a dozen of them on the spot if he had them after he explained how wonderful they were for oiling. Unless of course you've just practiced a lot like I have and I'll still do it the old-fashioned way. I'm attaching a link notice they even have a drawing of it in use. The advantage is the black one of the smallest diameter one will go through the hole jewel assembly. So everything is nice and clean you can apply the oil and as a bonus I don't remember how to do it but you can actually suck oil back out if you get too much. https://www.esslinger.com/bergeon-7718-1a-automatic-watch-and-clock-oiler/ then quantities of lubrication have changed with time. I'm attaching a PDF page 17 you are 30% would be considered unacceptable. cousinsuk.com Omega 8645_WI_40_rules for lubrication-4.pdf5 points

-

I think @JohnR725 rapps the most of it together in a good way. I only can give a couple of links from the same school on here. The first is a lecture on this subject and the second of the washing process with the balance in place. Cap jewel cleaning lecture. And the second shows a basic service and the oiling and cleaning.4 points

-

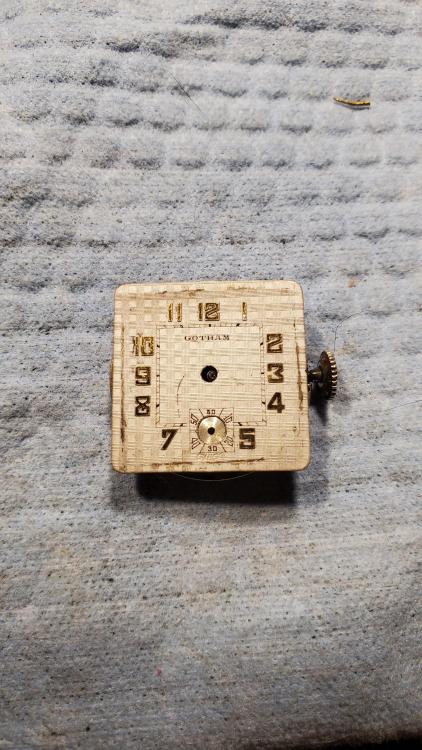

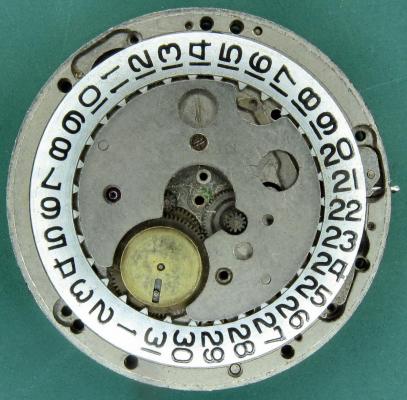

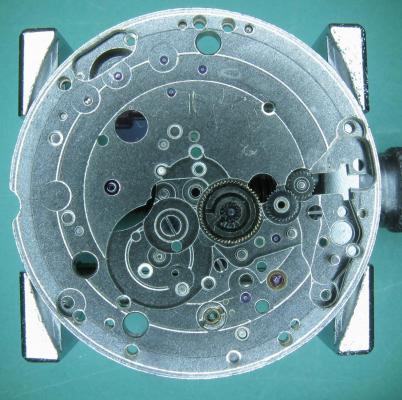

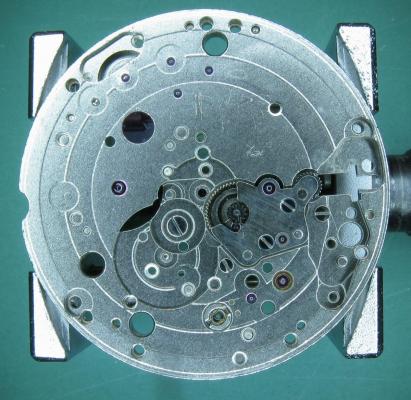

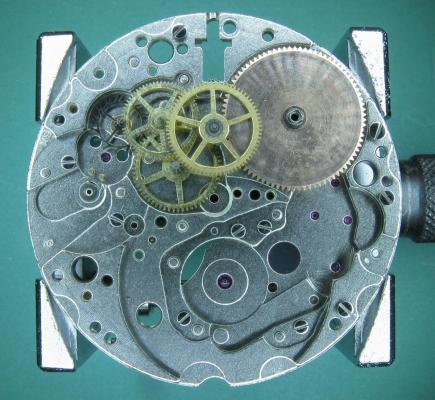

Anyone think this little guy is worth reviving. I think it just needs a long overdue service Sent from my iPhone using Tapatalk3 points

-

Got this coming. Sent from my SM-N975U using Tapatalk2 points

-

Unfortunately this is a really easy mishap to happen I speak from experience. However they will attach to a magnet so keep the watch well away and move a magnet over the suspected launch area. When found it must be de-magnetised. I have attached a PDF showing some of the variables and be aware some are similar but are different. I recently was given a skeleton "Rotary" watch that had been dropped and the top jewel & shock had come loose. Unfortunately the shock spring had logged inside the winding stem tube and was un-repairable. Looking at the lower jewel it very much looked like a Kif spring but it was in-fact a Seiko movement & spring and I had to modify a shock spring I had in stock. shock absorber – Watch-Wiki.pdf.pdf2 points

-

Spread a white sheet of paper or thin cardboard on a flat surface, drop the end stone on it flat side down facing the paper, put you index finger on end stone, pour a bit of naphta or lighter fluid over the paper, scrub the end stone over it as much as you like, end stone will clean incredibly. Under magnification you will inevitably see paper debrie around the permeter of the end stone, drop it in a small jar add ligher fluid, shake, save the extra fluid. I fish out the end stone out of the jar by my finger. No need whatsoever to blow dry since it is a stone, put a bit of Rodico on tip of a screw driver, another safe place for the end stone to stay put, oil , drop in chaton. Holding end stone in your tweezers is an unneccessary skill. Good luck.2 points

-

Today I'm finally able to wear my newly acquired Art Deco Gotham. It has an AS 340 beating inside. The case is amazing! I love the two tone gold and chrome scheme with enamel detailed engravings. I also love the swinging lugs. I've read these were called Driving watches. It was a bit of a challenge getting it to run consistently, but I think I have it sorted out. I'm not 100% sure what year it was made, but according to Ranfft the movement was produced from about 1920 to 1935...or there abouts. I'd guess about the mid 1920's for mine. If anyone knows how to date these older A. Schild movements, please let me know.2 points

-

lubrication in horology is such a interesting subject. If you do not oil at all at least for a little while the watch runs pretty decent because oil does have a dampening effect. Of course with time without lubrication it will wear out especially if its metal on metal bearings. So the theory on pallet fork lubrication being bad is the dampening effect. Then if the oil gets or goes bad with time like the old organic oils than the effect would be very dramatic. I think the more interesting thing to try would be I think it's 9000 the oil for quartz watches. Because quartz watch oil has to allow the quartz watch to step really fast or it's a problem. The pallet have to move really fast or it's a problem so it stands to reason the oil for quartz watches would work fine. the other reason they don't lubricate the fork is it's considered a non-rotating part it doesn't need lubrication. I think the last time I played with lubricating pallet fork pivots you have to go really really heavy or a lot before you'll start seeing a problem.1 point

-

Note sure yet, caravelle is a Bulova so possibly a Japan quartz. Here is the back. Sent from my SM-N975U using Tapatalk1 point

-

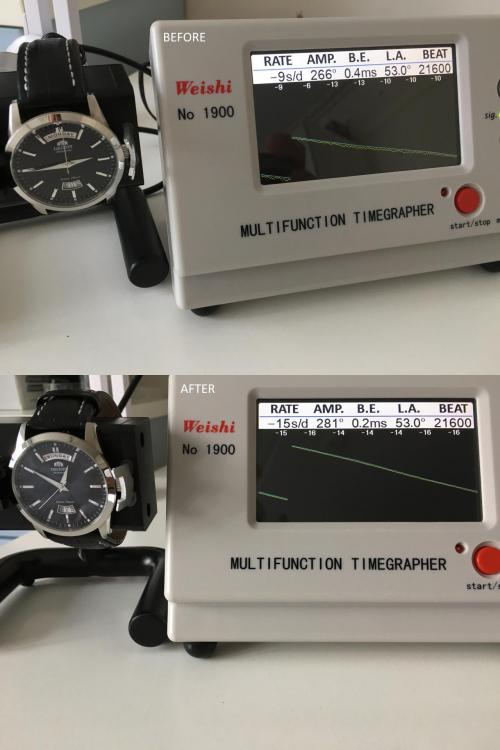

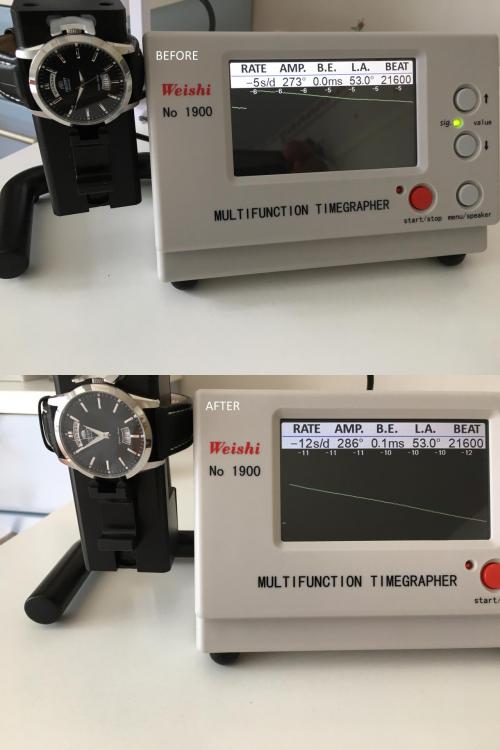

So, I have now oiled the pallet staff pivots. Below are the before and after pictures. I used an exceedingly small amount of Moebius 9010 on both jewels, not more than what would look like a ring around finger. I know it is near impossible, but it still feels like I might have underoiled. Doing the oiling I used my 40X stereo microscope which is truly a massive help. (This type of oiling reminds me of target shooting which I used to do, where you need to be able to breathe deeply and calmly, hold your breath, relax and be extremely focused on the target) I do not know what conclusions to draw. In some positions it looks like a slight improvement. I was surprised to see that it did not affect amplitude. If anything, the average amplitude even increased with 5 degrees. I guess a thicker oil, perhaps Moebius 9104 HP-1300, would have been a better option for creating a bit of drag. Not sure I want to re oil the pivots again, but if I do, I will let you know the result. Anyway, let me know your reflections! EDIT: I guess most of you already know, but to be sure, you will need to click on the images a couple of times to enlarge them.1 point

-

one of the things important to remember here is amplitude isn't entirely the most important thing if it would just remain consistent for 24 hours. lot of the watch companies that do publisher timing specifications typically don't worry about amplitude except at the end of 24 hours. then pallet fork lubrication if they're using 9415 there is a concern that a little is good too much is bad. So too much will cost you amplitude. So if you look at the attached document starting at page 13 you'll see a procedure. So the trying to go minimalistic to avoid problems.. then you really need to do some of the pendant/crown positions because resting on the pivot is absolutely ideal for timing. You're always going to lose amplitude in the pendant/crown positions and you still want to be above a certain amount. But that does depend upon the watch especially if you look at Omega's specifications. cousinsuk.com Omega 8645_WI_40_rules for lubrication-4.pdf1 point

-

I thought I saw a video a while ago from esslinger that amused me a bit, they show how to press in a crystal with a tensionring except the tensionring is still on the bench, but the process gives you an example of how it's done , as you see he uses the dies with a straighter edge which will compress the acryllic crystal from the sides. this will minimize the risk from cracking the crystal as if you try to push it in with the angular parts. The compression will make the tension ring shrink a bit and the crystal will slip on like a glove, if the crystal wasn't just a tad to large it would not resist water or dust coming into the case.1 point

-

If I might suggest a secondary opinion, you could leave the collet on the pivot. Since your hand seems to be bent in an u shape your hole got bigger, so gently pushing downwards on the sides of it will make the hole slightly smaller . You then can gently put it back with tweezers as the collet got the slip for it. While in place you can straighten it completely and it should sit in place. Next time you take the hands off you lift them at the bottom of the collet.1 point

-

Hi Have you pulled the hand off the collet?. If so then a pair of levers will be required to remove the collet, but do it in a plastic bag as if the collet is tight it will spring when released. Having done that you will have to fit the hand back on to the collet. One can open the tube a little using a broach but be careful to not take off too much. By The Way a few words of introduction would be appreciated from new members.1 point

-

1 point

-

1 point

-

The lecturer in that cap jewel oiling video has super steady hands and great control. If I repaired watches all day every day then I might develop that dexterity. Meanwhile, I use one of these (the smallest size) to hold cap jewels while I oil them https://www.cousinsuk.com/product/jewel-picker-upper-with-silicone-tips I put the hole jewel in the movement plate then pop the oiled cap jewel on top and tease it off the picker with fine tweezers. Similar to Nucejoe with rodico, but I find it easier to control.1 point

-

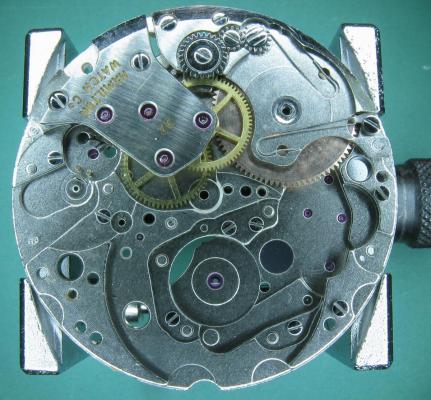

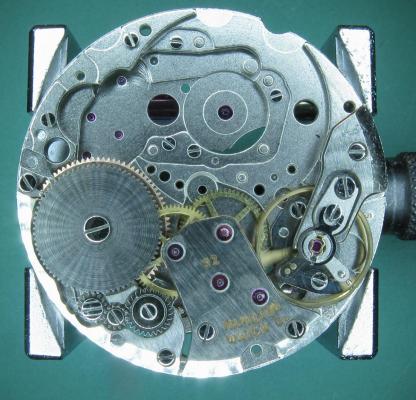

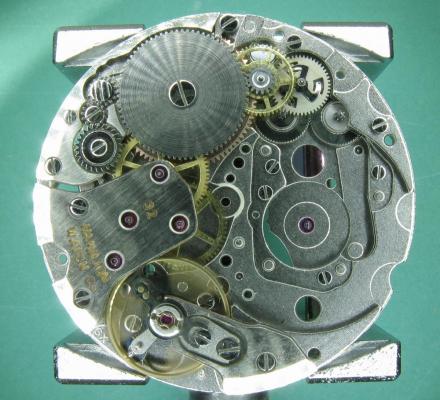

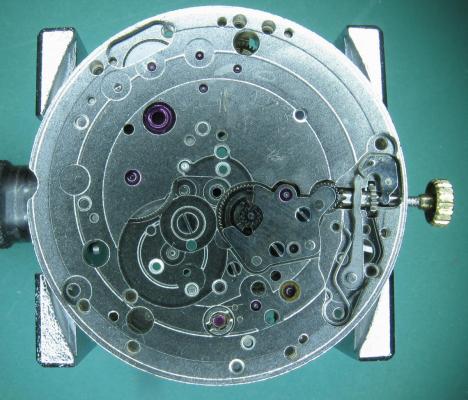

This is what I got up to over the Easter break. It was a project that I bought as a box of bits for a few quid about 4 years ago because although I had no idea what it was (the listing didn't say), it looked interesting and I fancied the challenge. It turned out to be a Hamilton Intra-Matic Westminster which the previous owner had tried to "fix", got as far as dismantling, and given up on. Cosmetically it was in good order but mechanically was not good. The rotor pinion had lost its bottom pivot, as had the second wheel (centre wheel in a more conventional wheel train). And because it had spent some time rattling around loose in the box of bits the hair spring was in a poor state, and what had me really stumped when it came to working out how it all went back together was a large and rather complicated looking wheel and pinion assembly for which I simply couldn't find a home. Any way, it was put to one side until I could track down a donor for the parts and to hopefully show me where the "spare wheel" went. The movement is a 30 jewel Hamilton 92 micro-rotor, which is a re-badged Buren 1281. Unfortunately (for me) this has been used in a number of higher end autos and also as the base movement in some big name modular chronographs because of its thinness, which means that they tend to hold 3 figure values even as spare parts donors so it took a while for me to track down a suitable candidate at the right price. However, I did manage in the end to nab one for just over £30 and it arrived at the beginning of April, so the fun could begin. No strip down on this one as the Hammy came to me fully dismantled, here is the donor as I got it. It's a Buren 1281, a bit grubby with some missing screws, and the minute hand pinion has seized onto the centre post. I later discover that the canon pinion (which is actually on the second wheel pinion) is loose and I reckon that someone had diagnosed the loose canon pinion, had tried to correct it by tightening what they thought was the canon pinion, which was in fact the minute hand pinion, onto the centre post, over did it, and caused the whole thing to seize, hence spare parts movement on eBay!!! I stripped out the second wheel (complete with canon pinion which I tightened), rotor pinion, balance and hair spring, and the main spring (which was in better shape than the Hammy one), and then put the parts through the cleaner; the Hamilton 92 parts had already been cleaned. And here we go with the good bit. The Hamilton 92 main plate; cleaned and ready for reassembly. I usually start with the wheel train when I build a movement back up but that's not possible here because the motion works bridge also carries the lower pivot jewel for the second wheel, so the motion works have to go in first. With the bridge in place you can see the pivot jewel in between the minute wheel and the intermediate wheel. The movement is flipped and the wheel train and barrel (cleaned and greased main spring, and braking grease on the barrel walls) are positioned. Train bridge and barrel bridge installed complete with crown wheel and intermediate winding wheels. At this point the end shake on all of the wheels was checked and the general free running of the whole train tested, then the pivots oiled. The ratchet wheel in place, the pallet fork installed and the escape wheel teeth / pallet jewels lubricated. The balance dropped in and off it goes. Then the auto winding reversers and reduction wheels go in. The three armed spring on the first reduction wheel is a ratchet which prevents the rotor from helicoptering during manual winding. Unfortunately it also gives the crown a very gritty feeling when you hand wind which takes a bit of getting used too but it is normal. Bi-directional flip-flop (for want of a better term) gear and auto wind ratchet in place. Cover plate on and the micro-rotor assembly installed. Turning things over again the keyless works go in. Then the calendar works, date wheel, and cover plate. Before the dial and hands go back on. Confirmation on the Timegrapher that all is well. The obligatory wrist shot. And something more formal for the album :-) This is now an absolute favourite of mine and has a permanent home in my collection. It took a lot of waiting to get the donor but it was well worth it. The watch has been running continuously since 11 April kept wound from wearing it when I get home from work in the evenings and at the weekend, and has remained within a few seconds of reference time. And the "spare wheel"..... was precisely that, it didn't belong with the box of parts that this project started out as. I do hope the seller didn't miss it :-)1 point

-

Have you looked into automatiic oilers? you can oil when the jewel assembly is in the mainplate and it dispenses what I think is the perfect amount of oil, or you can dispense twice or more .1 point

-

Yes, you got my meaning right on both accounts, stick the convex side to rodico so the end stone stays put even when you flip over to lower the end stone onto the chaton, and end stone doesn't rise when you remove the oiler. You said it better than I, you sound like you have done this before. Making a tent of plastic sheet or cover over the work or inside plastic bag, saves us a lot of searching on knees. Good to make a habbit of. Good luck.1 point

-

Thank you, Nucejoe. Do you use the rodico on the screwdriver to hold the stone down so it doesn't rise when removing the oiler? Check that, I think I understand. You "stick" to the convex side, oil the flat side while stuck to the screwdriver, then flip into chaton and hold the jewel down while removing the rodico-loaded screwdriver. Yes?1 point

-

1 point

-

1 point

-

If the machine doesn't clean them sufficiently after I've given them a rub with pegwood dipped in naphtha, then I submerge them in naphtha for a minute and then rub again, before a wipe across clean tissue paper. To oil, hold the sides of the cap jewels with tweezers but don't squeeze hard at all. If they ping then you may have "beaking" tweezer tips. Your oiler hand can rest on the bench top while applying which will keep it still. Do it inside a large clear plastic bag if you are paranoid of losing anything.1 point

-

The dial code (if there is one) may be on the dial in a position that makes it hidden when the movement is in the case. In other words, you may need to remove the movement from the case to see it. Watches after 1985 may have a different method of dating them. There is an incomplete list of possibilities here -> https://en.wikibooks.org/wiki/Budget_Watch_Collecting/Timex_date_codes When I zoom in on your picture above, it says "Taiwan", which suggests, like @JerseyMo stated that it is early 1980s. A nice enough watch, but not particularly rare. The Taiwan produced movements tend to be slightly lesser quality (due to cost cuts in later manufacturing runs to keep them competitive).1 point

-

1 point

-

Steel (alloys that are hardenable) is hardened by heating to its critical temperature then quenching, depending on the alloy the quench may simply be ambient air, water, or oil (there are other quenches but those are the main ones). The critical temperature for common hardenable steels is around 800 degrees C. A typical alloy used in watchmaking would be quenched in oil. When quenched, it will be fully hardened. In almost all cases fully hardened steel is undesirable. To reduce the hardness it will be heated to a temperature below its critical temperature, and this is tempering. Most watch components would be tempered to a "blue" state; the tempering ideally might take several minutes or more, but the cooling off time once at color (or temp, being more scientific) is not of any great importance. Blue steel is able to be filed, but not able to be sawed with normal metal cutting saw blades (this is the test some schools used to use on student work to see if they were heat treating correctly); it is also difficult to drill unless special drills are used. To reduce the temper on a piece of steel it would be heated past whatever color it was originally tempered to. The color range goes: straw, brown, violet, blue, light blue, then more or less the natural steel color. When tempered to its natural color it is still harder than in the annealed state, but not generally hard enough for use. To temper a watch arbor or staff, a typical technique would be to drill a piece of brass rod with an outside diameter of perhaps 3x the piece to be drilled, the drilled hole will just let the workpiece fit freely. The brass rod is heated with an alcohol flame and when the visible steel protruding from the hole is the desired color remove the rod. The steel will not cut as freely as annealed steel but much more easily than blue steel.1 point

-

1 point

-

Just be a bit careful if the cannon pinion sits so hard on the center wheel that it rotates train wheels in the wrong/opposite direction making the seconds hand move anti-clockwise. There's a video on the YouTube Watch Repair Channel about this. I'll see if I can find it a bit later. Oh BTW, well done!1 point

-

out of curiosity I went and read the rules and you're right you can have a URL but and I'm quoting from the guidelines which we all should read from time to time anyway. "It is not permitted for you to advertise or promote your product or commercial website without prior permission. You may place a link in your signature to your own personal (non-commercial) website if you wish." then the reason I was reading the rules were I get nervous if I post a link to anyone selling anything even if it's relevant. That's because there's other discussion groups that you can never place a link to anyone selling anything it's in violation. Or if you place a link to eBay it has to be a completed sales. So it looks like it's okay if I place a link to something relevant for the subject. On the other hand seeing this I went to my history file and found your website. Looking at it I do notice a problem? from your list up above one of the items is "Recognised qualification and experience" . The reason I bring this up is I went to a Seattle website a long multi-generation family of watch repair that actually still has their Rolex account which is quite remarkable. Don't even think about getting up Rolex parts account anywhere in the planet every. So well known and they had this (WOSTEP and/or CW21) certificates. this was something I noticed on your website I didn't see any reference to certificates or any associations with professional watch Association's? so in addition to all that expensive equipment some of which shall never use I suspect they're going to want to see some certificates from accredited schools or that you've taken the tests show your qualified. Then thinking about professional associations have you reached out to the BHI and asked them if they have any knowledge of how to get a Omega parts account?1 point

-

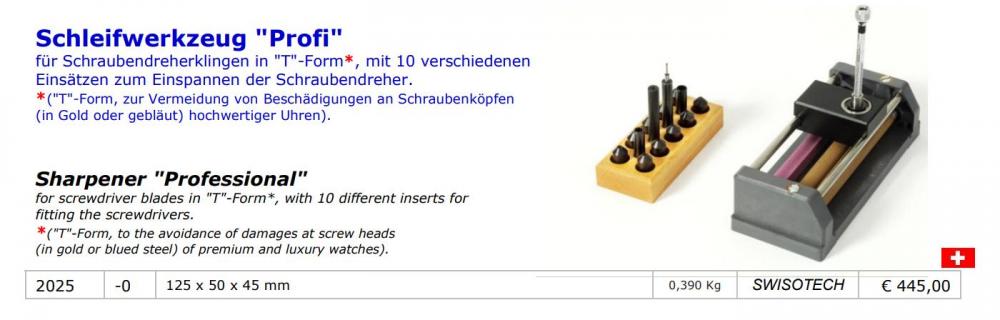

The first blade is for sure not shapened with a hollow shape, but it has a to hardened tip with brittle metal, one can se it flaking away which isn't good. In my book to get a really nice surface one can use both of these sharpeners with the horotech style one just must get it to fit good in the toolholder. Swisstech makes a similar one with a bunch of inserts so you always will get the perfect result, and fast, but always with quality the price is a downside. A screwdriver with a softer tip, like the one below made of berylium is almost impossible to get perfect without a good sharpening tool. And in the end it's like with racing with cars, a good car will take you a long way but it's the man behind the screwdriver that makes the difference1 point

-

There should be a dial code at the base of the 6 hour. the last two digits are the year made. Not seeing it, my guess is early 1980's Marlin Day Date- 106 movement. That is because I see the wavy lines indicating 'water resistant'. Not at all rare and very common.1 point

-

Hi Watcher OP's pic's of his blades don't look to me to be hollow ground. Perhaps you could enlighten us with your observation of the need for that particular tool? Thank you. Sent from my moto g(6) play using Tapatalk1 point

-

There are screwdriver sharpener tool of various designes and price for sale on online portals.1 point

-

Date changes as hands advance past hr24. At this point turn hands anticlock to hr8 then forward past hr24, this will change the date.1 point

-

Very common in older Wristwatch movements with date complications. It just requires the tedious practise of cranking forwards. A lot of people who wear watches in rotation tend to skip date setting on such watches. Quick set requires a separate cam which engages the date wheel teeth on the first pull out point to facilitate the rapid advance so it'll be very evident when you strip the dial side as it'll be connected to the keyless works where the date advance is usually over by the 9/10 on the dial position driven by the hour wheel.1 point

-

1 point

-

Hardly, as it's the duplicate of this one. jdrichard, please do not post duplicate topics, and post in the proper section. Otherwise it just makes difficult to help you.1 point

-

1 point

-

As @Graziano mentioned that he thought the movement was based on the ETA 2452, I thought you might find this post (ETA 2472 - Disassembling the automatic device) of mine useful. Also, if the date complication is similar to that of the ETA 2472 you might also find this post useful (ETA 2472 - Disassembling the date mechanism). Also, if this movement has a setting lever screw similar to the setting lever screw of an ETA 2472 that I serviced somewhat recently, it is extremely important to replace the setting lever screw before the barrel bridge is replaced. This is trickier than you might think as the setting lever screw can be replaced after the barrel bridge has been replaced but will lead to several problems that can be hard to foresee. You can read more about my ordeal with the setting lever screw here and here. So, if you your movement indeed is similar to my ETA 2472 you'll find my complete service walkthrough of it here including my lubrication suggestions based on ETA's technical communication for the 2824-2 as suggested by Graziano. The walkthrough consists of about 130 disassembly pictures and about 130 assembly pictures. Good luck!1 point

-

If looking for an authoritative 2824-2 servicing video check the one by our Host Mark Lovick1 point

-

I think after all this is a watch repair forum not a watch appreciation forum. So if any watchmaker like their craftmanship and so be it. BTW I wouldnt agree that a justification of watch brand depends on how many rich men wear it.0 points

-

I am not sure what are you talking about. Japanese never bought largely in the Swiss industry. Just recently some Chinese and other Asians bought dead brands, and one smaller Swiss movt manufacture. If you want to learn how things are evolving have a read to the below and other articles from the same magazine https://www.europastar.com/watch-knowledge/1004087450-mechanical-who-will-succeed-eta.html Again I am afraid that you have ignorance fueling prejudice. Seiko makes large SS watches because that's what the market demands, last time I checked that is the same other brands are also making. Then if you care about learning one thing or three about Japanese manufacture I suggest that you have a read about past and present Grand Seiko offering, and the long gone time when they were giving the Swiss an hard time at the Chronograph competition using a flat hairspring, before the nice hosts of the venue changed the rules to avoid further loss of face.0 points